© MDM INC.

WWW.MDMINC.COM

Efficiency and Longevity.

PROUDLY MADE

IN THE USA

© MDM INC.

WWW.MDMINC.COM

Efficiency and Longevity.

PROUDLY MADE

IN THE USA

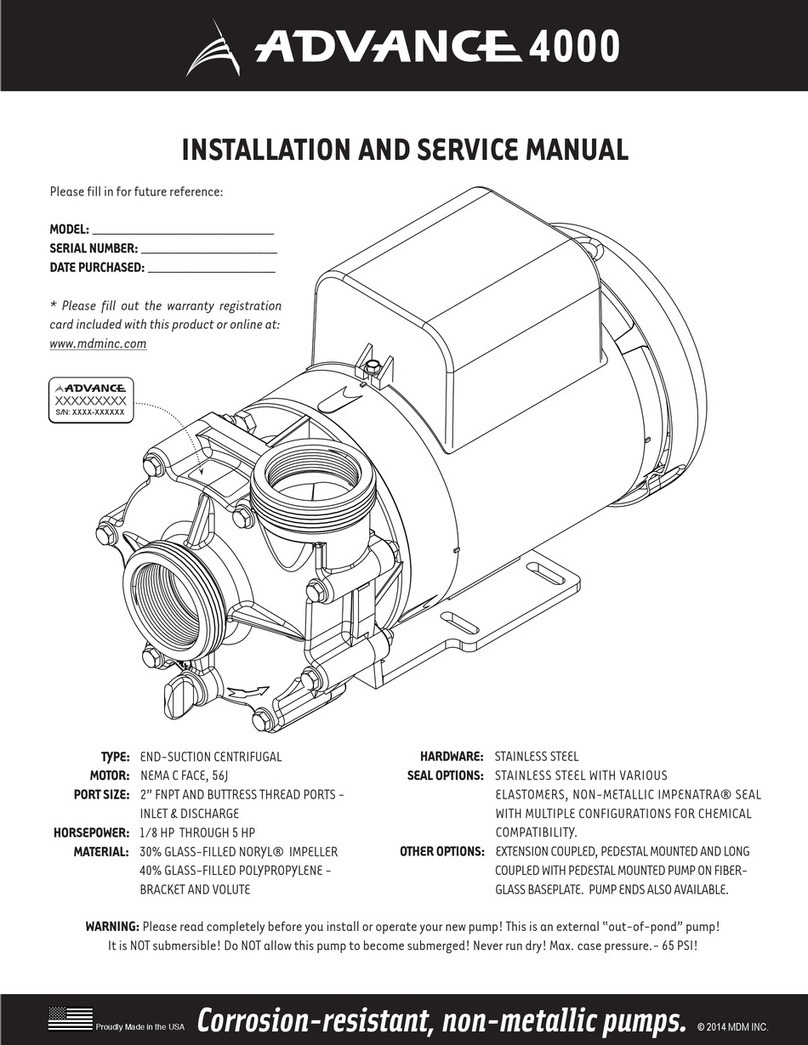

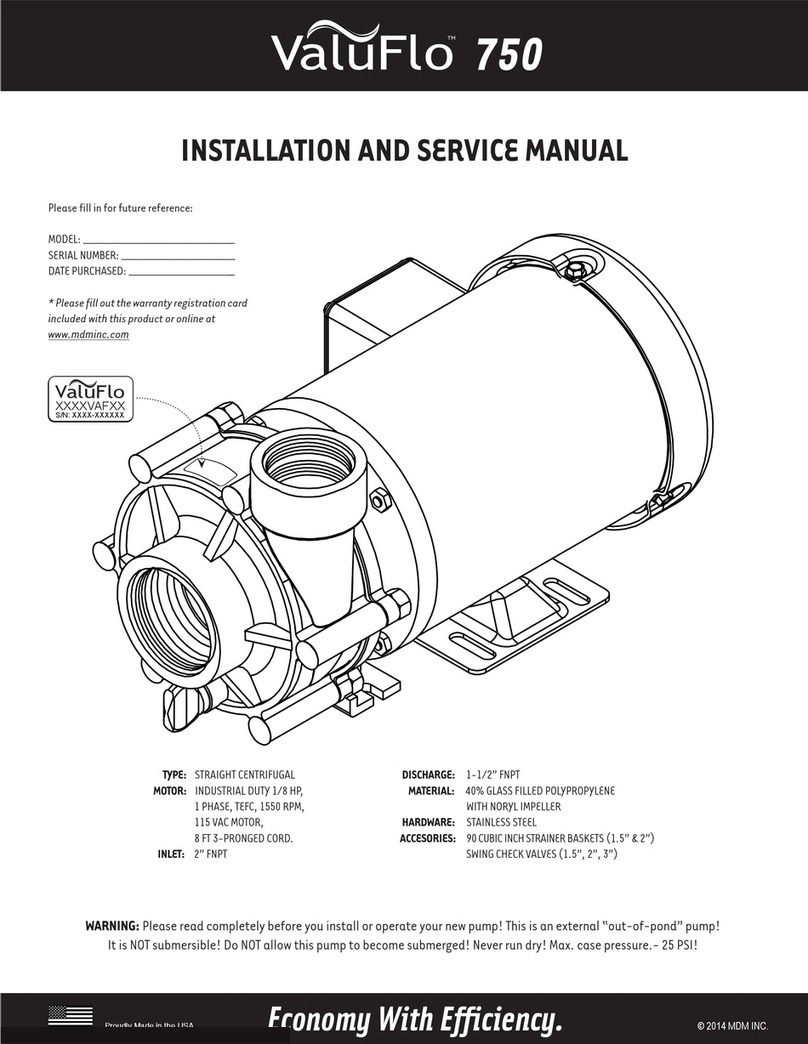

INSTALLATION AND SERVICE MANUAL

TYPE: SELF PRIMING CENTRIFUGAL

MOTOR: NEMA 56Y

HORSEPOWER: 1/3, 1/2 (1750 RPM) 2 (3450 RPM)

PRIMER ALPHA: 2” FNPT INLET AND DISCHARGE WITH 2” & 2 1/2” SLIP ADAPTERS

PRIMER CHAMPION: 2” FNPT INLET AND DISCHARGE WITH 2” SLIP ADAPTERS

MATERIAL: GLASS-FILLED POLYPROPYLENE

HARDWARE: STAINLESS STEEL HARDWARE

OPTIONS: SALTWATER SERVICE

ACCESORIES: SWING CHECK VALVES (1.5”, 2”, 3”)

WARNING: Please read completely before you install or operate your new pump. This is an external “out-of-pond” pump.

It is NOT submersible. Do NOT allow this pump to become submerged. Never run dry.

Model 3700PRM21 4900PRM21 6600PRM24 6800PRM19 7800PRM24 6300PRM77 8100PRM81 9300PRM83

INLET 2” 2” 2” 2” 2” 2” 2” 2”

DISCHARGE 2” 2” 2” 2” 2” 2” 2” 2”

MAX FLOW (gph) 3700 4900 6600 6800 7800 6300 8100 9300

MAX HEAD (feet) 21’ 21’ 24’ 19’ 24’ 77’ 81’ 83”

MAX POWER (watts) 228 310 457 369 504 1496 1807 2222

MAX CURRENT (amps) 2.76 @115V 3.37 @115V 4.61 @115V 3.93 @115V 5.02 @115V 8.7 @ 230 9.8 @ 230 11.4 @ 230

VOLTS 115/230 115/230 115/230 115/230 115/230 230 /115 230 /115 230 /115

MOTOR HP 1/2, 1/3 1/2, 1/3 1/2, 1/3 1/2, 1/3 1/2, 1/3 2 2 2

MOTOR TYPE 56Y 56Y 56Y 56Y 56Y 56Y 56Y 56Y

MOTOR ENCLOSURE TEFC TEFC TEFC TEFC TEFC ODP ODP ODP

®

PRIMER ®

PRIMER

MAINTENANCE WARNING: EYE PROTECTION IS STRONGLY RECOMMENED

Lubrication

Motor - Permanently Lubricated ball bearings - no service required.

Rotary Seal - Requires no lubrication after assembly.

Symptom Problem Resolution

No Flow

Insufficient Prime Prime system with water and purge all air from suction piping.

Install check valve.

Insufficient Power Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Flow Restriction

Ensure valves are open.

Ensure plumbing is clear, including suction strainers, check valves, etc.

Verify check valve orientation and direction of permitted flow.

Clean out leaves or other debris from basket strainer (if applicable).

Insufficient Prime

Prime system with water and purge all air from suction piping. The primer series pumps use low

RPM motors and achieving full system prime could take multiple hours. *This resolution pertains

only to the Primer Champion and the Primer Alpha models.

Air leak Fix air leaks at fittings, connections, priming pot lid, etc. This typically occurs on the intake side.

The priming pot lid o-ring can be lubricated with silicone grease.

System Incompatibility Verify hydraulic compatibility: i.e. pump & pipe are sized for the system.

Low Flow

Air leak Fix air leaks at fittings, connections, priming pot lid, etc. This typically occurs on the intake side.

The priming pot lid o-ring can be lubricated with silicone grease.

System Incompatibility Verify hydraulic compatibility: i.e. pump & pipe are sized for the system.

Insufficient Power Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Flow Restriction

Ensure valves are open.

Ensure plumbing is clear, including suction strainers, check valves, etc.

Clean out leaves or other debris from basket strainer (if applicable).

Insufficient Prime Prime system with water and purge all air from suction piping.

Cavitation

Verify airtight plumbing on the suction plumbing especially fittings.

Clean out leaves or other debris from basket strainer (if applicable).

Increase pipe size where possible.

Decrease suction pipe length, reduce the number of elbows, etc.

Verify hydraulic compatibility: i.e. pump and pipe are sized for the system.

Sporadic Operation

Insufficient Power Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Poor Ventilation Ensure adequate aiflow over motor to prevent overheating.

Excessive Noise

Cavitation

Verify airtight plumbing on the suction plumbing especially fittings.

Clean out leaves or other debris from basket strainer (if applicable).

Increase pipe size where possible.

Decrease suction pipe length, reduce the number of elbows, etc.

Verify hydraulic compatibility: i.e. pump and pipe are sized for the system.

Insufficient Power Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Flow Restriction

Ensure valves are open.

Ensure plumbing is clear, including suction strainers, check valves, etc.

Verify check valve orientation and direction of permitted flow.

PRIMER ALPHAPRIMER CHAMPION

S/N: XXXX-XXXXXX

XXXXPRMXX

PRIMER CHAMPION PRIMER ALPHA PRIMER POWER

Gasgacinch®is a registered trademark of Porter Manufacturing. Noryl®is a registered trademark of the General

Electric Company. Teflon®is a registered trademark of DuPont Company. Sequence®is a registered trademark of

MDM Incorporated. Compilation Installation Manual 2017.indd Adobe Indesign CC 03-28-17

PLEASE FILL IN FOR FUTURE REFERENCE:

MODEL: ___________________________

SERIAL NUMBER: ____________________

DATE PURCHASED: ___________________

* PLEASE FILL OUT THE WARRANTY REGISTRATION

CARD INCLUDED WITH THIS PRODUCT OR ONLINE

AT: WWW.MDMINC.COM

*The pump must be drained before servicing or if stored below freezing

temperatures. Periodic replacement of seals may be required due to normal

carbon wear.

MDM INCORPORATED

3345 N. Cascade Ave • Colorado Springs, CO • 80907

Toll Free Phone (800) 447-8342 • Fax (866) 425-1346