turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired

- Do not use accessories which are not speci-

cally designed and recommended by the tool

manufacturer. Just because the accessory

can be attached to your power tool, it does not

assure safe operation.

- Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the

power tool is maintained

PERSONAL SAFETY

- Stay alert, watch you are doing and use com-

mon sense when operating a power tool. Do not

use a power tool while you are tired or under

the inuence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury

-Use clamps or another practical way to se-

cure and support the workpiece to a stable

platform. Holding the work by your hand or

against the body leaves it unstable and may

lead to loss of control

USE AND CARE

-This machine may only be started and operated

by persons familiar with crosscut saws and

are aware of the dangers associated with the

operation of crosscut saws. Persons under 18

years of age may use this machine only in the

course of their vocationally training, under the

supervision of an instruction.

-These operating instructions are intended

for people with basic technical knowledge

regarding the operation of a machine like this.

Inexperienced persons are strongly advised

to seek competent advice and guidance from

an experienced person before operating this

machine.

-Keep bystanders, particularly children, out of

the danger zone. Do not permit other persons

to touch the machine or power cable while it is

running

- Do not let persons, especially children, not

involved in the work touch the appliance or the

extension cord and keep them away from the

work area.

- When not in use, the appliance should be

stored in a dry locked-up place, put of reach of

children.

- Use the right the appliance. Do not force small

appliances to do the job of a heavy-duty tool.

- Do not use the appliance for purposes not

intended, for example do not use circular saws

to cut tree limbs or logs.

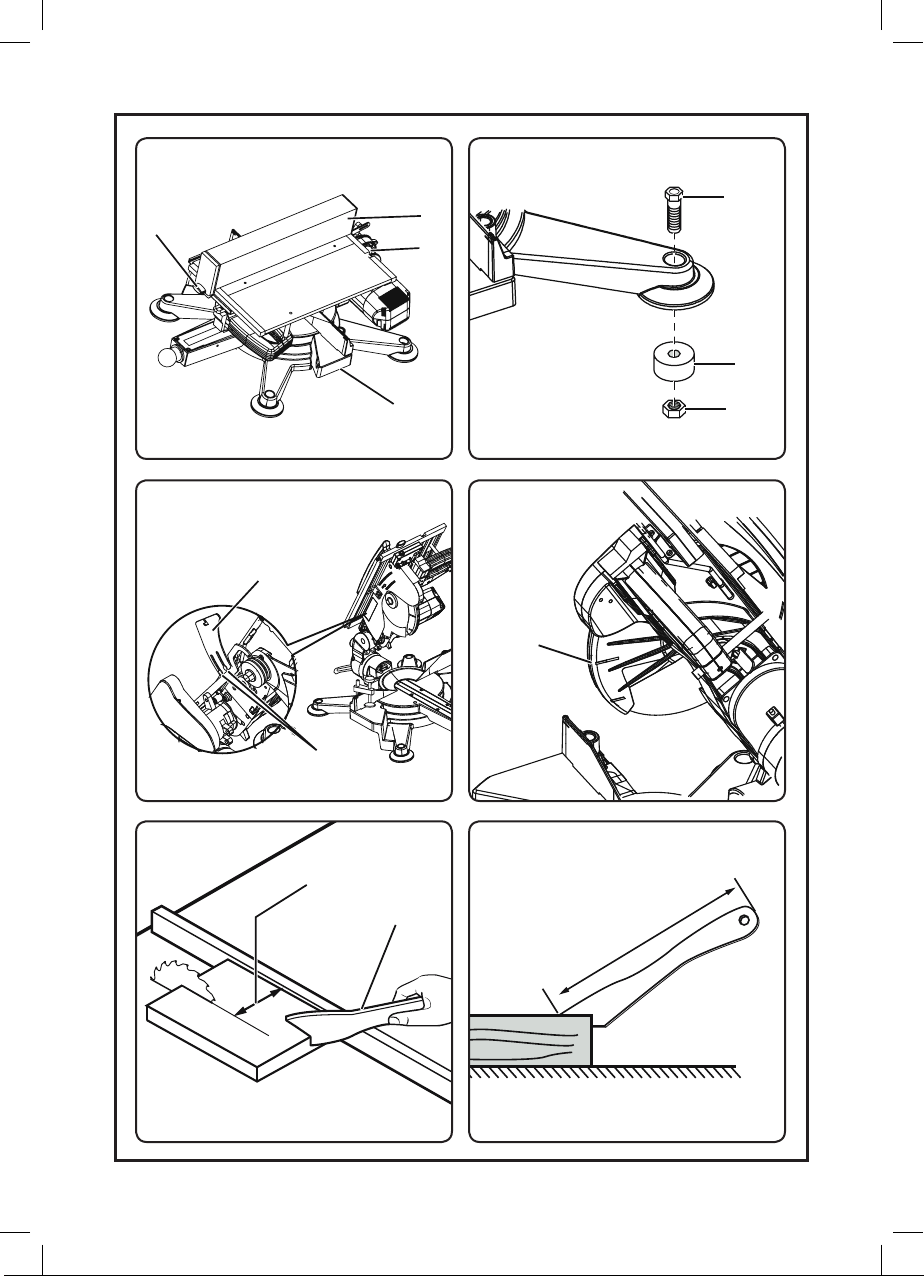

- If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

- Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

- Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control

-Follow instructions for lubricating, chain

tensioning and changing accessories.

Improperly tensioned or lubricated chain may ei-

ther break or increase the chance for kickback.

-Keep handles dry, clean, and free from oil

and grease. Greasy, oily handles are slippery

causing loss of control.

- Disconnect the appliance from the mains when

not in use and before undertaking any cleaning

task.

- Unplug the appliance from the mains before

replacing any accessory.

- Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury

- Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

the power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your nger on the switch or energizing pow-

er tools that have the switch on invites accidents

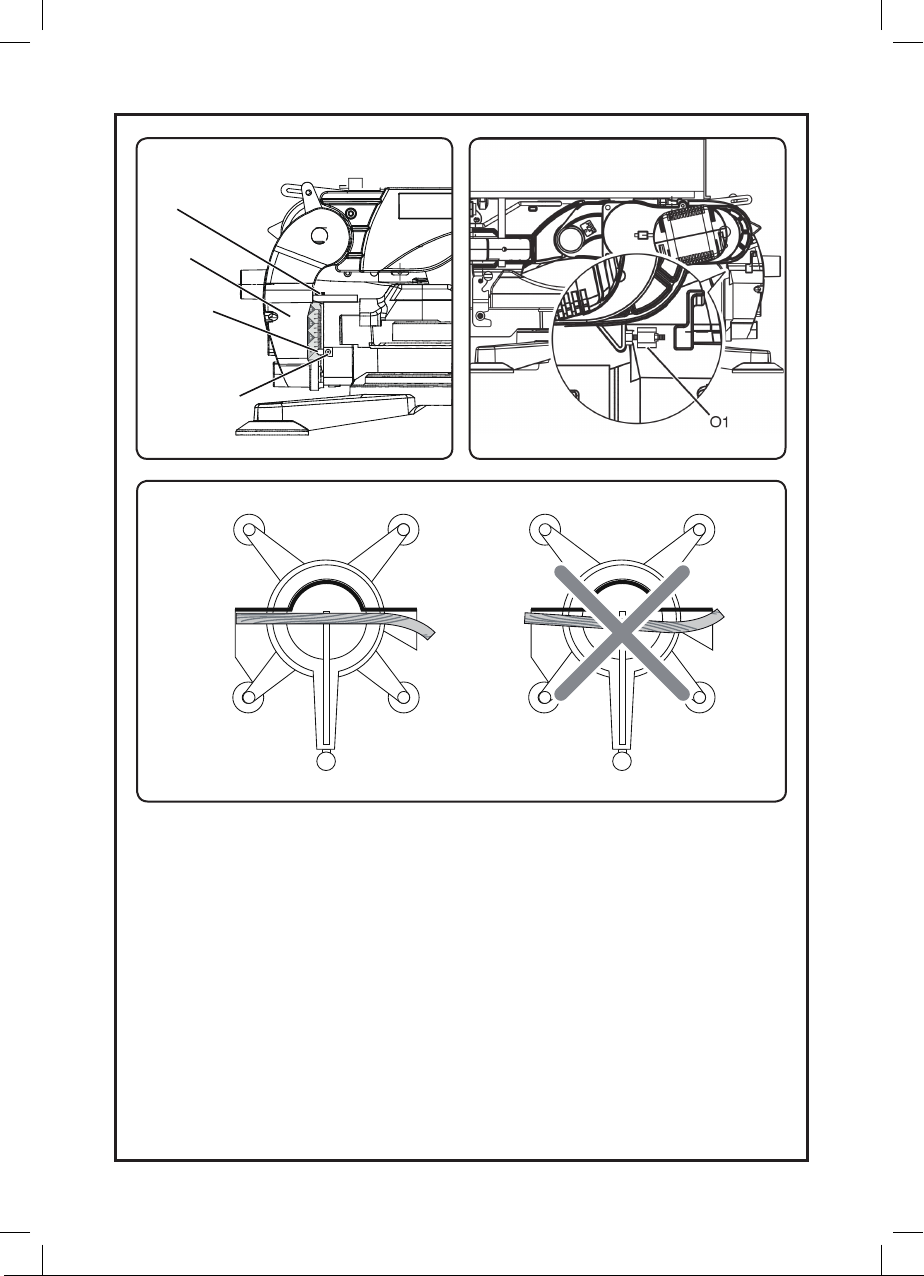

- Never use the machine without guard. Keep

guards in place.

-Always keep sufcient distance to the saw

blade. Use suitable feeding aids, if necessary.

Keep sufcient distance to driven components

when operating the machine.

-Wait for the saw blade to come to a complete

stop before removing cutoffs, scrap, etc, from

the work area.

-Do not attempt to stop the saw blade by pushing

the work piece against its side.

-Ensure that when turning ON no tools or loose

parts are left on or in the machine.

-Wear gloves when changing the cutting blade

-Store the saw blade(s) in such manner that

nobody can get hurt.

-Ensure that riving knife is correctly set when