Medva HLR240 BAC-1.3 User manual

INSTRUCTION MANUAL

AUTOMATIC GATE MECHANISM

HLR240 BAC-1.3

HLR360 BAC-1.3

Ed2. 27/08/18

Declaration of Conformity

Name or Company Name: Medva Mecanismos del Valles, S.L.

Address: C/ Natación 26-28 Pol. Ind. Can Roses - 08191 Rubí

Tax Identication Number (CIF/NIF): B-60528015

HEREBY CERTIFIES:

That hydraulic equipment HLR240 and R360 has been manufactured to be incorporated into a machine or to be

assembled with other machinery to manufacture a machine in accordance with Directive 2006/42/EC:

Meets the essential safety requirements of the following EEC directives.

2006/95/EC Low Voltage Directive.

2004/108/EC Electromagnetic Compatibility Directive.

Likewise, it declares that the machinery may not be operated until the machine in which it must be incorporated or of which it will be a

component has been identied and declared to comply with the terms of Directive 2006/42/EEC and subsequent amendments.

-We put the CE conformity marking on the machine

Plate number:

It is hereby certied in Rubí, on 24 May 2012

The Managing Director

ANTONIO ORANTES ZAMBRANO

SECURITY WARNING

Risk of crushing

Improper handling of machinery in operaon may pose a risk of injury to ngers and hands. During the installaon

process, extend the rod completely either hydraulically or electrically, and connect the front support manually with-

out electrical connecon. During operaon, avoid any type of handling of the rod, especially if the mechanical stop is

installed.

Electrical hazard

Contact may cause electric shock, so make sure the device is disconnected from the power supply prior to performing

any wiring manipulaon.

Ed2. 27-08-18

1 of 11

GENERAL SAFETY INSTRUCTIONS

SAFETY RULES FOR THE INSTALLER

• WARNING! In order to ensure personal safety, it is important to follow all instructions carefully. Improper installa-

tion or improper use may result in serious personal injury.

• This installation manual is an integral part of the product and must be delivered to the user. Keep this installation

manual and all information material.

• This product has been designed and built exclusively for the use indicated in this manual.

• Any application not indicated could be harmful to the equipment and/or represent a source of danger.

• To ensure proper operation of the mechanism and an adequate degree of safety, use only original spare parts,

accessories and xtures.

• Do not install the device in an explosive atmosphere. The presence of ammable gases or fumes implies a seri-

ous safety hazard.

• The mechanism has a torque and anti-crush controller in the BACN version. However, other safety devices (e.g.,

photocells, sensitive strips, etc.) must also be installed to prevent dangers arising from moving mechanical ac-

tions (crushing, dragging, shearing).

• For each installation it is necessary to use at least one light-signalling device, as well as a sign correctly attached

to the gate structure.

• Installation, electrical connection, adjustments and maintenance of the appliance must be carried out exclusively

by professionally qualied technical personnel. Wrong installation or improper use of the product can cause seri-

ous damage to people or property.

• Always install a dierential with a value of 0.03 A. and a thermomagnetic switch with an opening of the contacts

of at least 3 mm provided with overload and short circuit protection.

• Connect the yellow-green ground cable to the terminal marked with the symbol on the control panel, the safety of

this appliance is guaranteed only when the mechanism is connected to a proper ground installation according to

the applicable regulations.

• The mechanism must not be put into denitive operation before all the connections have been made, the e-

ciency of the safety devices controlled and the pushing force congured to the minimum, in compliance with the

regulations in force concerning automatic doors (Directive 89/392 and standards EN 12453 and EN 12445).

• Ensure gate structure is solid, balanced and suitable to be activated, ensure that the gate does not have friction

points during its movement

SAFETY RULES FOR THE USER

• In case of malfunction, do not attempt to repair and contact a specialist technician.

• Do not allow children or pets to approach the gate. Never let children stand or play with gate controls. Keep re-

mote controls away from children and users who are not authorized to operate them; keep controls where unau-

thorized users or children cannot access them.

• In the event of a power failure or emergency, you must know how to release the gate to be able to manipulate it

manually.

• Please keep these safety instructions. Please make sure everyone who uses or is near the gate is aware of the

hazards related to automatic gates. If you sell the property with the gate mechanism or sell the mechanism sepa-

rately, please provide the new owner with a copy of these safety instructions.

2 of 11

TECHNICAL DATA

MODEL: HLR

3 of 11

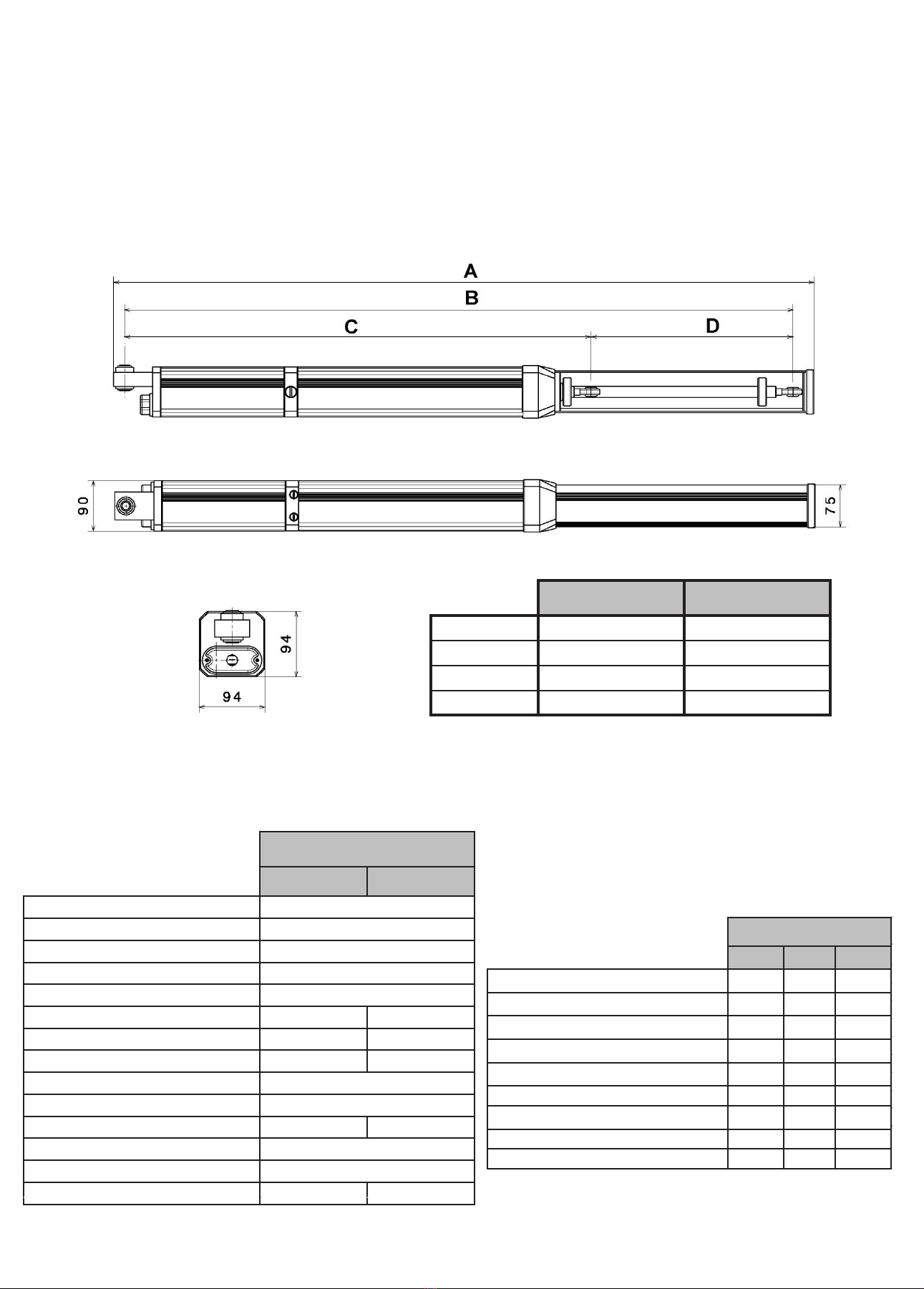

Dimensions HLR240 HLR360

A1050 mm 1290 mm

B952 mm 1192 mm

C710 mm 830 mm

D242 mm 362m/m

TECHNICAL DATA

HLR

240-1.3 360-1.3

Power supply 230 V 50HZ

Motor power rating 276 W

Absorbed consumption 1.3 A

Capacitor 12 uf

Maximum pressure 50 bar

Rod stroke length 242 mm 362 mm

Closing manoeuvre time 20 s 31 s

Opening manoeuvre time 17 s 26 s

Closing force 637 Kg

Opening force 508 Kg

Maximum gate length 4 m 6 m

Temperature range -15 to 80 °C

Thermal protection 100 °C

Group weight 11 Kg 12 Kg

FEATURES HLR

SB BAC BACN

ANTI-CRUSHING ●

HYDRAULIC CLOSURE OUTPUT ● ●

LOCK IN BOTH MANOEUVRES ● ●

LOCK AT CLOSURE ● ●

LOCK AT OPENING ● ●

REVERSIBILITY IN BOTH MANOEUVRES ●●●

WINDPROOF REGULATION ● ●

SOFT STOP AT CLOSURE ●●●

SOFT STOP AT OPENING ●●●

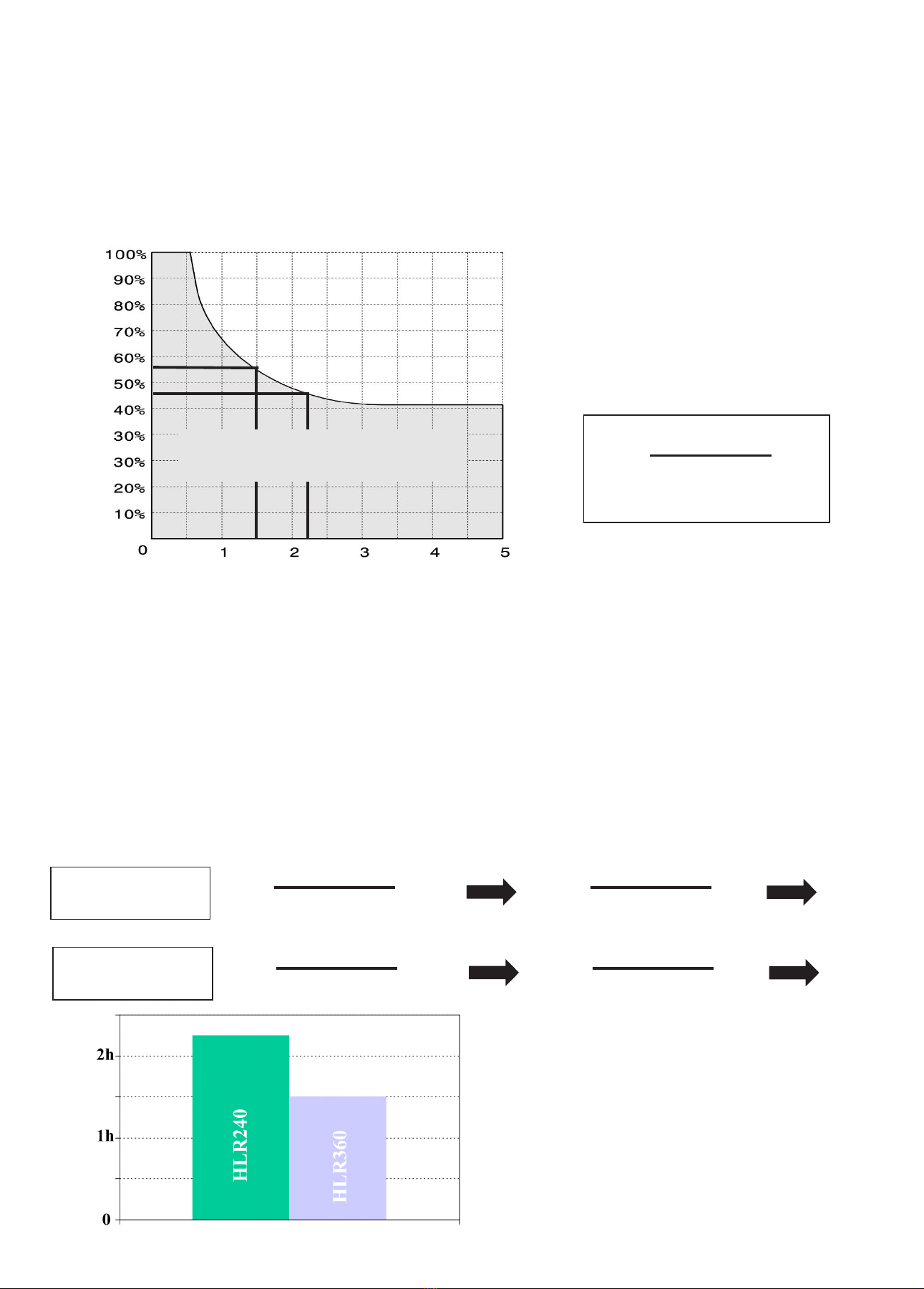

Ta+Tc

%F= x100

Ta+Tc+Tp+Ti

WORK AREA

CALCULATION FOR

HLR240

CALCULATION FOR

HLR360

EXAMPLE MODEL 360

EXAMPLE MODEL 240

(F) Utilisation Factor

USAGE FREQUENCY

The curve allows the calculation of the maximum working time (T) based on the utilisation factor (F).

To ensure proper operation it is necessary to be located inside the work area, shaded in grey.

The tests have been carried out at an ambient temperature of 22 °C; if the motor is at a higher ambient temperature or is

exposed to direct solar radiation, the utilisation factor may be reduced by up to 20%.

Time (Hours)

(T) Time (Hours)

%F: utilisation factor

Ta: opening time

Tc: closing time

Tp: pause time (between opening and closing)

Ti: time between complete manoeuvres

(opening-closing)

Graph.1

Note. To ensure the full closing and opening of the gate, it is necessary to increase the manoeuvring times by 5 sec-

onds.

There are time slots throughout the day, where vehicle trac is very high. Calculations should be made during that

time period.

Example.

What is the maximum working time for a gate that has a pause time of 20 seconds, and a time between full cycles

of 25 seconds?

Ta+Tc

%F= x100

Ta+Tc+Tp+Ti

Ta+Tc

%F= x100

Ta+Tc+Tp+Ti

Graph.2

17+20

%F= x100

17+20+20+25

26+31

%F= x100

26+31+20+25

45.12%

55.88%

CONCLUSION: when we transfer the data obtained to the

graph 1, the maximum usage period for the model 240 is 2h

and 15 min and for model 360 it is 1h and 30 min.

Whenever the dimensions of the gate and the dimensions of

assembly allow, it is advisable to use model 240.

4 of 11

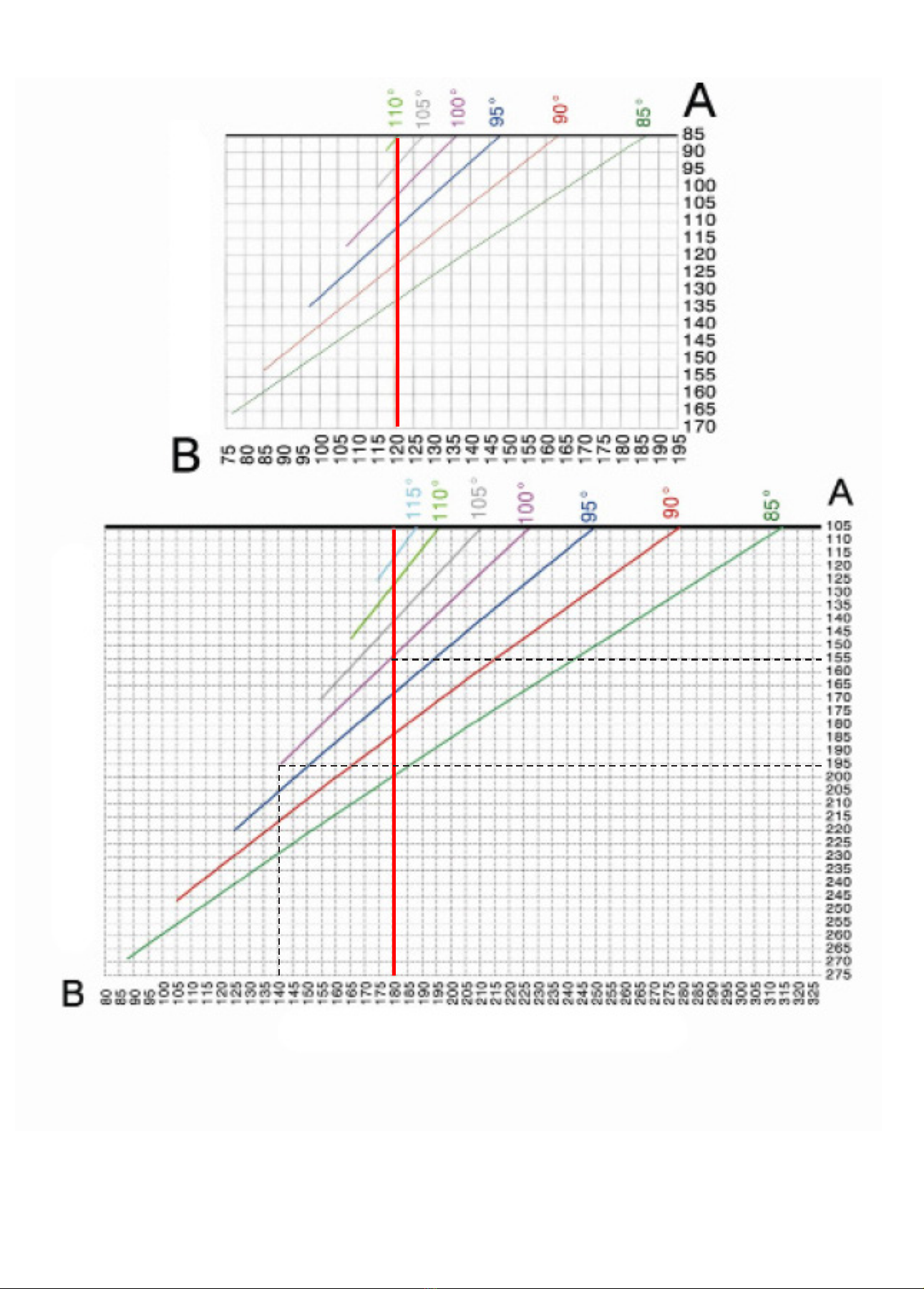

Fig. 2 Fig. 3

Fig..1

ASSEMBLY DIMENSIONS

Important: all dimensions are referenced from the center of the hinge.

*Measurements in millimeters.

5 of 11

MAXIMUM

DIMENSIONS

Max 2 m Max 4 m

Max 6 m

LIGHT

400KG

HLR 240

110°

HLR 240 - 95°

HLR 360 -115°

HLR 360

95°

MEDIUM

600KG

HLR 240

110°

HLR 240 - 95°

HLR 360 -115°

HLR 360

90°

HEAVY

800KG

HLR 240

110°

HLR 360

115°

HLR

OPENING INWARDS (Fig. 2)

M A B C

85° 195 185 90

90° 180 180 90

95° 165 180 90

100° 150 180 90

105° 140 180 90

110° 125 180 90

115° 115 180 90

120º 105 180 90

OPENING OUTWARDS (Fig. 3)

M A B C

85° 200 180 100

90° 180 180 100

95° 165 180 100

100° 150 180 100

105° 125 180 100

HLR

OPENING INWARDS (Fig. 2)

M A B C

85° 130 125 70

90° 120 120 70

95° 110 120 70

100° 100 120 70

105° 93 120 70

110° 85 120 70

115º 85 115 70

OPENING OUTWARDS (Fig. 3)

M A B C

85° 130 120 80

90° 120 120 80

95° 110 120 80

100° 100 120 80

SPECIAL DIMENSIONS OPENING INWARDS (Fig. 2, page 5)

We are occasionally forced to vary the standard dimensions for reasons of space when placing the supports, the above graphs refer to the both

automatic gate mechanism models (240-360) and when the opening is inwards.

The gates' opening degrees are shown at the top of each of the graphs, from these values a cross section line emerges on which dimensions A

and B may be obtained (Fig. 2, page 5). It is important to be as close to the thick vertical line as possible.

Dimension C remain constant in both motors, model 360 C=90 mm and model 240 C=70 mm.

Example: What would be the dimension A and what engine should I use to automate a gate with a 100° opening where B=140 mm? A motor

with a 360 mm stroke length and dimension A=195 mm (see example in graph of assembly dimensions 360 with thick discontinuous line,

special dimension).

Conclusion: We cannot choose model 240 because it goes beyond the positioning limits. The 360 mm stroke length motor allows higher

dimensions than the standard.

6 of 11

ASSEMBLY DIMENSIONS 240 (C=70)

ASSEMBLY DIMENSIONS 360 (C=90)

*Measurements in millimetres.

EXAMPLE (STANDARD)

EXAMPLE (SPECIAL DIMENSION)

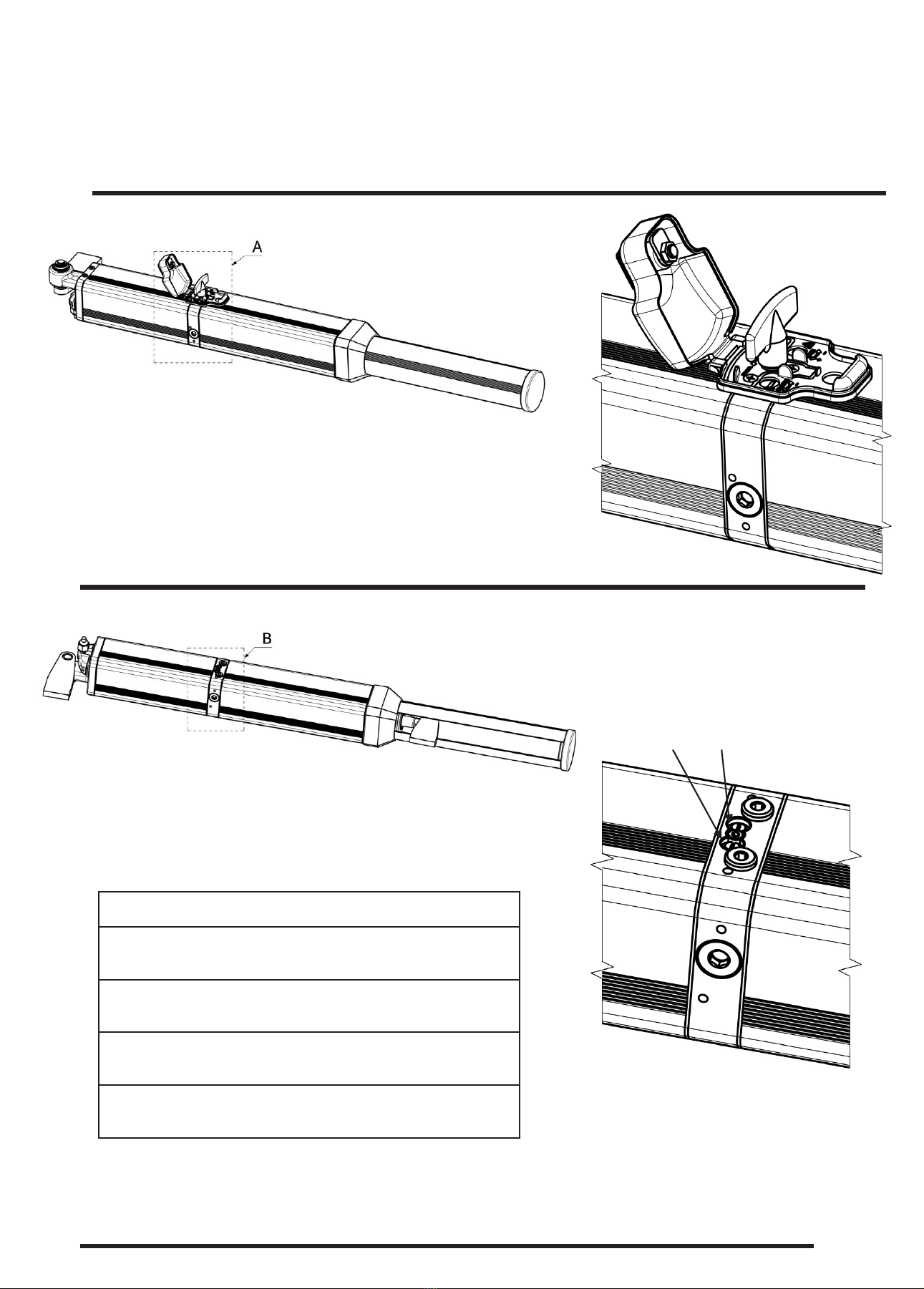

ASSEMBLY INSTRUCTIONS

7 of 11

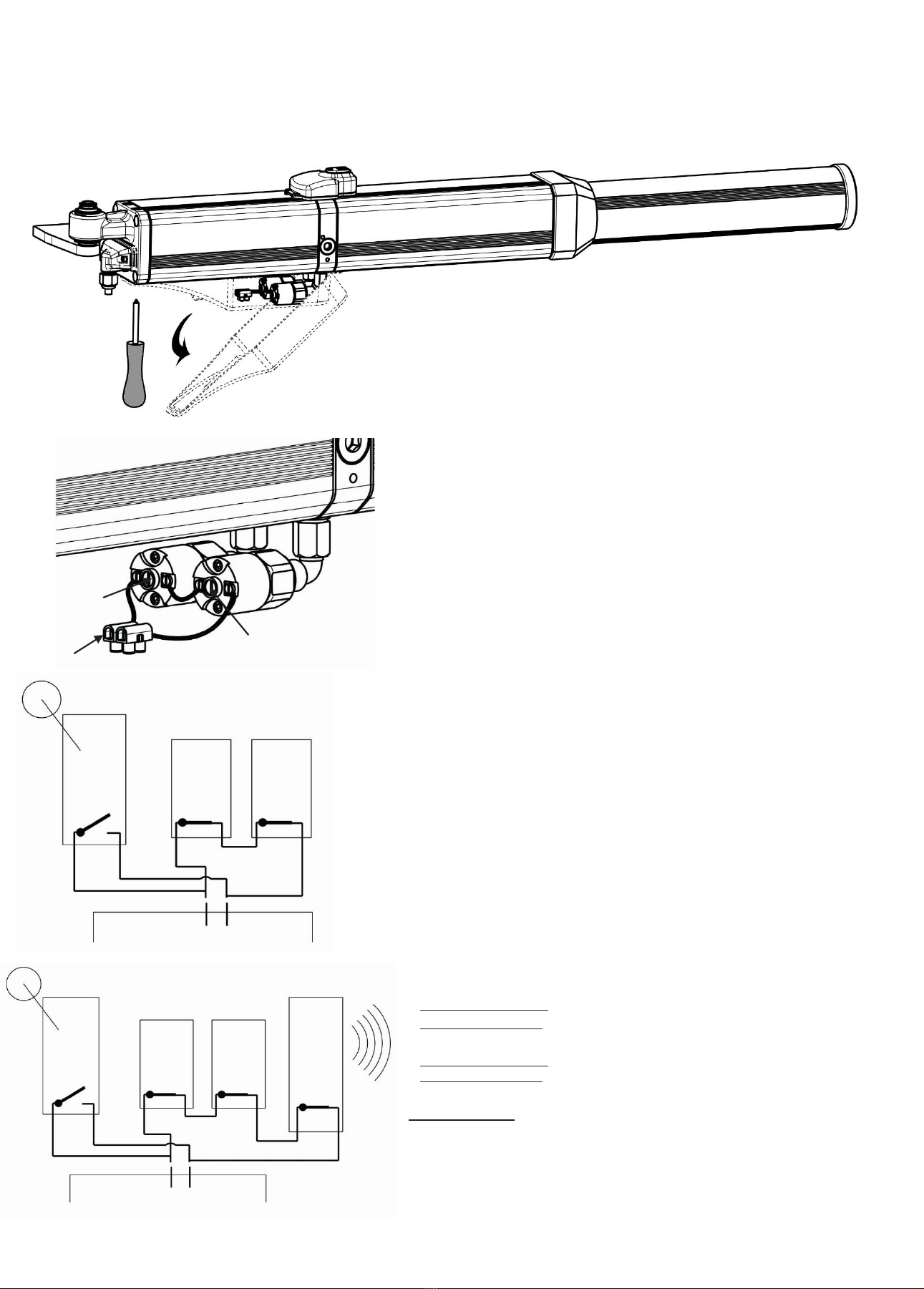

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 14

Fig. 15

1

2

1. Place the pillar support (Fig. 1, page 7) by trimming or supplementing the support according to A and B dimen-

sions of the table on page 5. Determine the height of the support where the gate has a rigid surface to secure the

front support, taking into account that there is a 15 mm gap between supports (Fig. 1, page 5).

2. In this step we will proceed to the electrical installation of the

device.

Connect the terminals according to the following diagram.

Proceed by extending the rod electrically until the end of its

stroke.

common

GROUND

capacitor

3. Trim or supplement the gate support according to dimension C of the table on page 5. Position the motor wit

the front support, with the rod fully extended (Fig. 2, page 7) and the ball joint threaded to the maximum (Fig. 3,

page 7). With the gate closed balance the motor and with the help of a spirit level (Fig. 4, page 7) mark the posi-

tion of the support on the gate and attach it to the mark made.

4. Assemble the motor and unscrew the ball joint about 3 turns to secure the closure, place the safety ring, insert

the gasket and secure the ball joint with the nut to the support (Fig. 6, page 7).

5. Manually operate the gate and open it about 10° less than the desired position, move the ring at the end of the

stroke on the rod (Fig. 9, page 7) to the telescopic bushing (Fig. 10, page 7) and attach it with the allen screw.

Now we can activate the motor electrically. Reposition the ring if the opening is not as desired.

6. Once the motor is working correctly, proceed to adjust the limiters (Fig. 11, page 7). The limiters are in charge

of controlling the force of the device, and are independent in the opening (blue limiter) and closing (red limiter)

manoeuvres. The screws will be handled with rotations of a maximum of 45°.

Proper force adjustment reduces the risk of damage to the installation and users.

7. Then adjust the soft closing and opening stop (Fig. 12, page 7). This valve is common to control the speed of

the device before completing the closing and opening manoeuvre, avoiding annoying bumping from the door.

The manipulation will be carried out with rotations of a maximum of 10°, if we close this valve completely, the

soft stop is lost (15 mm).

8.Finally, the rod cover (Fig. 13, page 7), the gasket (Fig. 14, page 7) and the case cover (Fig. 15, page 7) will be

press-tted.

ACTIVATING THE HYDRAULIC LOCK

When the actuation of the door lock is hydraulic, we have to take into account the type of door opening;

- for inwards opening (Fig. 2 of page 5) we

must connect the hose at the output of the 1/8 G

device in position 2.

- For outwards opening (Fig. 3 of page 5) we

must connect the hose in position 1.

8 of 11

EMERGENCY UNLOCKING

This valve allows us to perform the general unlocking to be able to

operate the door manually in the event of a power outage. To move

the door manually, simply turn 360° counterclockwise.

IMPORTANT: If the valve is not tightened (clockwise) the motor

does not run.

BAC AND WINDPROOF SYSTEM

View of the motor from below.

By manipulating the red and blue valve (located in the lower

part), we can select in which manoeuvre we want the gate to be

manually reversible.

The options are:

RED BLUE

View of the motor from below.

LOCKING OPERATION

The BAC system incorporated in the HLR device oers a wide variety of possibilities. Here is how it should

be manipulated to get the most out of its performance.

IMPORTANT: The partial opening of these valves works as an excellent windproof, and the hardness of

the gate may be adjusted with the motor at rest.

The gate requires a lock for gates that are longer than 1.8 m!

9 of 11

USING THE BAC VALVES

Red open - Blue closed

Lock on opening and reversible on closing.

Red closed - Blue open

Reversible on opening and lock on closing

Red closed - Blue closed

Lock on opening and closing

Red open - Blue open

Reversible on opening and closing

2

1

Pressure

switch N.C

Pressure

switch N.C

Photocell

N.C

Limit switch

N.A

Fig.2

1

Control panel

Safety contact

Fig.1

The anti-crush system oers great security throughout the gate's path, both

when closing and opening.

PRESSURE SWITCH CONNECTION.

To access the connection and regulation of the pressure switch remove the

screws located at the rear holding the pressure switch and pull it down as

indicated by the arrow (Fig. 1).

The pressure switch is a normally closed contact (NC), which opens when

the pressure regulated by the adjustment screw is exceeded (Fig. 2, No. 1).

The system consists of two pressure switches (Fig. 2), which are responsi-

ble for controlling the circuit pressure of both manoeuvres independently

when opening and closing. These are connected in series (Fig .3-Fig. 4). The

connection of the pressure switch signal to the control panel is made through

the two-joint strip (Fig.2, No. 2) to the safety contact inlet of the panel. It is

necessary to incorporate a limit switch in the closure, normally open (NO)

as indicated by the diagram in Fig.3. Its function is to override the pressure

switch when the gate reaches the end of its path, and is exercising force on its

frame. Its proper placement is essential to prevent the gate from reversing the

manoeuvre. This will be how the motor will communicate to the control panel

that it can increase the pressure because it has reached the end of its path and

it is not an obstacle that must be released. In order to be able to do without a

limit switch when opening, it is necessary for the panel to have the option that

when the gate is opening and nds an obstacle, reverses the manoeuvre for

one or two seconds so as to release the obstacle and stop. If the panel does not

have this option, we will need to place another limit switch (N.A) in parallel

when opening. In this system, it is essential for the control panel to have an

inhibition of the pressure switch during the start of the closing manoeuvre.

At start-up, the motor requires an increase in force and this option allows an

increase in pressure avoiding an unwanted reversal.

PHOTOCELL CONNECTION

When the control panel does not have an exclusive inlet for the photocell we

can connect it in series with the pressure switches (Fig. 4).

REGULATION

To increase sensitivity, turn it counter-clockwise, and to decrease sensitivity,

turn it clockwise. Turning will be done in 15-degree turns.

Handling the pressure switch according to the type of opening:

-When the door opens inwards (page 5, Fig. 2):

Opening adjustment, Fig. 1 pressure switch A (under the blue limiter)

Closing adjustment, Fig. 1 pressure switch B (under the red limiter)

-When the door opens outwards (page 5, Fig. 2):

Opening adjustment, Fig. 1 pressure switch B (under the red limiter)

Closing adjustment, Fig. 1 pressure switch A (under the blue limiter)

IMPORTANT! It must be handled in accordance with current standard UNE-

EN 12453.

Limit switch

N.A

Fig.3

Control panel

Safety contact

ANTI-CRUSHING SYSTEM

Fig. 4

Pressure

switch N.C

Pressure

switch N.C

10 of 11

*

*BAC system only

BOX CONTENT

SPARE PARTS ACCESSORIES

11 of 11

No. NAME Ref.

9 Unlock cap key 80284

10 Gusset 70141

11 Attachment bag 95008

12 Connection bag 95107

13 Unlock cap set 95138

14 End of stroke stop 95020

15 OILMEDVA-JV oil (1 litre) 70466

16 Ball joint and nut set A232.11003.K1

17 Emergency release key 80687

18 Unused unlock cap key 80858

19 16 µF capacitor 80497

20 Pillar supp. Kit and Gate supp. 240 A232.11001.K1

Pillar supp. Kit and Gate supp. 360 A232.11002.K1

21 Hydraulic lock A232.21002.00

22 Hydraulic hose (in metres) 80736

23 Hose assembly kit A232.22003.K1

No. NAME Ref.

1

HLR240SB A212.11100.00

HLR240BAC A212.11200.00

HLR240BACN A212.11201.00

HLR360SB A212.12100.00

HLR360BAC A212.12200.00

HLR360BACN A212.12201.00

2Installation manual 50208

3Pillar support 240 95006

Pillar support 360 95037

4 Protective cap 70284

5Rod cover 240 70154

Rod cover 360 70163

6 Rod cover cap 70046

7Gate support 240

Gate support 360

95007

95036

8Cable 4x0.75 L1.5m 95036

This manual suits for next models

1

Table of contents

Other Medva Gate Opener manuals

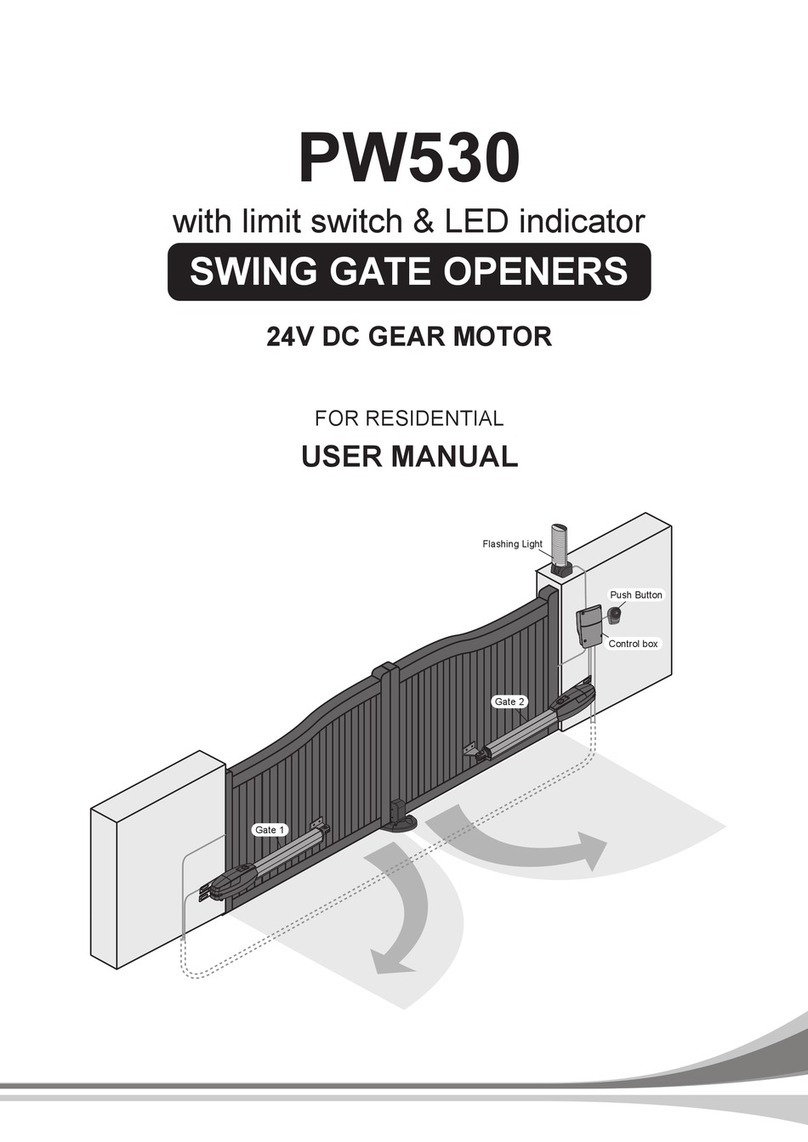

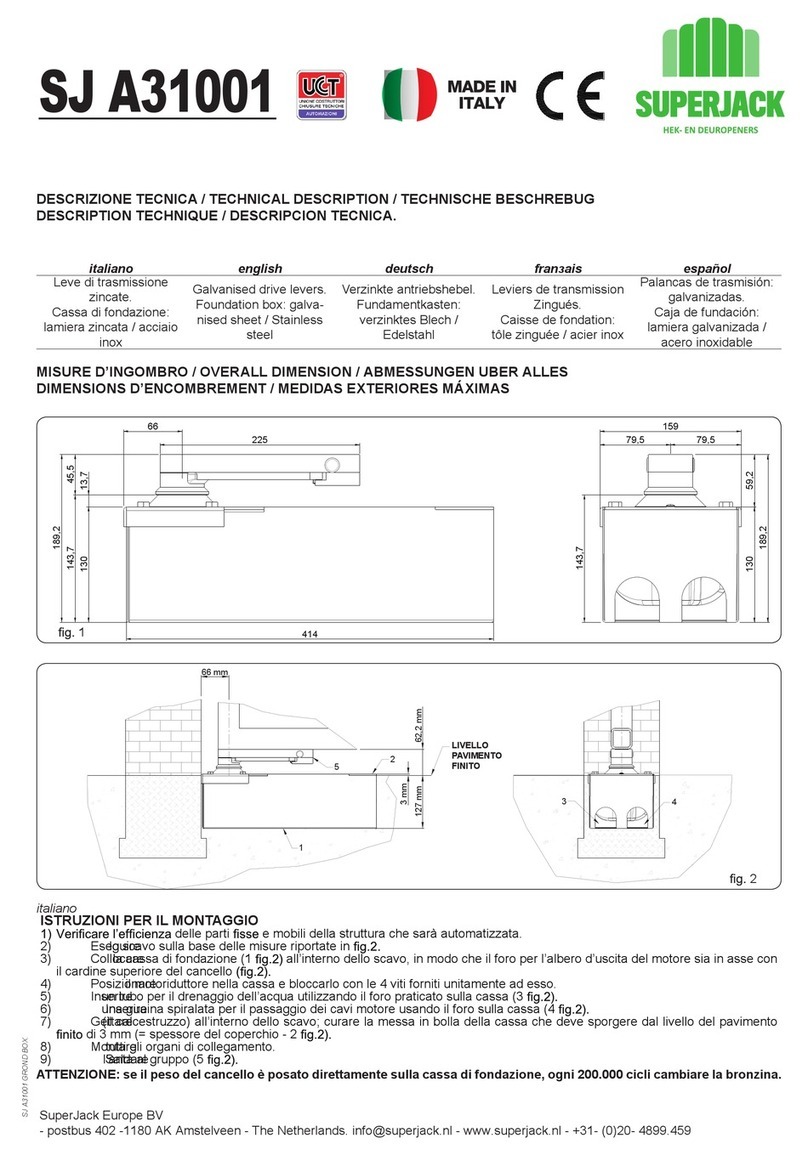

Popular Gate Opener manuals by other brands

Avidsen

Avidsen ZENIA250 quick start guide

GFA

GFA ELEKTROMAT KE 20.24-40,00 installation instructions

Chamberlain

Chamberlain ELITE Series quick start

Chamberlain

Chamberlain LA100 owner's manual

Benninca

Benninca RI.20T operating instructions

DITEC

DITEC entrematic TRAFFIC C Installation manual, maintenance, use

Allmatic

Allmatic MOVEO Series manual

tau

tau R18 series Use and maintenance manual

Merlin

Merlin G900 installation instructions

FAAC

FAAC Estate Slide E-SL 1200 Series instruction manual

Chamberlain

Chamberlain SL 1000-B1 Installation and operation instructions

Mighty Mule

Mighty Mule VEHICLE SENSOR installation manual