2PowerPoint®

Before initial usage of the RUD weld-on lifting

point PowerPoint®, please read carefully the

safety instructions. Make sure that you have

understood all subjected matters. Non-obser-

vance can lead to serious personal injuries

and material damage and eliminates warranty.

1 Safety instructions

ATTENTION

Wrong assembled or damaged weld-on lifting

points PowerPoint®as well as improper use

can lead to injuries of persons and damage of

objects when load drops.

Please inspect all lifting points before each use.

• Remove all body parts (ngers, hands, arms, etc.) out

of the hazard area (danger of crushing or squeezing)

during the lifting process.

• RUD weld-on lifting points PowerPoint®must only be

used by instructed and competent persons considering

DGUV rules 100-500 (BGR 500) and outside Germany

noticing the country specic statutory regulations.

• Attention: Other combinations with non RUD com-

ponents and chains are dangerous! These are not

permitted and RUD will not accept any warranty.

• Disassembling of ball-bearing by the user is not allowed.

• The stated WLL on the lifting point must only be ex-

ceeded in the vertical usage of the WPP/WPPH 5 t and

WPP/WPPH 8t acc. to table 5.

• Weld-on lifting points PowerPoint®must be rotatable in

the screwed tight status through 360 °.

• No technical alterations must be implemented on the

weld-on lifting points PowerPoint®.

• No people may stay in the danger zone.

• Jerky lifting (strong impacts) should be prevented.

• Always ensure a stable position of the load when lifting.

Swinging must be prevented.

• Damaged or worn weld-on lifting points PowerPoint®

must never be utilised.

2 Intended use of PowerPoint®

• Lifting points must only be used for lifting and manipu-

lating of loads according to the stated inclination angles

and the total weight of the load. Turning and ipping of

loads will be allowed due to the installed ball bearing

(with the WPP and VWBS-KA). But these lifting points

must not be used for a permanent turning action under

load.

• RUD weld-on lifting PowerPoint®must only be used in

the hereby described operation purpose.

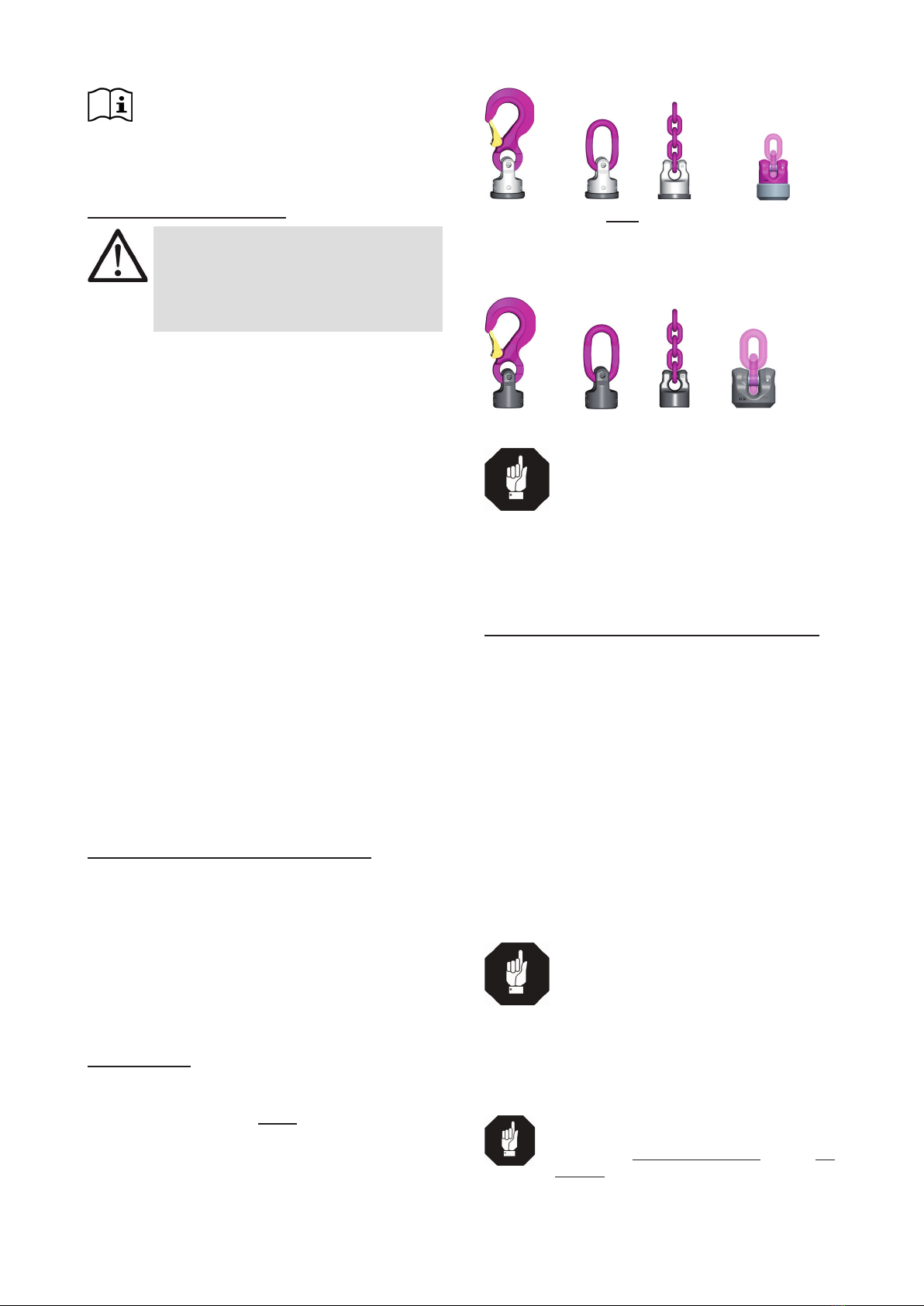

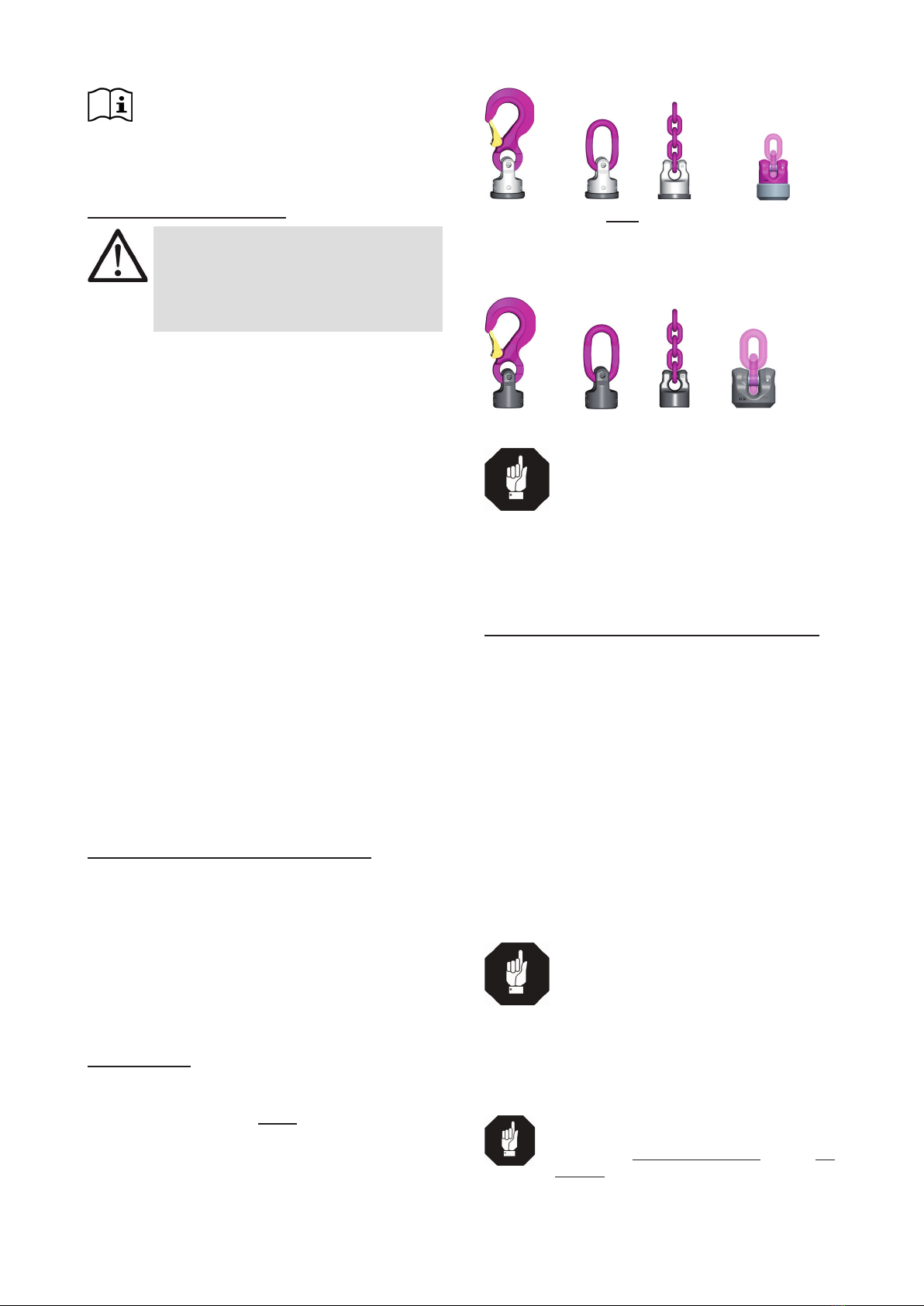

3 Variants

RUD weld-on PowerPoints®are compatible with the fol-

lowing components:

RUD-PowerPoint®able to rotate:

WPP-S (1): standard version

WPP-B (2): the lifting ring version for hook assemblies

WPP-VIP (3): direct chain connection

VWBS-KA-28 (4): direct chain connection 28 mm/VIP

(1) (2) (3) (4)

RUD-PowerPoint®xed:

WPPH-S (5): standard version

WPPH-B (6): the lifting ring version for hook assemblies

WPPH-VIP (7): direct chain connection

WPPH-KA-28 (8): direct chain connection 28 mm/VIP

(5) (6) (7) (8)

Pic. 1: versions

HINT

Combinations of eye connection parts and

chains, which are not specified by RUD

are prohibited. For changes or combina-

tions of not specified parts, RUD Ketten

will not take responsibility and liability.

With the variants WPPH-KA-28 and VWBS-

KA-28, only the direct chain connection is

possible (see table 6, page 7).

4 Assembly- and instruction manual

4.1 General information

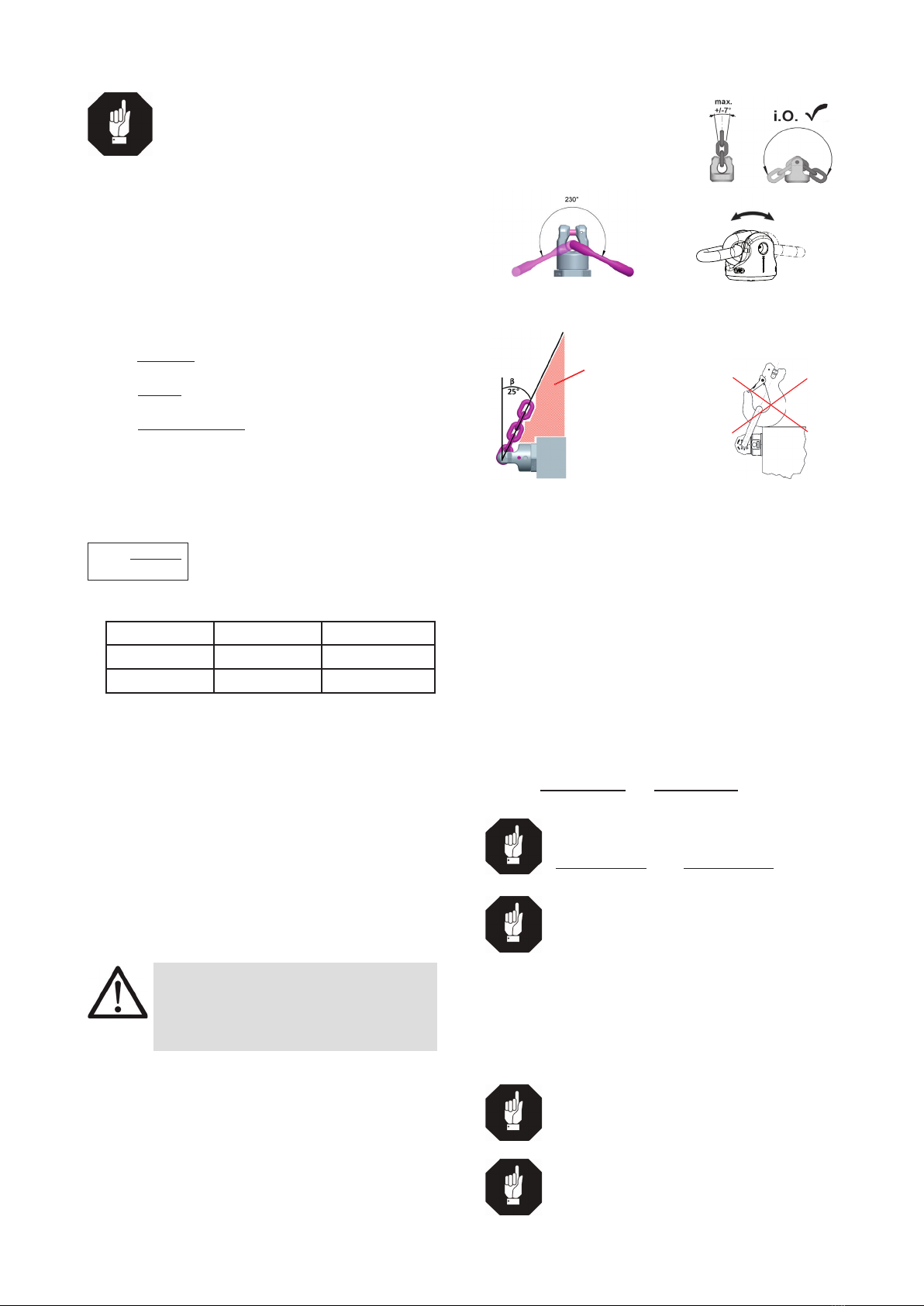

• Capability of temperature usage:

The use in high temperatures is not recommend due

to the grease in the ball- bearing, if you need it yet,

you must reduce the weight of load as follows:

-40° up to 200°C: no reduction

200° up to 300°C: minus 10 % (392°F up to 572°F)

300° up to 400°C: minus 25 % (572°F up to 752°F)

Temperatures exceeding 400°C are prohibited!

• RUD weld-on lifting points must not be used with ag-

gressive chemicals such as acids, alkaline solutions

and their vapours.

• The special pink-powder coating of the components

changed permanently the colouring, if the use was in

high temperatures. The colour deep black signals a use

over 400°C.

HINT

After use over 400°C (chain is coloures deep

black) is a continuing use not allowed.

The quality of the chain is not guaranteed.

• Please mark mounting position of lifting point with a

coloured contrast paint for better visibility.

• If the lifting points are used exclusively for lashing

the value of the working load limit can be doubled:

LC = 2 x WLL

HINT

If the lifting point is/was used as a lashing point,

with a force higher than the WLL, it must not

be used as a lifting point afterwards.

If the lifting point is/was used as a lashing

point, up to the WLL only, it can still be used

afterwards as a lifting point.