MECHAFIN PushPull User manual

Weldingaccessories- SwissQuality

MECHAFIN AG has the right to make changes to the operating manual without prior notice, which

may be necessitated due to printing errors or potential neglect of the information contained the-

rein, or further product development. Any changes will then be listed in newer editions.

Operating Instructions for Mechafin PushPull

Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023 1

Content

1. Assessment 2

1.1. EU Declarations of Conformity 2

1.2. Manufacturer's obligations 2

2. Product description 2

2.1. Product description 2

2.2. Intended use 2

2.3. Technical data 3

3. Safety instructions 4

3.1. Essential safety instructions 4

3.2. General safety instructions 4

3.3. Specific hazard instructions 5

3.4. Technical condition 5

3.5. Characterisation 5

4. Delivery contents 5

4.1. Transport 5

5. Function 6

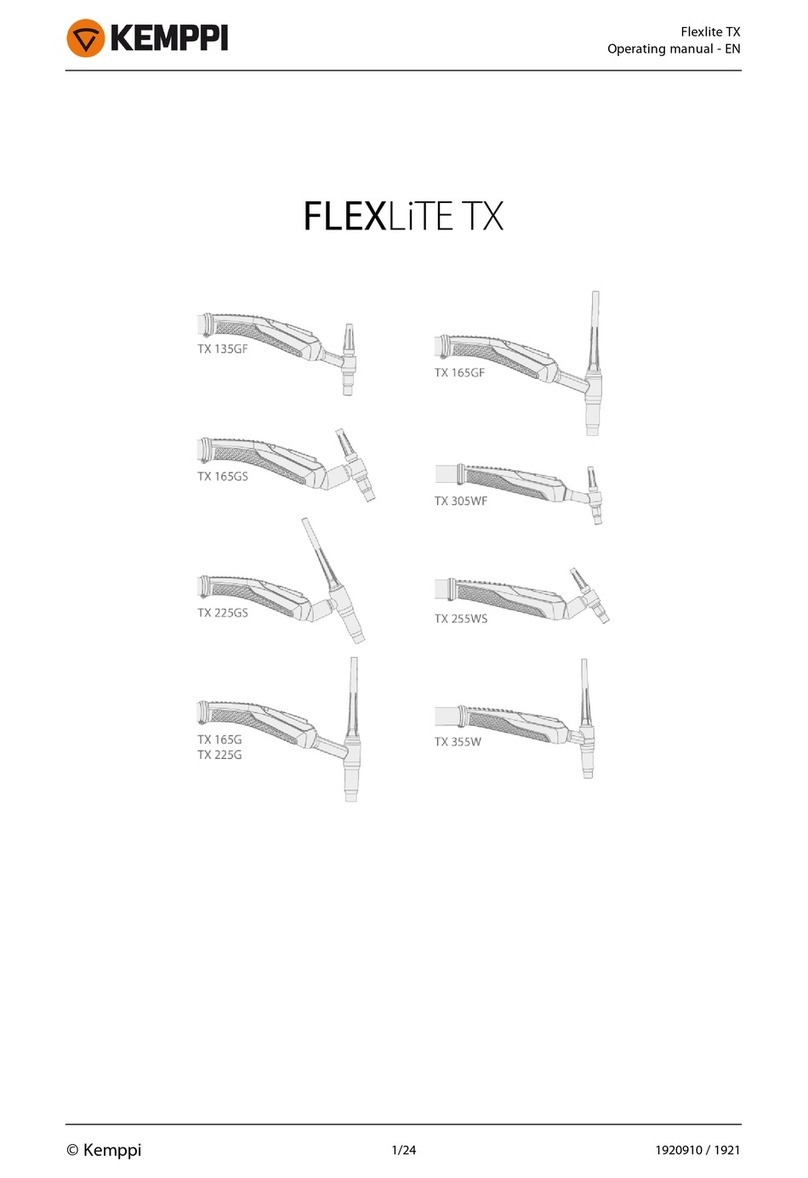

5.1. MIG/MAG welding torch 6

6. Commissioning the intermediate drive 6

6.1. Preparation for welding 7

6.2. Connecting 7

6.3. Introducing wire 8

6.4. Opening/closing the pressure arm 8

6.5. Changing the feed roller 9

6.6. Exchanging the wire guide 9

6.7. Exchanging the wire liner 10

6.8. Coolant (this is only required for liquid-cooled welding torches.) 11

6.9. Setting the shielding gas quantity 11

6.10. Application 11

7. The control unit 12

7.1. Overview 12

7.2. Technical data 12

7.3. Pin assignment 13

7.4. Operation of the control unit 13

7.5. Operation overview 14

7.6. Program modes 16

7.7. Commissioning the intermediate drive with the control unit 20

7.8. Calibration process of the control unit during commissioning 20

7.9. Fastening the control unit 21

7.10. Connecting the intermediate drive for welding 22

7.11. Starting the welding process 23

8. Operation 23

9. Maintenance I Cleaning 24

9.1. General information 24

9.2. Hose pack 24

9.3. Wire liner 24

10. Disassembly and disposal 25

11. Emergency 25

12. Warranty 25

13. Faults and how to remedy them 26

14. Accessories and wear parts 27

15. Length recommendation for the PUSH PULL 28

2Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023

1. Assessment

The MECHAFIN AG intermediate drive is exclusively intended to weld with shielding gas. Welding can

be carried out with inert gases (MIG), or active gases (MAG). The intermediate drive is intended for

industrial and commercial use. It is available as gas or liquid cooled. A cooling unit is required for the

liquid-cooled welding torches. The welding torches should only be operated with original MECHAFIN

AG spare parts.

1.1. EU Declarations of Conformity

In accordance with EC Low-Voltage Directive 73/23/EEC, Appendix 111, we

MECHAFIN AG

Chrummacherstrasse 3

8954 Geroldswil

Switzerland

hereby declare, that the intermediate drive described, on account of its construction and design, as well

as the version that we have put on the market, comply with the EC Directive's relevant essential health

and safety requirements. This declaration will become void if changes are made to the intermediate

drive that have not been agreed with us.

Harmonised standard used:

DIN EN 60 97 4-7 Light arc welding devices; Part 7 Torches

1.2. Manufacturer's obligations

National implementation of the Framework Directive (89/391/EEC), as well as the associated

individual Directives, particularly the Directive on the minimum requirements for health and safety

when contractors use equipment at work (89/655/EEC) as amended, must be observed and adhered

to. The Occupational Health and Safety Act and the Ordinance on Industrial Health and Safety must

be observed. The operator must also ensure that the wire feed system complies with EC Directive EMC

(89/336/EEC) in conjunction with welding devices, and that signal exploitation is installed from the

built-in welding current monitoring system against surface leakages so the power source can switch

off safely.

2. Product description

2.1. Product description

Depending on the design, MECHAFIN AG MIG/MAG welding torches are gas or liquid-cooled. The hose

pack of the intermediate drive is geared towards the respective torch cooling system. All elements form

a functional unit.

2.2. Intended use

Overburdening the intermediate drive or improper use is prohibited. Observing the prescribed operating,

maintenance and servicing conditions is also part of intended use. Wear and damage that can be at-

tributed to overloading or improper use are not covered by the warranty.

Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023 3

2.3. Technical data

General data (operating conditions)

Voltage type: DC voltage

Electrode polarity: usually positive

Wire types: All commercially-available round wires

Guide type: machine-guided

Voltage calculation: 113 V peak value, 141 V peak value

Protection type on the machine side

Connections (EN 60 529): IP3X, IP2X

Shielding gas: C02 or mixed gas M21 according to DIN EN 439

Hose packs:

Standard length L: 5.00m; 10.00m; 15.00 m; 20.00m; 25.00m

Coolant connection: Push-on nipple size NW 5

Cooling unit output: min. 800 to 1000 W

Standard control line: 2-wire

Model-specific data

Item number Cooling Connection for welding wire Wire Ø [mm] Length [m]

119864 Liquid Euro Steel 1.2 5.0

117218 Liquid Euro Steel 1.2 10.0

117219 Liquid Euro Steel 1.2 15.0

117217 Liquid Euro Steel 1.2 20.0

117220 Liquid Euro Steel 1.2 25.0

119915 Liquid Euro Aluminium 1.2 5.0

117215 Liquid Euro Aluminium 1.2 10.0

117216 Liquid Euro Aluminium 1.2 15.0

118458 Gas Euro Steel 1.2 5.0

117208 Gas Euro Steel 1.2 10.0

117209 Gas Euro Steel 1.2 15.0

117210 Gas Euro Steel 1.2 20.0

117211 Gas Euro Steel 1.2 25.0

119916 Gas Euro Aluminium 1.2 5.0

117204 Gas Euro Aluminium 1.2 10.0

117205 Gas Euro Aluminium 1.2 15.0

Attention: these products exclusively concern the PushPull.

The control unit must be ordered separately.

You will find the list with the control units and corresponding parts on page 27.

4Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023

3. Safety instructions

WARNING / CAUTION

A potentially hazardous situation is described here. If this is not reported, serious injuries and material

damage may result.

NOTE

A potential hazard is described here which indicates impaired work results and potential damage to

the equipment.

IMPORTANT

Describes usage tips and other helpful information.

This is not a signal for dangerous or harmful situations.

3.1. Essential safety instructions

This operating manual explains information to the user that is required for flawless and safe operation.

NOTE

No liability will be assumed by MECHAFIN AG If there is any material damage due to disregard of the

operating manual.

3.2. General safety instructions

• The operating manual must be diligently read and followed before work due to commissioning,

operation or transport.

• The operating manual must be provided with the product for reference. The operating manual must be

handed on when the product is passed on.

• The operating manuals of welding components such as welding power sources or wire feeding units

must also be observed.

• For gas cylinder handling, please refer to the gas manufacturer's or supplier's instructions, and

the compressed gas regulation.

• The respective country's accident protection regulations must be observed.

• Operating and maintenance work may only be carried out by specialists. A specialist is a person who,

due to their training, experience, skills and knowledge of relevant standards, can assess work carried

out by third parties and recognise potential hazards.

• Suitable fire protection equipment must be present at the workstation.

Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023 5

3.3. Specific hazard instructions

• Eye, skin and hearing damage may occur during light arc welding! Protective work wear must always

be worn for eye, skin and hearing protection according to the respective country's relevant regulations.

• Metal vapours that occur are very harmful, especially with lead, cadmium, copper and beryllium!

• Adequate ventilation or extraction must be ensured during welding. Specified MAC values (max.

allowable concentration) may not be exceeded.

• Work pieces that have been cleaned with chlorinated solvents or degreased should be rinsed with clear

water, otherwise there is a risk of gasification.

• A greasing bath containing chlorine should not be set up in proximity to the welding area.

• Other hazards may occur when using welding torches such as those due to electric current (power

source, internal circuit), welding spatter as a result of flammable or explosive substances, UV radiation

due to the light arc, smoke and vapours.

• The intermediate drive must always be used when it is closed.

• The housing is made of aluminium and carries the welding voltage. Although it is in the safe low

voltage range, the device must not be operated by pacemaker patients.

• The drive wheels have a strong torque and can injure fingers. Do not reach into the open wheels.

• When working on the intermediate drive, switch the welding unit off if possible.

3.4. Technical condition

• The specified performance data are the maximum determined limit values.

• Any overloading leads to destruction and thus grossly negligent destruction.

• It is forbidden to make physical changes without discussing them with the manufacturer.

• Use suitable protection against weather influences during outdoor use.

3.5. Characterisation

The following information is important for all queries:

• Labelling on connection housing on the machine side

• Visible item numbers or serial numbers

• Production stickers on the housing

4. Delivery contents

All intermediate drives are delivered fully assembled and checked ready for connection and operation.

• Intermediate drive

• Operating manual

NOTE

For order numbers and item numbers of equipment and wear parts, please refer to the order documen-

tation. Check that the equipment parts are correct for initial fitting.

4.1. Transport

The product is always diligently checked and carefully packed before dispatch. However, damage

occurring during transport cannot be excluded.

6Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023

Incoming control

Always check that the delivery contents are complete using the delivery note.

In the event of damage

Always check the delivery contents for damage via a visual check.

In the event of any complaints

If the delivery has been damaged during transport, get in touch with the forwarder immediately. Keep

the damaged packaging and the damaged delivery contents in case they are checked by the forwarder.

Document the damage, preferably with photos.

Packaging for returns

If possible, please use the original packaging and the original packaging material. If you have any

questions about the packaging or transport safety devices, get in touch with the supplier.

Storage in an enclosed room

CAUTION

Material damage

• Coolant that is still in the hose may freeze and damage the hose in the event of frost.

• It must be ensured that coolant is no longer present in the hoses in the event of frost.

Ambient air temperature during transport and storage: - 25°C to + 55°C

Relative humidity: up to 90% at 20°C

5. Function

The MIG/MAG intermediate consists of the following parts:

• Unit (push-pull system)

• Hose pack

• Control unit (plus cable)

5.1. MIG/MAG welding torch

Wires made of steel, aluminium, copper, nickel and stainless steel are conveyed through the welding

system for welding. The wires can be filling wires or solid wires. The light arc and the weld pool are

protected by inert gas (MIG) and active gas (MAG). The wires are conveyed by the contact tips. In this

case, the contact tip transfers the welding current to the wires. The light arc forms between the wire

and workpiece. The welding torches are either gas-cooled or liquid-cooled, and the hose pack has also

been designed accordingly.

6. Commissioning the intermediate drive

DANGER

Risk of injury

In the event of inadvertent start-up, during maintenance, installation or repair work.

Always take the following precautionary measures for the entire duration of the work:

• Pull out mains plug

• Shut off gas supply

• Switch off the power source

A B

Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023 7

6.1. Preparation for welding

Before commissioning, make sure that the liner that matches the wire is inserted (Chapter 6.7).

Please replace if necessary. The wire guide must also fit (Chapter 6.6).

NOTE

New wire liners or plastic wire guides must always be adapted to the hose pack.

Are the correct feed rollers used? If not, proceed according to (Chapter 6.5).

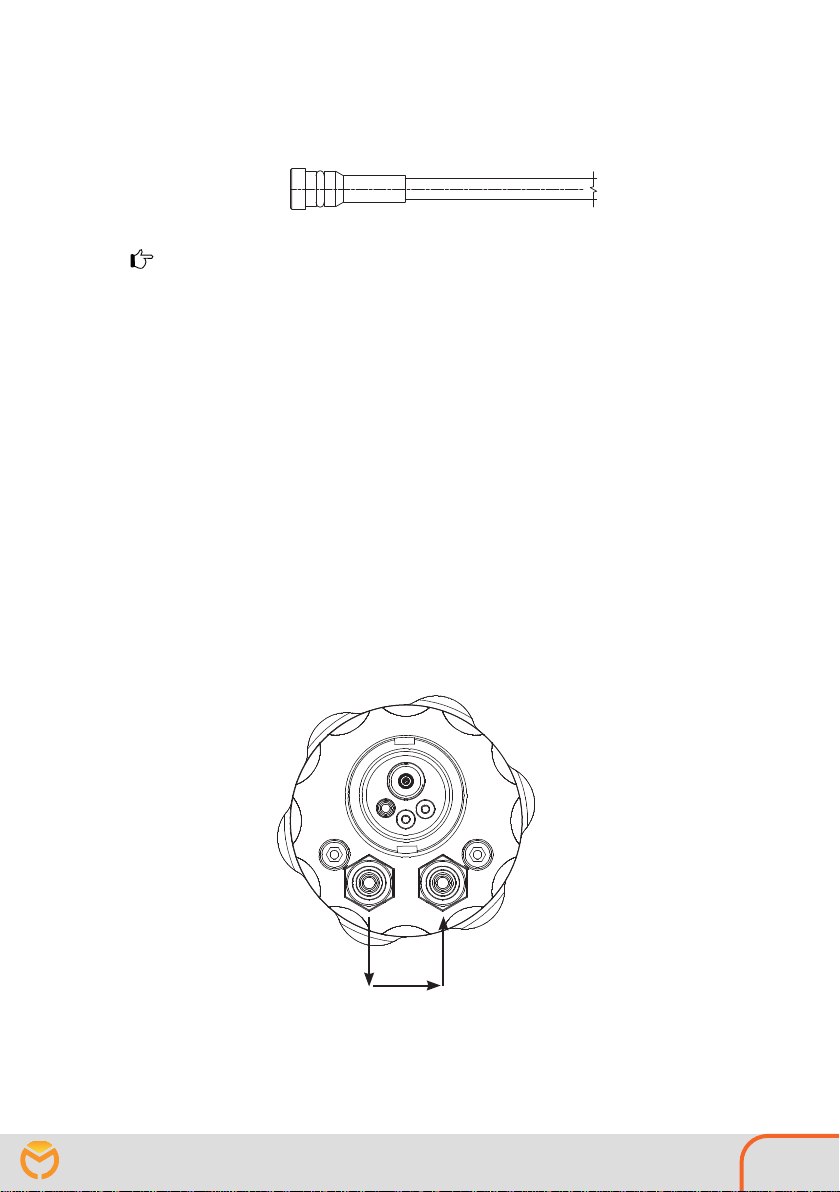

6.2. Connecting

Connect the hose pack of the intermediate drive to your wire feeder with a Euro plug (just like the

welding torch). Connect the two water connections (for the water-cooled intermediate drive) correctly.

Connect the motor / encoder plug with the corresponding connector of your machine.

Connect the welding torch (gas or liquid cooled) to the Euro plug of the intermediate drive.

For the connection of a gas-cooled welding torch, the water connections can be bridged in systems that

are intended for water cooling. This creates a connection between port A water supply (blue) and port

B water return (red). Application only when using a gas-cooled burner.

1

1

8Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023

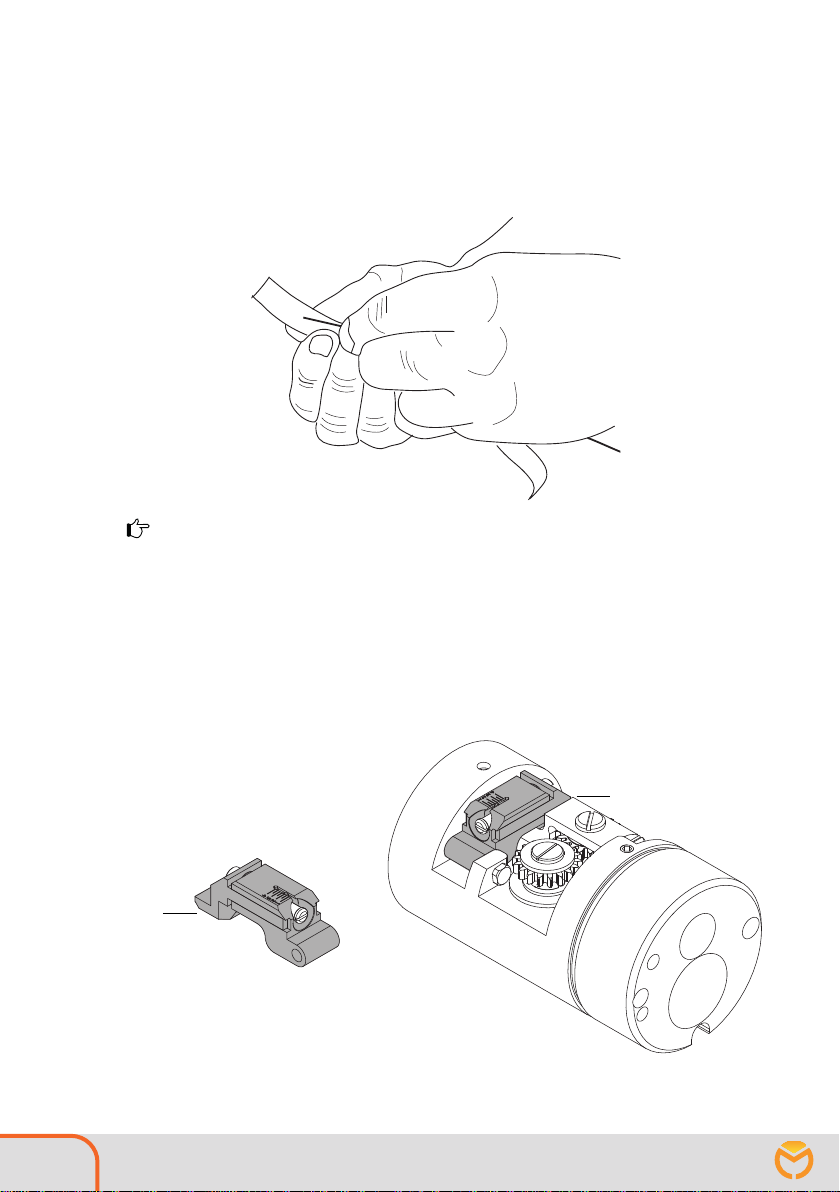

6.3. Introducing wire

Lay out the intermediate drive with stretched hose as straight as possible. Open the intermediate drive

in order to observe the correct wire feeding process. Place the wire reel in the feeding device of your

welding source. Deburr the cut welding wire with emery cloth or file. If the wire is deburred and reason-

ably straight, it will thread itself. In case of a fault, stop and insert the wire by hand into the wire guide.

NOTE

Deburr the interface on the wire every time the wire is changed.

6.4. Opening/closing the pressure arm

The wire can be extended in idle mode. In special cases you can open/close the pressure arm (dark grey)

manually. To do so, open the housing, unlock the bayonet and pull the slider back.

To open lift the pressure arm (dark grey) at position [1] with a slotted screwdriver.

To close, press the pressure arm down until it locks into place.

1

3

4

2

3

1

2

Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023 9

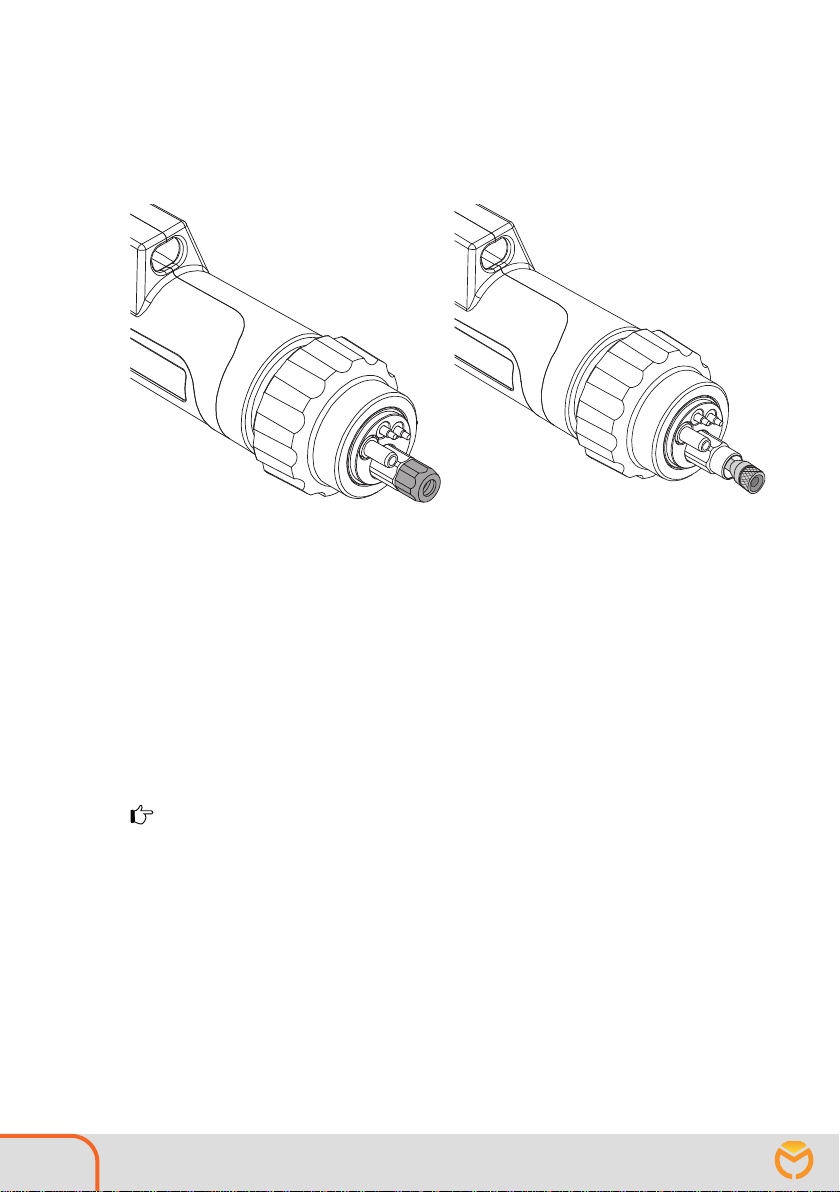

6.5. Changing the feed roller

Open the pressure arm. Open the fastening screw [1].

Remove the driving sprocket, then pull the feed roller [4] from the sprocket [3]. Then

replace the feed roller and reassemble in reverse order.

6.6. Exchanging the wire guide

Open the Allen screw [1]. Replace the wire guide [2]. For exact positioning, make sure that the notch

[3] is positioned under the Allen screw. Then carefully tighten the Allen screw again.

6.7. Exchanging the wire liner

10 Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023

Plastic wire guides with wire spiral attachment, can be used for aluminium, copper, nickel and stainless

steel wires. Lay the hose pack out straight. Then loosen the union nut (grey) with a size 12 open-end

wrench and remove it.

After removing the union nut the nipple of the wire guide spiral becomes visible. Use the same to pull

the wire guide spiral out of the hose pack.

There are wire guide spirals with firmly pressed nipples and wire guide spirals with clamping nipples. If the

nipple is not already firmly pressed, push it onto the wire guide spiral. Then insert the new wire guide spiral

intothehosepackandmeasurethelengththatprotrudesfromthecentraladaptertotheO-ringonthenipple.

Pull out the wire guide spiral again and cut off the measured length -1 cm, the cut edge must be

deburred.

Push the wire guide spiral back in and tighten the union nut again hand-tight with the open-end

wrench.

NOTE

Always check that the wire guide is fastened correctly.

Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023 11

6.8. Coolant (this is only required for liquid-cooled welding torches.)

WARNING

Risk of burns

Liquid-cooled torches will overheat if the coolant level is too low. Check

the coolant level in the cooling unit on a regular basis.

NOTE

The cooling system and welding torch must be thoroughly rinsed and filled every time initial installa-

tion is carried out, or whenever the hose pack is changed.

CAUTION

Material damage may occur

Damage to feed device and torch due to defective coolant connection. Be mindful of the flow and

return coolant connections on the cooling unit.

Coolant flow blue

Coolant return red

• Connect the hose on the welding torch from the blue coolant flow to blue quick-coupling NW5 on the

welding power source's cooling unit.

• Connect the hose on the welding torch from the red coolant return to the red quick-coupling on the

welding power source's cooling unit.

The coolant system is connected.

• Now rinse the welding torch with coolant, top up coolant if required.

• To do this, run the welding machine's own coolant flow program 2 to 4 times.

• The longer the welding torch is, the longer the coolant rinsing program must be used.

6.9. Setting the shielding gas quantity

NOTE

The type and quantity of the shielding gas to be used always depends on the welding task.

NOTE

To prevent a blockage due to impurities in the inert gas supply, briefly open the cylinder valve before

connection and thus flush out any impurities. This ensures a safe gas flow afterwards. All inert gas

connections must be gas-tight!

6.10. Application

Connect the shielding gas cylinder to the welding power source or the feed unit, then adjust the gas

flow quantity to the shielding gas cylinder's pressure reducer.

NOTE

Check

• before connecting to the feed unit that the correct wire guide (guide spiral or plastic core) has been

installed for the appropriate wire type in the welding torch's hose pack.

• that the equipment parts have been fitted on the torch elbow for appropriate wire diameters.

• that cooling unit functionality is ensured with liquid-cooled welding torch designs.

12 Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023

7. The control unit

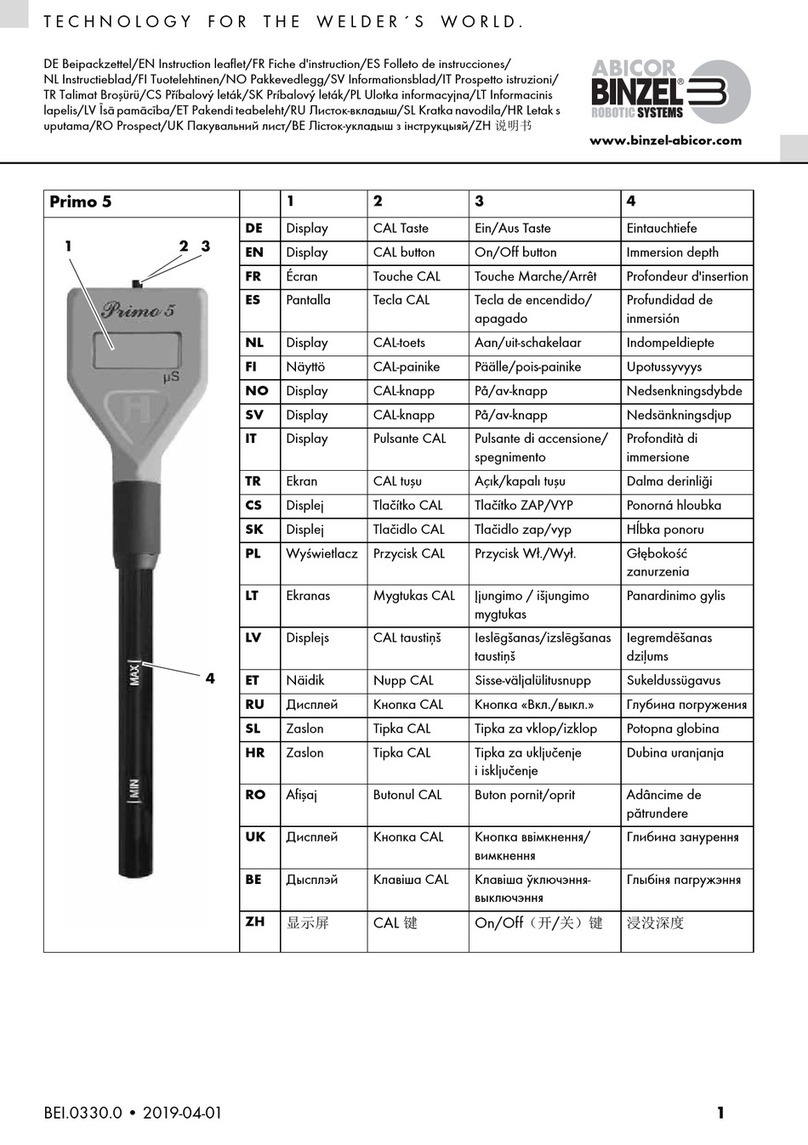

7.1. Overview

Front view

Rear view

7.2. Technical data

Protection type: IP67 (except debug BNC connectors)

Power supply: 100 .. 240 VAC, max. 2.0 A, 50/60 Hz

Fuse protection: 2.5 AT, 5 x 20 mm

Internal supply: 48 VDC, max. 1.6 A (75 W)

Reference input: 0 .. ±50 V, max. 5 mA

Motor output: ±3.6 V .. ±48 V, max. 3 A, software limited to 60 W

Max. motor acceleration: 30 m/min/s

Push-pull speed: ±1 m/min .. ±30 m/min

Fuse

On

O

DC In

DC-Motor

Reference

Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023 13

7.3. Pin assignment

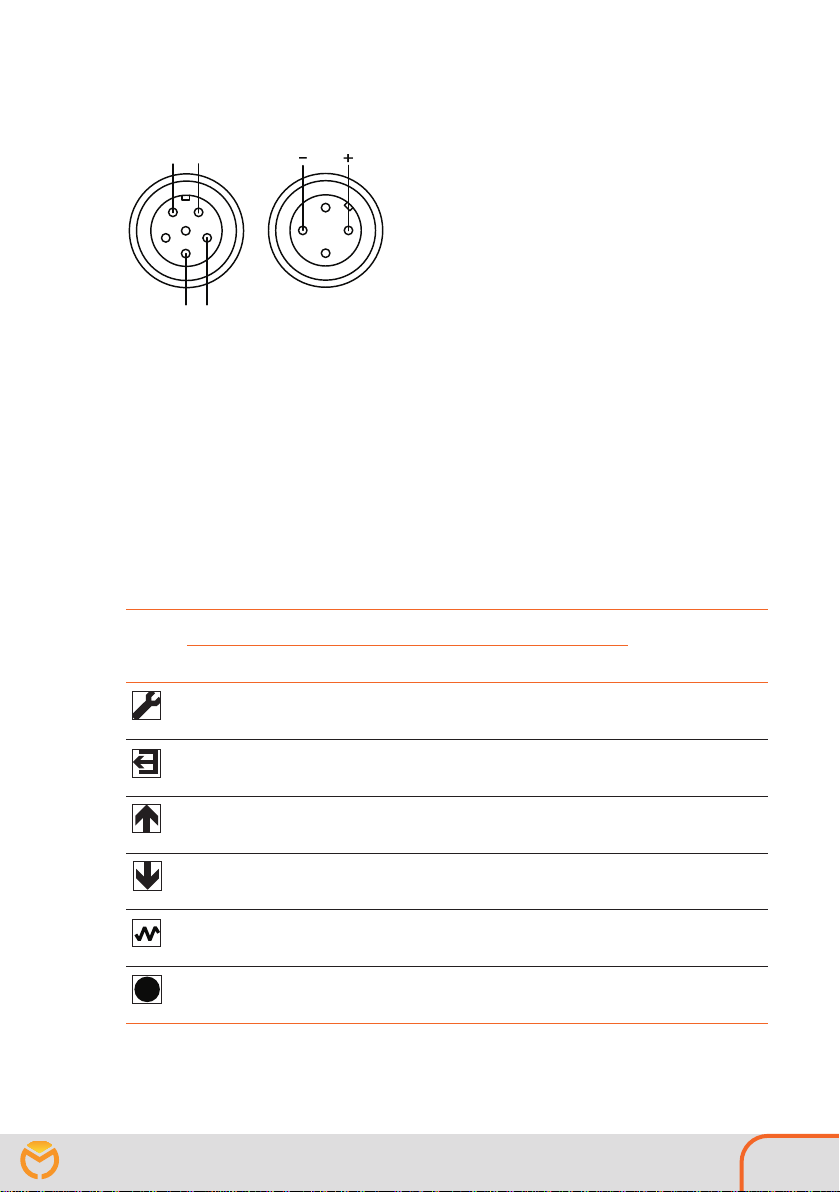

Reference motor

Test contact

The test contact of the reference connector is used for connection detection of the reference cable. The

two pins must be connected directly in the connector. The reference cable is connected to the power

supply (+/-) at the master motor of the feed unit in the welding power source with connection to the

supplied cable clamps.

7.4. Operating the control unit

The push-pull device is entirely operated with six push buttons. There are five different program modes:

Standby, Run, Parameter, Setup and Error. The button functions depend on the current program mode.

The table below provides an overview:

Program mode Button > 2s

press

Button Run / Standby Parameter / Setup Error

Change to

„Parameter“

status

no function

Change to

„Parameter“

status

no function

no function Back to „Run“ no function no function

no function Increase parameter

value no function Increase parameter

value quickly

no function Reduce parameter value no function Quickly reduce

parameter value

Switch on

push-pull

(Jog function)

no function

Switch on

push-pull

(Jog function)

Switch on

push-pull

(Jog function)

no function Confirm set parameter,

jump to next parameter no function no function

14 Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023

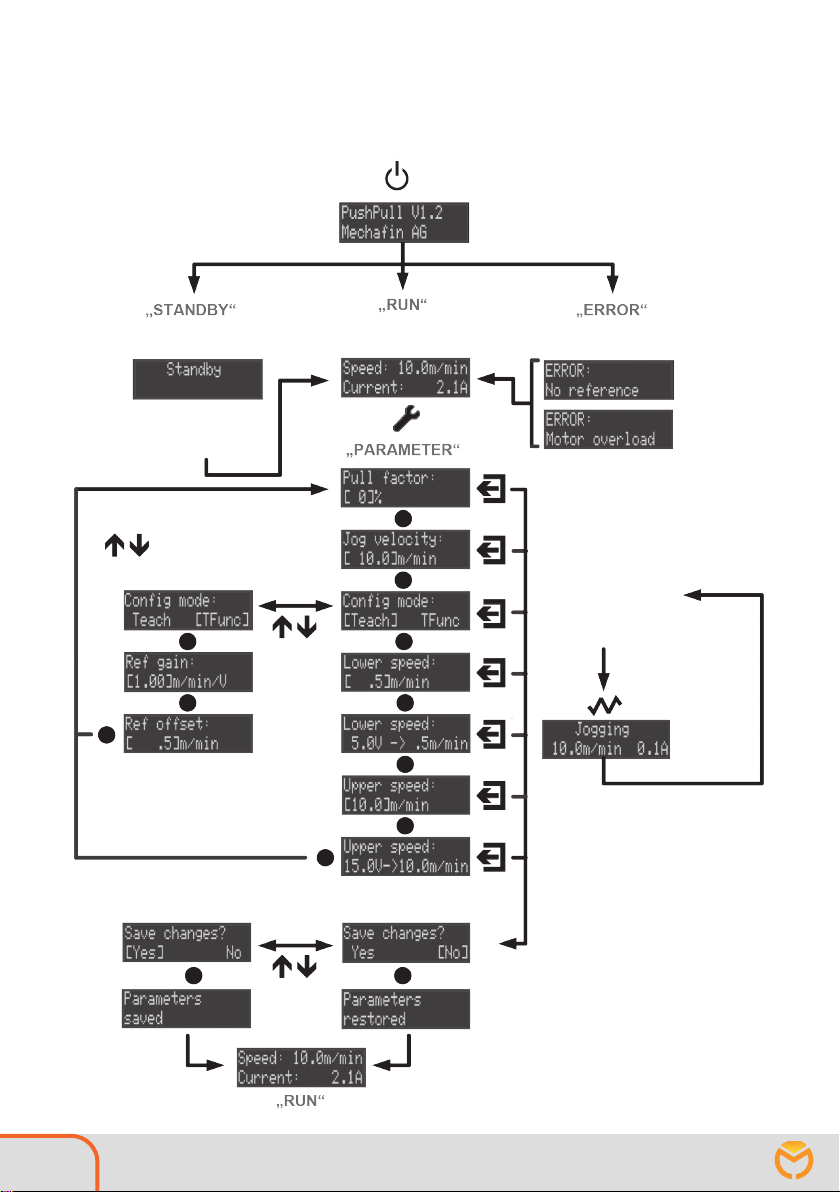

7.5. Operation overview

Operation in regular mode

Display for

5 seconds

No reference

Signal present

As soon as the reference signal

is present, automatic change

to "RUN" mode

Push-pull in operation

As soon as the error is eliminated,

automatic change to the

"STANDBY" or "RUN" mode

"STANDBY" mode

"RUN" mode

"Error" mode

The parameters can be

adjusted with the

"UP" and "DOWN" buttons.

Display for

3 seconds

Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023 15

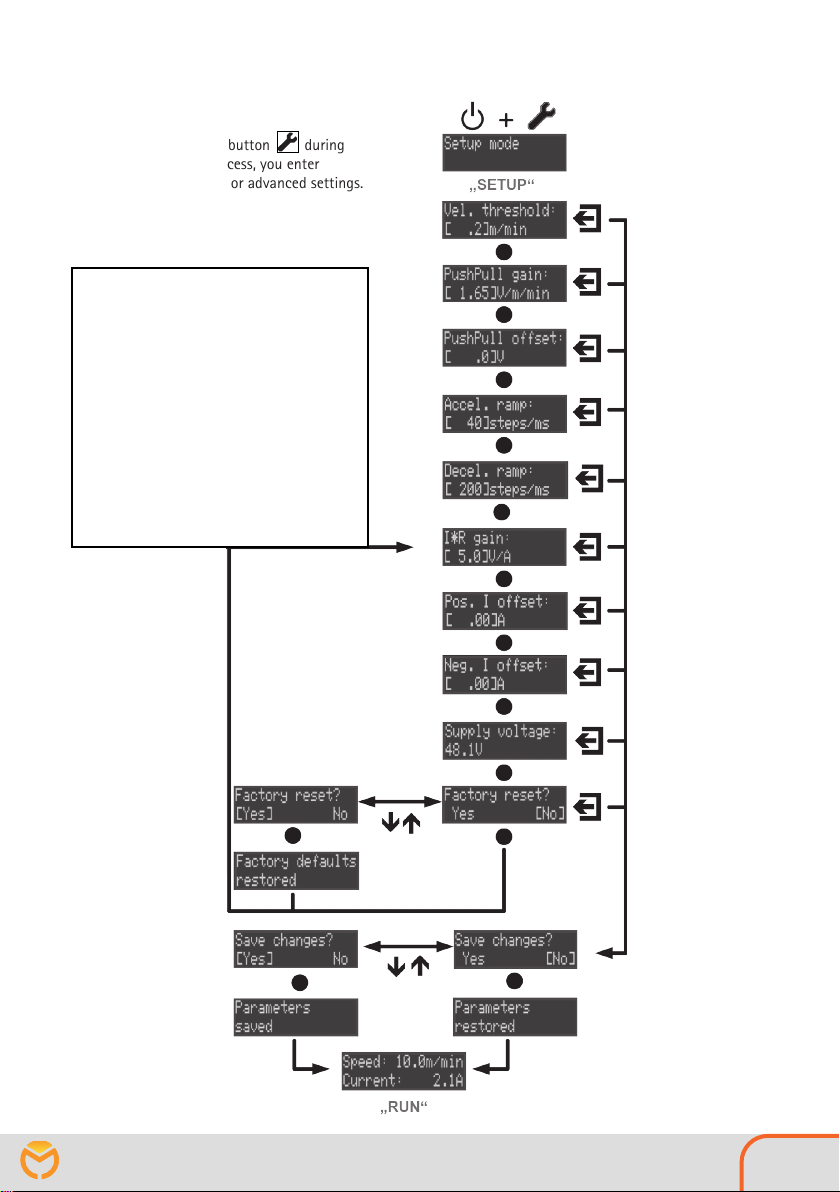

Operation in setup mode

By pressing the button during

the welding process, you enter

"SETUP MODE" for advanced settings.

Display for

3 seconds

Display for

3 seconds

Display for

3 seconds

The cable length is adjust here.

The cable length is calculated on the basis of

the following formula:

Length (m) x 0.08 + 3.4

5 m = value 3.8

10 m = value 4.2

15 m = value 4.6

20 m = value 5.0

25 m = value 5.4

The value in the scheme on the right corre-

sponds to a length of 20 m

16 Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023

7.6. Program modes

Standby mode

If the reference cable is connected, but no reference signal is present at the

input, the control unit is in standby mode. In this state the motor on the

push-pull unit is switched on and off. As soon as a voltage is measured at

the "Reference" input, the unit automatically switches to run mode and the

push-pull unit runs at the preset speed.

Run mode

In run mode, the push-pull unit operates at the speed specified at the "Ref-

erence" input. The current speed and motor current are shown on the dis-

play.

Parameter mode Pull factor: This value is used to set the percentage by which the push-pull

unit should run faster than the specified reference speed of the welding

machine. Value range: [0..30] %

Jog velocity Jog velocity: Push-pull velocity in jog mode. By pressing the Jog button

the program leaves the Run mode and the push-pull unit runs with the

speed set in this parameter. By entering negative values, the push-pull unit

can also be operated in the opposite direction.

Value range: ± [0..30] m/min

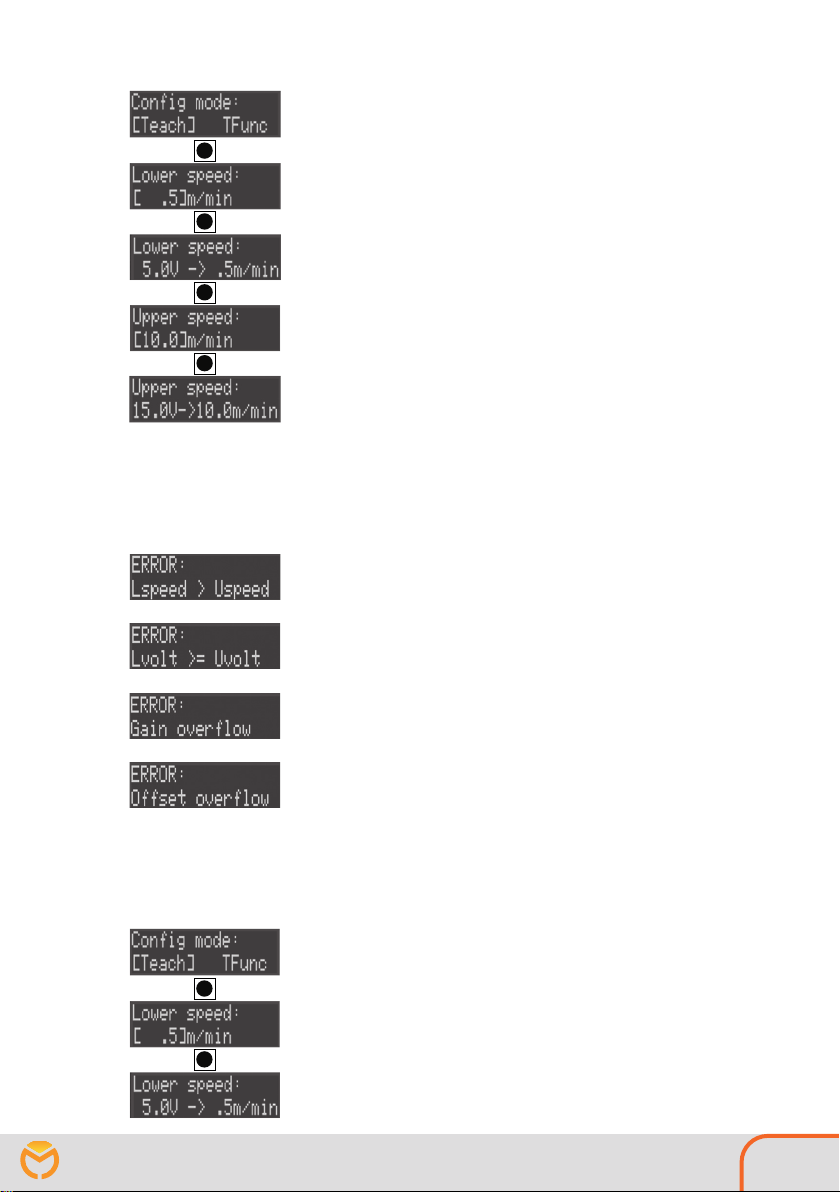

Teach config mode

In [Teach] config mode, a straight line equation for the speed control of the

push-pull unit is calculated on the basis of two defined speeds, depending

on the specified voltage at the reference input. For this purpose, the current

speed of the push-pull unit must be configured for two given reference

voltages, „Lower UREF“ and „Upper UREF“. . These recorded values must be

entered in the corresponding parameters „Lower speed“ and „Upper speed“.

[Teach] procedure

Lower

speed

Upper

speed

Lo

wer

U

REF

Upper

U

REF

v

UREF

Gain

Offset

Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023 17

1.) Select [Teach] config mode

2.) Lower speed: Lower speed reference value.

Value range: [0.1..30] m/min

As a check, the measured reference voltage is displayed at the current

speed „Lower speed“.

3.) Upper speed: Upper speed reference value.

Value range: [0.1..30] m/min

For control purposes, the measured reference voltage is displayed at

the current speed „UPPER speed“.

When saving the parameters, the two straight line points are converted

into gain and offset values and stored in the memory.

Possible error messages after setting the [Teach] parameters:

Ensure that the following conditions are fulfilled for the above men-

tioned parameters:

Lower speed ≤Upper speed

Lower UREF < Upper UREF

If these conditions are not fulfilled when exiting the parameter set-

tings, an error message is output (see images on the left).

If the calculated gain or offset is too high, this is also indicated by a

message. In all cases, after three seconds the system switches back to

the „Lower speed“ parameter.

If the dependence of reference voltage and speed is known, it can be

entered directly in „[TFunc] config mode“ using the two parameters

Offset and Gain.

1.) Select [Teach] config mode

2.) Ref gain: known gain of the line equation

Value range: [0.1..5.0] m/min/V

3.) Ref offset: known OFFSET of the line equation

Value range: ± [0..30.0] m/min

18 Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023

Setup mode:

Setup mode: In „Setup mode“ adjustments can be made to adjust the

push-pull control to a specific push-pull unit. These parameters should

normally only be changed by the manufacturer.

Vel. threshold: As long as the reference voltage or the target speed is

below the set threshold value, the push-pull unit is inactive („Stand-

by“).

PushPull gain: This parameter is used to adjust the gain of the transfer

function between the push-pull control and the push-pull motor.

PushPull offset: With this parameter the offset of the transfer func-

tion between the push-pull control and the push-pull motor can be set.

Accel. ramp: This value determines the steepness of the acceleration

ramp in PWM steps per millisecond (see below). Caution: Higher values

lead to higher load on the electronic components.

Decel. ramp: Decel. ramp: This value determines the steepness of the

deceleration ramp in PWM steps per millisecond (see below).

Caution: Higher values lead to higher load on the electronic com-

ponents.

I*R gain: This parameter sets the gain of the I*R compensation.

Pos. I offset: Correction value of the current measurement for positive

output voltages.

Neg.I offset:Correction value of the current measurement for negative

output voltages.

Supply Voltage: This value is used to control the internal

power supply.

Factory Reset: Default values are loaded for all parameters.

Note on the acceleration ramps:

The full range of the output voltage extends over 32,768 PWM steps.

A speed change of 1 m/min corresponds approximately (depending on

the load) to 1100 PWM steps. Thus a value of 40 steps/ms leads to an

acceleration ramp of about 35.5 m/min/s. An acceleration of 0 to 10 m/

min takes 282 ms.

Operating instructions Intermediate drive PushPull MECHAFIN AG 03 / 2023 19

Default values

A "Factory reset" loads the following parameter values:

Pull factor: [10] %

Jog velocity: [10] m/min

Ref gain: [0.2] m/min/V

Ref offset: [-0.3] m/min

Vel. Threshold: [0.3] m/min

PushPull gain: [1.65] V/m/min

PushPull offset: [0.0] m/min

Accel. ramp: [40] steps/ms

Decel. ramp: [200] steps/ms

I*R gain: [5] V/A

Pos. I offset: [0] A

Neg. I offset: [0] A

Error mode

No reference: The cable at the reference input is not connected. This is

detected by a wire jumper in the cable connector. As soon as the cable

is plugged in, the program returns to Run mode.

Motor overload: The motor was overloaded over a longer period of

time. The motor is switched off.

Attention: After about 30 seconds the motor is switched on again

and the program returns to Run mode.

Motor OTW: Over temperature warning of the motor driver on the

MMU 01 electronics. As soon as the temperature is back in the permit-

ted range, the program returns to the „Run“ state.

Motor FAULT: Protection mechanism of the motor driver on the MMU

01 electronics has responded, the motor is switched off immediately.

The error is cleared once the unit is switched into Standby mode

Table of contents

Popular Welding Accessories manuals by other brands

Lincoln Electric

Lincoln Electric ZIPLINE BOOM PACKAGE Operator's manual

RUD

RUD PowerPoint WPP Series Translation of the original instructions

dymax

dymax BlueWave Dymax Unpacking and setup instructions

Miller

Miller Classic Clearlight owner's manual

Würth

Würth WSH III 5-13 instruction manual

Lincoln Electric

Lincoln Electric W000315558 Safety instruction for use and maintenance