MECANIL SG220 G2 User manual

MECANIL SG220 / SG280

Manual

Mecanil Products

All rights reserved. Specifications are subject to alteration.

Mecanil Oy Ab can not be held responsible for possible type errors or inconsistencies in this spare parts list.

GENERATION 2

Model

Notes

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

☐

SG220 G2!

SG280 G2

•Works with 2 hydraulic lines, pressure/pressure (grapple open/close).

•Electric wire on the crane boom.

•Pushbuttons that can be installed in joystick.

☐

SG220 RC-T G2

SG280 RC-T G2

•Works with 2 hydraulic lines, pressure/pressure (grapple open/close).

•Integrated wireless control.

•Wireless control with handheld remote.

☐

SG220 RC-M G2

SG280 RC-M G2

•Works with 2 hydraulic lines, pressure/pressure (grapple open/close).

•Integrated wireless control.

•Wireless control with pushbuttons that can be installed in joystick.

☐

SG220 A G2

SG280 A G2

•Works with 2 hydraulic lines, pressure/pressure (grapple open/close).

•Electric wire on the crane boom.

•Pushbuttons that can be installed in joystick..

•Incl. collecting unit (multi-tree handling).

☐

SG220 A RC-M G2

SG280 A RC-M G2

•Works with 2 hydraulic lines, pressure/pressure (grapple open/close).

•Integrated wireless control.

•Wireless control with pushbuttons that can be installed in joystick.

•Incl. collecting unit (multi-tree handling).

"

© 2017 Mecanil Oy Ab

"

Page of 250

www.mecanilproducts.com

www.mecanil.fi

Contents

Model 2....................................................................................................................................

Notes 2....................................................................................................................................

Contents 3...............................................................................................................................

We thank 5...............................................................................................................................

Safety instructions 6................................................................................................................

General safety instructions 6............................................................................................................

Instructions for safe operation 7.......................................................................................................

Description of labels / Warning labels 8............................................................................................

Placement of labels on the product 9...............................................................................................

Installation 10............................................................................................................................

Recommendations and tips 10...........................................................................................................

Contents of the delivery 12.................................................................................................................

Radio control - handheld remote transmitter (RC-T) 12..........................................................................

Radio control - transmitter with separate pushbuttons (RC-M) 12..........................................................

Radio control - transmitter with separate pushbuttons and collectin unit (A RC-M) 13...........................

Cable control - without collecting unit 14.................................................................................................

Cable control - with collecting unit (A) 14................................................................................................

Basic installation instructions 15.........................................................................................................

Take in use - handheld remote (RC-T) 18..........................................................................................

Take in use - remote with push buttons (RC-M) with or without collecting unit 20..............................

Take in use - cable control with push buttons, with or without collecting unit (A) 22..........................

Control with the cranes own remote 24..............................................................................................

Use and Maintenance 27...........................................................................................................

Initial check before use 27..................................................................................................................

Check after first use 28.......................................................................................................................

Daily use and maintenance 29..........................................................................................................

Service 29...........................................................................................................................................

Chain lubrication 29............................................................................................................................

Tensioning the drive belt 30................................................................................................................

Check tension of the belt after tensioning or replacement 31.............................................................

Tensioning the saw chain 32...............................................................................................................

Replacing saw bar and saw chain 33.................................................................................................

Adjusting the speed of the saw bar 35................................................................................................

Lubrication points 36...........................................................................................................................

Hydraulics 37.............................................................................................................................

Valve set 37........................................................................................................................................

Hydraulic schematic 38.......................................................................................................................

Valve for collecting unit 39..................................................................................................................

Electronics 40............................................................................................................................

Electronics schematic 40....................................................................................................................

MRemote 1.0 logic 41.........................................................................................................................

Technical data 42.......................................................................................................................

"

© 2017 Mecanil Oy Ab

"

Page of 350

www.mecanilproducts.com

www.mecanil.fi

Measurements SG220 43...................................................................................................................

Measurements SG280 44...................................................................................................................

Technical data - wireless control 45....................................................................................................

Instructions for pairing transmitter to receiver 47................................................................................

Warranty conditions 48..............................................................................................................

Declaration of conformity 49......................................................................................................

Form - Warranty application 50.................................................................................................

"

© 2017 Mecanil Oy Ab

"

Page of 450

www.mecanilproducts.com

www.mecanil.fi

We thank

you for the confidence you’ve showed us in your choice of Mecanil SG220 or Mecanil SG280

grapple saw.

The Mecanil SG220 and SG280 grapple saw is a grapple suitable for felling of trees and branches

on sensitive areas such as in park areas, near power liness and other similar areas. The grapple

saw also works well to fell eg. energy wood. The grapple does not require any additional hydraulic

hoses and no auxiliary valves on the crane boom. The grapple is also easy to install and it works

with a small oil flow.

By using the product in a suitable manner and with regular maintenance it will serve you for many

years.

Read the instructions carefully!

Even if you have experience with this type of product, we recommend that you read our

instructions carefully to familiarize yourself with the product. The instructions contain information

that is essential for safety and efficiency, but also for the factory warranty to apply. When receiving

your purchased product, check that there are no shipping and transport damages on your product.

If there should be any damages or if parts are missing, contact your dealer immediately.

It is the user's obligation to familiarize him/herself with the use of the product and to follow the

instructions carefully. It is the responsibility of the user to make sure that the mounting and

connections between the grapple and crane are designed and adapted to handle the loads and

strains of the grapple with a safety margin. It is the responsibility of the user to ensure, for

example, that the vehicle has the necessary capacity to handle the use of grapple saw.

Mecanil Oy Ab reserves the right to change equipment and maintenance instructions as well as

data without prior information.

Summary!

1. Read the instruction.

2. Follow the instructions and contact your dealer if necessary.

3. Make sure the crane and hydraulic system are capable of handling a grapple saw.

4. Lubricate and service the grapple as mentioned in the instructions.

5. Have a professional repair any possible damages (even small ones) immediately.

6. Always work in a calm and foreseeing manner. "

Take special note of all warnings, considerations and notes contained in this

manual, which are marked with the following mark in the manual:

Manufacturer: Mecanil Oy Ab, Riksvägen 565, 07880 Liljendal, FINLAND

"

© 2017 Mecanil Oy Ab

"

Page of 550

www.mecanilproducts.com

www.mecanil.fi

Safety instructions

General safety instructions

Read the manual carefully before using the crane.

Familiarize yourself with the functions and usage of the grapple saw.

Be especially careful when connecting and disconnecting the grapple saw to the crane or

machine.

Extreme caution should always be exercised when using the grapple saw.

Make absolutely sure that no one is within a dangerous distance of the working grapple

saw.

The operator must always have a clear oversight of the work area.

Never insert your hand or any other body part into the machine assembly or under hanging

load during work or when the hydraulic system is active (pressurized).

Walking under a hanging load is always forbidden and the operator is not allowed to lift a

load over people in any circumstances.

Do not overload the grapple saw.

Extraordinary caution should be taken when working near electrical lines or other sensitive

areas. Keep the safety distances. Expect risk of unforeseen movements. Any local

guidelines and regulations for working near power lines must always be followed.

When working in cold or especially freezing temperatures, all movements should first be

performed carefully to soften seals in the cylinders and valves.

Never let an outside person handle the grapple saw / machine, before you make sure that

this person has understood all operating and safety instructions.

Always shut down the machine for maintenance, service and repairs. Care should always

be taken when servicing, servicing and repairs.

The tilt function is equipped with a shock valve to prevent overloading the cylinders and

other breakage.

The cylinder for the grapple claws is equipped with a load holding valve.

"

© 2017 Mecanil Oy Ab

"

Page of 650

www.mecanilproducts.com

www.mecanil.fi

Instructions for safe operation

It is strictly forbidden to be inside of the risk zone of the grapple saw or crane.

Extraordinary caution should be taken when working near electrical lines or other sensitive

areas. Keep the safety distances. Expect risk of unforeseen movements. Any local

guidelines and regulations for working near power lines must always be followed. Var

ytterst försiktig när du kopplar gripsågen till och från kranen eller maskinen.

The operator must always have a clear oversight of the work area.

Never insert your hand or any other body part into the machine assembly or under hanging

load during work or when the hydraulic system is active (pressurized).

Walking under a hanging load is always forbidden and the operator is not allowed to lift a

load over people in any circumstances.

Localize any problem before any mending attempts, this will prevent unnecessary work and

possibly worsening the situation.

The grapple saws hydraulic hoses and pipes must always be kept in good condition.

Replace any of these immediately when any weakening is detected, especially the ones

connected to the grapple claws. Inspections are to be done daily. Air in the hydraulic

system can cause unforeseen movements, so always “bleed” the system by driving the

cylinder end-to-end several times after replacing any part of the hydraulic circuit.

Use original parts, by using original parts will ensure a more problem free use of the

product. Also note that if a failure is a result of not using original parts, the user assumes all

risk.

Never let an outside person handle the grapple saw / machine, before you make sure that

this person has understood all operating and safety instructions.

Always use appropriate safety gear, like helmet, safety goggles etc.

The cylinder for the grapple claws is equipped with a load holding valve."

"

Leave the holding valve installed, when the grapple saw will be used for taking down

trees in pieces. (knuckle boom cranes, truck cranes, tele-handlers or similar)."

The valve prevents the the grapple from opening (and dropping the load) in case of a hose

break."

Uninstall the valve, if the grapple saw will be used to fell whole trees that will be cut at

ground level. (Forestry harvesters, forwarders, excavators or similar).

"

© 2017 Mecanil Oy Ab

"

Page of 750

www.mecanilproducts.com

www.mecanil.fi

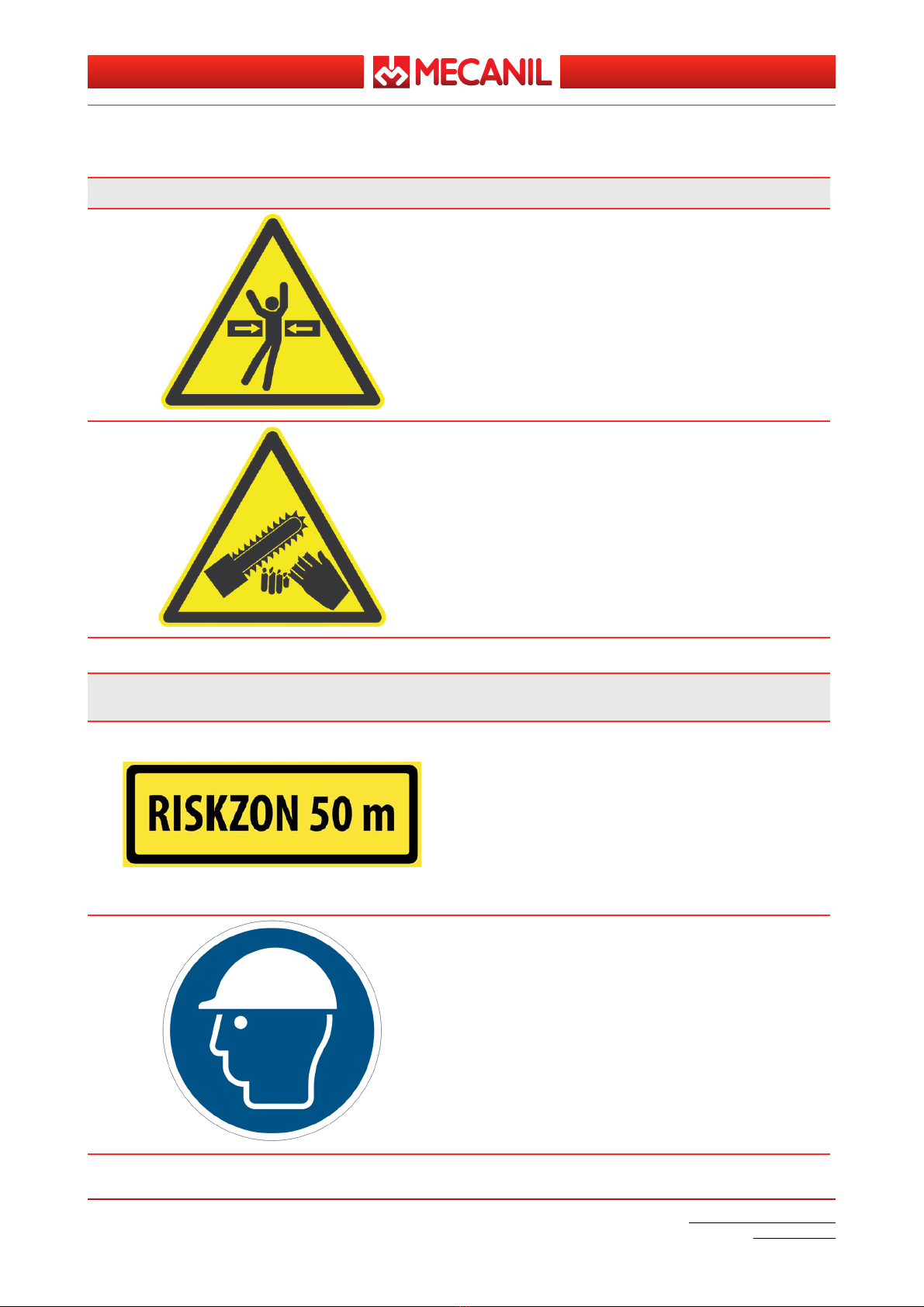

Description of labels / Warning labels

Labels and warning symbols on the grapple

Warning for risk of crushing

Be aware of the risk of being crushed by the

grapple arms, tilt function and other moving

parts on the grapple. Negligence may lead to

severe or fatal injuries.

Warning for the saw

Be aware of the risk of the saw.

The machine must always be turned off before

doing any maintenance, service or repairs on

the grapple saw. Negligence may lead to

severe or fatal injuries.

Other labels that also relate to the use of the grapple

saw

Risk zone 50 m (50 yards).!

The grapple saw also inherits all

possible warnings that applies to the

machine and/or crane it’s installed on

Eg. bigger risk zone.

Make sue you always have a clear view of the

working area. Negligence may lead to severe or

fatal injuries.

Usage of safety gear

Always use appropriate safety gear to avoid

injuries during your work.

"

© 2017 Mecanil Oy Ab

"

Page of 850

www.mecanilproducts.com

www.mecanil.fi

Installation

Recommendations and tips

There are some recommendations and tips to consider when installing the grapple saw.

The grapple saw can perform slightly different depending on the machine which it is mounted on.

Both the SG220 and SG280 grapple saw work very well on trucks with long cranes. The SG220

and SG280 with radio control are popular, because no power cable needs be installed along the

crane boom. Only 2 hydraulic lines are needed (grapple open & Grapple close)

"

© 2017 Mecanil Oy Ab

"

Page of 10 50

www.mecanilproducts.com

www.mecanil.fi

NOTE! Load holding valve on the grapple cylinder:!

Leave the valve installed, when the grapple saw is installed on a machine meant for

taking down a tree in smaller pieces. (Mobile cranes, tele handlers, knuckle boom

cranes or similar)

Uninstall the valve, if the grapple saw will be used to fell whole trees that will be

cut at ground level. (Forestry harvesters, forwarders, excavators or similar).

The machine must always be shut down when servicein or doing maintenance

work on the grapple saw!

SG220 and SG280 are to be mounted free hanging, with a rotator and link.

Fixed mounting is not allowed.

We recommend a minimum of ½” hydraulic lines along the boom. !

If quick connectors are used for the hydraulic lines, use one size bigger connectors in "

comparison to the hose size."

NOTE! No bleed line (from saw motor) needed..

If the hydraulic hoses are too small the saw will feel slow and counter (back) pressure will rise. "

The counter pressure should not exceed 50 bar (725 PSIs).

SG220 and SG280 can be installed on a variety; !

Trucks, forwarders, excavators etc.

These recommendations should be noted especially when installing the grapple saw on

a crane with a long boom. For example on a crane with a reach of 20-35 m (60 -120 ft), eg.

knuckle boom cranes, telehandlers or similar.

When installing on shorter cranes smal smaller lines will probably suffice.

The recommended oil flow for SG220 is approx. 50-80 l/min. (13 - 20 gpm).!

The recommended oil flow for SG280 is approx. 60-100 l/min. (15-26 gpm).!

The grapple saw will also work with less oil flow (eg. 40l/min.[10gpm]), but the saw will

then work slower.

Note! No bleed line (from saw motor) needed.

NOTE!

All machines are different.!

Different machines have different hydraulic pressure and flow.

Please contact the dealer or manufacturer for more information.

"

© 2017 Mecanil Oy Ab

"

Page of 11 50

www.mecanilproducts.com

www.mecanil.fi

Open-center valve for grapple function.!

For the chain lubrication pump to work as supposed, the pressure must be relieved from

the hydraulic circuit for the grapple function. This may be achieved by using a “open-

center” valve (on the cranes valve set), meaning that oil can freely flow in or out when no

function is activated. Relieveing pressure will allow the pump to reset and fill with

lubrication oil and again administer it when the saw function is initiated next time.

Keep Grapple close function initiated while using tilt up, tilt down or saw

functions. This produces oil pressure to the grapple saw. Tilt up and tilt down

functions will also work with keeping grapple open function activated.

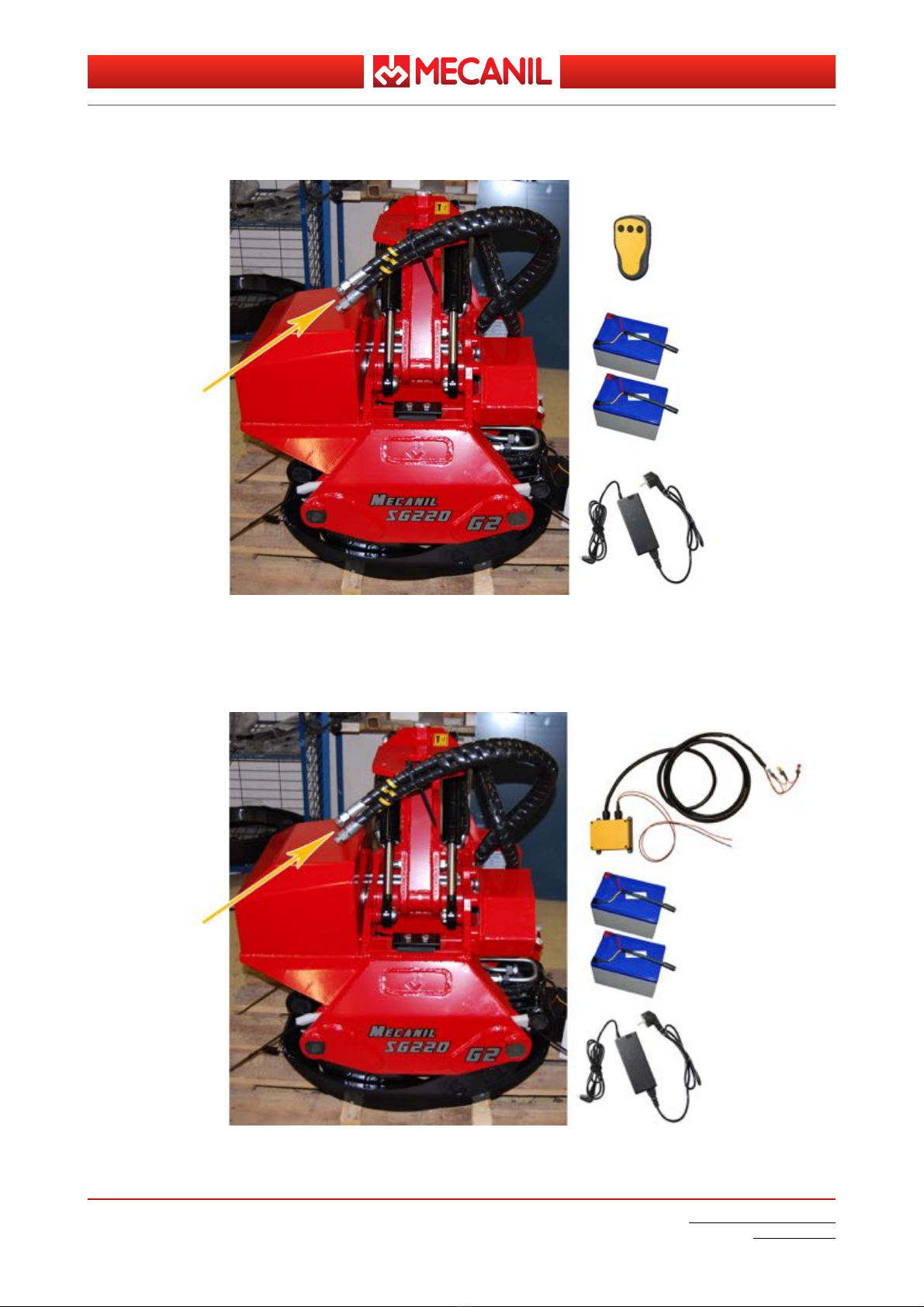

Contents of the delivery

Radio control - handheld remote transmitter (RC-T)

dkmfslkflsfd

If the grapple saw is ordered with rotator and link, the delivery will also include bolts for installation as well as hydraulic

fittings for the grapple hoses to rotator.

Radio control - transmitter with separate pushbuttons (RC-M)

If the grapple saw is ordered with rotator and link, the delivery will also include bolts for installation as well as hydraulic

fittings for the grapple hoses to rotator.

"

© 2017 Mecanil Oy Ab

"

Page of 12 50

www.mecanilproducts.com

www.mecanil.fi

Hydraulic hoses for

grapple open /

grapple close

Grapple close > <

Grapple open < >

Transmitter

2 pcs. batteries

1 pc. battery

charger

1 pc.

grapple saw

(SG220 or

SG280)

Hydraulic hoses for

grapple open /

grapple close

Grapple close > <

Grapple open < >

Transmitter

Power cable

Pushbuttons

1 pc.

grapple saw

(SG220 or

SG280)

2 pcs. batteries

1 pc. battery

charger

Radio control - transmitter with separate pushbuttons and collectin unit (A RC-M)

If the grapple saw is ordered with rotator and link, the delivery will also include bolts for installation as well as hydraulic

fittings for the grapple hoses to rotator.

"

© 2017 Mecanil Oy Ab

"

Page of 13 50

www.mecanilproducts.com

www.mecanil.fi

2 pcs. batteries

1 pc. battery

charger

1 pc.

grapple saw

(SG220 or

SG280)

Power cable

Pushbuttons

Transmitter

Hydraulic hoses for grapple open / close.

Grapple close > < Grapple open < >

Cable control - without collecting unit

If the grapple saw is ordered with rotator and link, the delivery will also include bolts for installation as well as hydraulic

fittings for the grapple hoses to rotator.

Cable control - with collecting unit (A)

If the grapple saw is ordered with rotator and link, the delivery will also include bolts for installation as well as hydraulic

fittings for the grapple hoses to rotator.

"

© 2017 Mecanil Oy Ab

"

Page of 14 50

www.mecanilproducts.com

www.mecanil.fi

Grapple saw

Push buttons

Control box

Power feed

Control cable

Grapple open/

close hydraulic

hoses

Push buttons

Grapple open/

close hydraulic

hoses

Control box

Power feed

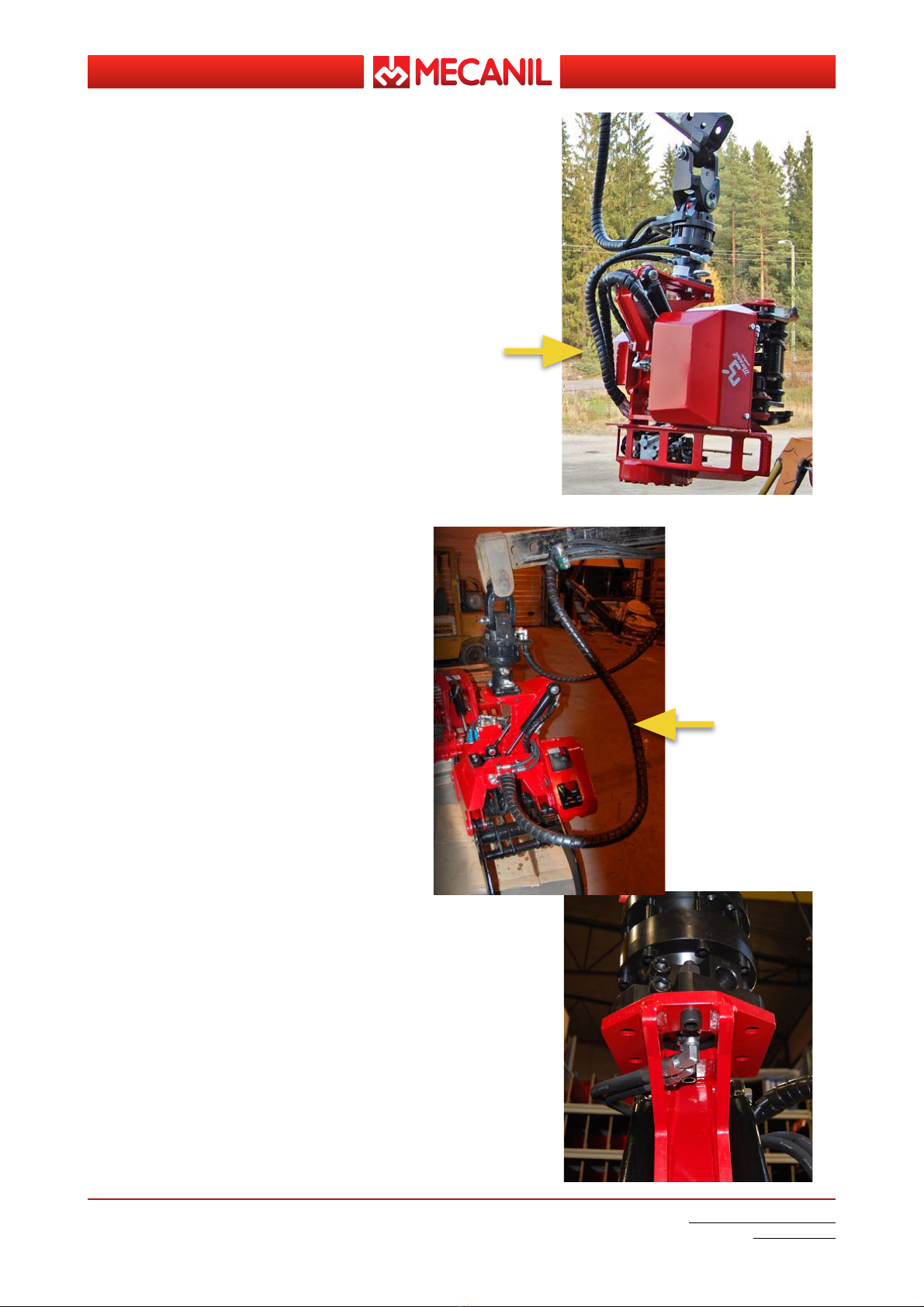

Basic installation instructions

Installation may vary depending on what type of machine it is installed on, all machines are

different.

Please contact the dealer or manufacturer for more information.

Install the grapple saw at the tip of the

crane. Mounting plate for rotator: 173/6."

(6 bolts)."

"

Use rotator and link."

"

If a rotator with axle is used.

An adapter flange needs to be used "

between the rotator and the

grapple saw."

"

NOTE!!

Recommendation: use!

1/2” hoses to the grapple saw, to

ensure enough oil flow to the

grapple saw. (approx 50-80 l/min.).!

This may apply especially when the

unit is installed on a machine with a

long boom. (eg. a truck crane, !

knuckle boom crane).

It also helps to install 1/2” hoses

close to the tip of the crane slangar på sista ändan av

kranen.

Eg. if the crane has a JIB, the JIB

can have bigger hoses.

!

!

The grapple saw will also work with less oil flow but the saw will run slower.

If fast connectors are used on the hydraulic hoses, use one dimension bigger connectors in

comparison to the hoses, as fast connectors often restrict oil flow significantly."

NOTE!#TAKE EXTREME#CAUTION#WHILE#INSTALLING#THE#UNIT,

AS#THERE#IS#EVIDENT#RISK#FOR#GETTING#CRUSHED.

MAKE#ABSOLUTELY#SURE#THAT#THE#MACHINE#IS#TURNED#OFF#DURING#THE##########

INSTALLATION!

"

© 2017 Mecanil Oy Ab

"

Page of 15 50

www.mecanilproducts.com

www.mecanil.fi

Link

Rotator

Grapple saw

Rotator"

SG220 or SG280 with radio control:

To allow free endless) rotation for the grapple saw "

you need a rotator with the option of channeling the "

oil for grapple open / close through the axle of the"

rotator.

In other cases the hydraulic lines can be installed to

bypass the rotator."

"

"

"

"

SG220 or SG280 with cable control:!

Use a hydraulic hose to shield the control

cable. Hose size approx. 1/2”-3/4”.

Preferably bundle the grapples open and

close hydraulic hoses togehter with the

shield-hose for the control cable,"

bypassing the rotator.

Note!!

Make sure the channels through the rotator

are big enoug to ensure the needed oil flow

to the grapple saw. !

!

The fittings for the grapple functions may also be

connected from the bottom of the rotator (depending

on the rotator model).

"

© 2017 Mecanil Oy Ab

"

Page of 16 50

www.mecanilproducts.com

www.mecanil.fi

Grapple open/

close hydraulic

hoses

SG220 or SG280 with cable control:

Install the control cable to the cabin.

Make a junction for the cable on one or several points along the boom.

This can be done in many ways depending on what kind of base machine the grapple saw is

installed on.

This is to prevent the need to change the whole cable if a break were to occur.

Some examples.

Example 1:

Example 2:

Example 3:

"

© 2017 Mecanil Oy Ab

"

Page of 17 50

www.mecanilproducts.com

www.mecanil.fi

Take in use - handheld remote (RC-T)

NOTE! Read page 27 (inspection before use) before using the product.

Charging the battery:

The delivery contains two batteries and on 110-240 V battery charger for the grapple saw.

If you wish to charge the batteries in the machine (12V or 24V) an inverter needs to be used.

The batteries are LiFePO4 batteriesr and need a smart-charger to be charged.

Ask your dealer for more information.

When the battery is empty, disconnect it to prevent damages to the battery. (The battery will

usually get empty very suddenly).

For example, even if it’s the end of your work day when the battery runs out, do not leave it

connected. As the grapple saw’s electrical system still is active and could deep-discharge the

battery. Deep-discharging a LiFePo4 battery may destroy the cells indefinitely.

"

© 2017 Mecanil Oy Ab

"

Page of 18 50

www.mecanilproducts.com

www.mecanil.fi

Remote - buttons

Functions:

1. Tilt up

2. Tilt down

3. Saw

Grapple open / close functions are

activated via the cranes integrated controls.

Keep the grapples close function activated while using the

grapple saws functions. This produces hydraulic pressure to

the circuit.

Controlling the grapple saw by remote safely:

SG220 RC-T and SG280 RC-T is controlled only by the remote.

No additional control box is to be installed.

Example:

Install a small plate to the side of the canes remote, where the grapple saw’s remote can be

placed. The grapple open / close functions are controlled by the original control for the crane.

"

© 2017 Mecanil Oy Ab

"

Page of 19 50

www.mecanilproducts.com

www.mecanil.fi

Take in use - remote with push buttons (RC-M) with or without

collecting unit

NOTE! Read page 27 (inspection before use) before using the product.

Charging the battery:

The shipment includes two batteries and on 110-240V charger for the remote.

If one wishes to charge the battery from a 12V or 24V system the charger needs to be

connected to an appropriate inverter.

The batteries are based on LiFePo4 technology and always need to be charged with a smart

charger meant for LiFePo4 batteries with an appropriate Ampere feed.

Ask your dealer or the manufacturer for more information.

When the battery runs out disconnect the the battery to prevent any damages to the battery.

The battery will run out very abruptly, as it’s electronically controlled by a circuit that will

disconnect the load when charge gets too low.

For example, even if it’s the end of your work day when the battery runs out, do not leave it

connected. As the grapple saw’s electrical system still is active and could deep-discharge the

battery. Deep-discharging a LiFePo4 battery may destroy the cells indefinitely.

"

© 2017 Mecanil Oy Ab

"

Page of 20 50

www.mecanilproducts.com

www.mecanil.fi

Pushbuttons - Functions:

The grapple open / close functions are controlled by the

original integrated controls.

Keep the grapple’s close function activated to use the units other

functions, this build hydraulic pressure in the circuit. Grapple

open function will also allow the tilt up and down functions to

run. For safety reasons, the saw will only run with grapple close

function activated.

= Tilt up (brown cable)

= Tilt down (yellow cable

= Saw (purple cable)

= Collecting unit (green cable)

This manual suits for next models

9

Table of contents