Translation of the "original operating instructions"

Pos: 5/Ü berschriften/1/Ü berschrift Inhaltsverzeich nis@ 0\ mod_14133763 29993_6.docx @ 58 @ @ 1

Contents

=== Ende der Liste für Te xtmarke Inhaltsverzeich nis== =

1Notes to the user....................................................................................................................................4

1.1 The purpose of these operating instructions ......................................................................................4

1.2 Ways we present the information .......................................................................................................4

2Liability and warranty ............................................................................................................................4

2.1 Delivery contents ................................................................................................................................4

2.2 Liability................................................................................................................................................5

2.3 Warranty .............................................................................................................................................5

2.4 Copyright.............................................................................................................................................5

3Safety information..................................................................................................................................5

3.1 Presentation of safety information......................................................................................................5

3.2 Intended uses .....................................................................................................................................6

3.3 Misuse.................................................................................................................................................7

3.4 Risks in dealing with the BioMaster®..................................................................................................7

3.5 Operator's responsibilities ..................................................................................................................9

3.6 Personnel responsibilities...................................................................................................................9

3.7 Personnel qualifications......................................................................................................................9

3.8 Safety devices ..................................................................................................................................10

3.9 Safety marking..................................................................................................................................11

4Transport...............................................................................................................................................12

4.1 Unpacking.........................................................................................................................................13

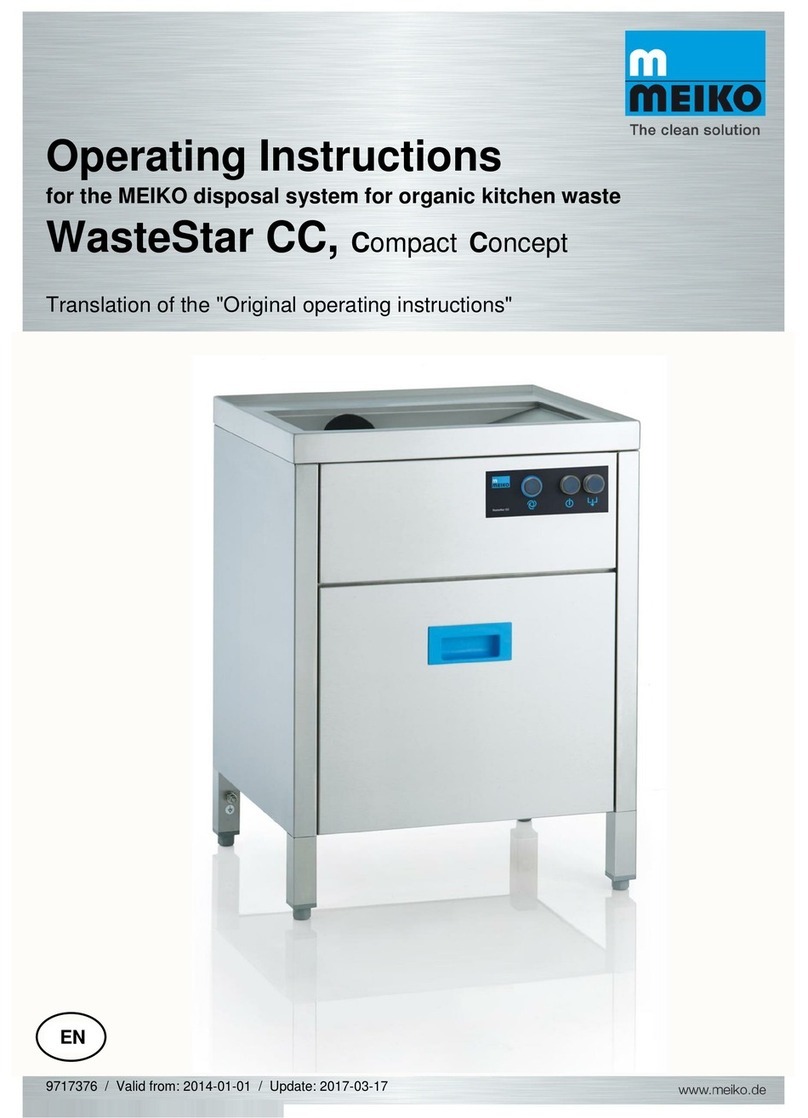

5Structure and function.........................................................................................................................13

5.1 Function............................................................................................................................................13

5.2 Main group BioMaster®.....................................................................................................................14

5.3 Control elements...............................................................................................................................15

5.4 Loading chute ...................................................................................................................................16

5.5 Technical equipment.........................................................................................................................17

6Installation.............................................................................................................................................18

6.1 Unpacking and setting up.................................................................................................................18

6.2 Connections......................................................................................................................................18

6.2.1 Electrical connection.....................................................................................................................18

6.2.2 Cold water connection ..................................................................................................................19

6.2.3 Connecting the biomass transport pipe........................................................................................19

7Commissioning.....................................................................................................................................19

7.1 Safety information.............................................................................................................................19

7.2 Process water quantity .....................................................................................................................20

7.3 Venting the water supply, pump test run, leak check.......................................................................20

7.4 Carry out test run with pure water ....................................................................................................21

7.5 Handover and commissioning report................................................................................................21

8Operation...............................................................................................................................................21

8.1 Safety information.............................................................................................................................21

8.2 Switching on .....................................................................................................................................22

8.3 Opening and closing the lid ..............................................................................................................22

8.4 Filling.................................................................................................................................................23

8.5 Starting the automatic homogenisation cycle...................................................................................24