M E A S U R E M E N T S Y S T E M S I N T E R N A T I O N A L

Page 2

MSI-3750 Digital Weight Indicator

◆

User Guide

TABLE OF CONTENTS

INTRODUCTION....................................................3

3750 Display.......................................................3

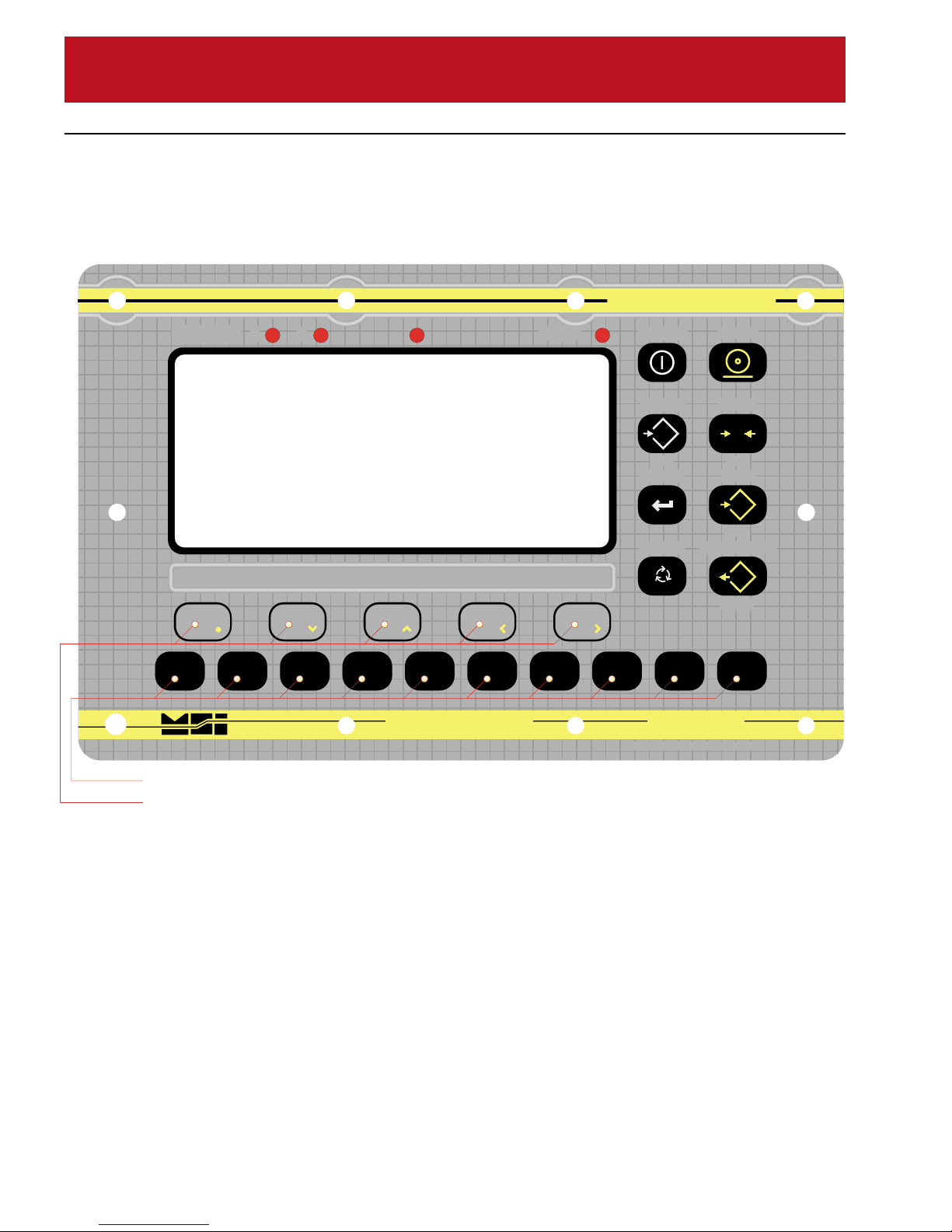

3750 Front Panel ................................................ 4

Features .............................................................5

Batteries (Option) ...............................................6

Load Cell Hookup ............................................... 7

SECTION 1 – SCALE OPERATION ...................... 8

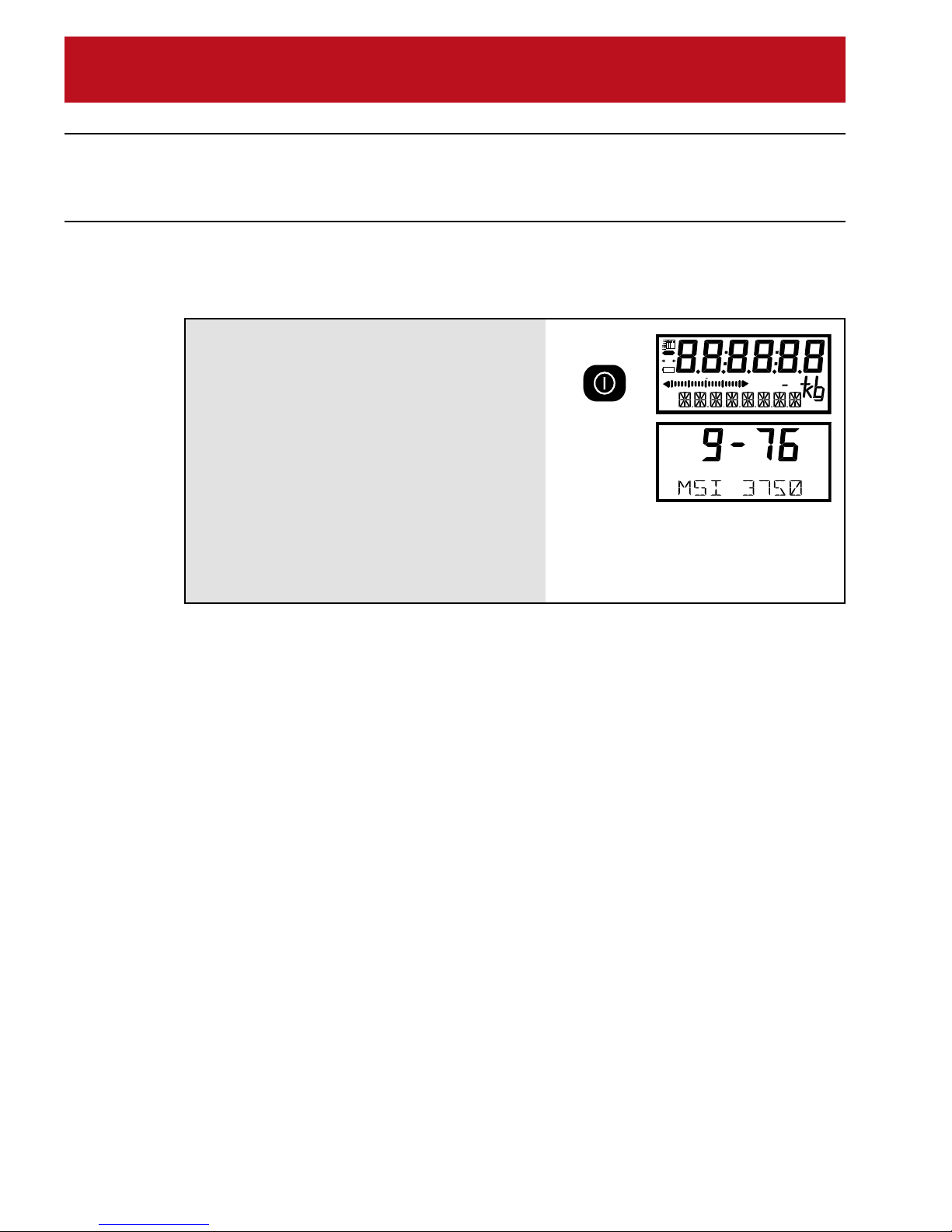

Power .................................................................8

Zero ....................................................................9

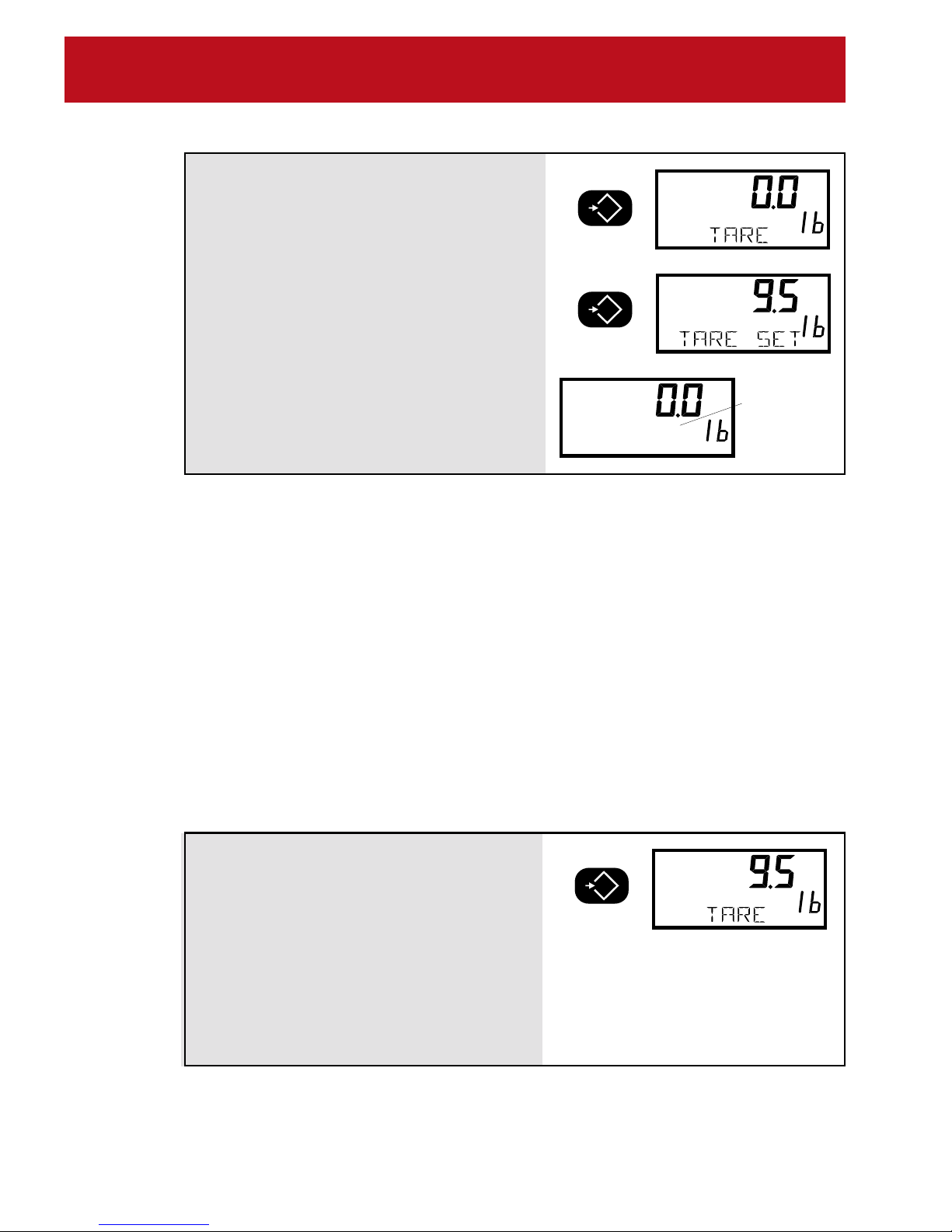

Tare..................................................................... 9

Setup Tare ........................................................ 13

Net/Gross .........................................................16

Units .................................................................16

Setup Units ....................................................... 17

Peak Hold (Function Key Option) ..................... 18

Print .................................................................. 19

Test ................................................................... 19

SECTION 2 – FUNCTION KEYS ......................... 20

Setup Function Keys ........................................20

SECTION 3 – ID CODES..................................... 22

ID Code Organization ....................................... 22

Using ID Codes ................................................24

Setup ID Codes ................................................ 30

ID Code String 1 & String 2 .............................. 33

SECTION 4 – TOTAL / STATISTICS....................35

Total .................................................................. 35

Auto Total..........................................................36

Total Menu (Setup Total)................................... 37

View Total .........................................................40

Clear All Totals.................................................. 42

Statistics (Option) ............................................. 42

Definitions And Formulas.................................. 43

Using Statistics ................................................. 44

SECTION 5 – 3750 METER SETUP.................... 46

Main Setup Menu .............................................46

Filter.................................................................. 47

LCD Contrast.................................................... 48

Real Time Clock/Calendar................................ 49

Setup Power Menu ........................................... 50

LCD Backlight................................................... 51

Bargraph Menu................................................. 52

Lock .................................................................. 54

SECTION 6 – SET POINTS................................. 58

Setup Set Points Menu..................................... 58

Set Point 1 Through Set Point 8 ....................... 60

Using Set Points ............................................... 62

Enabling / Disabling Set Points ........................66

Using The MSI 3750 As A Grading Scale ......... 67

Relay Output Option ......................................... 69

Relay Applications ............................................ 70

Logic Output (Set Point 8) ................................72

Test Set Point Relays ....................................... 73

SECTION 7 – COMMUNICATION PORTS.......... 74

Electrical Conformance .................................... 74

Comm Port Cabling .......................................... 75

Data Configuration............................................ 78

Output Control .................................................. 78

Comm Port Setup Menu ................................... 80

Comm Port Parameters Menu.......................... 81

Printer / Output Formatting ............................... 85

Example Printer Formatting.............................. 88

Programming The End Of Line String ..............91

Editing The Print String..................................... 93

General Text/Control Character Entry ..............94

Serial Output “@” Commands ..........................95

Computer Operation ....................................... 107

SECTION 8 – SCALE CALIBRATION................ 112

Calibrate General Information ........................ 112

Enable Calibration .......................................... 112

Calibrate Setup Menu..................................... 114

To Select Legal Standard ............................... 114

To Calibrate (Standard Calibration) ................ 116

Calibration Error Messages ............................ 118

Reset Calibration ............................................ 120

Reset All ......................................................... 120

Initial Calibration ............................................. 122

To Enable/Disable AZM .................................. 125

To Adjust The Motion Band............................. 127

Coarse Zero.................................................... 128

Raw Counts .................................................... 129

Calibration Flowchart......................................131

APPENDIX A – SPECIFICATIONS & OPTIONS 132

Specifications .................................................132

Options ........................................................... 133

Meter Mounting Bracket .................................135

APPENDIX B – ASCII TABLE ............................136

APPENDIX C – MENU MAPS............................ 137

APPENDIX D – WIRING CONNECTIONS ........ 141

Load Cell Connections ...................................141

RS-232 Connections ......................................141

2nd Comm Port & RS-485 Connections......... 142

Auxiliary Digital Input ...................................... 142

Relay Option Board Connections ...................143

The MSI Limited Warranty .................................144