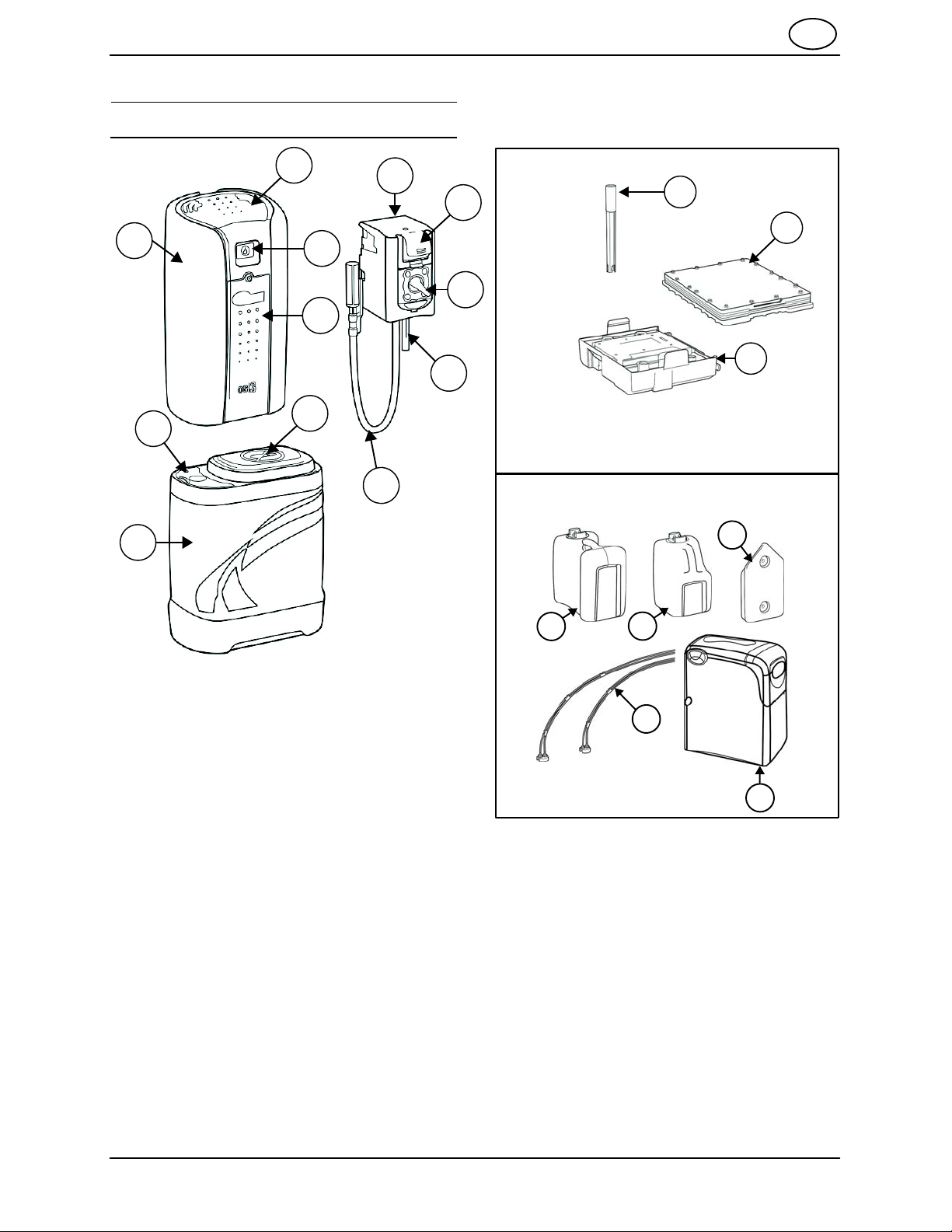

EN OPERATION

OS3 DM20036 (3−2018)

2

IMPORTANT SAFETY INSTRUCTIONS −SAVE THESE INSTRUCTIONS

The following precautions are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or

unsafe practices that could result in

severe personal injury or death.

FOR SAFETY: To identify actions that must be

followed for safe operation of equipment.

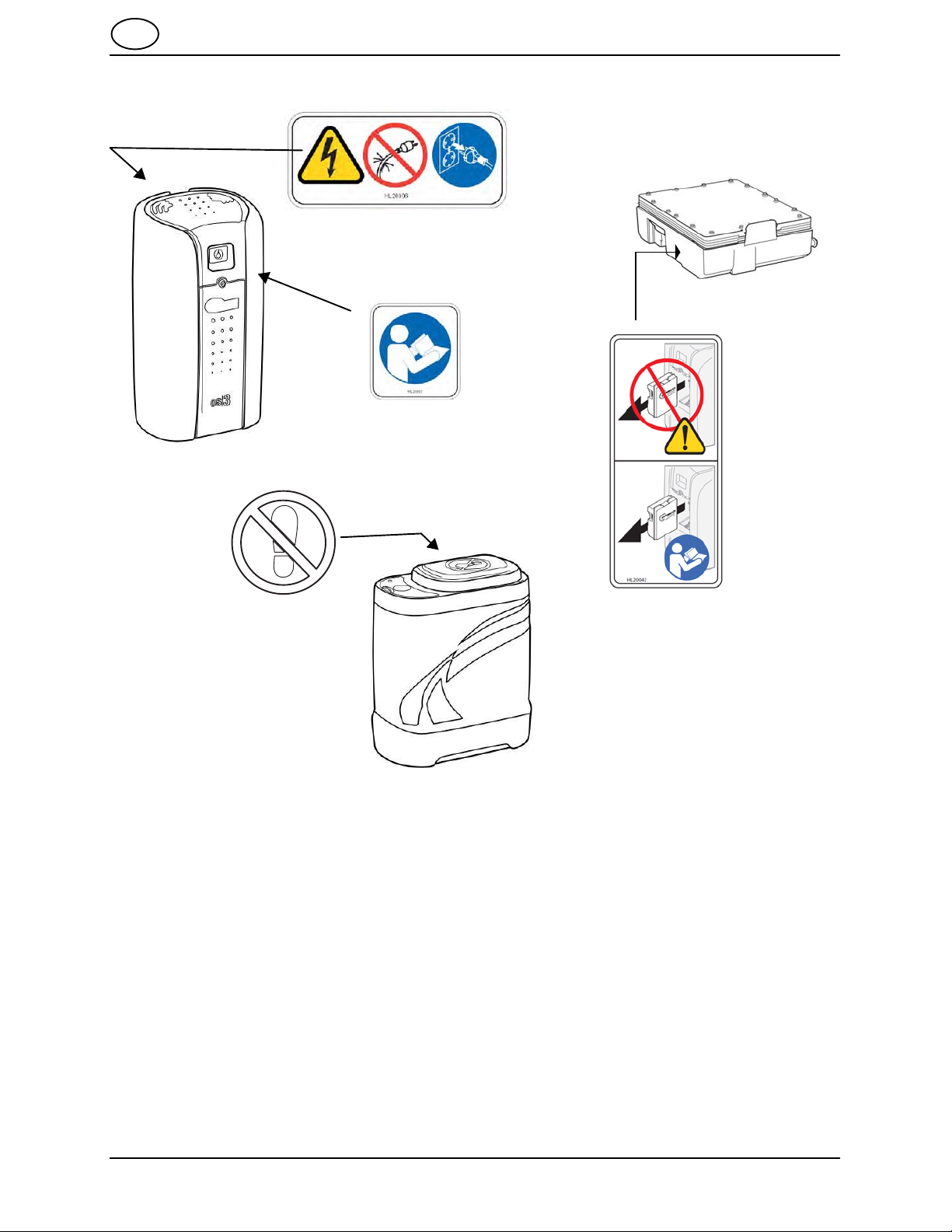

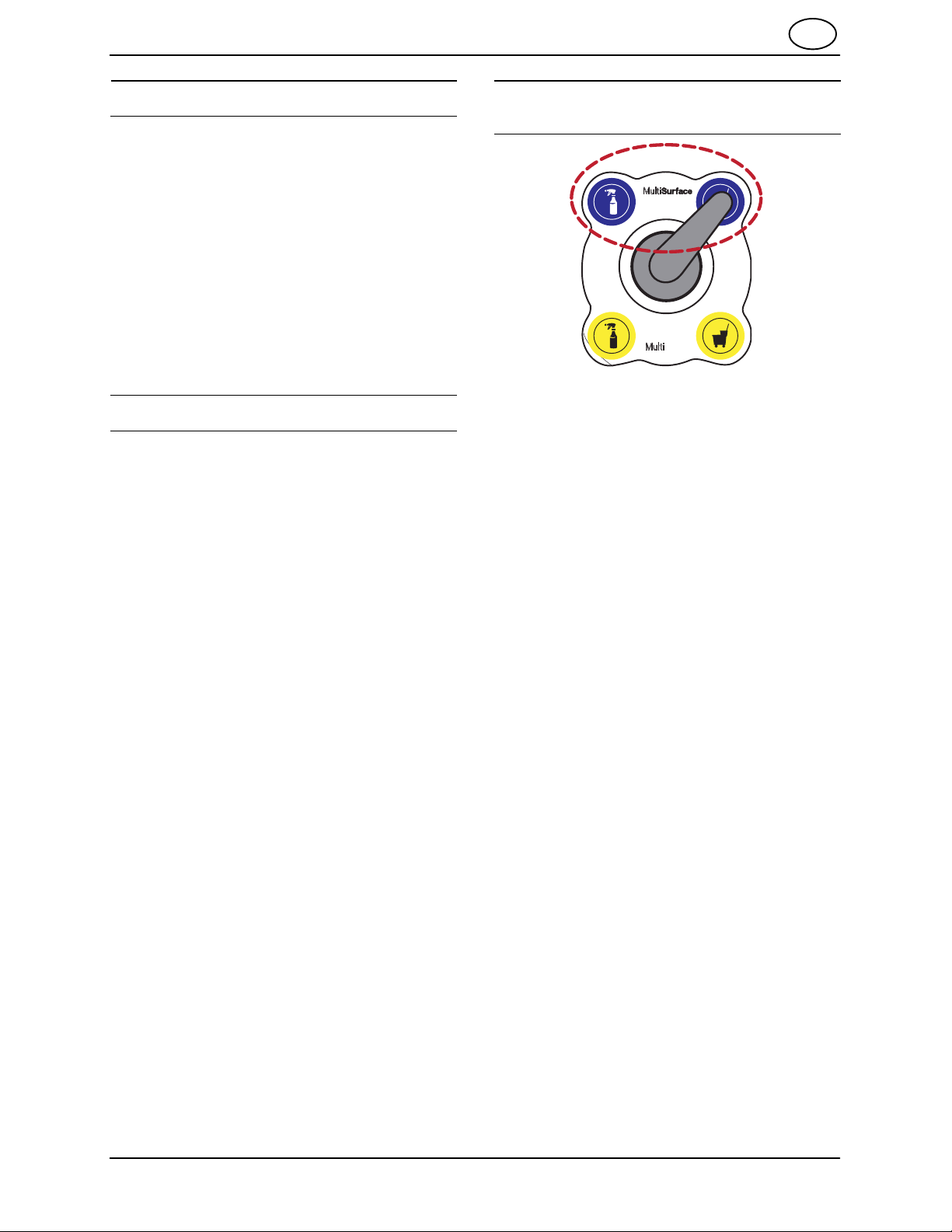

This machine is designed solely for creating,

storing, and dispensing Orbio MultiSurface

cleaner and MultiMicro 200 Solution.

The following information signals potentially

dangerous conditions to the operator or

equipment. Read this manual carefully. Know

when these conditions can exist. Locate all safety

devices on the machine. Then, take necessary

steps to train machine operators. Report machine

damage or faulty operation immediately. Do not

use the machine if it is not in proper operating

condition.

WARNING: Electrical Hazard

−Do not operate with damaged power

cord.

−Unplug power cord before servicing

machine.

−Do not modify plug. If the power cord

is damaged or broken, it must be

replaced by the manufacturer or its

service agent or a similarly qualified

person in order to avoid a hazard.

WARNING: Electrical Shock Hazard.

Do not use outdoors. Do not expose to

rain / moisture. Store indoors.

This machine may be equipped with

technology that automatically communicates

over the cellular network. If this machine will

be operated where cell phone use is restricted

because of concerns related to equipment

interference, please contact a Tennant

representative for information on how to

disable the cellular communication

functionality.

FOR SAFETY:

1. Do not operate machine:

−Unless trained and authorized.

−Unless operator manual is read and

understood.

−Under the influence of alcohol or

drugs

−Unless mentally and physically

capable of following machine

instructions.

−If it is not in proper operating

condition.

−In outdoor areas. This machine is for

indoor use only.

−If water supply is turned off, unplug

machine until water supply is restored,

then plug machine in.

2. When using machine:

−Use only as described in this manual.

−Do not use water softener as a step.

−Keep children and unauthorized

persons away from machine.

−Do not allow to be used as a toy.

−Follow site safety guidelines

concerning wet floors.

3. When servicing machine:

−Unplug cord from wall outlet.

−All work must be done with sufficient

lighting and visibility.

−All repairs must be done by trained

personnel.

−Do not modify the machine from its

original design.

−Use Tennant supplied parts or

approved replacement parts.

−Do not remove e−module unless

operator manual is read and

understood.