Media Technologies Brick-HD Specification sheet

Brick-HD Video Wall Processor

Product User Guide

Media

Technologies

Copyright Media Technologies 2011

Page 2 of 18

CONTENTS

1

INTRODUCTION.....................................................................................................................................................3

2

INSTALLING THE CONTROL SOFTWARE......................................................................................................3

3

CONTROL USING RS232 .......................................................................................................................................4

4

BRICK-HD IP NETWORK CONFIGURATION..................................................................................................5

5

BRICK-HD CONTROL VIA IP ..............................................................................................................................6

6

VIDEO INPUTS ........................................................................................................................................................7

7

VIDEO OUTPUTS....................................................................................................................................................8

8

ALIGNING THE VIDEO WALL IMAGE .............................................................................................................9

9

CONTROL SCRIPTS.............................................................................................................................................11

10

SAFETY / SEGURIDAD ....................................................................................................................................15

11

COMPLIANCE ...................................................................................................................................................16

12

SPECIFICATION ...............................................................................................................................................17

Copyright Media Technologies 2011

Page 3 of 18

1INTRODUCTION

This guide is intended for initial processor setup only - consult the HELP function in the

control software for more detailed information.

Most Brick-HD video wall processor features can be setup using the using the display and rotary

switch on the front of the unit. Rotating this switch scrolls through menus on the display. Push the

switch to activate modes or to select a sub-menu.

Alternatively the control software supplied can be used with a Windows based PC to provide a more

user friendly graphical interface as described in this guide. The control software requires a

connection to the Brick-HD. This can be either RS232 via a PC COM port, or via a network using

the Ethernet port. The COM port is easier to set up. Also if the processor is initially connected via a

serial port it will simplify the network configuration process.

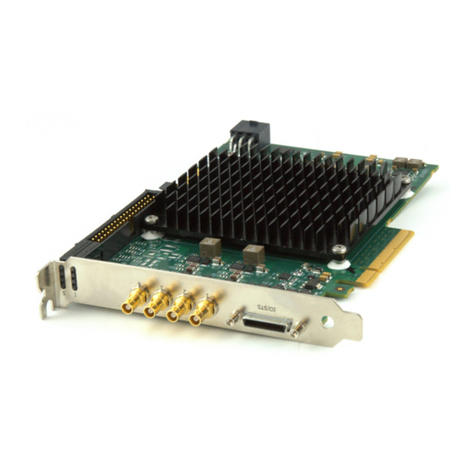

All video input and control connections to the processor are at the front. Video outputs are at the

rear. Video input and output modes are selected using the control software or manually using the

front panel display.

2INSTALLING THE CONTROL SOFTWARE

Insert the software CD in the drive and the installer should automatically run. If it does not run, use

Windows explorer to run the installation file BrickHD3.msi

If the Windows installer does not work, create a directory called ‘BrickHD’ in the ‘Program Files’

directory using Windows Explorer. Then copy all the files and directories in the ‘Software Files’

directory on the CD to the new BrickHD directory in Program Files on your PC.

Create a short cut on your desktop to Program Files\BrickHD\vwctrl.exe

Create a new directory in My Documents called ‘BrickHDProjects’ to use for your projects.

If you manually install the software, you will need to manually delete these directories to remove the

software.

Analogue Video

Inputs Manual

Configuration

Serial Control Port

(RS232)

Display

Menu

DVI Video Input

Network

Control Port

Video Outputs

at Rear

Earth Testing

Point

Copyright Media Technologies 2011

Page 4 of 18

3CONTROL USING RS232

Connect the PC to the Brick-HD Host RS232 port using the cross-over cable supplied (also known

as Null Modem cable).

If your PC does not have a built in COM port, a USB-Serial adapter can be used. Install the drivers

for your adapter before starting the Brick-HD Control software application.

Install the Brick-HD control software and start the application.

From the File menu, select Setup. Select the desired PC COM port from the pull down menu. Click

Save Settings, click OK.

The PC should now be in communication with the

processor.

Once the COM port is set, configure the number of

installed processors. If there is more than one processor

connected, each will need a different unit ID. If it is

necessary to change a device's unit ID, connect one unit

at a time to the PC using the serial cable and select the

required unit ID using the appropriate button and click

Set Unit ID this will programme the processor with

this ID. The processor will then only respond to

commands referencing this ID.

The settings can be saved and applied automatically

next time the software is run using the Save settings

button. This will update the file "BrickHD.ini",

typically located in user specific directory

“My Documents\BrickHDprojects”.

Click on Auto for the software to scan each unit and set the installed flag to confirm the correct

configuration of the chain.

In addition, to check communication with all the processors, read back the version information

using the File/Hardware Info menu.

The processor can be controlled using just the RS232 COM port, however a network connection is

required to update the software or to transfer configuration files to the processor. The processor can

continue to be controlled using the serial port when the network connection is established. File

transfers will be performed using the network connection but remaining control is via the serial port.

In this mode, the IP address of the Brick-HD will be determined via the serial connection, so there is

no need to further configure the PC software. It is necessary to enable IP communication on the

Brick-HD however.

Copyright Media Technologies 2011

Page 5 of 18

4Brick-HD IP NETWORK CONFIGURATION

The processor network port is permanently enabled. It will auto-configure for 10/100BaseT and

auto-sense the connection direction. It is not necessary to use a cross-over cable to connect the

network port directly to a network port on a PC. The status of the Ethernet connection can be

viewed from the front panel display.

If the display is blank, press the front panel button. Rotate the Select front panel knob or click the

Down button in the Display panel dialog to select the Ethernet status display. This will display the

MAC address and the Ethernet status.

By default the processor will be configured to acquire a network (IP) address using DHCP. If the

processor is connected to a router that supports DHCP the processor can be connected immediately

using an Ethernet cable and powered-up. The IP address assigned can be seen on the front panel

display as part of the start-up process. Once the processor has started the IP address can be

determined by rotating the front panel knob clockwise to the IP parameters page.

If DHCP is not going to be used, do not connect the Ethernet cable just yet, otherwise the processor

will take some time start-up as it is trying to perform a DHCP transaction that will ultimately time

out.

If the processor is connected to the controlling PC using a serial port, as described in the previous

section, the IP parameters can be set using the PC application. Select File/Config from the main

menu to select the dialog box shown below.

The MAC address is pre-configured. It can be

set to any value (provided it is unique on the

LAN it’s connected too). To make the address

unique select the “Set MAC from Serial

Number” button and enter the processor serial

number.

If DHCP is going to be used, check the enable

DHCP box. You can also configure the

remaining IP values even if DHCP is being

used. These will only be applied if DHCP

fails.

The SNTP (internet time) server address is

optional. This will not be populated by

DHCP. The server can be either an SNTP or

an NTP server.

The TFTP server service should be enabled

(checked). The other services are optional.

In order for the software to communicate with the processor over the network, the MTCP (Media

Technologies Control Protocol) box must be checked to enable it on the processor.

Copyright Media Technologies 2011

Page 6 of 18

At this stage the remaining fields can be left with their initial settings. Click OK to save the settings

and exit the dialog. The processor needs to be reset to apply the new IP configuration. If the

Ethernet cable was unplugged previously because DHCP was not being used, plug it in now.

5Brick-HD CONTROL VIA IP

The Brick-HD must be configured for IP communication before attempting to connect to it using the

PC control software. The easiest way of doing this is as described in the previous section. If there is

no PC with a serial port available it is still possible to set-up the processors network interface.

If the processor successfully acquires an IP address via DHCP the PC control software can be set up

to use this IP address. The configuration can then be changed using the Remote Configuration

dialog e.g. to set a static IP address. A static IP address is preferable, since addresses assigned by

DHCP servers can change, unless the DHCP server is configured to map a specific address to the

MAC address.

Alternatively if there is no DHCP server, use the front panel display to configure the IP parameters.

If the display is blank, press the control button to wake it up. Rotate the button clockwise to select

the configuration menu. Press to select configuration mode. Rotate the button to the IP option and

press the button to select it. You can then program each of the parameters in the same way by

rotating the button to select the menu item and pressing the button. Once a menu item is selected,

enter each field by rotating the button and then pressing it to use the setting.

Each menu level has an Exit option at the end which if selected drops back to the previous level. If

the button is pressed and rotated anti-clockwise before being released it will move back one field, or

exit from the menu selection if it’s the first field. If the button is pressed, rotated clockwise and

released it will cancel the current setting and go back to the menu.

Once all the necessary IP fields have been configured the processor needs to be rebooted to apply

the new settings.

Once the IP network is working, to configure the PC software for a network connection, select

File/Setup from the main menu. Click the Configure-IP button.

Type the IP address corresponding to the address assigned (via

DHCP or by configuration via the front panel display). The Port

number must be set to 5000. The shared secret should initially

be left blank. Click OK and then try and connect via TCP/IP to

the processor by clicking on the Remote (TCP/IP) button. The

connection should be established almost immediately.

If successful the status bar will show TCP/IP in the bottom left hand corner of the software window.

Leave the Set-up dialog and select the File/Config menu option. The remaining configuration

parameters can now be set. At this point a shared secret between the PC and processor can be set, so

that next time a connection will be authenticated. This is done using the Remote Configuration

dialog shown on the previous page.

If connection fails - and an authentication failure message is shown in the control software status

bar, the processor may have an invalid shared secret configured. This can be deleted using the front

panel display. It is not possible to set the shared secret via the front panel display.

Copyright Media Technologies 2011

Page 7 of 18

6VIDEO INPUTS

The processor has one DVI input one analogue component, one composite and one s-video input.

Only one video input can be displayed on the video wall at one time. Future software upgrade

will allow two inputs to be displayed.

Changing Video INPUT Settings

The software can be used to control up to four processors in parallel. Select the processor to be

configured using the buttons in the configure unit box. To configure all units the same, using unit 0

as the master use the "*" select all button.

If a valid signal is present on the

selected input, the Lock box will

be green, if not locked it will be

red. The processor can be set to

automatically determine the

video standard on the selected

input by checking the "Auto

standard detect" box.

Alternatively the video input

signal parameters can be

configured manually if the box is

unchecked. To set the processor

to the manually configured

parameters click Update.

If the video standard is known use manual configuration as lock will be faster. In automatic mode,

the processor will take a few seconds to measure the input signal. It is possible to select the

automatic option to configure the input initially and revert to the manual mode once it has locked.

The Standard Definition (SD) buttons are greyed out since current versions of firmware do not yet

support any SD video formats via the Composite/S-Video inputs.

IMPORTANT

Select SAVE to configure the processor to use these values as power-up defaults.

Copyright Media Technologies 2011

Page 8 of 18

7VIDEO OUTPUTS

The rear panel has 16 DVI connectors which are used to output DVI directly via a standard DVI

cable, or analogue outputs – typically Component – using a break-out cable or DVI to component

adapter.

Default mapping of outputs to monitors in a 4x4 video wall array is given in the table below. The

inner borders show default mappings for 2x2 and 3x3 video wall arrays.

CH-01 CH-02 CH-03 CH-04

CH-05 CH-06 CH-07 CH-08

CH-09 CH-10 CH-11 CH-12

CH-13 CH-14 CH-15 CH-16

Changing Video OUTPUT Settings

There are three possible output modes, Digital, Analog Component YPrPb or RGB. All all are via

the rear panel DVI connectors. One mode only can be used at one time.

If supported by the installed firmware each output has

a 2 dimensional pixel interpolation filter. This can be

enabled or disabled in both directions independently.

If the installed firmware version does not support the

interpolation filter, these options will also be greyed

out.

Outputs can also be selectively disabled to save

energy consumption. If you are running a small video

wall this is highly recommended.

Once configured the settings can be saved in the

processor flash memory. These saved settings will be applied after a software reset or power-up.

The settings can also be copied to the editor cut/paste buffer, using the copy button. The

configuration can then be pasted into a text file as part of an effects script.

The software can be used to control up to four processors (more using extended commands). Select

the processor to be configured using the buttons in the "configure unit" box. To configure all units

the same, using unit 0 as the master use the "*" select all button.

IMPORTANT

Select SAVE to configure the processor to use these values as power-up defaults.

Copyright Media Technologies 2011

Page 9 of 18

8ALIGNING THE VIDEO WALL IMAGE

The monitor alignment feature allows various monitor layouts to be configured. The gaps between

the monitors (bezels) can be compensated for. It is also possible to move rows and columns of

monitors to account for video walls with a different aspect ratio to the input signal.

IMPORTANT

The alignment capability provided by the processor cannot compensate for mis-aligned

monitors. Monitors should all be aligned using the manufacturer features.

The processor must be aligned for each split (magnification factor) that is going to be used for each

video standard.

To align the monitor array first make sure the monitors are cabled as expected. Selecting an

individual monitor in the array will cause the corresponding channel to display a blue colour wash.

If the channel does not appear in the correct position in the array instead of moving the cables it's

possible to achieve the same effect in software. See the channel mapping section below.

Next select a split to align the video wall using the Split button, e.g. 4x4.

If monitors with no over scan are used, it is possible to align the

magnified image to compensate for the monitor border using the Bezel

button. Enter the outside dimensions of the monitor in the Bezel width

and height fields and the image size in the Picture width and height

fields. The values can be in inches or millimetres – however all 4 values

must use the same measurement unit. The outer dimension should

include any gap between the monitors.

Click on apply to try the values or click OK, to apply and exit from the dialog. To position the

image, select Pan and use the sliders to move the image Up/Down and Left/Right.

Copyright Media Technologies 2011

Page 10 of 18

To manually adjust individual rows click on a row (A,B,C,D) to select a row to adjust, Use the

slider on the left to move that row up/down relative to the other rows. The same action is possible

on columns (1,2,3,4).

If the split is less than the maximum it will repeat. So for example, in the case of a split of 2 on a

4x4 wall, columns 2 and 4 will have the same video image and alignment as will columns 1 and 3.

To completely erase the settings for all splits for the current video standard, use the Default button.

To clear the current selected row or column and set it back the default use the Clear button.

When complete, the alignment can be saved in a file on the processor using the Save button. The

saved configuration will be applied on power-up/reset. The split selected will also be re-applied at

the same time.

The video wall must be aligned for each split and image resolution that will be used. If the Bezel

button is used, the entered values will be saved to that they can be easily re-applied with other splits

and input image sizes.

IMPORTANT

When you have finished aligning the image, click SAVE at the left side to ensure the processor

registers the alignment values on power-up.

Monitor – Output Channel Mapping

The mapping of output channels to a position in the video wall array can be changed using the

Channel Mapping feature. To map a channel using the alignment dialog either click on the monitor

you want to move then click Swap, (or simply left click on the monitor). The selected monitor will

be highlighted in yellow. Then click on the monitor position you want it to occupy. The monitor

positions will be swapped. The effect will be immediately visible on the video wall if video is being

displayed.

To re-dimension the video wall from it's normal default mapping use the Dimension button. This

will automatically allocate the channels in rows and columns from a starting point. Click on a

monitor to select this prior to clicking the Dimension button. For example the apparently odd

mapping for a 5x5 video wall can be changed to linear row/column count using this feature. When

the Dimension button is pressed a further dialog box will appear allowing the row/column and split

details to be entered.

The new monitor mapping can be saved using the Save button in the channel mapping box. The

mapping can also be copied to the editor cut/paste scratch pad, using the Copy button. The mapping

configuration can then be pasted into a text file as part of a sequence.

Channels can also be mapped dynamically as part of a timed sequence script to create effects.

IMPORTANT

When you have finished mapping the channels click on SAVE MAP in the channel mapping

to ensure the new map is applied on power up.

Copyright Media Technologies 2011

Page 11 of 18

9CONTROL SCRIPTS

The processor can be controlled using text file scripts “sequences” created within the control

software environment. Sequences can be downloaded to the processor for stand-alone operation.

The Sequence Buttons Dialog box is available from main menu Buttons or by right clicking in the

main window client area.

The dialog box provides 10 tabbed pages of buttons which comprises a project. Each button calls up

a sequence file. The highlighted button in the action group determines what will happen if one of the

buttons on the tabbed section is left clicked, using the mouse. If the button is right clicked a menu

will appear presenting a set of actions, which is a shortcut way of performing an action on the

sequence file associated with the button, if that action isn't selected. Right clicking on the space

where a button could be placed presents a different menu to create a new button or paste a

previously cut button.

The default action is to run the

Sequence file.

To create a new project - or select an

existing project click on the Project

button in the Action group at the top

of the screen. This will present a file

dialog box. Use this to either move

to a suitable directory and enter the

name of a new project, or navigate to

a directory and click on an existing

project and click Open.

Project files have the extension .EFX

To run the sequence, select the Run action and left click on the button.

To move a button, select the Cut action and click on the button. Left click on a spare button to place

it. It is possible to change pages in this state. The Cut button will be remembered and can be pasted

more then once. This only duplicates the button - there is still only one underlying sequence file.

To permanently delete a button, select the Delete action and click on the desired button. This will

only delete the button, not the associated sequence file.

To edit the sequence associated with the button click on Edit in the action group, then the desired

button. If the sequence file exists it will be opened in the editor. If not a dialog box asking to create

the file will be presented.

To exit from the dialog box click Done. If changes to the project have been made you will be

prompted to save these changes. If this request is cancelled the button dialog will remain, If the

answer is No, changes since the last save are lost.

Copyright Media Technologies 2011

Page 12 of 18

Adding Sequence Buttons

To add buttons to the project click New in the Action group. This will disable all existing buttons on

the tab and show all the spare button positions. A different page can be selected in this state. Click

on a spare button. A dialog box will appear allowing the name of the button and path to a sequence

file to be entered. An open file dialog box can be used to locate the sequence file if Browse is

selected. The sequence file does not have to exist at this point - the name of a new file can be

entered.

By convention the file should have the

extension .SEQ Alternatively, if a sequence file

exists that you want to map to a button - from

another project for example, open a Windows

Explorer window (My Computer) and browse to

the directory the file is located in. Left click on

the file and drag it to the tabbed area and release

the mouse button.

This will "Drag and Drop" the file to the project. A button will be created using a short form of the

filename. This can be changed if required using the Rename action button.

Renaming a Sequence Button

Renaming a button is similar to adding a button. Select Rename from the Action group and left

click on the button to rename it. A dialog box

will appear with the existing legend and

filename values populated. These can be

edited. Click Ok to save the new values.

Installing Sequences in the Processor

It is possible to download a sequence to the processor Flash memory and have it execute on the

processor itself. Execution can be manually triggered using the front panel display or by any other

control device capable of sending RS232 characters.

Default RS232 format is 19200 bit/s, 8 Data bits, 1 Stop bit and no Parity.

IMPORTANT

For file transfer, the processor must have the TFTP service enabled and have IP connectivity

via the network as described in the Network Control section above.

To download a sequence click on Install action followed by the button you want to download. This

will invoke the sequence compiler. If successful, the compiled sequence, now in a proprietary

format, will be downloaded to the processor. The filename used is derived by the software from the

PC filename - but this can be changed prior to downloading if required. The extension ".SFB" must

be used for files to be executed by the processor.

In a multi-processor installation, sequence files are generally only installed on processor with ID =

0. Messages in the downloaded sequence intended for slave processors are sent by processor 0 to the

Copyright Media Technologies 2011

Page 13 of 18

addressed processor. Slave processors behave in the same way as if they were being controlled by a

remote PC.

It is possible to install sequences on processors other than ID = 0 by selecting the target processor

via the Unit check box in the setup dialog. Changing the Unit ID from the "Unit ID" group of

buttons changes the unit ID in compiled sequences but does not set the primary unit.

Executing a Sequence

When a sequence is run the software reads the lines of text from the file into memory and begins

interpreting them. If an error is detected a dialog pops up indicating the error. At this point it is

possible to select an option to open the file and go directly to the line causing the error.

The line number currently being executed is displayed. The time-code, relative to the time the

sequence stared is also displayed. Since lines execute quickly, only lines with a "wait" command

will be displayed in the line number box for a sustained period. At this point the Skip button will be

enabled.

To skip over the wait command, click the Skip button. Execution will continue until then next wait

statement.

To pause indefinitely click the Pause button. The name of the Pause button will change to Run.

Click this Run button to resume execution.

To exit the sequence at any point click Stop.

If the Done button is clicked when a sequence is running, the sequence will be abandoned and the

dialog box closed.

If the sequence contains a REM statement, the Tabbed page of buttons is replaced by a text window

while the sequence is running. REM statement text is displayed in this window. If a REM statement

does not cause the text window to appear and a button from the tabbed page of buttons is clicked,

the current sequence is aborted and the new sequence selected runs.

Running Downloaded Remote Sequences

Sequences can be compiled and downloaded to the processor flash filing system. The downloaded

sequences can then be mapped to a single ASCII character for single RS232 character sequence file

execution. Compilation and downloading is done using the Buttons dialog: right click the sequence

button to be downloaded and select install. The processor must be connected via the network.

Sequence files are held in processor flash filing system directory A:/sequence/ The file defining the

mapping between single RS232 characters and compiled sequence files is seqmap.conf in the same

directory.

From the main menu select Sequence/Remote. A list of files will be read from the remote unit

when the dialog box is opened (if no files have been downloaded a file error will be flagged).

To run a downloaded sequence file, select the line containing the sequence file and click Run. To

stop any executing sequence click Stop. There is no need so select a specific sequence file to stop a

running sequence.

To delete a downloaded sequence file, select the line containing it and click Delete.

Copyright Media Technologies 2011

Page 14 of 18

To modify a line entry, select the line to modify and click Modify, or just double click the line. This

will pop up a further dialog box allowing the associated character code and comment for the file to

be amended.

The Char and Dec fields are essentially the

same. The Char field shows the ASCII

character. The Dec field shows the decimal

equivalent of that character. Changing one

field will cause the other to update with the

appropriate value. If the decimal number is

outside the displayable ASCII character

range the Char field will be blank.

Files mapped to ASCII characters in the

range 0..9 (decimal 48 to 51) can be invoked

using the Sequence Keypad dialog or from

the front panel display.

Copyright Media Technologies 2011

Page 15 of 18

10 SAFETY / SEGURIDAD

This equipment should be installed by a professional audio-visual equipment technician.

Este equipo debe ser instalado por un técnico de equipos profesionales de audio-visuales.

This unit must comply with local wiring regulations and be earthed via the mains inlet connector for safe

operation. An earth stud is provided for electrical safety testing as indicated in the diagram on Page 3 of this

guide.

Esta unidad debe cumplir con las normas de cableado locales y estar conectado a tierra a través del

conector de entrada de corriente para una operación segura. Un montante tierra se proporciona para las

pruebas de seguridad eléctrica como se indica en el diagrama de la página 3 de esta guía.

All servicing must be undertaken only by qualified service personnel. There are no user serviceable parts

inside the unit.

Todos los servicios deben ser realizadas únicamente por personal de servicio calificado. No hay piezas que

el usuario dentro de la unidad.

Do not operate this equipment in wet conditions or allow water to splash on this unit.

No utilice este equipo en condiciones de humedad o permitir a la salpicadura de agua en esta unidad

Do not plug in, turn on or attempt to operate an obviously damaged unit.

NO conectar, encender o intento de explotar una unidad dañada, evidentemente.

Ventilation openings must never be blocked – clean filter regularly.

Las aberturas de ventilación no deben ser bloqueadas - Limpie el filtro con regularidad.

Replace fuses only with the same type and rating as marked on the unit.

Sustituir fusibles SÓLO con el mismo tipo y clasificación como está marcado en la unidad.

Ensure that the supply voltage available at the installation site meets the voltage range marked on the unit.

Asegúrese de que la tensión de alimentación disponible en el sitio de la instalación cumple con el rango de

tensión marcado en la unidad.

This unit contains a lithium battery – do not dispose in fire.

Esta unidad contiene una batería de litio - No tire al fuego.

IMPORTANT

As with any electrical equipment, the unit should be checked for chassis earth continuity before

installation, and periodically.

Do not attempt to check electrical safety using any of the video connectors or control connectors or

fixings or the unit will be damaged and the warranty voided.

IMPORTANTE

Como con cualquier equipo eléctrico, la unidad se debe comprobar el chasis para la continuidad de la tierra

antes de la instalación, y periódicamente.

NO intento de verificar la seguridad eléctrica utilizando cualquiera de los conectores de vídeo o de control o

de fijación o conectores de la unidad dañada y será anulada la garantía.

Copyright Media Technologies 2011

Page 16 of 18

11 Compliance

This product conforms to the following Product Specifications and Regulations:

EMC (Class B): EN 55103-1:2009 Electromagnetic compatibility — Product

family standard for audio, video, audio-visual

and entertainment lighting control apparatus

for professional use - Part 1: Emission.

EN 55103-2:2009 Electromagnetic compatibility — Product

family standard for audio, video, audio-visual

and entertainment lighting control apparatus

for professional use - Part 2: Immunity.

SAFETY: EN 60065:2002+A1:2006

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive 2006/95/EC, the

EMC Directive 2004/108/EC, and carries the CE-marking accordingly.

This Device complies with Part 15 Subpart B of the FCC Rules of the USA. Operation is subject to

the following two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired operation.

The product was tested in a typical configuration.

Product Disposal Instructions

The symbol shown here and on the product means that the product is

classed as Electrical or Electronic equipment and should not be disposed

with other household or commercial waste at the end of its working life.

The waste of Electrical and Electronic Equipment (WEEE) Directive

(2002/96/EC) has been put in place to recycle products using best available

recovery and recycling techniques to minimise the impact on the environment, treat any hazardous

substances and avoid increasing landfill.

Contact your supplier and check the terms and conditions of your purchase contract to ensure this

product is not mixed with other commercial waste for disposal.

Copyright Media Technologies 2011

Page 17 of 18

12 Specification

This specification is preliminary and subject to change. Before specifying this equipment for your

project, please contact us for current feature support.

Design Concept Purpose-designed video hardware for reliability (not based on PC hardware).

Software upgradeable hardware with lifetime updates via our website.

Enclosure 19-inch 2U rack mounting or free standing (detachable brackets).

Size: 455 mm x 275 mm x 88 mm. Weight: 6 kg.

Video Wall Array Formats Single processor supports up to 16 monitors.

Stack multiple processors for larger video walls to 256 monitors and beyond.

Compatible with consumer LCD and Plasma TV panels, Projectors and DVI PC Monitors.

You can compensate for large monitor / bezel gaps.

Future software releases : Feather projector overlaps, etc.

Video Resolution SD, ED, HD and Graphics resolutions supported at pixel rates up to 90 MHz.

SD : 720 x 480/576 (PAL/NTSC/SECAM).

ED/HDTV : 525i, 625i, 525p, 625p, 720p/50-60, 1080i/50-60, 1080p/24-30

RGB Graphics Digital (DVI) : HDTV Modes, Graphics (up to 1280 × 800 @ 60 Hz).

Video Inputs One video source displayed on video-wall

Video inputs switched by software, external command, or real-time sequence.

1x DVI-D input (programmable EDID, HDCP not supported).

1x Analog Component input (Phono/RCA Triple-Jack).

1x Analog Composite-video input (Phono/RCA Single-Jack).

1x Analog S-video input (4-pin Mini-DIN).

Future software release : two independent sources displayed simultaneously.

Video Outputs Up to 16 monitors - use multiple Brick-HD processors to build larger video walls.

16x Analog outputs (via DVI connector): Component, Composite-video, S-video.

16x DVI outputs (HDCP not supported).

Display Effects Square and Anamorphic Magnifications scaling to any video wall array size.

24-bit colour washes different colours on each video wall monitor.

Many other effects in development with free upgrade for existing customers.

Processor Control IP Networking via Ethernet 10/100BaseT interface providing HTTP and FTP.

RS232 Control / Daisy Chain and Brick-HD can control slave RS232 equipment.

Control software included in price with lifetime updates via our website.

Environmental monitoring and logging.

Manual configuration via 2x20 character display with rotary encoder menu selection.

Download configurations to processor for real time clock / external trigger activation.

Power Typical energy consumption < 25W. Internal 75W AC mains power unit.

IEC C14 Connector, Auto-switching 100VAC to 240VAC, 2A 60/50 Hz.

Environment Integral low noise fans with user changeable fan filter.

Storage: -14° to +140°F (-10° to +60°C) / 10% to 80%, non-condensing.

Operating: +41 to +95°F (+5 to +35°C) / 10% to 80%, non-condensing.

Warranty 1-year parts and labour.

Copyright Media Technologies 2011

Page 18 of 18

For further information on our products, please contact us.

USA and Canada:-

Media Technologies LLC

1843 S. Cleveland Terrace

Joplin MO 64804

USA

Telephone : 1-(314)-259-1982

Fax : +1-417-626-7986 (US eFax)

: Press send on announcement.

Email : sales@mediat.us

Web : www.mediat.us

Latin America, Asia, United Kingdom and Europe:-

Media Technologies Ltd.

361 Mill Road

Mile End

Colchester

Essex, CO4 5GG

United Kingdom

Telephone : +44-1206-585026

Fax : +1-417-626-7986 (US)

: Press send on announcement.

Email : sales@mediat.co.uk

Web : www.mediat.co.uk

Media Technologies reserves the right to make changes in its products

without notice in order to improve design and performance.

The information in this document is believed to be accurate in all respects at the time of

printing, but is subject to change without notice. Media Technologies assumes no

responsibility for any errors or omissions, and disclaims responsibility for any

consequences resulting from the use of the information included herein. Additionally,

Media Technologies assumes no responsibility for the functioning of features or

parameters not described.

Table of contents

Popular Media Converter manuals by other brands

GoMax Electronics

GoMax Electronics MX-5004MZ2-UF user manual

Westermo

Westermo ODW-620-F1 user guide

Elation

Elation DMX-BRANCH/4 user manual

Parallax Power Supply

Parallax Power Supply 7100 Series Power Center Owner's operation guide

ANTIFERENCE

ANTIFERENCE CONEXER DMHD02 user manual

Appsys ProAudio

Appsys ProAudio Flexiverter MADI user manual