Meinertz FloorLine User manual

FloorLine

Installation

Instructions

GB

1

2

3

4a

4b

5

5

7

8

9

6

10

11

11

12

13

14

17

15

15

8

16

17

2 Maj 2007

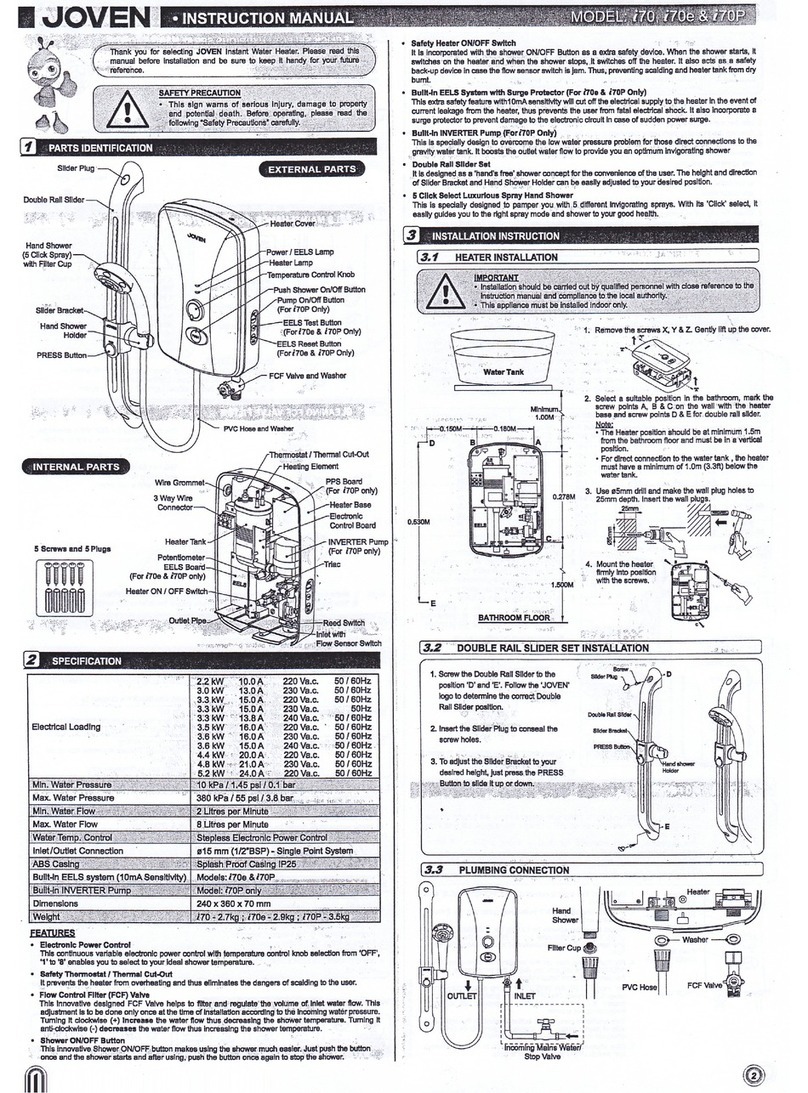

FloorLine Panels - overview

1. Floor grating (aluminium)

2. Moulding strip (Santoprene)

3. Guide prole (aluminium)

4a. Finned pipe, ow (copper)

4b. Finned pipe, return (copper)

5. Velcro tape

6. Flexible pipes

7. Motor

8. Fan (aluminium)

9. Bearing block (aluminium/brass)

10. Fan coupling (plastic)

11. Pipe xture (aluminium)

12. Installation prole (aluminium)

13. Panel end (aluminium)

14. CHM motor control print

15. Motor connection

16. Connection cable and terminals

17. Adjustment blocks (aluminium)

Maj 2007 3

FloorLinePanel-overview .................................page2

Contents ..................................................page3

Introduction...............................................page4

Unpackingthepanel.......................................page5

Positioning of installation ttings. . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Installingthepanel ........................................page6

Checkingthejoints........................................page8

Powerconnection .........................................page8

Adjustingthepanel........................................page9

Openingtheguideprole..................................page9

Connecting several panels in series. . . . . . . . . . . . . . . . . . . . . . . . . page 11

Diagram: Control with TWW room thermostat . . . . . . . . . . . . . . page 13

Diagram: Control via external CTS signal. . . . . . . . . . . . . . . . . . . . page 14

Operatingconditions......................................page15

Contents

Read these installation instructions

carefully before installing the Convec

FloorLine panel.

The installation of FloorLine panels is

divided into pre-installation and nal

installation.

Pre-installation comprises installation of

ttings and any shut-o valves connected

to the heating system as well as electric

wiring.

Final installation comprises the panel

itself, which should be installed as late

in the building process as possible to

provide the best protection of mechanical

parts against dust and paint residue, as

well as shocks, impacts and other damage.

Installation duct

The panels are supplied with self-jointing

rubber strips, which “absorb” small

inaccuracies in the installation duct.

To achieve the visually best result, it is

necessary to observe the measurements

of the installation duct as precisely as

possible, particularly the duct width of

139 mm (see page 6).

Adjustments

The FloorLine panels are equipped with

integrated adjustment screws, which

enable accurate adjustment of the panel

height to align with the oor level.

Please ensure that all adjustment screws

are resting on the base to achieve maxi-

mum stability.

4 Maj 2007

NB!

All electrical and plumbing work must be

carried out by authorised electricians and

plumbers.

Introduction

Before installation

Before installation of the panel the fol-

lowing should be completed:

System pipes, ow and return

External wiring for CHR/BMS and

power supply

Check! Measurements of the instal-

lation duct and level of nal oor

Check! Panel number

•

•

•

•

Maj 2007 5

Unpacking the panel 1/3

Check the panel number on the box.

Break the seal on the box.

Unpacking the panel 2/3

Open the box.

Lift the gratings o the panel and place

them on the opened part of the box.

NB! Avoid mixing gratings from dierent

panels as they are cut to individual

dimensions.

Remove the panel from the box.

Unpacking the panel 3/3

Under the panel is a protective sheet of

strong cardboard. Use this to protect the

panel against dust, impacts, etc.

6 Maj 2007

Positioning of installation ttings 1/2

139 ± 1 mm

63 - 73 mm

Check that the installation duct meets the

specied dimensions. If the duct is deeper

than 73 mm, a stable support must be cre-

ated for the panel.

Duct length can be calculated as follows:

• Panels shorter than 6000 mm: the length

equals total panel length + 5 mm.

• Panels longer than 6000 mm: the duct

is extended further 1 mm per meter panel.

Positioning of installation ttings 2/2

65 mm

½“

Fix the enclosed installation tting to the

base of the installation duct.

Connect the system pipes.

NB! Check that the ow and return pipes are

correctly positioned.

Installing the panel 1/4

1. Flow

2. Return

3. Flexible pipes

4. Terminal

5. Motor

Maj 2007 7

Installing the panel 2/4

Lower the FloorLine panel into the

installation duct.

Installing the panel 3/4

Attach the exible pipes to the installation

ttings.

NB! The enclosed gaskets must be used.

Installing the panel 4/4

Tighten the joints with a moderate torque.

You are recommended to use an NV24 open

ring spanner (order no. 088H4821).

8 Maj 2007

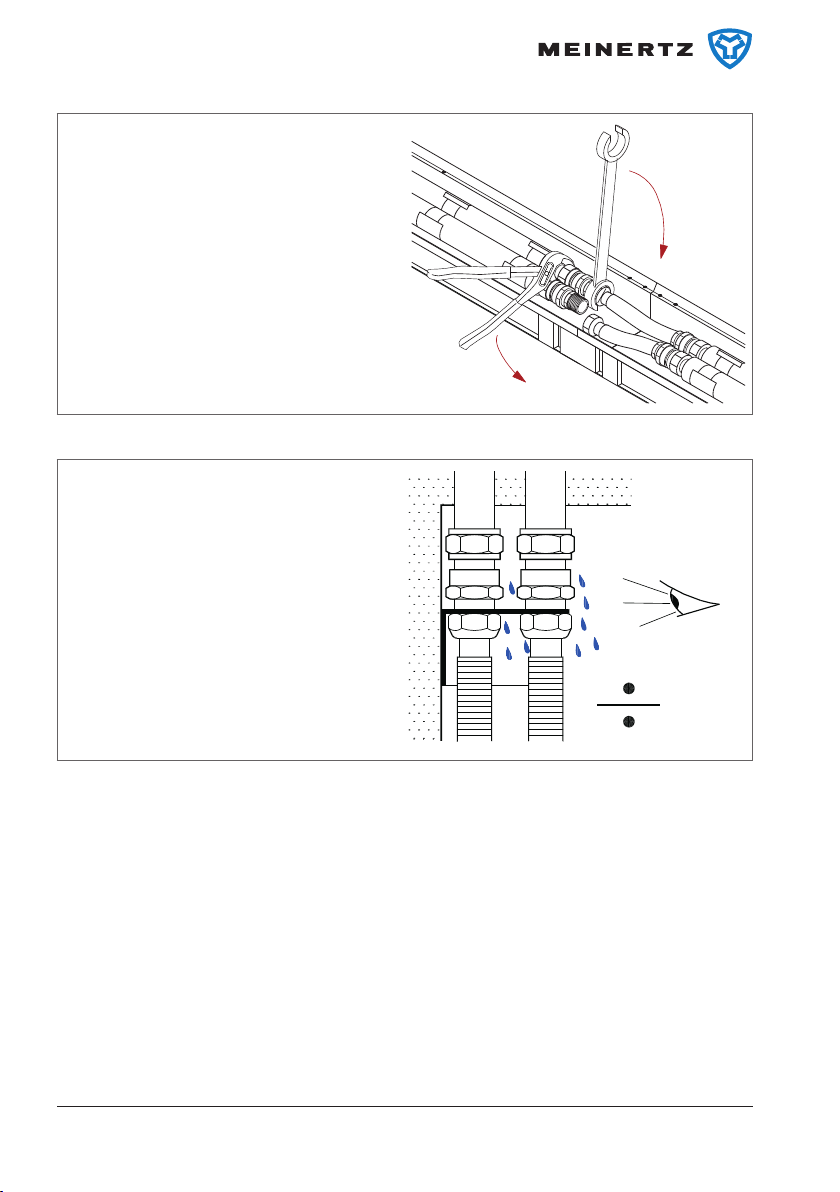

Checking the joints 1/1

After tightening, pressurise the system and

check for possible leaks.

Power connection 1/2

Connect cables from the CHR room

thermostat (or BMS system) and from

the 24 V power supply.

Power connection 2/2

Wiring must be carried out according to the

electrical curcuit diagrams on page 13-14.

Maj 2007 9

Adjusting the panel 1/2

Adapt the panel to the oor height using

the integrated adjusting screws located at

suitable intervals along the full length of the

panel.

Use a 2.5 mm Allen key.

NB! On account of the panel’s load strength,

it is important for all adjusting screws to be

adjusted correctly.

Adjusting the panel 2/2

Put the oor grating in place and check that

it is aligned with the oor surface.

Opening the guide prole 1/4

Remove the oor grating from the panel.

10 Maj 2007

Opening the guide prole 2/4

Release the guide prole from the pipe

xture by pulling sightly.

Repeat this along the full length of the

panel.

Opening the guide prole 3/4

The guide prole can now be lifted to give

access to the base of the panel.

Opening the guide prole 4/4

When the guide prole is closed, secure it

with light pressure on the Velcro pads.

Maj 2007 11

Connecting several panels

in series 1/5

A

Push the panels together.

The joint blocks (A) ensure precise panel

jointing.

Extend the exible pipes to reach the ttings

on the next panel.

Connecting several panels

in series 2/5

To give room for thermal expansion, pull the

panels 2 mm apart.

Connecting several panels

in series 3/5

1

1

2

2

Insert gaskets between the exible pipes

and the ttings before fastening.

12 Maj 2007

Connecting several panels

in series 4/5

Tighten the exible pipes with an NV24 ring

spanner.

NB! Always hold the pipe in place in the

panel with multigrip pliers.

Connecting several panels

in series 5/5

After tightening, pressurise the system and

check for leaks.

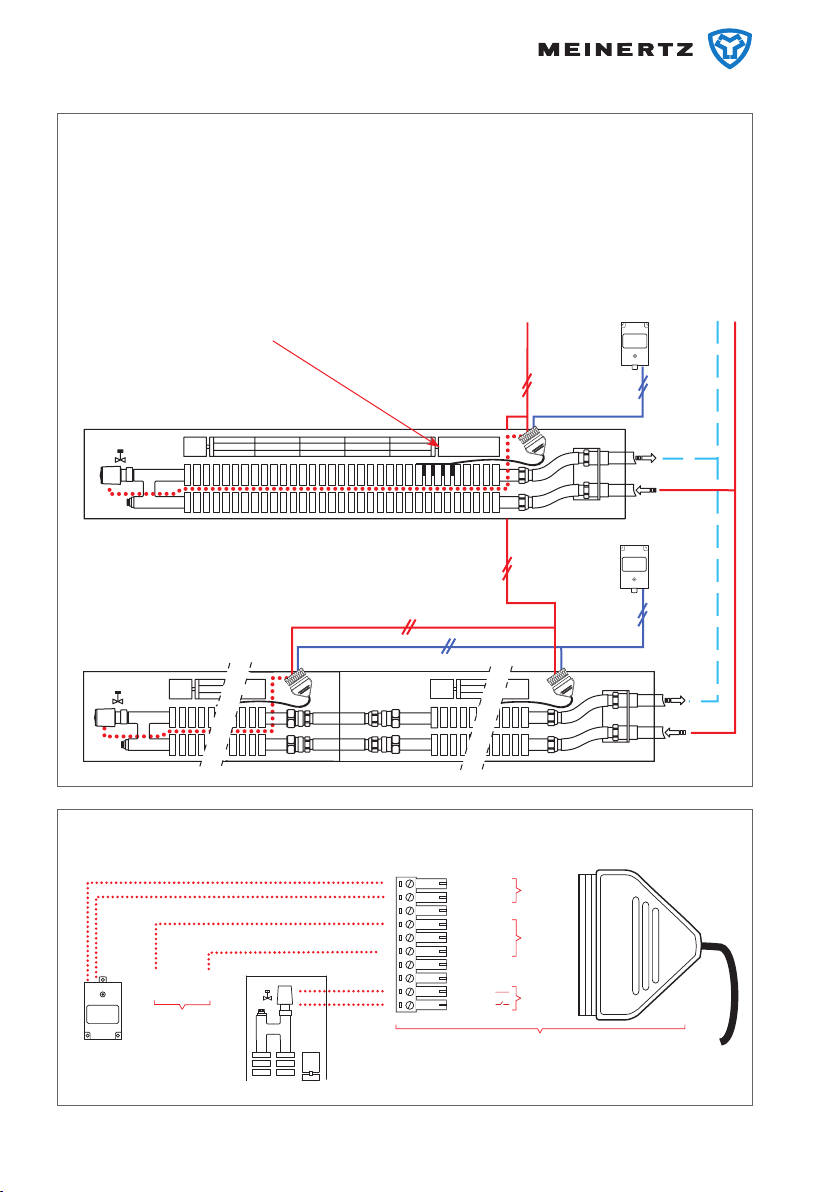

24 Vdc

0 Vdc

24 Vdc

0 Vdc

Heat/Cool

RPM (0-10 V)

H. valve +

H. valve -

CHR

24 Vdc

max. 1.1A

Power supply

(22-28 Vdc)

Panels in series

Stand-alone (ST) panel

1

2

3

4

5

6

7

8

9

10

1 2 3 4 5 6

24 Vdc

GND

24 Vdc

GND

H/C

RPM

HV +

HV -

CV +

CV -

Maj 2007 13

System with CHR room thermostat

A CHR can control up to 10 Convec pan-

els in the same room.

A Convec panel can be supplied with a

valve to control ow through the panel.

Wiring

Supplied from factory

TDM

power

supply

CHR room

thermostat

CHM motor control CHR

room

thermostat

TDM

power

supply

TDM

power

supply

CHR

room

thermostat

NB! CHR room thermostats and CHM motor

control have a common “0”.

1

2

3

4

5

6

7

8

9

10

24 Vdc

GND

24 Vdc

GND

H/C

RPM

HV +

HV -

CV +

CV -

0-10 V0

14 Maj 2007

System with BMS control

A Convec panel can be controlled directly

from a BMS system by a 0-10 V signal.

Control of min. and max. fan speed is

performed by the BMS system. However,

the CHM motor control will continue to

Wiring

Supplied from factory

TDM

power

supply

BMS system

CHM motor control

BMS system

TDM

power

supply

TDM

power

supply

perform the panel control, e.g. stopping

the motor if blocked or the control of

any decentralized valves.

NB! Water supply valves are connected

to cooling outputs 9 and 10.

24 Vdc

0 Vdc

24 Vdc

0 Vdc

Heat/Cool

RPM (0-10 V)

C. valve +

C. valve -

BMS system

24 Vdc

max. 1.1A

Power supply

(22-28 Vdc)

Panels in series

Stand-alone (ST) panel

Maj 2007 15

Operating conditions

Operating pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 bar

Test pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 bar

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -10 - 60 °C

Water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 85 °C

Water quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .VDI 2035

16 Maj 2007

For further information please

contact:

MEINERTZ A/S

Sverigesvej 11

DK-8660 Skanderborg

Phone +45 8652 1811

Fax +45 8652 1515

www.meinertz.com

Table of contents