MEGAGEN Z150 User manual

MODEL Z150 OPERATOR'S

MANUAL

megagen

LIMITED megagen Z SERIES WARRANTY

This limited warranty is issued by megagen for the supply of the following products: megagen Z

Series Generators.

2DESCRIPTION AND WARRANTY PERIOD

Machine: Without prejudice to the legal warranty, megagen. extends the warranty on manufacturing

defects relating to the equipment supplied up to a period of 4 (four) years/ 4000 hour (whichever comes

first) from the date of sale (invoice). Therefore, the total legal and limited warranty period will be 4 (four)

years/ 4000 hour (whichever comes first) from the invoice date. The determination whether the product is

defective will be made by Axiom Equipment Inc. in its sole discretion, considering the general

performance given by the product.

3WARRANTY TERMS AND CONDITIONS

The guarantee is valid provided that:

•The products are stored, installed, used and maintained in compliance with the technical

specifications indicated in the product marking (with specific reference to the voltage and operating

temperature), to the instructions supplied with the product, to what is indicated in the respective

catalogs and to the standards in force;

•Installation and maintenance are carried out by qualified technical personnel, all service records must

be available for warranty purposes;

•The reported defect affects the functionality of the product;

•The product has not been modified, altered or treated with chemicals or in any other way in any way;

•The product covered by the guarantee is made available to megagen for further technical

analysis for the time necessary to carry it out;

•The defect is reported in writing, by certified or registered email with return receipt to megagen

within 30 (thirty) days from the receipt of the products (in the case of apparent defects) or from the

discovery of the defect (in the case of hidden defects) by sending a photographic feedback of the

label on the product;

In the event that the defect is recognized by megagen, megagen will choose at its discretion

whether to repair or replace the defective product with the same product or an equivalent one, taking into

consideration the technical evolution of the products and that of their components. Any technical

intervention or replacement (partial or complete) of the product carried out pursuant to the warranty will

not in any case give the right to extensions or renewals of the same beyond 4 (four) years/ 4000 hour

(whichever comes first) from the invoice date. The repair and replacement of the product recognized as

defective by Axiom Equipment Inc. does not include costs or expenses for its removal or reinstallation.

Axiom Equipment Inc. is not responsible for, and therefore will not reimburse, any consequential loss or

indirect, compensatory or other damage suffered due to a defective products, such as, by way of example

and not limited to, shipping costs, assembly costs, on-site installation, any downtime costs, loss of profit

or overall cost of buyers.

4. EXCLUSIONS AND LIMITATIONS

This limited warranty does not cover:

•Labour costs and expenses, equipment and warehouse costs and expenses, or any other extra costs

relating to and / or resulting from any intervention necessary to repair the defect (such as, by way of

example, costs / expenses for assembly, disassembly, and transport of defective appliances, to be

repaired or new products which will be the sole responsibility of the customer);

•Electrical products subject to wear which are comparable to consumables;

•Products made on specific customer request;

•Damage to products due to negligence, transportation or unforeseen and unforeseeable events that

do not fall within normal conditions of use (such as, for example, electric shock and lightning);

•Appliances not used for the purpose for which they were made;

This warranty does not guarantee the integrity of the painting when the product is used in a saline

environment or in the presence of corrosive agents.

In no event megagen will be liable for accidental, compensatory, consequential, indirect, special or

other damages. The liability of megagen for a defect in the product will in any case be limited to the

amount actually paid for that defective product.

The performance and duration of the LEDs are not guaranteed if the fixtures are installed in environments

with the presence of chemical substances that are not compatible with the LEDs themselves. Our

technical office is available to check the compatibility of the LEDs we use in relations to the substances

present in the environment where the luminaires are installed.

5. APPLICABLE LAW AND JURISDICTION

This limited warranty, as well as its execution, interpretation and all questions concerning the validity and

effectiveness of the same, will be governed by Canadian Law.

It is the responsibility of the owner to register the engine and alternator with each OEM for warranty

purposes.

SPARE PARTS

Spare parts manual is available for this unit.

WARRANTY VOID IF NOT REGISTERED

megagen

ELECTRIC POWER GENERATOR

DEALER INSPECTION REPORT SAFETY

______ Guards/ShieldsInstalled&Secured

______ AllDecalsInstalled&Legible

______ SafetyChainonHitch(Ifontrailer)

______ ReviewOperatingandSafetyInstructions

______ TirePressureChecked(Ifontrailer)

______ WheelBoltsTorqued(Ifontrailer)

______ InspectElectricalSystem

______ CheckOilLevelinHydraulicReservoir

______ LubricateMachine

______ CheckEngineFluidLevels

WARRANTY REGISTRATION FORM & INSPECTION REPORT

IhavethoroughlyinstructedthebuyerontheabovedescribedequipmentwhichreviewincludedtheOperator’s

Manualcontent,equipmentcare,adjustments,safeoperationandapplicablewarrantypolicy.

Date _______________________________ Dealer’sRep.Signature ____________________________

Signature ____________________________

TheaboveequipmentandOperator’sManualhavebeenreceivedbymeandIhavebeenthoroughlyinstructed

astocare,adjustments,safeoperationandapplicablewarrantypolicy.

Date ________________________________ Owner'sSignature ________________________________

WARRANTY REGISTRATION

Thisformmustbefilledoutbythedealerandsignedbyboththedealerandthecustomeratthetimeof

delivery.

Customer’sName __________________________Dealer'sName ___________________________

Address __________________________________ Address ________________________________

City,State/Prov.,Code _______________________City,State/Prov.,Code _____________________

PhoneNumber(_____) ___________________

GeneratorModel ___________________________

SerialNumberAlternator _____________________

UnitSerialNumber _________________________

SerialNumberEngine _______________________

Delivery Date ______________________________

WHITE YELLOW PINK

MEGAGEN DEALER CUSTOMER

SERIAL NUMBER LOCATIONS

Always give your dealer the serial number of your megagenZ150generatorwhenorderingparts

orrequestingserviceorotherinformation.

The serial number plates are located where indicated. Please mark the number in the space provided for

easy reference.

Model Z100

Serial Number Machine ___________________________

Engine ___________________________

Alternator ___________________________

z150

ENGINE ALTERNATOR

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1 Introduction .......................................................... 1

2 Safety .................................................................... 3

2.1 GeneralSafety ....................................................... 4

2.2 EquipmentSafetyGuidelines ................................ 5

2.3 SafetyTraining ....................................................... 6

2.4 SafetySigns ........................................................... 6

2.5 StorageSafety ....................................................... 6

2.6 PreparationSafety ................................................. 7

2.7 InstallationSafety .................................................. 7

2.8 MaintenanceSafety ............................................... 8

2.9 Lock-OutTag-OutSafety........................................ 8

2.10 BatterySafety ........................................................ 8

2.11 OperatingSafety .................................................... 9

2.12 TireSafety .............................................................. 9

2.13 TransportSafety ..................................................... 9

2.14 ElectricalSafety ..................................................... 9

2.15 DieselEngineSafety ............................................10

2.16 RefuelingSafety....................................................10

2.17 RefillingDEFSafety ..............................................11

2.18 Sign-OffForm ...................................................... 12

3 Safety Sign Locations ....................................... 13

4 Operation ............................................................ 15

4.1 TotheNewOperatororOwner ............................ 15

4.2 MachineComponents .......................................... 16

4.3 MachineBreak-In ................................................. 18

4.4 Pre-OperationChecklist ....................................... 18

4.5 Controls ............................................................... 19

4.6 MachinePreparation ............................................ 22

4.7 Operation ............................................................. 26

4.9 Storage ................................................................ 31

4.12 Transport .............................................................. 32

5 Service and Maintenance .................................. 35

5.1 Service ................................................................. 35

5.2 Maintenance ........................................................ 41

6 Trouble Shooting ............................................... 45

7 Specifications .................................................... 47

7.1 Mechanical ........................................................... 47

7.2 BoltTorque ........................................................... 49

7.3 ElectricalSchematic ............................................ 50

8 Index ................................................................... 51

1

1 INTRODUCTION

Congratulations on your choice of a megagen Z150 generator and welcome to megagen's quality line

of generating equipment. This equipment is designed and manufactured to meet the needs of a customer who

needs a portable, cost-effective source of electrical power.

Safe, efficient and trouble free operation of your new megagen Z150 generator requires that you, and

any-one else who will be operating or maintaining the machine, read, understand and practice ALL of the

Safety, Operation, Maintenance and Trouble Shooting recommendations contained within this Operator's

Manual.

This manual applies to all Z150 generators manufactured by megagen. Certain options

may be available to specifically tailor the generator to your operation and may not be included in this

manual. Please contact the manufacturer regarding additional information about these options. Use the

Table of Contents and Index as a guide to find specific information.

The information in this manual is accurate based on products produced at the time of publication. The manufac-

turer reserves the right to make technical updates, corrections and product revisions at any time without notice.

The warnings in this manual and on decals on the unit are not all inclusive. If using a procedure or operating

techniques that the manufacturer does not specifically recommend, verify that it is safe for others. Also, make

sure the procedure does not render the equipment unsafe.

Keep this manual handy for frequent reference and so that it will be passed on to new operators or owners. Call

your megagen dealer if you need assistance, information or additional copies of this manual.

2

3

The Safety Alert symbol identifies

important safety messages on your

megagen generator and in the

manual. When you see this symbol,

be alert to the possibility of personal

injury or death. Follow the instruc-

tions in the safety message.

2 SAFETY

SAFETY ALERT SYMBOL

If you have any questions not answered in this manual or require additional copies or the manual is damaged,

please contact your dealer or megagen, Phone: 1-866-918-6976, Email: service@axiomequipmentgroup.

com.

Accidents Disable and Kill

Accidents Cost You Money

Accidents Can Be Avoided

Why is SAFETY important to you?

This Safety Alert symbol means

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

3 Big Reasons

DANGER - Indicates an imminently hazardous situ-

ation that, if not avoided, will result in

death or serious injury. This signal word

is to be limited to the most extreme situa-

tions, typically for machine components

that, for functional purposes, cannot be

guarded.

WARNING - Indicates a potentially hazardous situ-

ation that, if not avoided, could result

in death or serious injury, and includes

hazards that are exposed when guards

are removed. It may also be used to alert

against unsafe practices.

CAUTION - Indicates a potentially hazardous situ-

ation that, if not avoided, may result in

minor or moderate injury. It may also be

used to alert against unsafe practices.

SIGNAL WORDS:

Note the use of the signal words DANGER,

WARNING and CAUTION with the safety

messages. The appropriate signal word for each

message has been selected using the following

guide-lines:

4

2.1 GENERAL SAFETY

• Readandunderstandthe

Operator's Manual and all safe-

ty signs before supplying pow-

er to, operating, maintaining or

adjusting the generator.

• Onlytrained,competentpersonsshalloperatethe

generator. An untrained operator is not qualified to

operate this machine.

• Provideafirst-aidkitforuseincase

of an accident. Store in a highly vis-

ible place.

• Provideafireextinguisherforusein

case of an accident. Store in a highly

visible place.

• Installandproperlysecureallguards

and shields before

operating.

• Wearappropriate

protective gear. This

list includes but

is not limited to:

- Protective shoes

with slip resis-

tant soles

- Protective glasses

or goggles

- Heavy gloves

- Hearing protection

• TurnmachineOFF,placeallcontrolsintheirOFF

position, shut down and lockout power supply,

and wait for all moving parts to stop before servic-

ing, adjusting, maintaining, repairing or cleaning.

• Donotdamagethismanual,donotremoveortear

any pages and keep it away from moisture and

heat sources. Please note that the drawings con-

tained in the manual are merely to help you iden-

tify the parts described and, therefore, they might

not correspond precisely to your product.

• Knowtheemergencymedicalcenternumberfor

your area.

• Reviewsafetyrelateditemswithalloperators

annually.

SAFETY

YOU are responsible for the SAFE operation and

maintenance of your megagen generator. YOU

must ensure that you and anyone else who is going

to operate, maintain or work around the machine be

familiar with the operating and maintenance proce-

dures and related SAFETY information contained in

this manual. This manual will take you step-by-step

through your working day and alerts you to all good

safety practices while operating the generator.

Remember,YOU are the key to safety. Good safety

practices not only protect you but, also the people

around you. Make these practices a working part of

your safety program. Be certain that EVERYONE op-

erating this machine is familiar with the procedures

recommendedandfollowssafetyprecautions.Re-

member,mostaccidentscanbeprevented.Donot

risk injury or death by ignoring good safety practices.

• ReadandunderstandtheOperator'sManual

and all safety signs before supplying power to,

operating, maintaining or adjusting the generator.

• Generatorownersmustgiveoperatinginstruc-

tions to operators or employees before allowing

them to operate the machine, and at least annu-

ally thereafter.

• Themostimportantsafetydeviceonthisequip-

ment is a SAFE operator. It is the operator’s re-

sponsibility to read and understand ALL Safety

and Operating instructions in the manual and to

follow these. Most accidents can be avoided.

• Apersonwhohasnotreadandunderstoodallop-

erating and safety instructions is not qualified to

operate this machine. An untrained operator ex-

poses himself and bystanders to possible serious

injury or death.

• Donotmodifytheequipmentinanyway.

Unauthorized modification may impair the func-

tion and/or safety and could affect the life of the

equipment.

• Themanualcomeswiththeoriginaldocumen-

tation for the engine and the alternator: we rec-

ommend keeping it all in a safe place and have

qualified personnel to carry out operations. In

case of transfer of equipment ownership, attach

all the documentation, as it is an integral part of

the product.

• Ourcustomerserviceandtechnicalassistance

department is available to assist you in any way.

• Onlyusegenuinepartsincasereplacementis

required; failure to comply will void your warranty

automatically.

5

2.2 EQUIPMENT SAFETY GUIDELINES

• Safetyoftheoperatorandbystandersisoneof

the main concerns in designing and developing a

machine. However, every year many accidents oc-

cur which could have been avoided by a few sec-

onds of thought and a more careful approach to

handling equipment. You, the operator, can avoid

many accidents by observing the following pre-

cautions in this section. To avoid personal injury or

death, study the following precautions and insist

those working with you, or for you, follow them.

• Inordertoprovideabetterview,certainphoto-

graphs or illustrations in this manual may show an

assembly with a safety shield removed. However,

equipment should never be operated in this con-

dition. Keep all shields in place. If shield removal

becomes necessary for repairs, replace the shield

prior to use.

• Replaceanysafetysignorinstructionsignthatis

not readable or is missing. Location of such safety

signs is indicated in this manual.

• Neverusealcoholicbeveragesordrugswhich

can hinder alertness or coordination while oper-

ating this equipment. Consult your doctor about

operating this machine while taking prescription

medications.

•Under no circumstances should young chil-

dren be allowed to work with this equipment.

Do not allow persons to operate or assemble

this unit until they have read this manual and

have developed a thorough understanding of

the safety precautions and of how it works.

Reviewthesafetyinstructionswithallusers

annually.

• Thisequipmentisdangeroustochildrenand

persons unfamiliar with its operation. The opera-

tor should be a responsible, properly trained and

physically able person familiar with the machinery

and trained in this equipment's operations. If the

elderly are assisting with work, their physical limi-

tations need to be recognized and accommodated.

• Neverexceedthelimitsofapieceofmachinery.If

its ability to do a job, or to do so safely, is in ques-

tion - DON'T TRY IT.

•Donotmodifytheequipmentinanyway.

Unauthorized modification result in serious injury

or death and may impair the function and life of the

equipment.

• Thecontentsofthismanualarenotbinding.The

manufacturer reserves the right to make chang-

es and improvements to accessories and details

without altering the essential characteristics of the

model described and illustrated here and without

committing to promptly updating this manual.

• Inadditiontothedesignandconfigurationofthis

implement, including Safety Signs and Safety

Equipment, hazard control and accident preven-

tion are dependent upon the awareness, concern,

prudence, and proper training of personnel in-

volved in the operation, transport, maintenance,

andstorageofthemachine.ReferalsotoSafety

Messages and operation instruction in each of the

appropriate sections of the auxiliary equipment

and machine Manuals. Pay close attention to the

Safety Signs affixed to the auxiliary equipment

and the machine.

• Thismachineisdesignedtogeneratehighvoltage

electrical power that can injure or kill if not oper-

atedproperly.Readoperator'smanualandfollow

all instructions.

6

2.3 SAFETY TRAINING

• Safety is a primary concern in the design and man-

ufacture of our products. Unfortunately, our efforts

to provide safe equipment can be wiped out by a

single careless act of an operator or bystander.

• Inadditiontothedesignandconfigurationof

equipment, hazard control and accident preven-

tion are dependent upon the awareness, con-

cern, prudence and proper training of personnel

involved in the operation, transport, maintenance

and storage of this equipment.

• Ithasbeensaid,"Thebest

safety feature is an informed,

carefuloperator."Weaskyou

to be that kind of an operator.

It is the operator's responsibility

to read and understand ALL Safety and Operating

instructions in the manual and to follow these.

Accidents can be avoided.

•Working with unfamiliar equipment can lead

to careless injuries. Read this manual, and the

manual for your auxiliary equipment, before

assembly or operating, to acquaint yourself

with the machines. If this machine is used by

any person other than yourself. It is the ma-

chine owner's responsibility to make certain

that the operator, prior to operating:

i. Reads and understands the operator's

manuals.

ii. Is instructed in safe and proper use.

• Know your controls and how to stop generators

and any other auxiliary equipment quickly in an

emergency.Readthismanualandtheoneprovid-

ed with your other equipment.

• Trainallnewpersonnelandreviewinstructions

frequently with existing workers. Be certain only

a properly trained and physically able person will

operate the machinery. A person who has not read

and understood all operating and safety instruc-

tions is not qualified to operate the machine. An

untrained operator exposes himself and bystand-

ers to possible serious injury or death. If the elder-

ly are assisting with work, their physical limitations

need to be recognized and accommodated.

2.4 SAFETY SIGNS

• Keep safety signs clean and legible at all times.

• Replacesafetysignsthataremissingorhavebe-

come illegible.

• Replacedpartsthatdisplayedasafetysignshould

also display the current sign.

• Safety signs displayed in Section 3 each have a

part number in the lower right-hand corner. Use

this part number when ordering replacement

parts.

• Safety signs are available from your authorized

DistributororDealerPartsDepartmentorthe

factory.

How to Install Safety Signs:

• Besurethattheinstallationareaiscleananddry.

• Besuretemperatureisabove50°F(10°C).

• Determineexactpositionbeforeyouremovethe

backingpaper.(SeeSection3).

• Removethesmallestportionofthesplitbacking

paper.

• Alignthesignoverthespecifiedareaandcareful-

ly press the small portion with the exposed sticky

backing in place.

• Slowlypeelbacktheremainingpaperandcare-

fully smooth the remaining portion of the sign in

place.

• Smallairpocketscanbepiercedwithapinand

smoothed out using the piece of sign backing

paper.

2.5 STORAGE SAFETY

• Storethegeneratoronafirmlevelsurface.

• Ifrequired,makesuretheunitisfirmlyblockedup.

• Makecertainthatallmechanicallocksandjacks

are safely and positively connected before storing.

• Storeawayfromareasofhumanactivity.

• Donotallowchildrentoplayonoraroundthe

stored generator.

• Lockoutpowerbyturningoffmastercontrolpanel

or junction box and padlocking the door shut to

prevent electrocution or unauthorized start up of

the generator.

• Ifmountedonatrailer,placechocksinfrontof

and behind the tires before unhooking from tow

vehicles.

7

2.7 INSTALLATION SAFETY

• Reviewlayoutoftheworksite.Positiongenerator

where it can provide maximum power with mini-

mal interference with the access and operation of

other equipment. Select a different position if there

is interference.

• Positiongeneratorbaseortraileronasolid,level

surface to avoid tipping, sliding or falls during op-

eration. Avoid placing the unit on a surface with a

slopeofover10°.

• Positionmachinesotheengineexhaustisdirect-

edawayfrompersonnelontheworksite.Directthe

gases away from the worksite.

• Usegroundterminalinsideframetogroundunitin

compliance with local laws and regulations.

• Donotoperatemachinewithwethandsorclothing.

• Allelectricalwires,plugs,socketsandothercom-

ponents must always be in good condition when

operating.

• Closeandlatchthedoorsduringnormalopera-

tion. Open and latch the doors when the engine is

stopped and machine is being serviced.

• Keepenginecoolingslotsondoorsandframe

clean to allow engine to cool when running. Clean

when trash plugs slots.

• Donotplaceanyitemsnexttoexhaustormuf-

fler to prevent burns or items from catching on fire

from high temperatures.

• Stopengineanddisconnectpowerifamalfunc-

tion occurs. Identify and resolve the malfunction

before turning machine on and resuming work.

2.6 PREPARATION SAFETY

• Neveroperatethegeneratorandauxiliaryequip-

ment until you have read and completely un-

derstand this manual, the auxiliary equipment

Operator's Manual, and each of the Safety

Messages found on the safety signs on the gen-

erator and auxiliary equipment.

• Personalprotec-

tion equipment in-

cluding hard hat,

safety glasses,

safety shoes, and

gloves are recom-

mended during

assembly, instal-

lation, operation,

adjustment, main-

taining, repair-

ing,removal,ormovingthegenerator.Donotal-

low long hair, loose fitting clothing or jewelry to be

around equipment.

•PROLONGED EXPOSURE

TO LOUD NOISE MAY CAUSE

PERMANENT HEARING LOSS!

Motors or equipment attached

can often be noisy enough to

cause permanent, partial hear-

ing loss. We recommend that you wear hearing

protection on a full-time basis if the noise in the

Operator's position exceeds 80db. Noise over

85dbonalong-termbasiscancauseseverehear-

ing loss. Noise over 90db adjacent to the Operator

over a long-term basis may cause permanent,

total hearing loss. NOTE: Hearing loss from loud

noise(fromtractors,chainsaws,radios,andother

suchsourcesclosetotheear)iscumulativeover

a lifetime without hope of natural recovery.

• Clearworkingareaofdebris,trashorhiddenob-

stacles that might be hooked or snagged, causing

injury, damage or tripping.

• Operateonlyindaylightorgoodartificiallight.

• Besuremachineisproperlyanchored,adjusted

and in good operating condition.

• Ensurethatallsafetyshieldingandsafetysigns

are properly installed and in good condition.

• Beforestarting,givethemachinea"onceover"for

any loose bolts, worn parts, cracks, leaks, frayed

belts and make necessary repairs. Always follow

maintenance instructions.

8

2.8 MAINTENANCE SAFETY

• Readandunderstandalltheinformationcontained

in the Operator's Manual regarding operating, ser-

vicing, adjusting, maintaining and repairing.

•Turn machine OFF, shut down and lock out

power supply and wait for all moving parts to

stop before servicing, adjusting, maintaining

or repairing.

• Followgoodshoppractices:

- Keep service area clean

and dry.

- Be sure electrical out-

lets and tools are properly

grounded.

- Use adequate light for the

job at hand.

• Makesureallguardsanddoorsareinplaceand

properly secured when operating the generator.

• Donotworkongeneratorelectri-

cal system unless the power cord

is unplugged or the power supply is

locked out. Lock-out tag-out power

source before performing any main-

tenance work.

• Afireextinguisherand

first aid kit should be kept

readily accessible while

performing maintenance

on this equipment.

• Disconnectloadfrompowersupplyandwaitfor

tall moving parts to stop before performing any

service or maintenance or work on them.

• Donottouchengine,manifold,pipesandmuffler

while engine is running. Allow engine to cool be-

fore performing any service work on it.

• Alwaysreplaceguardsandshieldsandclose

doors when service and repair work has been

completed.

• Donotremoveradiatorcapwhenengineisrun-

ning or still hot to prevent leaks and scalding

burns.

2.9 LOCK-OUT TAG-OUT SAFETY

• EstablishaformalLock-OutTag-Outprogramfor

your operation.

• Trainalloperatorsandservicepersonnelbefore

allowing them to work around the generator.

• Providetagsattheworksiteandasign-upsheet

to record tag out details.

• Donotserviceormaintainthegeneratorunless

motor is OFF and the power locked out with the

master switch.

2.10 BATTERY SAFETY

• Keepallsparksandflamesawayfrombatteries,

as gas given off by electrolyte is explosive. Always

wear gloves.

• Avoidcontactwithbatteryelectrolyte:washoffany

spilled electrolyte immediately.

• Wearsafetyglasseswhenworkingnearbatteries.

• Donottipbatteriesmorethan45°toavoidelectro-

lyte loss.

• Toavoidinjuryfromspark

or short circuit, disconnect

battery ground cable be-

fore servicing any part of

the electrical system.

9

2.11 OPERATING SAFETY

• ReadandunderstandtheOperator’sManualand

all safety signs before operating, maintaining, ad-

justing or repairing the generator.

• TurnmachineOFF,placemastercontrolsin

their OFF position shut down and lock out power

source, unplug power cord and wait for all moving

parts to stop before servicing, adjusting, repairing

or unplugging.

• Keepallelectricalcomponentstight,dryandin

good repair.

• Cleartheareaofbystanders,especiallysmall

children.

• Replaceallwornorfailedcomponentsimmediate-

ly with megagen approved parts.

• Installandsecureallguardsbeforeoperating.

• Keephands,feet,hairandclothingawayfrom

moving parts.

• Reviewworksite.Positiongeneratortoprovide

electrical power accessibility and minimal interfer-

ence with other equipment.

• Theunitgeneratessufficientelectricalpowertoin-

jure or kill. Follow appropriate safety procedures.

• EstablishaformalLock-Out/Tag-Outprogramfor

your operation and train all operators and service

personnel before allowing them work with and

around the generator.

• RequireallpersonneltousePersonalProtective

Equipment(PPE)whenoperatingorservicingthe

machine.

• Donotstandorclimbonmachinewhenrunning.

Keep others off.

• Keeptheworkingareacleananddry.

• Reviewsafetyinstructionsannually.

2.12 TIRE SAFETY

• Failuretofollowproperprocedureswhenmount-

ing a tire on a wheel or rim can produce an explo-

sion which may result in serious injury or death.

• Donotattempttomountatireunlessyouhavethe

proper equipment and experience to do the job.

• Haveaqualifiedtiredealerorrepairserviceper-

form required tire maintenance.

• Whenreplacingworntires,makesuretheymeet

the original tire specifications. Never under-size.

2.13 TRANSPORT SAFETY

• Makecertainthatyouareincompliancewithlocal,

state/provincial and federal regulations regarding

transporting equipment on public roadways.

• Makecertainthatallwheelsandtiresareingood

repair and that tires are inflated to proper pressure.

Donotunder-inflateorover-inflate.

• Makecertainthatallwheelbolts/lugnutsaretight-

enedtopropertorquespecifications(refertospec-

ificationchartinSection7.2).

• Secureandlockaccessdoorsbeforetransporting.

• RaisejackintoitsfullyUPpositionandsecurewith

lock pin.

• Donotparkgeneratoronasteepslope.

• Besurethatanynecessarysigns,reflectorsand

lights required by law are in proper place and are

clearly visible to oncoming and overtaking traffic.

• Besurethatthegeneratorispositivelyhitchedto

the towing vehicle. Use a safety cable to assure a

safe hitch hook-up when transporting.

• Usea3/4tonpickuporlargertrucktotowmachine.

• Donotallowanyonetorideonthegeneratordur-

ing transport.

• Cleartheareaofobstaclesandunnecessary

personnel.

• Donotplaceanyobjectsorloadsontheframeto

prevent changing the center of gravity or overload-

ing the frame.

• Donotexceedasafetravelspeedof90km/55mph

with trailer. Slow down for corners and rough sur-

face conditions.

2.14 ELECTRICAL SAFETY

• Usetheterminalinsidetheframetogroundunitin

compliance with local laws and regulations.

• Allelectricalwires,plugs,socketsandothercom-

ponents must always be in good condition when

operating.

• Turnmasterbatteryandelectricalswitchesoff

when shutting down unit.

• Donotoperatemachinewithwethandsorclothing.

10

2.15 DIESEL ENGINE SAFETY

BEFORE STARTING ENGINE, READ AND UNDER-

STAND THE OPERATING AND MAINTENANCE IN-

STRUCTIONS THAT CAME WITH YOUR ENGINE.

WARNING: DO NOT

• DONOTrunengineinanenclosedarea.Exhaust

gases contain carbon monoxide, an odorless and

deadly poison.

• DONOTplacehandsorfeetnearmovingorrotat-

ing parts.

• DONOTstore,spill,orusefuelnearanopen

flame, or devices such as a stove, furnace, or wa-

ter heater which use a pilot light or devices which

can create a spark.

• DONOTrefuelindoorswhereareaisnotwellven-

tilated. Outdoor refuelling is preferred.

• DONOTfillfueltankwhileengineisrunning.Allow

enginetocoolfor5minutesbeforerefuelling.Store

fuel in approved safety containers.

• DONOTremovefueltankcapwhileengineis

running.

• DONOToperateengineiffuelisspilled.Move

machine away from the spill and avoid creating

any ignition until the fuel has evaporated.

• DONOTsmokewhenfillingfueltank.

• Wheneverpossible,graduallyreduceengine

speed before stopping.

• DONOTrunengineaboveratedspeeds.This

may result in injury.

• DONOTtamperwithpartswhichmayincrease

the governed engine speed.

• DONOTtamperwiththeenginespeedselected

by the original equipment manufacturer.

• DONOTstrikeflywheelwithahardobjectormetal

tool as this may cause flywheel to shatter in opera-

tion. Use proper tools to service engine.

• DONOToperateenginewithoutamuffler.Inspect

periodically and replace, if necessary. If engine is

equipped with muffler deflector, inspect periodical-

ly and replace, if necessary with correct deflector.

• DONOToperateenginewithanaccumulationof

grass, leaves, dirt or other combustible materials

in the muffler area.

• DONOTusethisengineonanyforestcovered,

brush covered, or grass covered unimproved land

unless a spark arrester is installed on the muffler.

The arrester must be maintained in effective work-

ing order by the operator. In the State of California

theaboveisrequiredbylaw(Section4442ofthe

CaliforniaPublicResourcesCode).Otherstates

may have similar laws. Federal laws apply on fed-

eral lands.

• DONOTtouchhotmuffler,cylinderormanifold

because contact may cause burns.

• DONOTrunenginewithaircleaneroraircleaner

cover removed.

WARNING: DO

• ALWAYSdisconnectbatterybeforeservicingen-

gine to prevent accidental starting.

• DOexaminemufflerperiodicallytobesureitis

functioning effectively. A worn or leaking muffler

should be repaired or replaced as necessary.

• DOusefreshfuel.Stalefuelcangumfuelinjection

system.

• DOcheckfuellinesandfittingsfrequentlyfor

cracksorleaks.Replaceifnecessary.

2.16 REFUELLING SAFETY

• Handlefuelwithcare.Itishighlyflammable.

• Allowenginetocoolfor5minutesbeforerefuel-

ling. Clean up spilled fuel before restarting engine.

• Donotrefuelthemachinewhile

smoking or when near open flame or

sparks.

• Fillfueltankoutdoors.

• Preventfiresbykeepingmachine

clean of accumulated trash, grease

and debris.

11

2.17 REFILLING DEF SAFETY

Composition

DieselExhaustFluid(DEF)ismadefromamixtureof

purified water and urea. The formula is stable, color-

less, non-toxic, and similar to baking soda in its alka-

linity(pH).Itisnotafuel,butitisusedtoreducethe

level of nitrogen oxides in the exhaust to meet emis-

sions control standards.

Purpose

In the Selective Catalytic Reduction (SCR) system,

DEFisinjectedintotheexhaust.ItconvertstheNO2

into nitrogen gas and water vapor, which are harm-

less components of air.

Storing

The ideal temperature range for storing DEF is be-

tween32°Fand86°F,anditsaverageshelflifeis3

years.Keep DEF out of direct sunlight, and do not

store it in temperatures below 32°F.Because of its

alkalinity,DEFuidcancauseoxidizationinthesame

way that oxygen rusts raw steel, so it needs to be

stored in plastic or stainless steel containers.

What to know when filling your DEF tank

DEFtanksaredesignedsothattheopeningwillonly

accepta DEFfillnozzle.Astandardnozzlefordie-

sel fuel will not fitintotheDEFtankopening.This

safeguard ensures that only the proper fluid can be

pumped into the tank.

DEFtankswillholdbetween15and50gallons,de-

pending on the size and horsepower of your equip-

ment. Be sure to keep enough reserves on hand, as

equipmentwillceasetooperateoncetheDEFtank

is dry.

When to refill the tank

A DEF gauge has been added to most new equip-

ment that will show the fluid level and indicate when

it is time to refill.

WhentheDEFuidlevelreacheslessthan10%ca-

pacity, a series of warnings will alert the operator.

IftheDEFtankcontainslessthan5%ofitscapac-

ity, the equipment engine power will de-rate. The

DEFtankneedstobefilledonceforevery3to4

times that you refuel with diesel fuel. The frequency

will vary with operating conditions.

Table of contents

Other MEGAGEN Portable Generator manuals

Popular Portable Generator manuals by other brands

Homelite

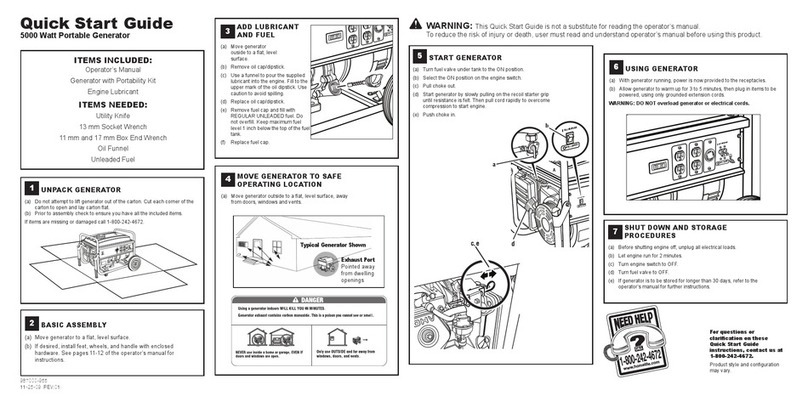

Homelite HG5000 Series quick start guide

Westinghouse

Westinghouse iGen4500DFcv quick start guide

Generac Power Systems

Generac Power Systems Guardian ULTRA SOURCE 004583-0 owner's manual

GE

GE HOME NERATOR SYSTEMS Installation and start-up manual

Porter-Cable

Porter-Cable PCI2200 instruction manual

Westinghouse

Westinghouse WGen10500TFc user manual