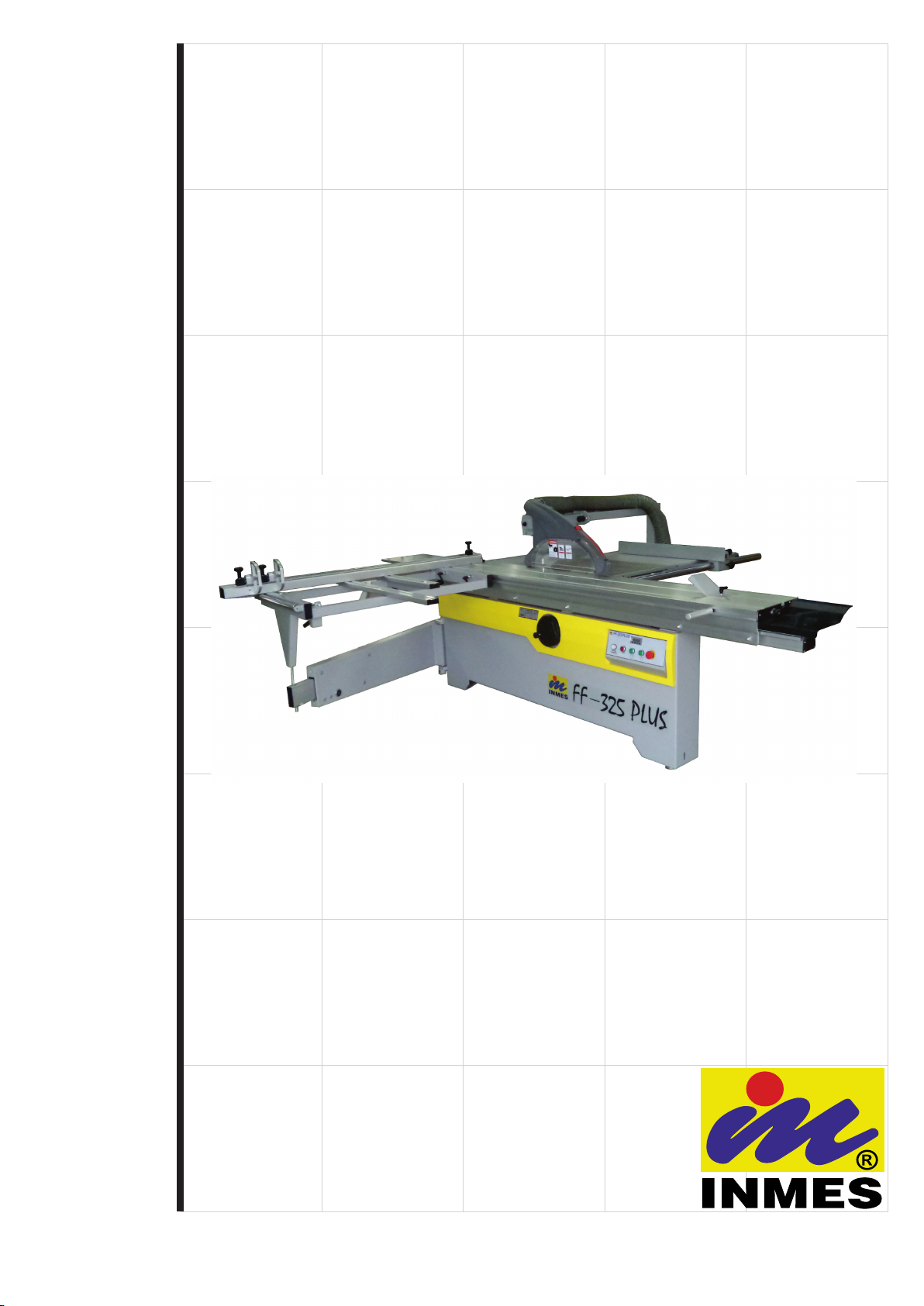

Inmes FF-325 PLUS User manual

OPERATIONS MANUAL

SLIDING TABLE SAW

FF-325 PLUS

05040784

Http://www.inmes.com.br

!!! For your safety !!!

Read the manual instructions.

LANGUAGE : ENGLISH

INMES Industrial Ltda – Sliding table saw FF-325 Plus 1

Dear customer,

Thank you so much for allowing us to share the experience of using an Inmes product.

The following manual has been formulated by our technical team especially for you to guide you in using

this equipment safely and productively.

The FF-325 Plus Square Mower was developed with the latest technology to solve your needs.

wood sheet cutting problems, allowing you to get the most cost-effective sheet metal cutting, plus a great

finish enhancing the furniture even more.

Visit our website and learn about our releases and other product lines.

http://www.inmes.com.br

If you need to find a nearest Authorized Technical Assistant on our site.

Write down here the serial number of your equipment.

Note: INMES Industrial LTDA. reserves the right to change this manual without prior notice.

INMES Industrial Ltda – Sliding table saw FF-325 Plus 2

ÍNDICE

1. GENERAL INFORMATIONS......................................................................................................................4

1.1 Introdution................................................................................................................................................4

1.2 Machine identification.............................................................................................................................4

1.3 Service recomendations ...........................................................................................................................4

2. SAFETY PRECAUTIONS............................................................................................................................5

2.1 Security rules ...........................................................................................................................................5

2.2 Organizational risks.................................................................................................................................6

2.3 Safety notices and information’s signs ....................................................................................................6

3. SPECIFICATIONS........................................................................................................................................7

3.1 Knowing the sliding table saw FF-325 PLUS .........................................................................................7

3.2 Technical specifications...........................................................................................................................8

3.3 Eletrical installation.................................................................................................................................8

3.4 Noise level ...............................................................................................................................................9

3.5 Dust Collector (Pic.3.5) ...........................................................................................................................9

3.6 Safety mechanisms (Pic.3.6)..................................................................................................................10

4. INSTALLATION ........................................................................................................................................11

4.1 Package contents (Pic.4.1).....................................................................................................................11

4.2 Loading and unloading equipment (Pic.4.2)..........................................................................................12

4.3 Characteristics of the installation area (Pic.4.3) ....................................................................................13

4.4 Installation of moving parts...................................................................................................................13

4.4.1 Extender table installation (Pic.4.4.1).............................................................................................14

4.4.2 Dust collector and hose bracket istallation (Pic.4.4.2)....................................................................14

4.4.3 Cross table installation (Pic.4.4.3)..................................................................................................14

4.4.4 Stop installation (Pic.4.4.4).............................................................................................................15

4.4.5 Ruler guide installation (Pic.4.4.5).................................................................................................15

4.4.6 Ruler installation (Pic.4.4.6)...........................................................................................................15

5. SETTINGS...................................................................................................................................................16

5.1 Scratch adjustment (Pic.5.1) ..................................................................................................................16

5.2 Extension table level adjustment (Pic.5.2)............................................................................................16

5.3 Precise ruler adjustment (Pic.5.3)..........................................................................................................17

6. Operation procedures...................................................................................................................................17

6.1 Turning the machine on and off (Pic.6.1)..............................................................................................17

6.2 Workspace (Pic.6.2)...............................................................................................................................18

6.3 Working with the saw............................................................................................................................18

6.3.1 Working with the saw extender (Pic.6.3.1).........................................................................................18

6.3.2 Working with the saw (Pic.6.3.2) .......................................................................................................19

6.4 Proper use of the machine (Pic.6.4).......................................................................................................19

7. MAINTENANCE ........................................................................................................................................20

7.1 Saw blade replacement (Pic.7.1)............................................................................................................20

7.2 General cleaning (Pic.7.2)......................................................................................................................20

INMES Industrial Ltda – Sliding table saw FF-325 Plus 3

7.3 General lubrication (Pic.7.3)..................................................................................................................21

7.4 Saw machine lubrication table (Pic.7.4)................................................................................................21

7.5 Spare and discard...................................................................................................................................21

8. TROUBLESHOOT GUIDE (Pic.8.0)..........................................................................................................22

INMES Industrial Ltda – Sliding table saw FF-325 Plus 4

1. GENERAL INFORMATIOS

1.1 Introduction

This machine is designed to make straight or angled cuts, especially on wood sheets.

Some information and illustrations in this manual may differ from the machine you own, the

descriptions and illustrations are based on a machine containing all options. Theref

ore, refer only to

information connected with the purchased machine configuration.

With this manual we would like to promote the information necessary for the maintenance and proper

use of the machine. Our technical support network is available for any technical problems, new parts or any

other requirements that may be necessary for the development of your activity.

This manual must be read and understood by the operator before operating the machine. This will

promote greater knowledge of the product's operation for greater safety and better results.

For readability, this manual has been divided into parts highlighting the most important operations. For

a quick search of the topics, it is recommended to consult the index. To mark the importance of some basic

passages we highlight these through symbols that show their proper procedure.

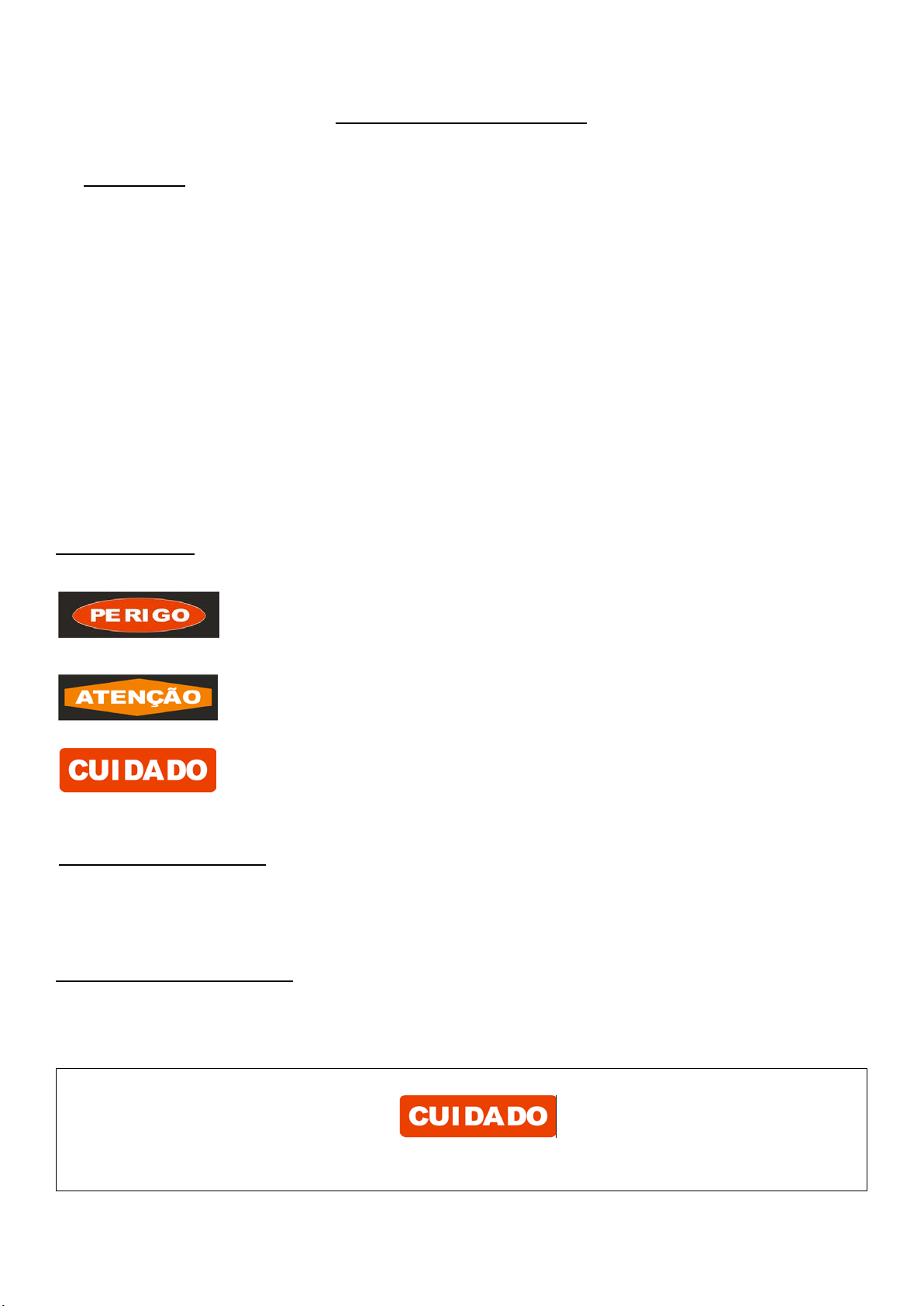

Safety Warnings:

Safety information that, if not followed, will pose a serious risk to the operator.

Safety information which, if not followed, could pose a serious risk to the life of the

operator.

Safety information which, if not followed, could injure the operator.

1.2 Machine identification

There is a machine nameplate, containing company data, year of manufacture, serial number and

technical specifications.

1.3 Service Recommendations

We request that only trained and authorized persons may service or perform any operation involving

disassembly of the machine. Follow the instructions in this manual for the correct use of your equipment.

Only trained and authorized personnel should use and service the machine after reading the instruction

manual. Respect accident prevention regulations, general safety rules as well as industrial medicine rules.

INMES Industrial Ltda – Sliding table saw FF-325 Plus 5

2. SAFETY PRECAUTIONS

2.1 Security rules

Read the instruction manual carefully before you start using, storing, moving or doing any other

operation with this machine.

- The manufacturer disclaims any liability for damage to persons or objects which may be caused by any

failure to comply with safety rules.

- The machine operator must be trained by a qualified person to operate this machine.

- It is strictly forbidden to use the machine under the influence of alcohol, drugs or medications.

- All operators must be properly trained in the use, adjustment and operation of the machine.

-

Operators should read the manual carefully, paying particular attention to warnings and safety notes. In

addition, they must be informed of the hazards associated with the use of the machine and the precautions

to be taken, and must also be instructed to periodically inspect the guards and safety equipment.

- Before moving, adjusting, repairing or cleaning, disconnect the machine from the mains.

-

After a long period of disuse, the machine belts may loosen, this causes an increase in blade downtime

(downtime should be less than 10 seconds) immediately tighten the belts.

- The work area around the machine must always be kept free and clean to allow immediate access to the

control panel.

- Never use blades other than those prescribed for use with the machine. The material to be cut must not

contain metal parts.

- Never cut parts that may be too small or too large while respecting the capabilities of the machine.

- Do not cut pieces of wood that contain visible defects (cracks, knots, metal parts, etc.).

- Never put your hands between the moving parts of the machine.

- Keep your hands away from the saw; Feed the saw with the help of a pusher.

- Keep unauthorized persons away from the machine.

- Never use cracked or challenged broken saw blades.

- Do not use the blade beyond the speed limits imposed by the manufacturer.

- Carefully wipe the surface of the blade and make sure that the blade is horizontally well positioned and

undamaged.

- Always wear gloves to hold the blade.

- Mount the blade in the correct cutting direction of the machine.

- Never start the machine without being properly protected by the safety material.

- Fit the suction ducts to a correct exhaust system; Collectors should always be on while the machine is on.

- Never open the safety door while the machine is operating.

- Some unpleasant experiences have shown that operators wearing objects such as watches, bracelets and

rings are in danger because they can cause serious accidents, so remove any of these objects before

operating the machine.

- Button and fasten the work clothes to the operator's body.

- Remove any hanging or loose clothing as it may get caught in the moving parts of the equipment, causing

accidents.

- Always wear strong shoes in accordance with the appropriate regulations of each country.

- Wear goggles, ear protectors and correct masks.

- Never let unauthorized persons operate, adjust or tidy up the machine.

- The manufacturer is not responsible for any damage caused by arbitrary modifications to the machine.

- Any transportation, assembly or disassembly must be done by trained personnel who have been qualified

for the specified operation.

-The operator should not leave the machine at any time without turning it off.

INMES Industrial Ltda – Sliding table saw FF-325 Plus 6

- During any work break turn off the machine.

- In case of a long period without using the machine, unplug the machine from the power supply.

- The method of operation to be followed in the event of an accident or equipment breakdown should be:

first the machine should be disconnected from the mains immediately, and then it is recommended to seek

assistance from authorized persons.

2.2 Organizational Risks

Despite the observations, all the safety recommendations and the use according to the rules described

in the manual, some risks may still be present, among them the most recurring ones are:

- Contact with the blade.

- Contact with moving parts (straps, straps, etc.).

- Repulsion of parts.

- Accidents caused by pieces of wood or fragments.

- Mechanical shocks with the blade.

- Electrocution by contact with uninsulated parts.

- Danger caused by a badly installed blade.

- Reverse rotation of the saw blade due to incorrect electrical installation.

- Danger caused by inhalation of dust caused by using the machine without dust extraction.

Remember that the use of any sawing machine poses serious risks. Use proper care and concentration for all

machine types (even the simplest). The greatest security is in your hands.

2.3 Safety notices and information’s signs

These signals must be applied to machines; in some cases they indicate hazardous conditions, in others

they serve as an indication. Always be very careful when operating this equipment.

SAFETY WARNINGS:

Risk of injury to eyes. Wear safety goggles.

Use ear protectors.

Danger of electric shock. Do not access this area with the machine turned on.

Read and understand the instruction manual before using the machine.

INMES Industrial Ltda – Sliding table saw FF-325 Plus 7

INFORMATIONS NOTICES:

Indicates technical characteristics, steering and tilt, locked or released, etc. Carefully follow directions to

simplify use and adjustment of the machine.

Warnings have been described graphically and do not require further explanation.

3. SPECIFICATIONS

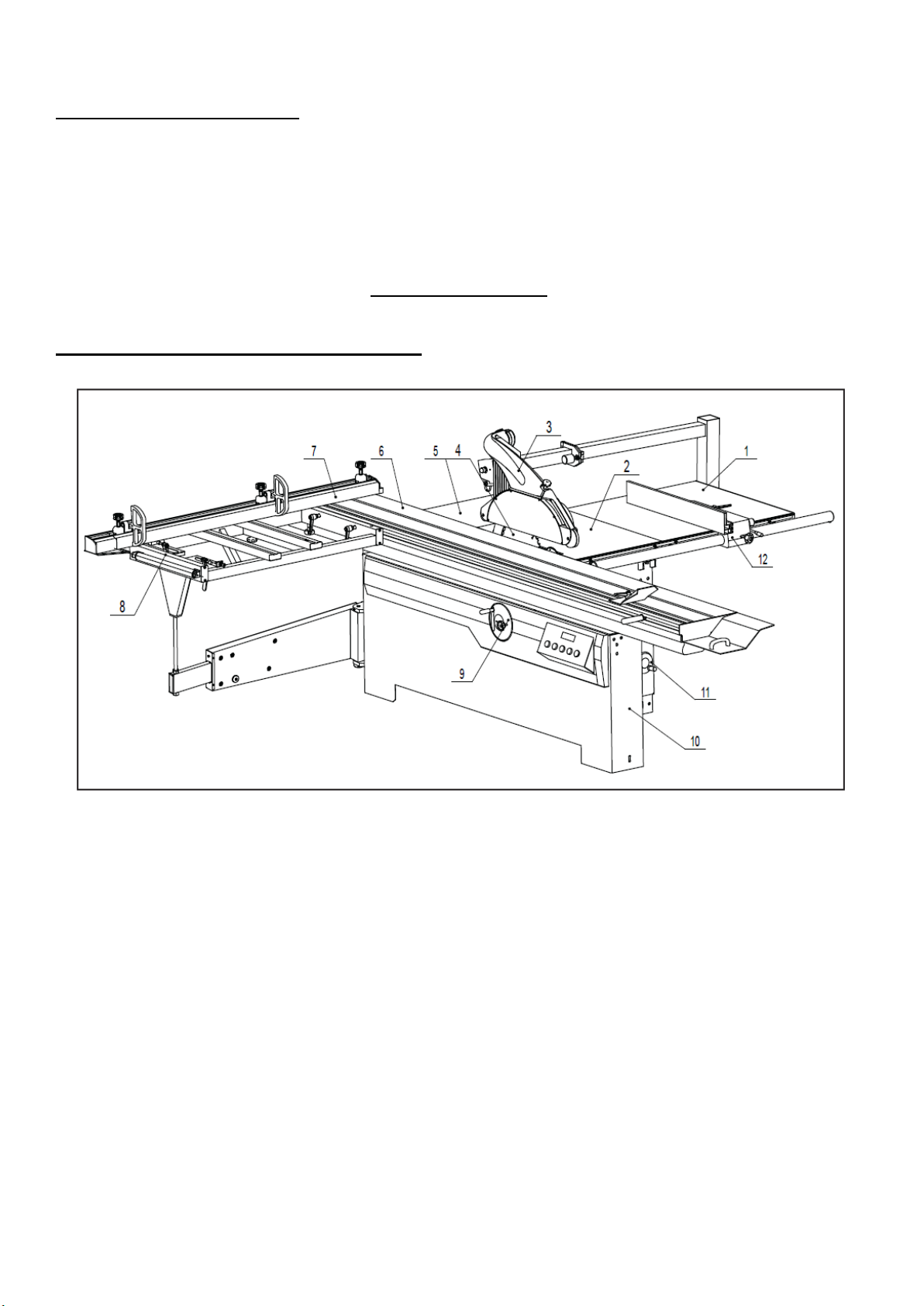

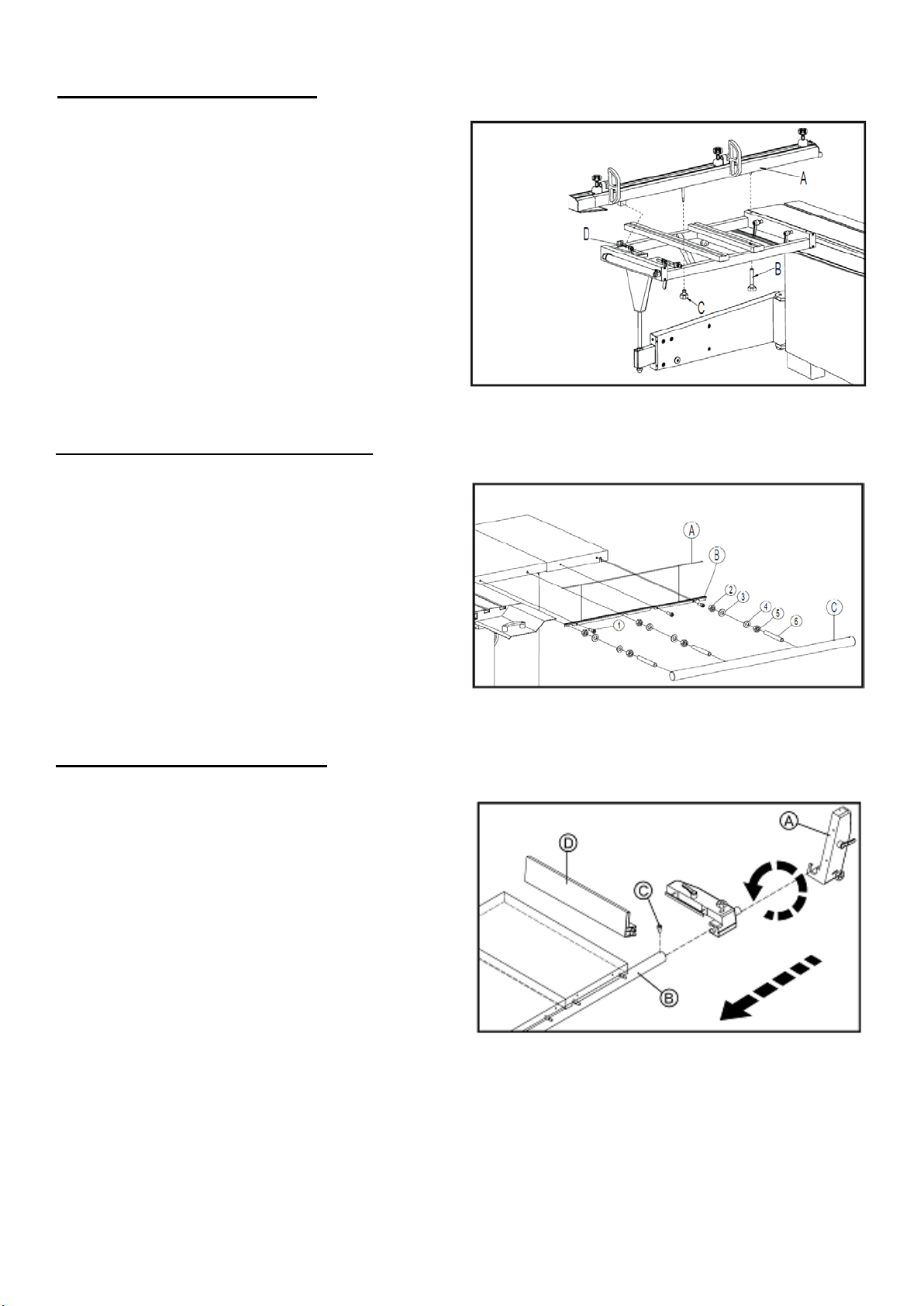

3.1 Knowing the sliding table saw FF-325 Plus

1- Right extension table;

2- Main table;

3- Dust collector;

4- Saw blade;

5- Auxiliary table;

6- Car;

7- Sliding table stop;

8- Cross table;

9- Blade tilt adjustment knob;

10-Structure;

11-Height adjustment knob;

12-Right table ruler;

INMES Industrial Ltda – Sliding table saw FF-325 Plus 8

3.2 Technical specifications

SPECIFICATIONS

Motor voltage

220V/60Hz Single

220/380V/60HzThree

Main engine power

3,0cv

5,5cv

Scratch motor power

3/4cv

3/4cv

Max diameter of saw

315mm

315mm

Minimum saw diameter

250mm

250mm

Main blade speed

4000rpm

4000rpm

Scratching blade diameter

120mm

120mm

Speed scratched blade

8000rpm

8000rpm

Tilt blade

90° ~45°

90° ~45°

Main table measure

800x530mm

800x530mm

Right extensor measure

800x820mm

Ruler Max Capacity

1300mm

Max Height cutting saw 300mm

95mm-90° , 70mm-45°

Max Height cutting saw 250mm

70mm-90° , 49mm-45°

Table Dimensions

3200x375mm

Movable table offset

3350mm

Cross table

1200x630mm

3.3 Electrical installation

Electrical installation must be done by qualified and trained personnel.

- Main connections must be made by a terminal box.

- Replacement of the power cord on the machine should only be performed by a qualified electrician.

- Plug the machine's Power cords into an electrical outlet: 380V±10% or 220V±10%

according to the

model in hand of the FF-325 Plus

-

We recommend installing properly sized circuit breakers for this machine. With the mains voltage at

220V, a 20A circuit breaker is recommended, and at 380V, a 16A circuit breaker is recommended. For a

single phase 220V machine a 25A circuit breaker is recommended.

To prevent electric shock or fire, any maintenance or repair to the electrical system should only be

done by trained electricians using genuine parts of the machine.

INMES Industrial Ltda – Sliding table saw FF-325 Plus 9

3.4 Noise level

The maximum noise level of this equipment = 100dB (A).

The measured noise levels are emitted only by the machine in question and are not necessarily safe

levels for the job. Even if there is an exposure relationship these data provided cannot serve as a basis for

knowing whether precautionary measures should be taken or not. Factors that may affect operator exposure

to hearing damage that excessive noise may cause include exposure time, environmental characteristics as

well as other noise-

emitting sources such as different adjacent machines operating simultaneously.

Permitted exposure also varies from country to country. Even so, this information allows the operator to

better assess damage and risk.

Another factor that reduces noise exposure are:

- Choice of the correct blade.

- Frequent machine and blade maintenance.

- Frequent use of hearing protectors.

Always wear earplugs.

3.5 Dust collector (Pic. 3.5)

Always work with the exhaust system, turning on the hood and the saw machine at the

same time.

Dust pickup

Item

Ø Outfall

Speed

A

4”

20m/s

B

4”

20m/s

(Pic. 3.5)

INMES Industrial Ltda – Sliding table saw FF-325 Plus 10

Proper dust exhaustion eliminates the risk of dust inhalation by the operator and others working in the same

location, and provides better machine operation. The table shows the minimum air velocity and the velocities

related to each suction operation.

Check that the suction system guarantees these values on your inlet connection.

Inlet Mouth Diameter:

A - Blade dust collector........ Ø4 ”

B - Lower dust pickup......... Ø4 ”

Connect the nozzles to the exhaust system with flexible hoses or tubes of suitable diameter. Lock them with

cable ties. The connections must be positioned out of the operator's path while using the machine.

3.6 Security mechanisms (Pic. 3.6)

This machine is equipped with the following safety equipment (Pic. 3.6).

A - Security key;

This equipment stops the machine when the lower blade guard plate D is open to operate the saw.

B - Saw blade protection;

Serves to prevent the operator from touching the saw blade

C - Emergency Button;

When the button is pressed the power will be completely cut off from the machine immediately, this is a

mechanically pressed emergency button, to turn it off simply by turning the knob clockwise.

(Pic. 3.6)

INMES Industrial Ltda – Sliding table saw FF-325 Plus 11

4. INSTALLATION

Assembly should be done by a trained and experienced person.

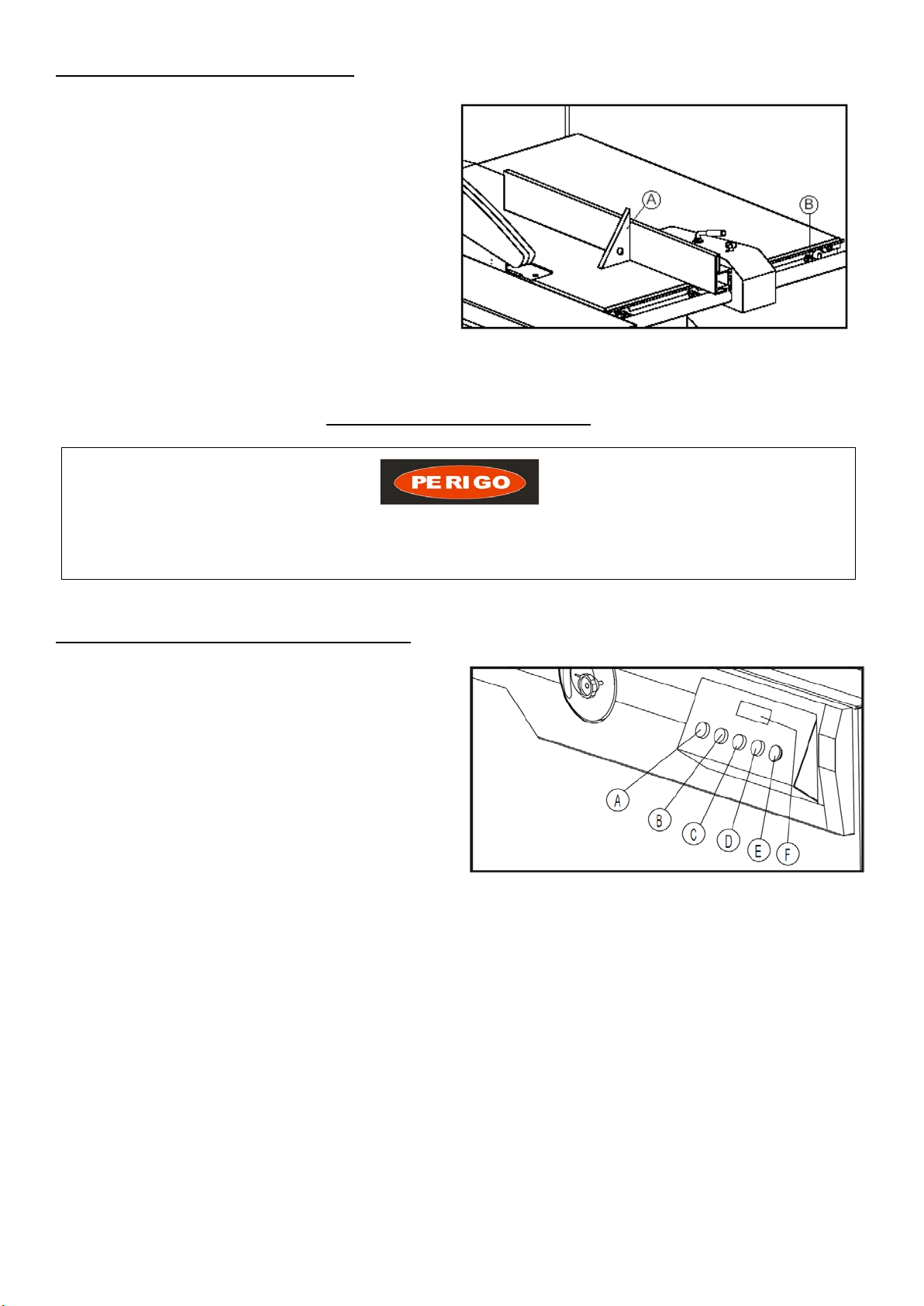

4.1 Package Contents (Pic. 4.1)

The machine is supplied partially assembled. Before using the machine, it must be assembled

completely and correctly.

- When unpacking the machine the following components are included for initial assembly.

- If any parts are missing do not attempt to assemble the machine or turn it on until the parts are obtained

and installed correctly.

Total content:

1 - Blade Dust Pickup;

2 - Auxiliary table;

3 - Cross table;

4 - Sliding table stop;

5 - Cross table support;

6 - Ruler guide;

7 - Scale meter;

8 - Ruler;

9 - Right Extending Table;

10 - Sliding table;

(Pic. 4.1)

INMES Industrial Ltda – Sliding table saw FF-325 Plus 12

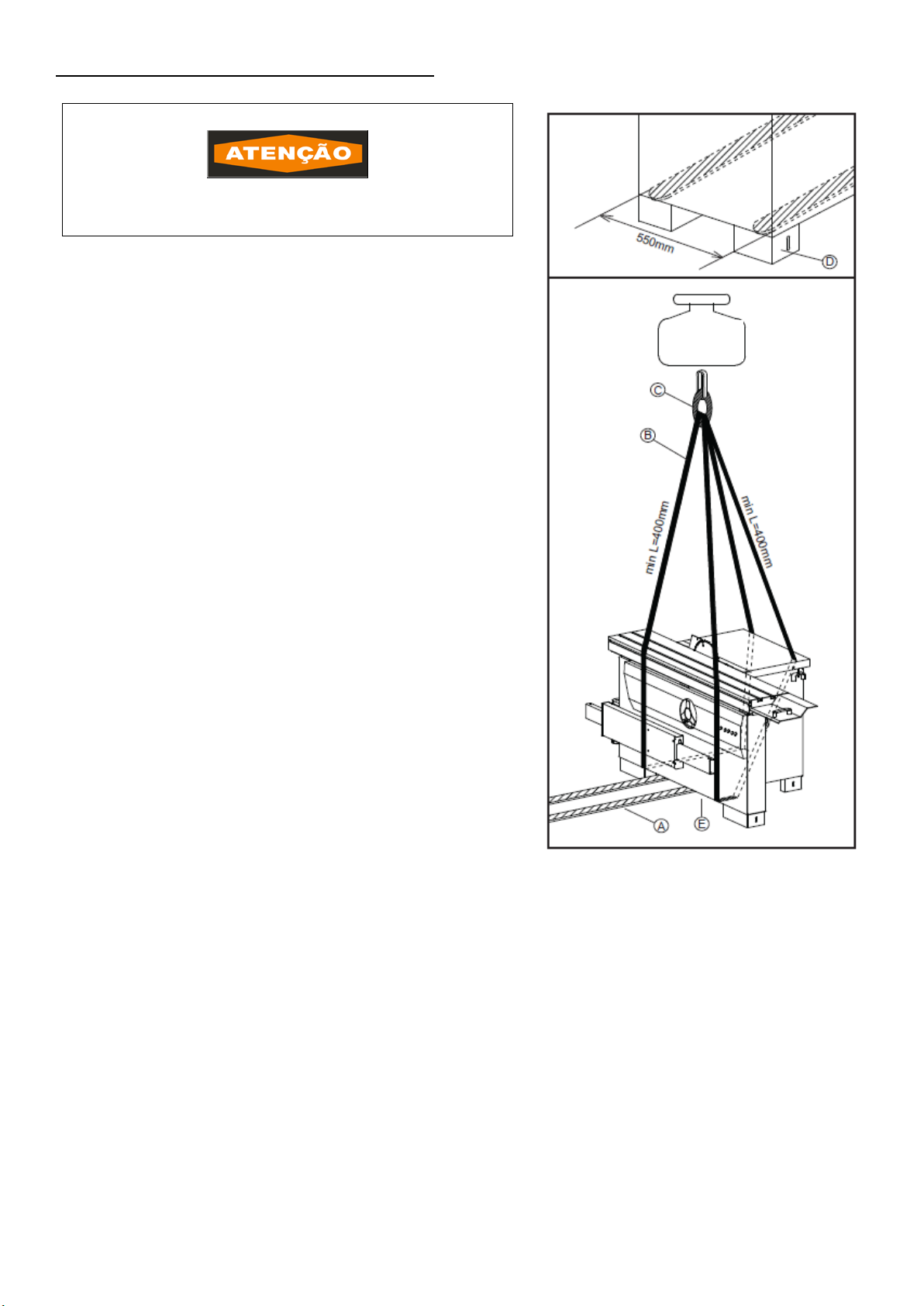

4.2 Loading and unloading equipment (Fig. 4.2)

When loading and unloading this equipment, avoid

mechanical shocks to prevent damage to persons and the

machine itself. Make sure no one is wrapped around the

equipment used to move the machine while it is being moved.

This machine should be lifted by a crane or forklift. Before

you begin handling the

equipment to its correct location,

remove any parts that were used for shipping or packing that

are still in the machine. Check that the carrying equipment

capacity is adequate for the indicated machine weight Pic.4.2

If transporting by forklift proceed as follows:

Adjust fork width A to 500mm

- Insert the forks A as shown in the figure corresponding to

the nameplate E making sure that the forks are aligned with

the back of the rear feet D of the machine.

If a crane is available, proceed as follows:

- Provide two B-

belts of sufficient length and capacity

(minimum belt length must be 4 meters).

- Raise the belts and position them as shown in Fig. 4.2.

- Adjust the belts at the tip of crane C with the force required

to lift the machine.

- Move the crane slowly

so that the belts adjust until the

machine can be stable.

-

Carefully lift the crane slowly without the equipment

swinging, after which move the machine to its proper place.

-

Remove all protective grease from unpainted tables and

surfaces using kerosene or by-products. Do not use solvents,

petroleum or gas oil, which may damage the paint or rust

parts of the machine.

This equipment should only be transported by persons

specially trained to perform this type of operation.

(Pic. 4.2)

703

kg

INMES Industrial Ltda – Sliding table saw FF-325 Plus 13

4.3 Characteristics of the installation area (Pic. 4.3)

It is prohibited to install the machine in explosive environments.

The installation area should be selected by assessing the required workspace depending on the size of the

parts to be cut. It is also necessary to check the capacity of the floor and the

surface used so that the

machine can rest equally on its entire base.

A power source and exhaust duct should be near the location of the machine which should be well lit.

Pinning to the floor:

The machine must be attached to the floor.

- Use a pin / nut A to level the feet and check that the machine is secured and allocated.

- Fix expansion pin D to the floor, use Washer / Lock washer C and hex nut. B to tighten the pins.

Note: This item does not come with the machine.

(Pic. 4.3)

4.4 Installation of moving parts

Some elements will be disassembled from the main machine frame due to packing and shipping needs.

These parts should be installed as follows.

Tighten all bolts and nuts tightly. If this is not done correctly, there is a risk that the machine will trip or

cause danger to the operator or another person.

INMES Industrial Ltda – Sliding table saw FF-325 Plus 14

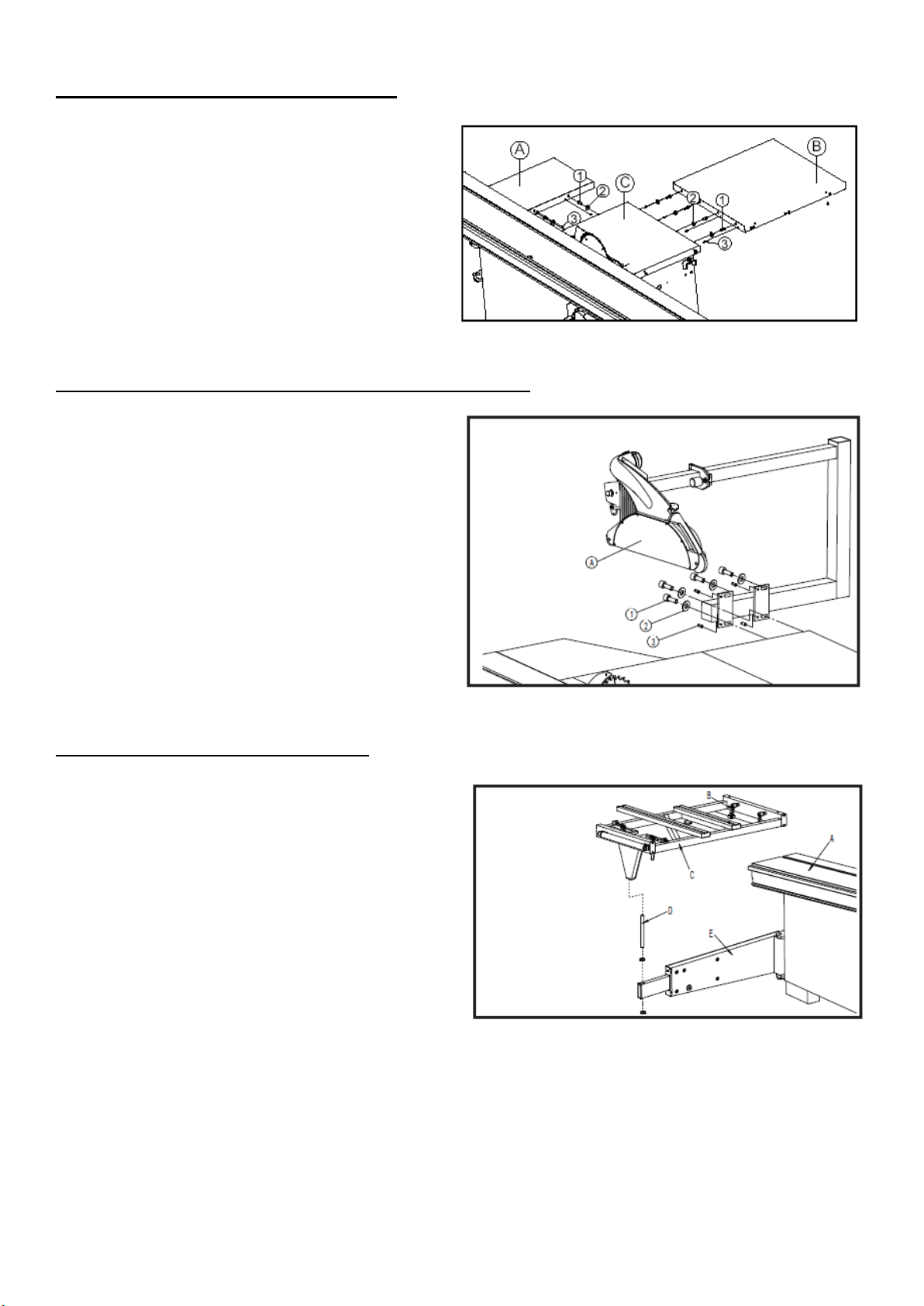

4.4.1 Extender table installation (Pic. 4.4.1)

Tools required for assembly:

- Wrench 17mm.

- Allen wrench 4mm.

- Install extension tables A to main table C with

Screw 1 and nut 2. Pic. 4.4.1

-

Install adjusting screw, three, for precise

adjustment.

(Pic. 4.4.1)

4.4.2 Dust collector and hose bracket installation (Pic. 4.4.2)

Tools required for assembly:

- Allen10mm wrench.

- Allen wrench 4mm

-

Install dust collector A to the machine frame

with parts 1, 2 and 3.

(Pic. 4.4.2)

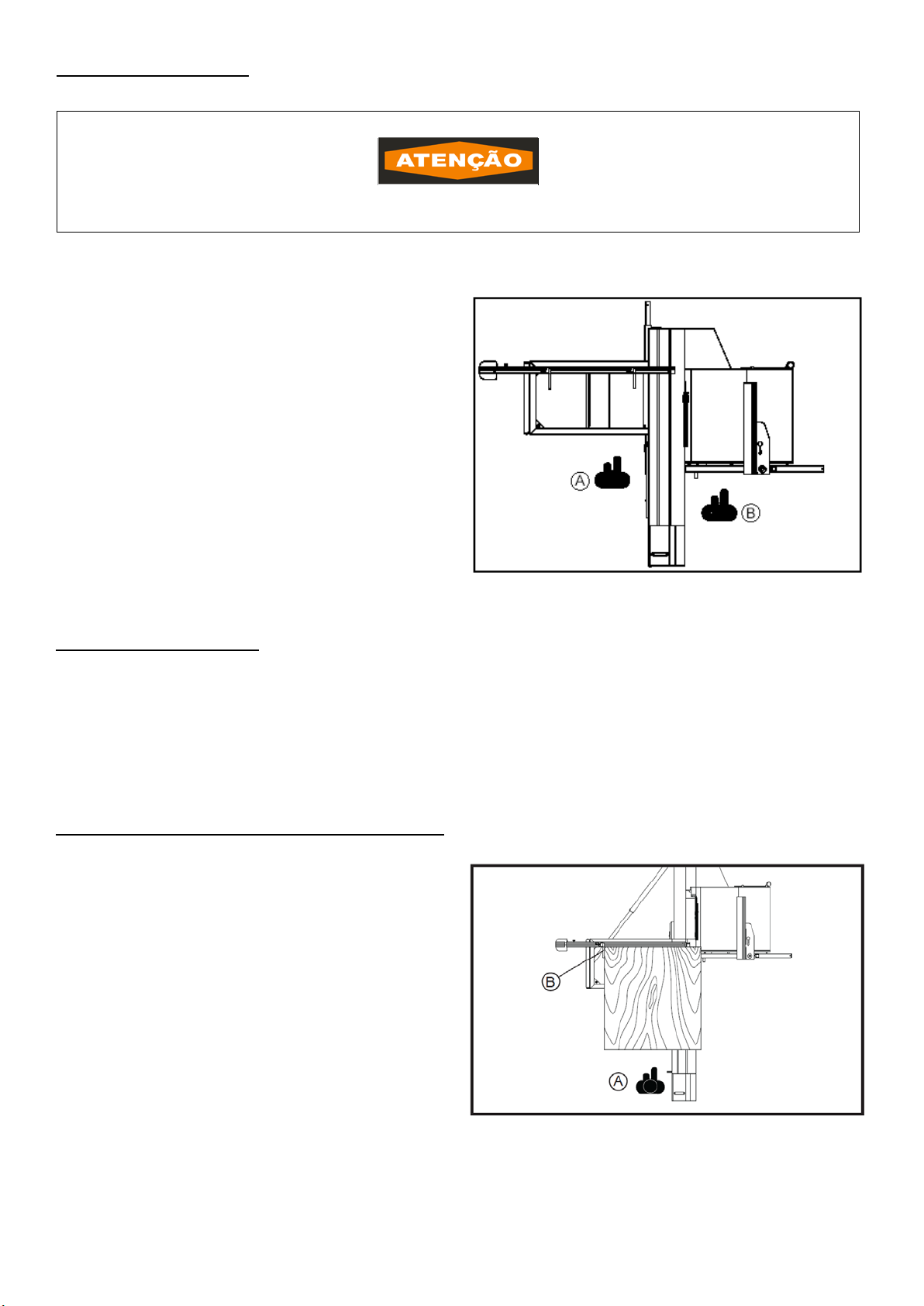

4.4.3 Cross table installation (Pic. 4.4.3)

Place the transverse table C into the car seat A.

- Insert pin D into the cross table bracket C and the

carriage bracket table bracket E

- Fix the planks using knobs B.

(Pic. 4.4.3)

INMES Industrial Ltda – Sliding table saw FF-325 Plus 15

4.4.4 Stop installation (Pic. 4.4.4)

- Place the stop pin A in the socket on the cross table

and mount the knob B to the pin.

-

Attach knob C that secures the stop angle

adjustment.

-

Handle D is designed for perpendicular micro

adjustment between the stop and the blade.

(Pic. 4.4.4)

4.4.5 Ruler guide installation (Pic. 4.4.5)

Tools required for assembly:

- Wrench 24mm.

- Allen wrench 5mm.

- Install ruler B on the fixed table with screw 1.

- Install scale A on scale B socket.

-

Install screw6 in guide C, then mount guide to

tables with parts 2, 3, 4, 5.

(Pic. 4.4.5)

4.4.6 Ruler Installation (Pic. 4.4.6)

- Install the ruler bracket A to guide B as shown.

- Install screw C to ruler guide B.

- Install ruler D to bracket fitting A.

(Pic. 4.4.6)

INMES Industrial Ltda – Sliding table saw FF-325 Plus 16

5. SETTINGS

When handling saw blades, always wear gloves for protection.

5.1 Scratch Adjustment (Pic. 5.1)

When cutting panels covered with finishing

materials, the use of scribe D is required.

Position the scribe blade to have a 1-1.5mm

depth cut.

Proceed as described in this manual if necessary to

adjust the striker to the blade.

-

Loosen handle A and adjust the height of the saw

blade using handle C.

-

Loosen handle B and adjust the scribe saw

sideways so that it aligns with the main saw using

handle D.

(Pic. 5.1)

5.2 Extension table level adjustment (Pic. 5.2)

Tools Required:

- Scale.

- Backlash Calibrator.

- Allen4mm wrench.

13mm mouth spanner.

- Spanner17mm.

-

Place the ruler B on the main table and the

extension table. Use the

Reg to check the

unevenness formed.

-

Loosen screws A moderately using the 17mm

wrench.

- Loosen nut C using 13mm wrench and adjust table

by turning screw D using 4mm Allen wrench.

- Retighten all screws A.

- Retighten all C nuts.

(Pic. 5.2)

For each saw height adjustment, check the alignment of the tracker. If necessary adjust.

INMES Industrial Ltda – Sliding table saw FF-325 Plus 17

5.3 Precise ruler adjustment (Pic. 5.3)

Tools required for assembly:

- Ruler, Square, Depth Gauge

- Feeler clock.

- Wrench 24mm.

- Use square A and the probe to check the 90 °

angle between the table and the ruler. Loosen the

4 axes B, and precisely adjust their positions for

good perpendicularity.

-

Use the ruler, probe and depth gauge to check

that the ruler is parallel to the blade.

- Loosen the 4 axes B and adjust the ruler so that

it is precisely parallel with the blade.

(Pic. 5.3)

6. OPERATION PROCEDURES

Take special care while the sawing machine is turned on and never operate the machine without guards

and safety equipment in place and operating in perfect condition. Never put your hands in contact with

the saw blade when it is turning.

6.1 Turning the machine on and off (Pic. 6.1)

The panel buttons are arranged as shown in figure

6.1.

- A is the main power lamp.

- B is the button to turn off the main power.

- C is the button to turn on the saw power.

- D is the button to turn on the scribble power.

- And it is the emergency button which turns off all

power to the machine.

- F is the display indicating the angle of inclination

the saw is currently in.

(Pic. 6.1)

INMES Industrial Ltda – Sliding table saw FF-325 Plus 18

6.2 Workspace (Pic. 6.2)

This machine is designed for single operator use only. The plastic pusher should be used when small

parts are cut and when necessary push the part against the ruler and stop.

A - Working with the saw (square)

B - Parallel Cut Side

(Pic. 6.2)

6.3 Working with the saw

The choice of the method to be used for cutting with the angle cutter depends on the size of the

material to be cut and the type of material used.

To cut laminated wood, the use of the scratcher is indispensable to prevent splinters. When the tracker is

not required lower it completely below table level.

6.3.1 Working with the extender table (Pic. 6.3.1)

- Place the piece to be cut on the extension table.

aluminum stop B

-

Stay in position A and push the extension table

forward to make the cut.

(Pic. 6.3.1)

Table of contents

Other Inmes Saw manuals