© 2014 MDM INC.

Economy With Efficiency.

© 2014 MDM INC.

Economy With Efficiency. © 2014 MDM INC.

Economy With Efficiency.

Proudly Made in the USA Proudly Made in the USA

© 2014 MDM INC.

Economy With Efficiency.

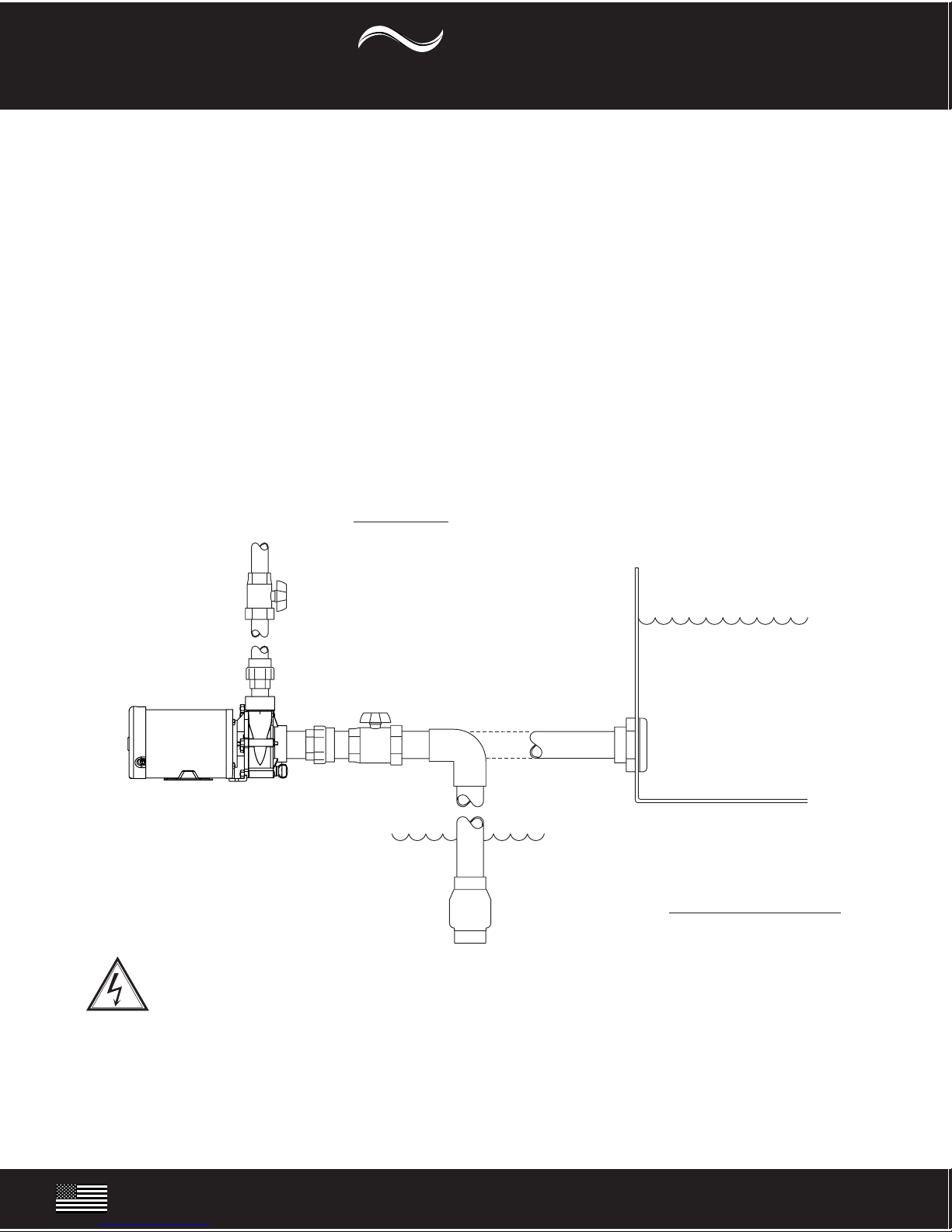

INSTALLATION

Please read carefully! When properly installed, the Valuflo™ 750 will provide dependable, trouble-free service.

1. Do not submerse the unit in water - it is not a submersible pump. Do not allow the pump to become submerged during transient periods, such as heavy rain,

run-off, etc.

2. Locate the pump as near the water source as possible. A flooded suction is preferred.

3. The pump is not self-priming. Therefore, if the fluid level is below the pump, a swing check valve must be installed below water level. The pump and inlet line

must be primed prior to start up. Do not run pump dry! For non-flooded installations, a strainer basket and check valve are recommended.

4. Mount the motor base to a secure, immobile foundation.

5. Use only plastic fittings on both the inlet and discharge ports. Seal the inlet & discharge fittings with Teflon™ pipe dope. These fittings should be self-supported

and in neutral alignment with each port (i.e., Fittings must not be forced into port alignment which may cause premature line failure or damage to the pump volute).

6. Never restrict the inlet! Keep both inlet and discharge lines as free of elbows and valves as possible. Always use pipe of adequate diameter. This will reduce

friction losses and maximize output. Never use an inlet line of smaller diameter than the discharge line. Minimize the suction lift.

7. For additional plumbing tips, review MDM’s website: www.mdminc.com for pond plumbing and pump installation hints.

ELECTRICAL HOOK-UP

CAREFULLY, EXAMINE THE POWER CORD BEFORE USE. DO NOT USE THIS POWER CORD IF THERE IS ANY VISIBLE DAMAGE. DO NOT USE THIS POWER CORD IN WATER OR IF

THE MOTOR OR ELECTRICAL RECEPTACLE IS IN CONTACT WITH ANY STANDING WATER! THIS POWER CORD SHOULD ONLY BE PLUGGED INTO A PROPERLY INSTALLED 115

VAC GFI RECEPTACLE! ALWAYS TEST CYCLE A GFI RECEPTACLE TO DETERMINE ITS CONDITION BEFORE USE!

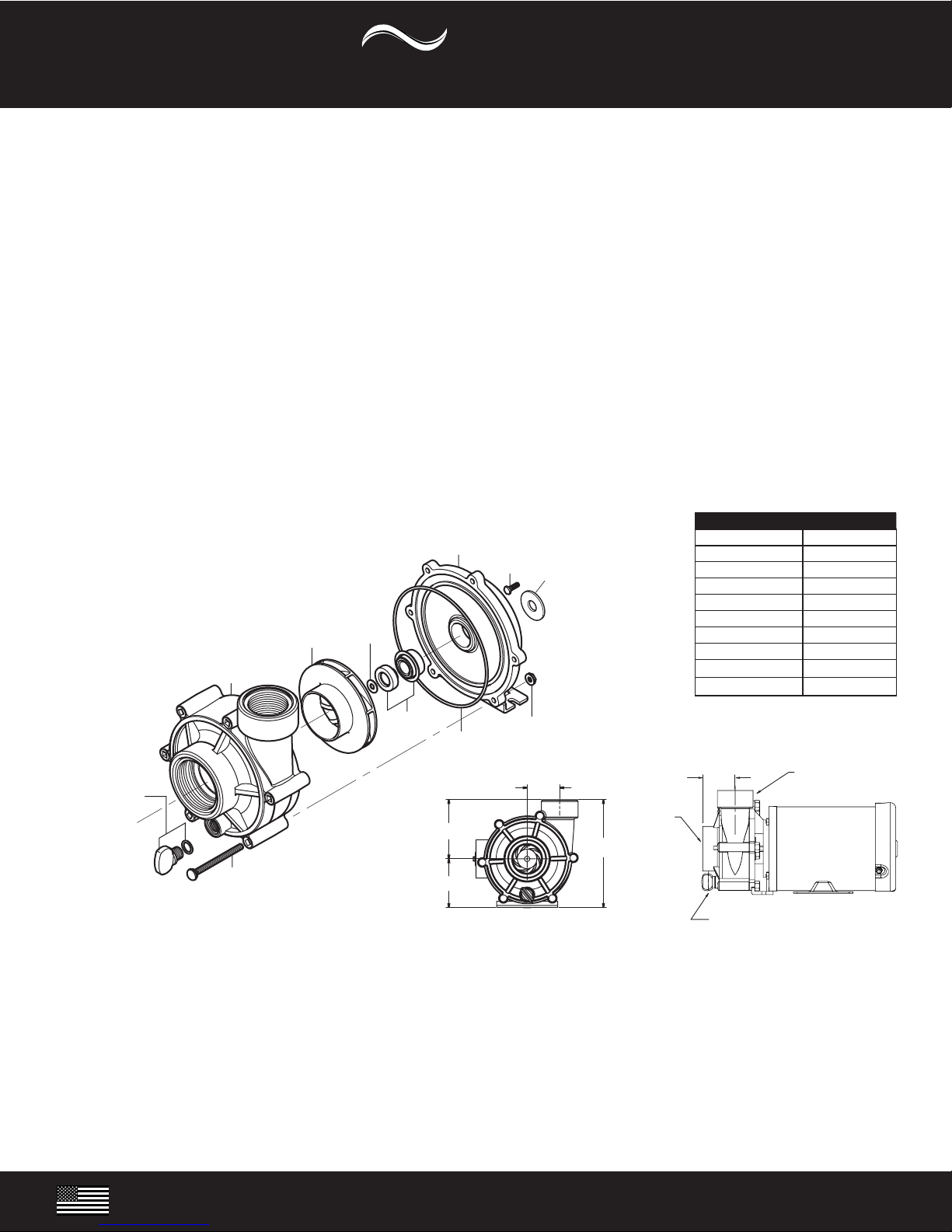

DISASSEMBLY

1 . Shut off power to the motor before servicing any pump!

2. Unplug the power cord.

3. Disassemble the volute from the bracket - six P-Bolts and six flanged lock nuts. The volute may remain attached to the plumbing to help simplify re-installation.

4. Lock the shaft by placing a screwdriver blade into the shaft slot at the fan end of the motor. Unthread the impeller from the motor shaft - Take care not to misplace the

small metal impeller washer.

5. Remove the ceramic, with rubber boot, from the impeller hub (if you are replacing the seal).

6. Loosen the four M-Bolts attaching the bracket to the motor. Rotate the bracket counter-clock wise until the screw heads are located in the large key hole slots. Lift off

the bracket from the motor.

7. Remove the carbon-graphite seal assembly from the bracket by pressing it out from the motor-side of the bracket.

Do not pry it out with a screwdriver from the pump cavity-side of the bracket (if you are replacing the seal)!

PUMP END ASSEMBLY

1 . Inspect all pump parts (O-ring, O-ring groove, impeller hub ID, motor shaft, etc.) and clean if necessary.

2. Apply sealant to the bracket bore ID wall and around the seal case - follow sealant mfg. instructions. We recommend using Gasgacinch®.

Silicone sealant can also be used.

3. Press the carbon graphite seal into the bracket while taking care not to touch or damage the carbon graphite face. Never touch or apply pressure to

the carbon graphite seal face!

4. Screw four M-Bolts five complete turns into the threaded holes located on the motor face.

5. Mount the bracket to the motor by aligning the key holes over each bolt head, then rotate clockwise which will position the small key hole slot under each bolt

head. Tighten each bolt with a wrench to secure the bracket to the motor (8-25 lb. in.).

6. Carefully, lubricate the seal seat elastomer OD and impeller hub ID with water. Press the seal seat into the impeller hub making certain that the ceramic is in

evenly - the sealing surface should be parallel with the impeller hub.

7. Apply CLEAN water to the carbon-graphite and seal seat sealing surfaces. Do not use silicon lubricants or grease!

8. Lock the shaft by placing a screwdriver blade into the shaft slot at the fan end of the motor. Thread the impeller onto the motor shaft (Insure that the small

impeller washer is in place on the impeller). Thread until the washer securely contacts the shaft shoulder.

9. Seat the large O-ring into the bracket O-ring groove.

10. Assemble the volute onto the bracket with six P-Bolts (10-24 x 2 3/4” carriage bolts) and six flanged lock nuts. Tighten in a cross pattern (30 lb. in.).

11. Install the drain plug and O-ring, into the volute drain hole.

12. Before operating the Valuflo™ 750, allow a proper cure time for the sealant used in step 2.

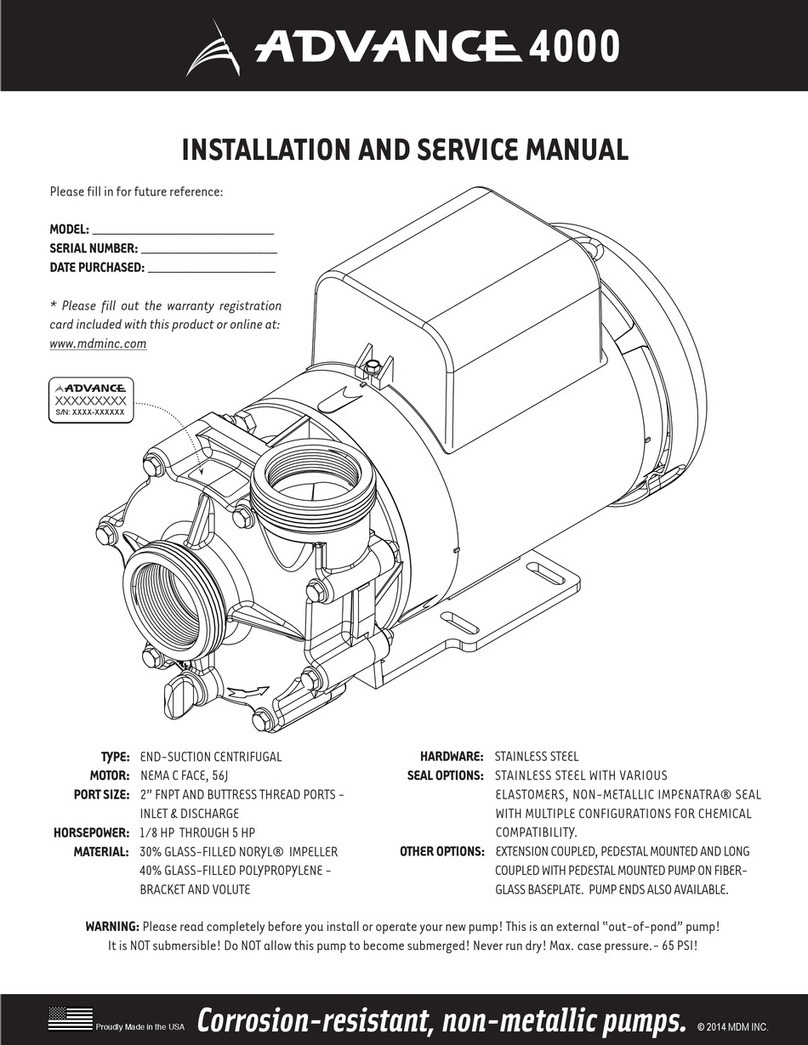

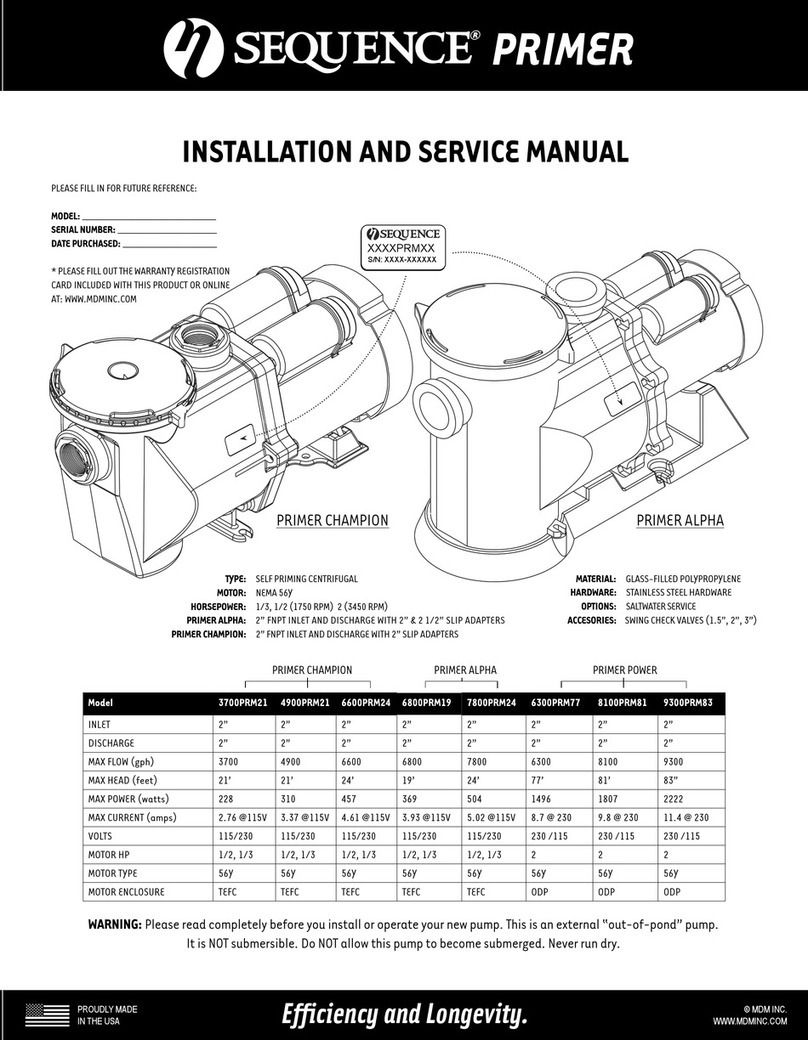

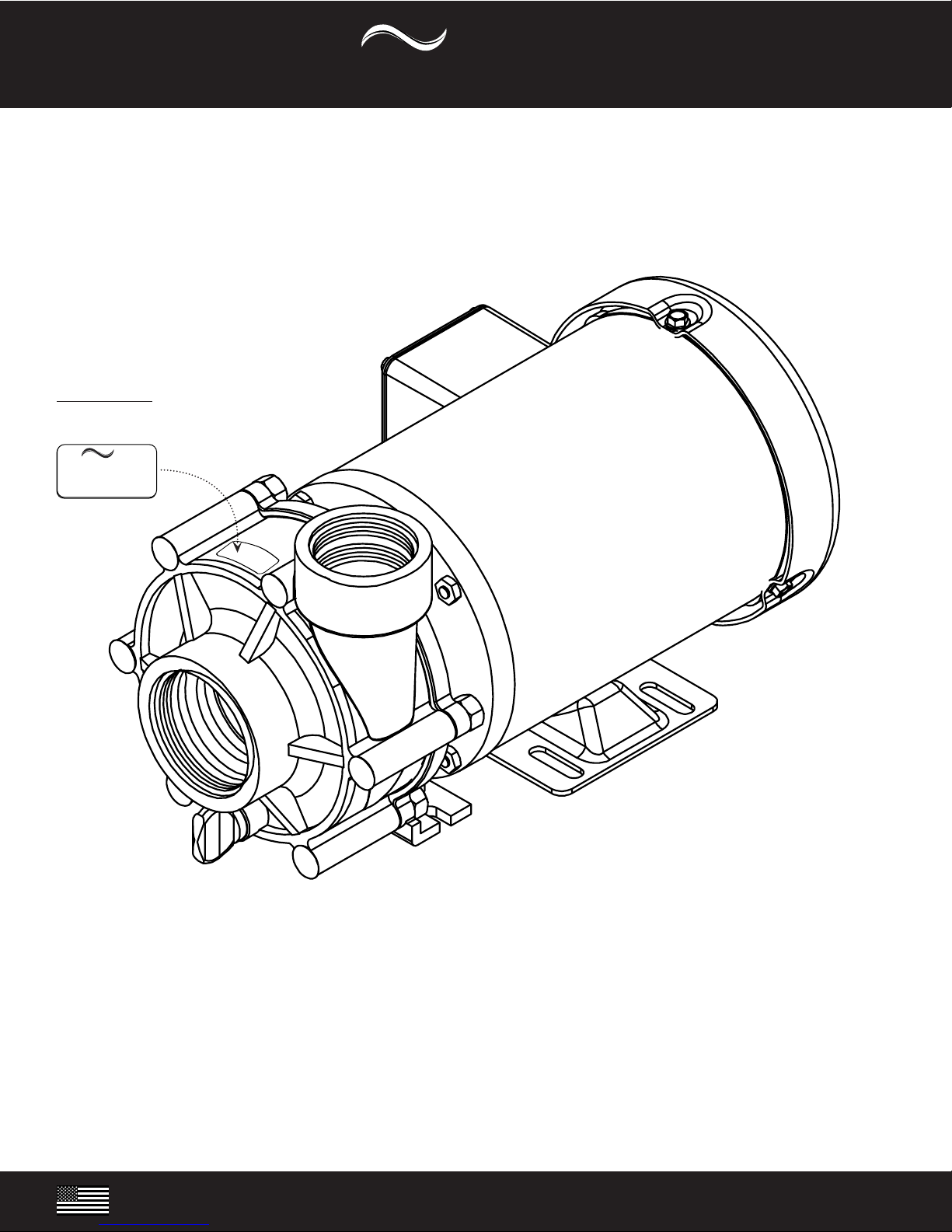

We congratulate you on your choice of the Valuflo™ 750 centrifugal pump! Its leading edge design provides you with high output at a minimal operating cost.

It is carefully constructed to give you long term, reliable service. To insure proper performance, we urge you to carefully follow the instructions in this manual.

If you have any questions, please call your supplier for assistance.

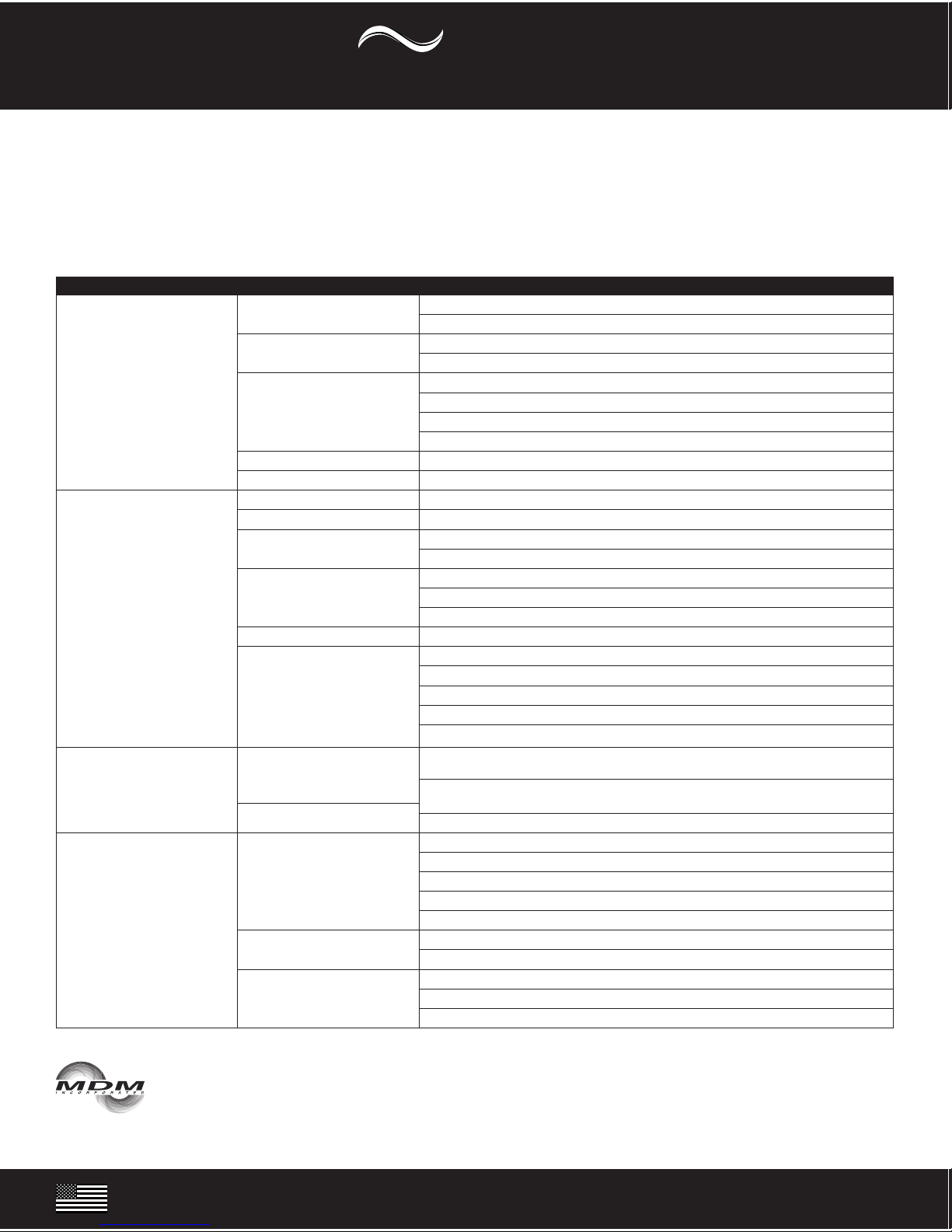

PUMP

BALL VALVE

BALL VALVE

SUCTION LIFT

FLOODED SUCTION

SWING CHECK VALVE

VOLUTE

IMPELLER

IMPELLER

WASHER

BRACKET

M BOLT

FLANGED

LOCK NUT

LARGE

O-RING

SS SEAL

P-BOLT

DRAIN PLUG

& O-RING

3.86

3.07

1.89

7.00

DESCRIPTION MDM P/N

DRAIN PLUG 1000.110 LG

O-RING, DRAIN PLUG E014B70

VOLUTE 750.070 LG

LARGE O-RING 750.061

IMPELLER 750.059

WASHER, IMPELLER 750.012M

SS SEAL 750.0414

BRACKET 750.030 LG

HARDWARE KIT 750.502

SLINGER 750.010

Note: These part numbers are only for standard

models within the Valuflo™ 750 series.

WARNING: DO NOT RUN DRY!

WARNING: ALWAYS SHUT OFF ELECTRICAL POWER BEFORE INSTALLATION AND / OR SERVICING THIS PUMP! ALL ELECTRICAL WIRING SHOULD

MEET STATE AND LOCAL ORDINANCES. NOTE: THE PUMP MOTOR IS DESIGNED FOR 115 VAC 60HZ POWER ONLY! WARNING: SHUT OFF ELECTRICAL

POWER BEFORE INSTALLATION AND / OR SERVICING THIS PUMP! 230V 50HZ MOTORS AVAILABLE - CONTACT YOUR SUPPLIER FOR INFORMATION.

SLINGER

ValuFlo

750

ValuFlo

750

2.19

2” INLET

FNPT

1.5” FNPT

DISCHARGE

0.25” DRAIN PORT FNPT (PLUGGED)

Motor illustration is for reference only.

™ ™