Mecon mag-flux F5 User manual

MeconGmbH Phone +49(0)223760006-0 Fax +49(0)223760006-40 page 1to4

Röntgenstraße 105 www.mecon.de info@mecon.de Mecon01/2007

D-50169Kerpen

ElectromagneticflowSensor

mag

-

flux

F5

Fig.1electromagneticflowsensor mag-flux F5

__ Application

Electromagneticflowmetersaresuitableformeasuringthe flow

ofalmostall electricallyconductingliquids,aswellassludges,

pastesandslurries.

Aprerequisiteisthat the mediummusthaveacertainminimum

conductivity.The temperature,pressure,viscosityanddensity

have noinfluence onthe result.

Thisspecialdesignofan electromagneticflowmeter(MID)is

particularlysuitableformeasuringtheflowofextremelysmall

quantitiesandespeciallyforusewith proportioningandbatching

systems.Inconjunctionwith thetransmittersIntermag

2/Transmag2,complextasks can besolvedusingtheintegral

softwareforbatchingapplications.Typicalapplicationscan be

foundinthefoodindustry,thedosingofchemicalsin

photographicsystems,andthedosingofmedicinesinmedical

fields.

When usingthealternatingfieldtechnique with thetransmitter

Transmag2,even verysmallflowscan beexactlymeasuredasa

resultofthe largermagneticfieldandthe zerostability.

The flowsensors mag-flux F5areusedmainlyinthefollowing

industries:

·Waterandwaste waterplants

·Chemicalandpharmaceuticalindustry

·Food- andbeverage industry

·Mining,cementandmineralmaterials

·Pulp- andpaperindustry

·Steelindustry

·Powergenerationanddistribution.

The flowsensorarecombinedwith thetransmittersIntermag

2/Transmag2andare only available asremoteversions.

__ Special features

·Meteringtubemadefromhighcorrosion-andtemperature

resistant zirconium oxide

·Meteringtube innerdiameter2mm(0,078")andabove

·smallestmeasuringranges:

o0to5l/h(0to0,022 USgpm) with constantfield

o0to3l/h(0to0,0132USgpm) withalternatingfield

·verylowminimum conductivity:

o10 S/cm with constantfield

o0,1 S/cmwith alternatingfield

·robustandinterference-freeasaresultofclosedsteel

housing

·differentprocessconnectionsandmaterials

oThread:DIN,NPT,BSP

oFlange: DIN,ANSI,JIS

oClamp

oDIN11851

oandmoreuponrequest

·differentprocessconnectionmaterials

oMat.No. 1.4571

oHastelloy C4W.Nr.2.4610

oPVDFwith earthingringmadefromHastelloyC4

mat.No. 2.4610

oTitanium

oandmoreuponrequest

____________________________________________________________

__ Noteof application

·The operatorofthesemeasuringinstrumentsisresponsiblefor

suitability,properuseandcorrosionresistanceoftheused

materialswith regardtothemeasuringmaterial.Itmustbe

ensuredthatthematerialsselectedforthemeterpartsin

contactwiththemediumaresuitablefortheusedprocess

media.

·Beforereplacingthe measuringtubes,checkthatthe meteris

freeof hazardousmediaandisnotpressurized.

·The unitmayonlybeusedwithinthepressureandvoltage

limitsspecifiedonthe ratingplate.

·The flowmetercomplieswith therequirementsofthePressure

EquipmentDirective97/23/EC,article3,paragraph3.The

mosthazardouspermissiblemediaarethe fluidsdefinedin

group1.

·Provideatouchguardforsurfacetemperaturesof>70°C.

Thistouchguardmustbedesignedinawaythat the max.

allowable ambienttemperature ontheunitisnotexceeded.

·The sensormustnotbeaffectedbyexternalloads.

·The unitsaredesignedforpredominantly recumbentload.

WWW.TEESING.COM | +31 70 413 07 50

MeconGmbH Phone +49(0)223760006-0 Fax +49(0)223760006-40 page 2to4

Röntgenstraße 105 www.mecon.de info@mecon.de Mecon01/2007

D-50169Kerpen

ElectromagneticflowSensor

mag

-

flux

F5

__ Installation

The measuringprincipleisgenerallyindependentofthe flow

profile.Ideally,thedeviceshouldbeinstalledinapipeline,which

hassufficientstraight tubingbeforeandafterthe measuring

point.Ingeneral,aninletpath ofmin.5xdia.andanoutflow

zone ofmin.2-3x dia.isrequired.

Providedthatconstantturbulencedoesnotenterthe areain

whichthemeasurementtakesplace(e.g.afterelbows,during

tangentialfeedsorifthe valveinfrontofthesensorispartially

open).Insuchcasesmeasurestonormalize theflowprofileare

necessary.Suitable measuresinthisrespectare:

·increasingtheinletandoutletzones

·usingflowconditioners

·reducingthe innerdiameterofthe pipe

Fig.2Installationin horizontalandverticalpipelines

Installationmaybehorizontalorvertical(Fig.2)butitmustbe

ensuredthat theaxesoftheelectrodesrun horizontally(the

directionarrowmarks the electrodeaxes) toavoidmeasuring

errorsduetodepositsorairbubblesonthe electrodes.

Fig.3Installation between pipeelbows,valvesandpumps

The inletandoutletzonesmustbekeptstraight (Fig.3).

Fig.4Installationin aconstantly filledpipe

The flowmeasuringdevicemustbeinstalledsothatthe

measuringpipecannotrunemptyandisalways filledwith

medium.Thesensormustbeinstalledinaculvertinthecaseof

an unfilledpipe oronly afreelevelline (outlet).

Fig.5Installationin pipeswithout emptying

The sensorshouldnotbeinstalledinpipesectionswith afree

pipeoutletwhichcouldrunempty(e.g.downpipes).When

installinginadownpipemakesurethat the pipeisalways filled

100% with the medium.

Fig.6Installation at the highest point

Avoidinstallationat the highestpoint ofthepipedue to

accumulationof gas.

Fig.7Installation of severalsensors,eitherin seriesorin parallel

Ifseveralsensorsareseriesconnected,thedistancebetween the

individualsensorsmustbeatleastequaltothelength ofone

sensor.Iftwoormoresensorsaretobeconnectedinparallel,

thedistancemustbe atleast1m.

WWW.TEESING.COM | +31 70 413 07 50

MeconGmbH Phone +49(0)223760006-0 Fax +49(0)223760006-40 page 3to4

Röntgenstraße 105 www.mecon.de info@mecon.de Mecon01/2007

D-50169Kerpen

ElectromagneticflowSensor

mag

-

flux

F5

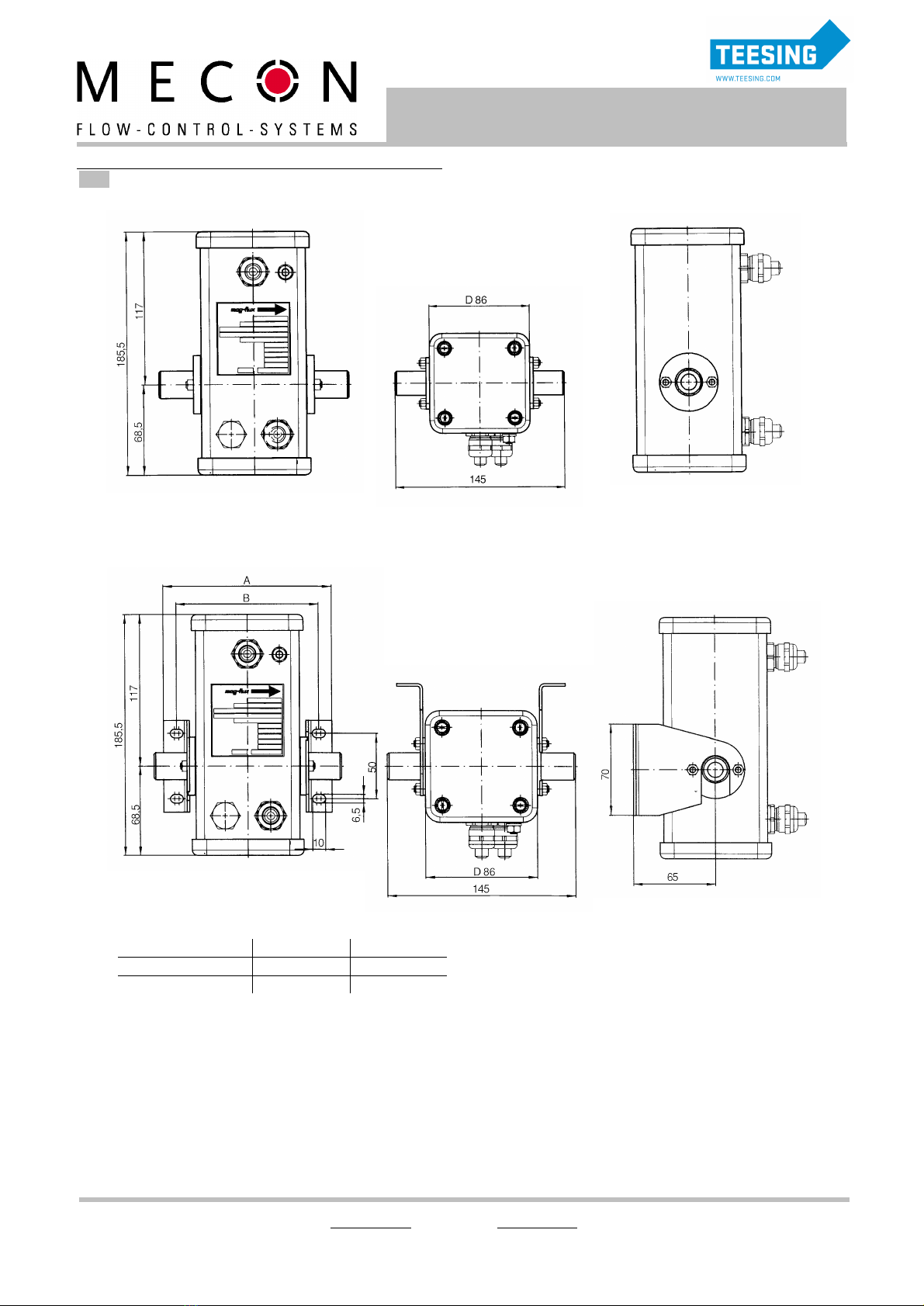

__ Dimensions

X1: if flange connectionmaterialisPVDF,installationdimension

is160mm!

Connectionmaterial DimensionA DimensionB

Metal 133 132

Plastic 140 120

Fig.2ElectromagneticflowSensor

mag

-

flux

F5(without wallmount),dimensionsin mm

Fig.3ElectromagneticflowSensor

mag

-

flux

F5(with wallmount),dimensionsinmm

X

1

X

1

WWW.TEESING.COM | +31 70 413 07 50

MeconGmbH Phone +49(0)223760006-0 Fax +49(0)223760006-40 page 4to4

Röntgenstraße 105 www.mecon.de info@mecon.de Mecon01/2007

D-50169Kerpen

ElectromagneticflowSensor

mag

-

flux

F5

__ TechnicalData

Applicationfield see page1

Measuringprinciple pulsedconstant field(DC)

pulsedalternatingfield(AC)

Inlet

Nominaldiametermeteringtube Measuringrange

Constant field Alternatingfield

2mm (0,078”) 5-110 l/h 3 -110 l/h

4 mm (0,156”) 25 -450 l/h 15 -450 l/h

8 mm (0,312”) 100 -1800 l/h 60 -1800 l/h

12 mm (0,47”) 200 -4000 l/h 120 -4000 l/h

Measuringaccuracy

Errorof measurement ±0,5%of measuredvalue

0,25 m/sto10 m/s

Repeat accuracy ±0,15 %of measuredvalue

0,25 m/sto10 m/s

Operational conditions

Mountingposition verticalorhorizontal

Max.operatingtemperature 150°C/302°F

Pressurelimits 25 bar/362,5psi

higheruponrequest

Temperature Max.pressure

°C °F Bar Psi

0-50 32 -122 10 145

60 140 8,5 123

70 158 7,5 109

80 176 6,5 94

90 194 5,5 80

100 212 4,5 65

110 230 3,8 55

Pressure/temperaturelimitswith

PVDFconnections(DIN8062)

120 248 3,0 44

Protection class IP67/IP68

Minimumconductivity

·with constant field

·with alternatingfield

>10 S/cm

>0,1 S/cm

Specifications

Design Fully-weldedsteelfittingwith cover

madeof aluminium

Weight approx.3kg

Cableinlet

·with constant field

·with alternatingfield

2x M16 x 1,5/2x½”NPT

3x M16 x 1,5/3x½”NPT

Material

·Meteringtube

·Sensorhousing

·Process connection

Zirconiumoxide

Steel

Stainless Steel,Hastelloy,PVDF

Electrodes

·Material

·Design

Platinum99,9%,sintered

Flat electrode

__ Orderingdata

ElectromagneticflowSensor

mag-flux

F5

M

A

G

5

6

1

-

0

0

-

0

Measuringprinciple

•alternatingfield

3

•constantfield

4

Nominaldiameterofmeteringtube

•2mm

D

•4mm

E

•8mm

F

•12mm

G

Process connection

•G1/2,mat.No.1.4571

A

•G1/2,HC4(mat.No.2.4610)

B

•G1/2,PVDFwithHC4-earthingrings(mat..No.2.4610)

C

•G1/2,Titanium

S

•NPT1/2",mat.No.1.4571

D

•NPT1/2",HC4(mat.No.2.4610)

E

•NPT1/2",PVDFwithHC4-earthingrings(mat.No.2.4610)

F

•DN15 PN25 DIN2501,mat.No.1.4571

H

•DN15 PN25 DIN2501,HC4(mat.No.2.4610)

J

•DN15 PN25 DIN2501,

K

PVDFwithHC4-earthingrings(mat.No.2.4610)

•1/2"Tri-Clamp,mat.No.1.4571

L

•1"Tri-Clamp,mat.No.1.4571

N

•1/2"ANSIB16.5150RF,mat.No.1.4571

Q

•1/2"ANSIB16.5150RF,

T

PVDFwithHC4-earthingrings(mat.No.2.4610)

•otherconnections/materials

Z

Gasketmaterial

•EPDM

2

•Kalrez

3

Wallmount

•without

0

•with

1

Screwedgland

•M16x1,5

C

•NPT1/2"

B

Degree of protection

•IP67/NEMA5

B

•IP68/NEMA6mit5mfirmlyconnectedcable

C

•IP68/NEMA6mit10mfirmlyconnectedcable

D

Furtherdesigns

•Measuringrange<10l/h

A11

•TAGplateinscriptioninenglish

B11

•with3-pointcalibrationcertificate

B06

•with6-pointcalibrationcertificate

B07

•Silicone-freematerials

Y04

•TAGplatestainlesssteel

Y17

WWW.TEESING.COM | +31 70 413 07 50

Table of contents

Other Mecon Accessories manuals