MEFE—Mitchell Engineering Food Equipment Pty Ltd

23 Storie Street Clontarf QLD 4019 Australia

Page 3

+617 3283 4536

Free AU 1800 669 006

1. Technical Specicaons

2. Introducon

We strongly advise you to carefully read all instrucons in this manual.

If you wish to make the best use out of the meat tenderiser / Oyster Shucker and exploit all of its possibilies, you must be

thoroughly familiar with its performance and operang features.

Maintenance requires just a few simple operaons that may be carried out by the operator.

To ensure a long life and minimize operang costs, you should carefully follow the rules given in this booklet.

The manufacture has designed the meat tenderiser / oyster shucker to ensure safe operang condions: Exclusion or removal

of these safety features installed by the manufacturer will seriously undermine the guaranteed safety condions.

To ensure these condions you must also fully comply with the instrucons regarding the installaon and power supply of the

meat tenderiser / oyster shucker.

The meat tenderiser / oyster shucker must be installed in a work environment free of corrosive agents.

The installaon site must not be subject to explosion.

The manufacture company is not liable for any breakdown, accidents or faults caused by a failure to observe (or to apply) the

instrucons contained in this booklet. It is likewise not liable for any modicaons, variaons or the installaon of accessories

not previously authorized.

Use only ORIGINAL spare parts.

This instrucon booklet is an integral part of the meat tenderiser / oyster shucker and can be accessed at any me via

www.mefe.com.au, on the products page. The features, informaon and drawings published in this booklet are the exclusive

property of the manufacturer company.

No part of this publicaon may be reproduced or transmied in any form.

Please note: To prevent overheang the best pracce is to run the unit for no more then 15mins uninterrupted, followed by

a 5min cool down before further use. The machine should be used with a duty cycle of 75%.

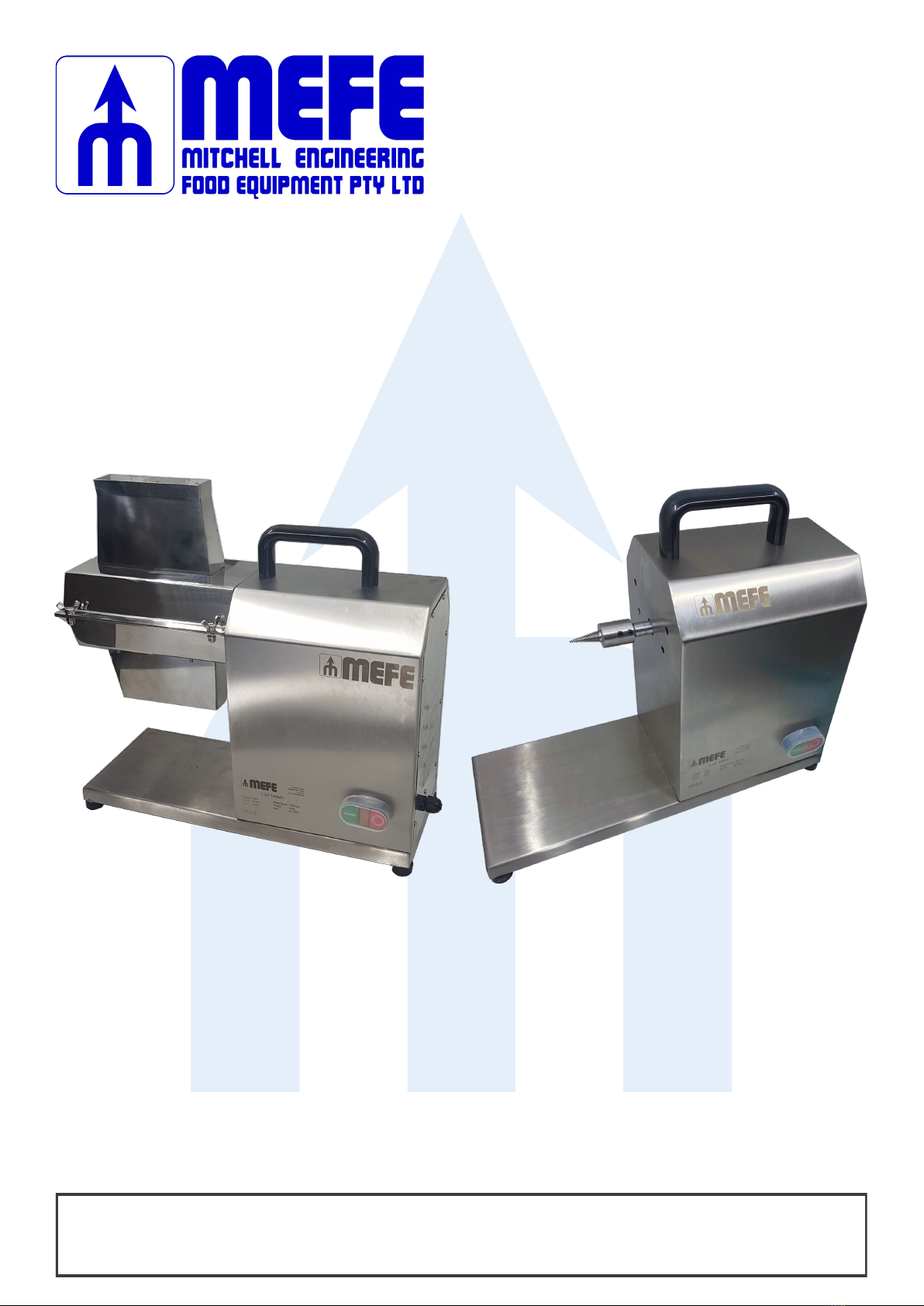

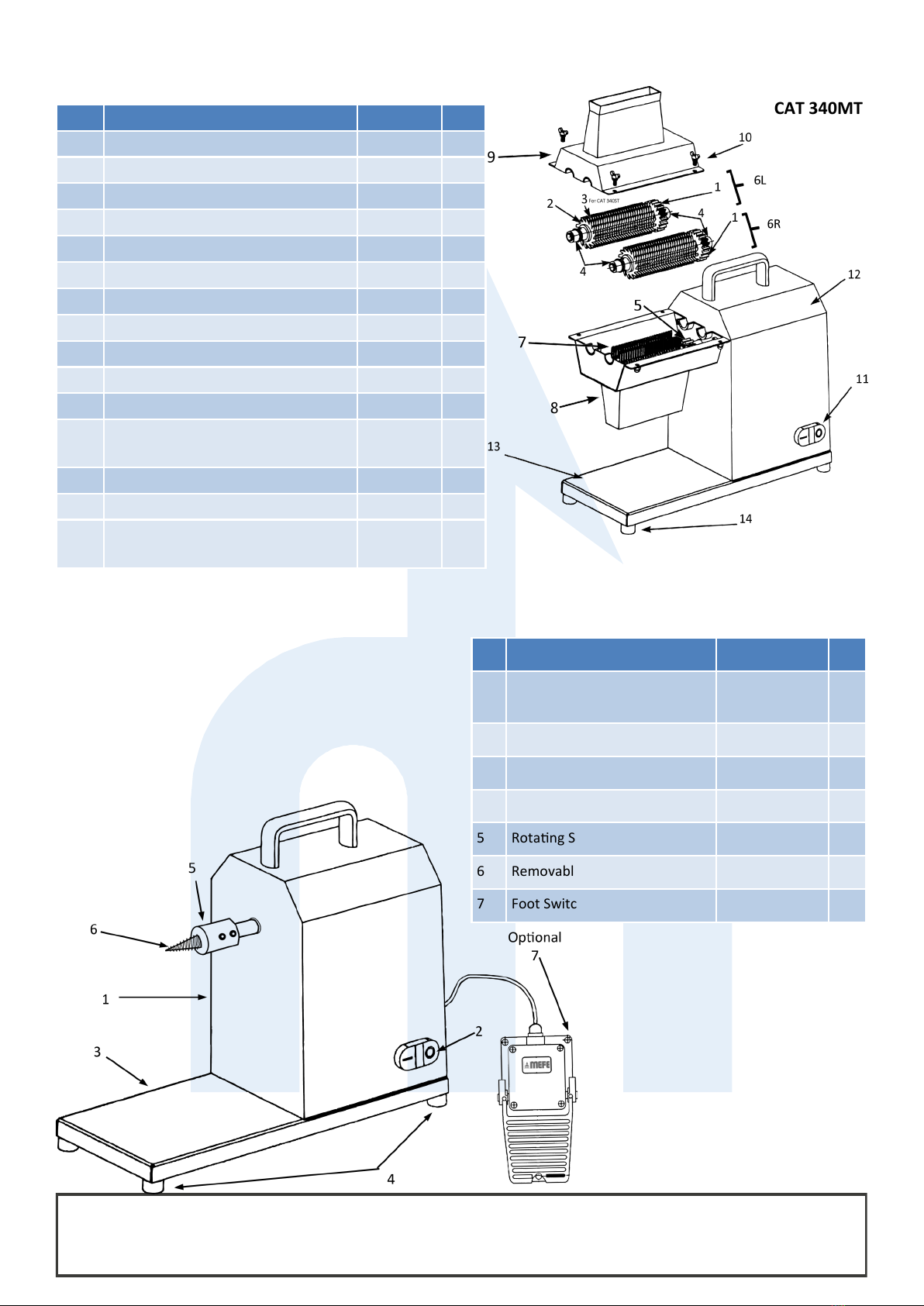

Meat Tenderiser — CAT 340MT

3. Operang Instrucons

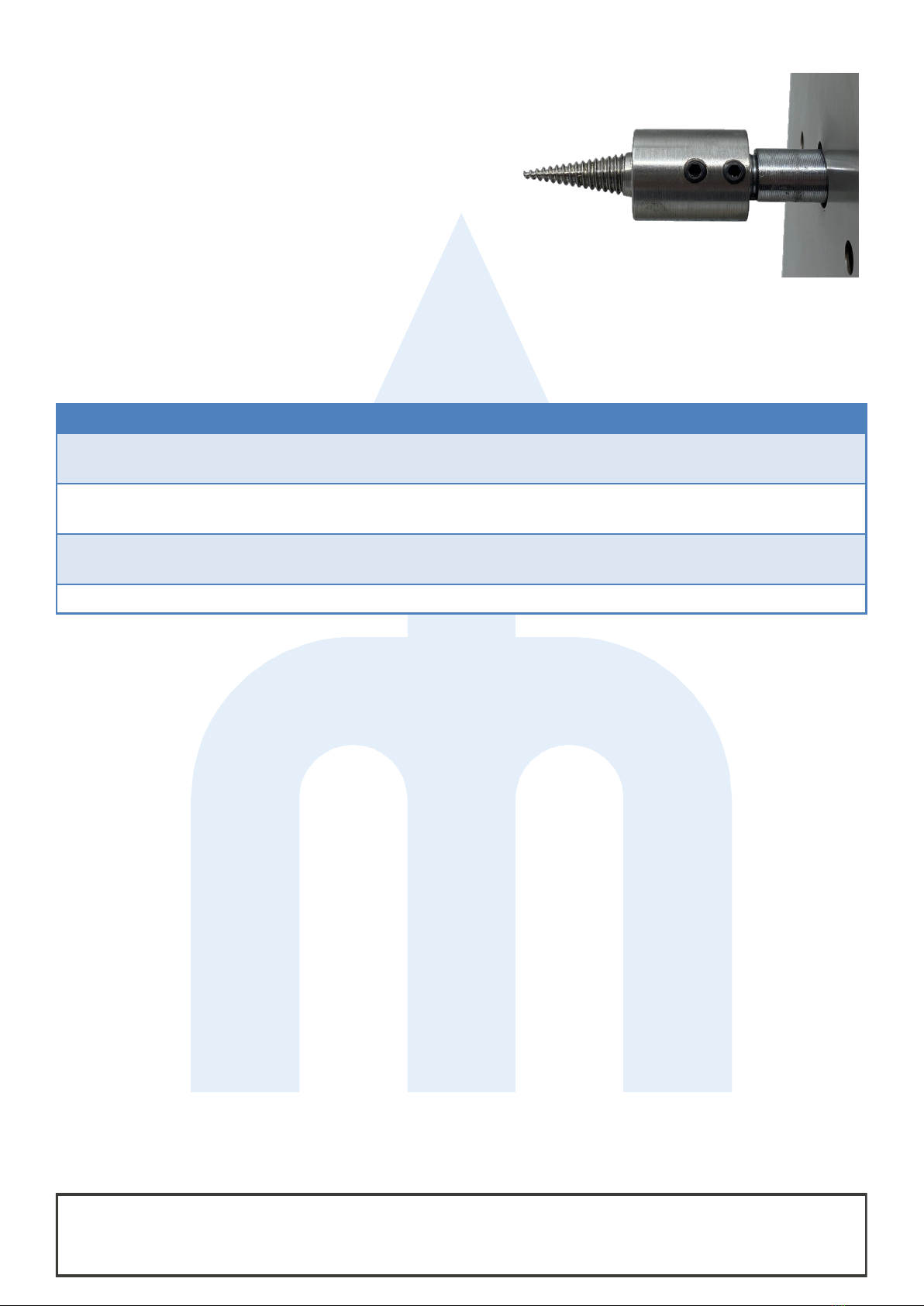

1. Be sure to follow the operang instrucons and safety guidelines for

the motor unit onto which you install the meat tenderiser or stripper

aachment.

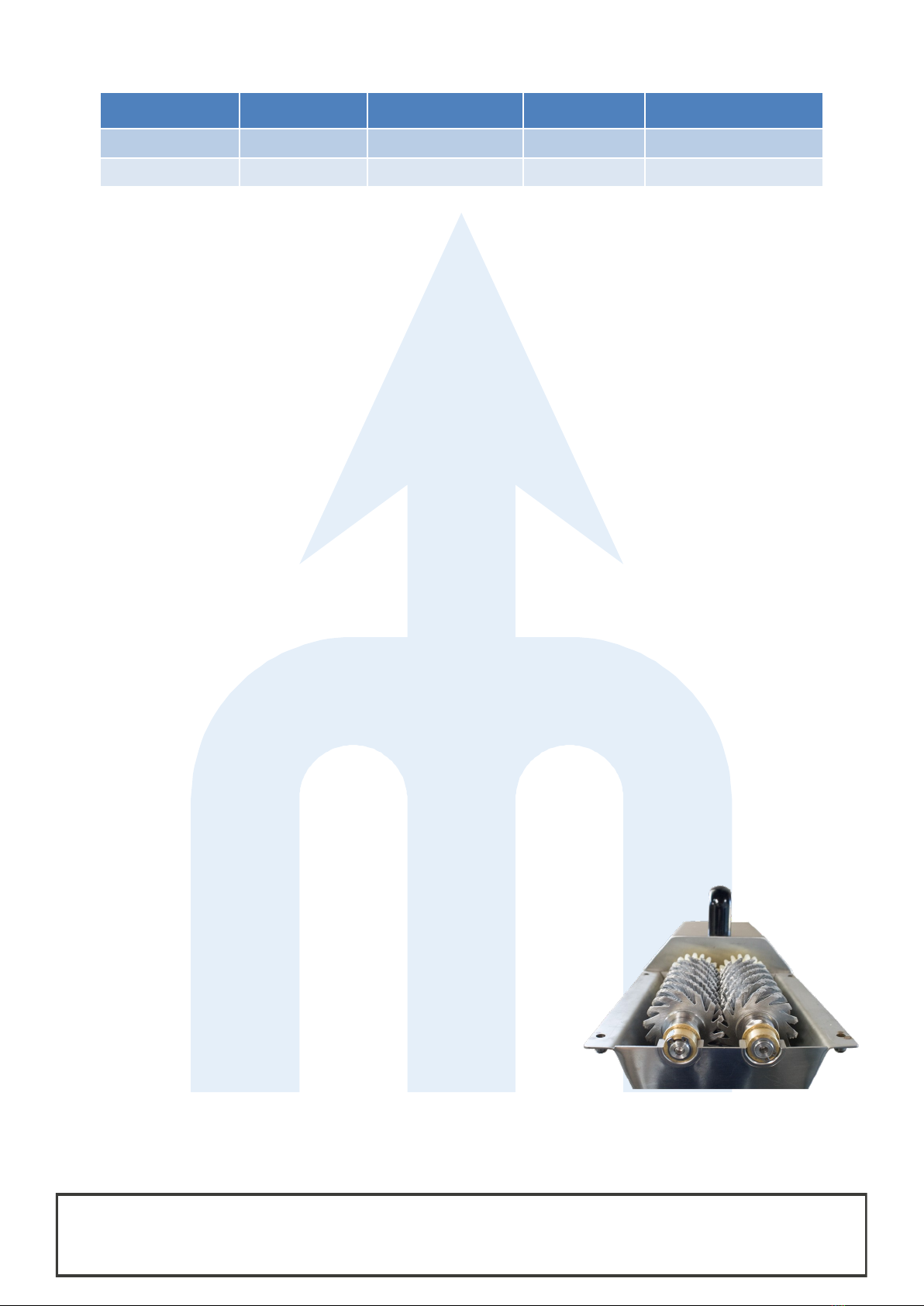

2. Make sure the combs are securely posioned with the teeth of each

comb almost vercal so that when sha is inserted the comb is run-

ning or touching the sha

3. Make sure the two knife assemblies have their teeth poinng away

from each other, as shown in image, before starng the machine.

Model Supply voltage Rotaon speed Motor Packaging size (L x W x H)

CAT 340MT 110/220V 180 r/min 450W 430 x 420 x 170mm

CAT 340OS 110/240V 180 r/min 450W 430 x 420 x 170mm