meitav-tec MTS/SUPER User manual

Touch Screen Wall Panel

MTS/SUPER

Owner’s manual and technician settings

-2-

-3-

Index

1. Owner’s Manual ………………………………………………..... 4

1.1 Quick Guide……………………………………………………. 4

1.2 Turning the unit ON or OFF………………………………….. 5

1.3 Adjusting the set-point temperature ………………………... 5

1.4 Switch between temperature scales ……………………….. 5

1.5 Switching between System modes………………………….. 6

1.6 Switching between Fan speeds …………………………….. 6

1.7 Fan on demand (Auto fan)….……………………………….. 7

1.8 Lock the thermostat’s buttons….…………………………….. 7

1.9 Timer for turning the thermostat off…………………………. 7

2. Installation Instructions……..………………………………..... 8

3. Wiring Configuration and DIP Switches…….……………..... 11

4. Technician Settings …….……………………………………..... 18

1. Owner’s manual

-4-

Fan

only

*Auto

mode

Heat Cool

*Auto

speed

High Low

Press to switch between

fan speeds:

Med.

*In Auto mode, the active

mode will flash

System ON

Press and hold to lock the

thermostat’s buttons

(set-point must be other

than 10ºC/50ºF)

Press and hold

to enter technician settings

(set-point must be equal to

10ºC/50ºF)

Set-point

adjustment

Temperature

scale

Modes

indication

Ambient /

Set-point

temperature

display

Fan speeds

indication

Press to

turn

system

ON or OFF

Press to switch between

system modes:

*In Auto speed, the active

speed will appear

System OFF

1.1 Quick Guide

1.2 Turning the unit ON or OFF

Press the button to turn the unit ON – system mode and fan

speed symbols will appear on display.

Press again to turn the unit OFF – the symbols will disappear.

1.3 Adjusting the set-point temperature

While the thermostat is ON, press the or buttons – the

set-point temperature will flash.

Press again to adjust the set point.

Unit ONUnit OFF

-5-

1.4 Switching between temperature scales

Press and hold the button to switch between temperature

scales.

Note: set-point must be other than 10ºC,11ºC/50ºF,51ºF

Press the button to

switch between system

modes:

1.5 Switching between system modes

Fan

only

Auto

mode

HeatCool

Notes:

- During demand for cooling (cooling active), the will flash.

- During demand for heating (heating active), the will flash.

1.6 Switching between fan speeds

Press the button to

switch between fan speeds:

Low

speed

Medium

speed

High

speed

Auto

speed

Note: When Auto speed Is

selected, the word “AUTO”

and the active fan speed

will appear on display

-6-

The selection of system modes may be disabled depending on

system configuration.

The selection of fan speeds may be disabled depending on system

configuration.

-7-

1.7 Fan on demand (Auto fan)

Press and hold the button to activate or deactivate

fan on demand (Auto fan) function.

Notes:

- When activated, the fan will run with demand for cooling

or heating.

- The fan on demand function cannot be activated with

“Fan only” mode.

AUTO FAN

active

This option may be disabled, depending on system configuration.

1.8 Lock the thermostat’s buttons

Press and hold the button to lock or unlock the thermostat’s

buttons. When locked, the icon will appear on display.

1.9 Timer for turning the thermostat off

Press and hold the button – the hours for the off-timer will

appear on display. Adjust the timer using the and buttos.

Range: 0...10 Hours

Note: Set “0” to disable the timer.

2. Installation Instructions

-8-

The MTS/SUPER Thermostat designed for flush mounting in the room

to be controlled. It should be located where the occupant can easily

read the display and use the controls.

If the built in temperature sensor is being used to measure room

temperature, the panel should be placed where the temperature is

representative of the general room conditions, away from cold or warm

air draughts, radiant heat and direct sunlight.

The panel should not be installed on an outside wall.

- The standard installation height is 1.5 meter (5 feet) from the floor.

WARNING: Risk of Electric Shock and Property Damage.

Disconnect power supply before making electrical connections.

The installation is to be performed by a qualified electrician.

WARNING: The integrated circuits in the controller are

sensitive to static currents. Take suitable precautions.

2. Installation Instructions (cont’)

-9-

Installation procedure:

1. separate the front display from the back plastic cover by inserting a a

small flat screwdriver into each of the three slots as shown in the

picture and rotating it gently.

2. Remove the front display and keep it in a safe place.

3. Connect the wires as shown in the enclosed wiring diagram. All

terminals accept 1x0.5mm2/24 AWG.

4. If necessary, make changes to the DIP switches position as

explained in this manual.

5. Place the thermostat in the electrical box and tighten up the 2 screws

(Gewiss Box - GW 24 203).

6. Adapt the front frame-panel into its place, by pushing it towards the

wall.

1 2

5 6

3 4

-10-

2. Installation Instructions (cont’)

* For T1,0 functionality – refer to parameter P8 in the technician settings section.

** For IN1,0 functionality – refer to parameter P9 in the technician settings section.

3. Wiring configuration and DIP Switches

T2 change over sensor / Soft

start in heat sensor / Remote

OFF switch / Remote economy

switch / External PIR

11

12

13

14

15

N

L

16

T1

0

IN1

0

*External sensor / Soft start in

heat sensor / Deicing in cool

sensor / Door switch (options)

Supply

230VAC

AO1

AO2

B

A

See options on

next pages

See options on

next pages

Not in use

- 11 -

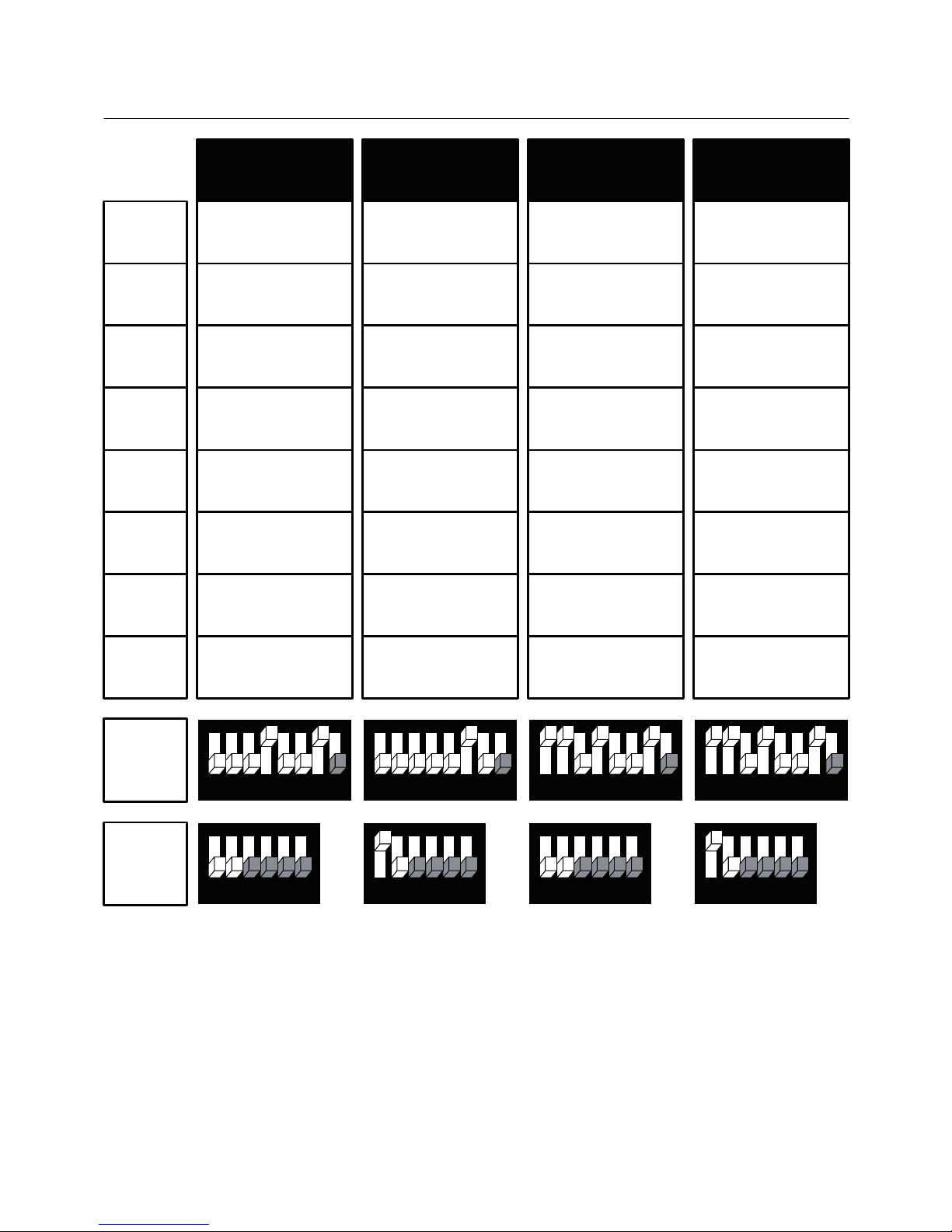

3. Wiring configuration and DIP Switches – AC systems

-12-

HC32-1S

11

12

13

14

15

16

AO1

AO2

Heat element 3

Heat element 2

Fan (1 speed)

Compressor 2

Compressor 1

Heat element 1

(see SW1.4 HC)

X

X

HP42-1S

Heat element 1

Heat element 2

Fan (1 speed)

Compressor 2

Compressor 1

Heat pump

(see SW1.4 HP)

X

X

HP22-3S

Fan medium

Fan high

Fan low

Compressor 2

Compressor 1

Heat pump

(see SW1.4 HP)

X

X

HP21-3S

Fan medium

Fan high

Fan low

Heat element

Compressor 1

Heat pump

(see SW1.4 HP)

X

X

87654321

654321

SW1

SW2

87654321

654321

87654321

654321

87654321

654321

SW1.4 = HP: ON – Heat pump active in cool, OFF – Heat pump active in heat

HC: ON – Electrical heater, OFF – Oil/Gas heater (no fan)

SW1.5 = ON: Disable compressor delay, OFF – Enable compressor delay

S2.3 – S2.6 – Not in use

HP - Heat pump system HC - Non heat pump system ## - Heating/Cooling stages

3. Wiring configuration and DIP Switches – AC systems

-13-

11

12

13

14

15

16

AO1

AO2

HC21-3S

Fan medium

Fan high

Fan low

Heat element 2

Compressor 1

Heat element 1

(see SW1.4 HC)

X

X

SW1

SW2

87654321

654321

HP22-VFS

Compressor 2

Compressor 1

Heat pump

(see SW1.4 HP)

X

Fan VFS

87654321

654321

HP21-VFS

Heat element

Compressor

Heat pump

(see SW1.4 HP)

X

Fan VFS

87654321

654321

HC21-VFS

Heat element 2

Compressor 1

Heat element 1

(see SW1.4 HC)

X

Fan VFS

87654321

654321

SW1.4 = HP: ON – Heat pump active in cool, OFF – Heat pump active in heat

HC: ON – Electrical heater, OFF – Oil/Gas heater (no fan)

SW1.5 = ON: Disable compressor delay, OFF – Enable compressor delay

S2.3 – S2.6 – Not in use

HP - Heat pump system HC - Non heat pump system ## - Heating/Cooling stages

VFS -FanVFS

Fan medium

Fan high

Fan low

Fan medium

Fan high

Fan low

Fan medium

Fan high

Fan low

3. Wiring configuration and DIP Switches – Fan coil systems

-14-

2-Pipe 3S

11

12

13

14

15

16

AO1

AO2

Fan high

Fan medium

Fan low

Heat element

Cool/Heat valve

X

X

X

2-Pipe PID 3S

X

X

X

2-Pipe VFS

Heat element

Cool/Heat valve

X

X

Fan VFS

2-Pipe PID VFS

Heat element

X

X

Cl/Ht valve PID

Fan VFS

87654321

654321

SW1

SW2

87654321

654321

87654321

654321

87654321

654321

SW1.4 = Enable/Disable 2nd heating stage: ON – Enable, OFF – Disable

SW1.5 = Chilled beam option (fan will not run with 1st stage cooling) – SW1.5 ON

S2.3 – S2.6 – Not in use

PID = Cool/Heat (Cl/Ht) valve PID VFS = Fan VFS

Fan high

Fan medium

Fan low

Heat element

Cl/Ht valve PID

Fan high

Fan medium

Fan low

Fan high

Fan medium

Fan low

3. Wiring configuration and DIP Switches – Fan coil systems

-15-

11

12

13

14

15

16

AO1

AO2

SW1

SW2

SW1.4 = Enable/Disable 2nd heating stage: ON – Enable, OFF – Disable

SW1.5 = Chilled beam option (fan will not run with 1st stage cooling) – SW1.5 ON

S2.3 – S2.6 – Not in use

C-PID = Cool valve PID H-PID = Heat valve PID VFS = Fan VFS

4-Pipe 3S

Fan high

Fan medium

Fan low

Heat element

Cool valve

Heat valve

X

X

4-Pipe 3S C-PID

Heat valve

X

X

87654321

654321

87654321

654321

Fan high

Fan medium

Fan low

Heat element

Cool valve PID

4-Pipe VFS

Fan high

Fan medium

Fan low

Heat element

Cool valve

Heat valve

X

Fan VFS

87654321

654321

3. Wiring configuration and DIP Switches – Fan coil systems

-16-

11

12

13

14

15

16

AO1

AO2

SW1

SW2

SW1.4 = Enable/Disable 2nd heating stage: ON – Enable, OFF – Disable

SW1.5 = Chilled beam option (fan will not run with 1st stage cooling) – SW1.5 ON

S2.3 – S2.6 – Not in use

C-PID = Cool valve PID H-PID = Heat valve PID

HC-PID = Cool and Heat valves PID VFS = Fan VFS

Heat element

Cool valve

X

Heat valve PID

Fan VFS

Heat element

X

X

Cool valve PID

Heat valve PID

87654321

654321

87654321

654321

Fan high

Fan medium

Fan low

Heat element

X

Heat valve

Cool valve PID

Fan VFS

4-Pipe 3S H-PID

Heat element

Cool valve

X

Heat valve PID

X

87654321

654321

87654321

654321

Fan high

Fan medium

Fan low

Fan high

Fan medium

Fan low

Fan high

Fan medium

Fan low

3. Wiring configuration and DIP Switches – Fan coil systems

-17-

11

12

13

14

15

16

AO1

AO2

SW1

SW2

Floor heating – the fan will not run with 1st stage heat

SW1.4 = Enable/Disable 2nd heating stage: ON – Enable, OFF – Disable

SW1.5 = Chilled beam option (fan will not run with 1st stage cooling) – SW1.5 ON

S2.3 – S2.6 – Not in use

C-PID = Cool valve PID H-PID = Heat valve PID

HC-PID = Cool and Heat valves PID VFS = Fan VFS

Floor heating

Cool

Heat

X

X

87654321

654321

Fan high

Fan medium

Fan low

4-Pipe 3S C-PID

Floor heating

Floor heating

X

Heat

Cool valve PID

X

87654321

654321

Fan high

Fan medium

Fan low

8

Floor heating

Floor heating

X

Heat

Cool valve PID

Fan VFS

87654321

Fan high

Fan medium

Fan low

654321

4. Technician Settings

Enter technician settings

-18-

(Press and hold)

Adjust the set-point temperature to 10ºC.

To enter technician settings, press and hold the button for

5 seconds.

Use the button to advance to the next parameter.

Use the button to return to return to the previous parameter.

Press the button or wait 60 seconds to exit technician settings

and return to normal display.

4. Technician settings (cont’)

P1 – Offset for temperature readings calibration

Range: -6…+6°C / -9…+9°F.

Default: 0°C / 0°F.

P2 – Set point limit for cooling

Range: 5…35°C / 41…90°F.

Default: 5°C / 35°F.

P3 – Set point limit for heating

Range: 5…35°C / 41…95°F.

Default: 35°C / 95°F.

P5 – Lock the [Mode] button

“01” - [Mode] button Locked

“00” - [Mode] button unlocked (default)

P6 – Lock the [On/Off] button

“01” - [On/Off] button Locked

“00” - [On/Off] button unlocked (default)

P4 – Lock the [Fan] button

“01” - [Fan] button Locked

“00” - [Fan] button unlocked

- 19 -

- 20 -

P7 – Lock the [+] and [-] buttons (Set buttons)

“01” - [+] and [-] buttons Locked

“00” - [+] and [-] buttons unlocked (default)

P8 – Functionality of T1 terminals

“00” - T1 terminals are not in use (default)

“01” - External sensor

“02” - Soft start in heat sensor (FC), Deicing in cool (AC)

“03” - Door switch

4. Technician settings (cont’)

P9 – Functionality of In1,0 terminals

“00” - In1,0 terminals are not in use (default)

“01” - T2 (Change over sensor)

“02” - *T3 (Soft start in heat sensor)

“03” - Remote On/Off switch

“04” - Remote Economy switch

“05” - External Passive Infrared detector (PIR)

* Where T1 terminals are used for external sensor,

the In1,0 terminals can be used for T3 sensor.

P10 – Window contact (terminals In1,0) polarity

“00” - Normally open (default)

“01” - Normally close

This manual suits for next models

4

Table of contents

Popular Touch Panel manuals by other brands

Monoprice

Monoprice 21825 user manual

COMFILE

COMFILE CPCV5 Series Hardware manual

OHAUS

OHAUS Ranger 3000 Series instruction manual

Intelligent Home

Intelligent Home Cronus Installation and user manual

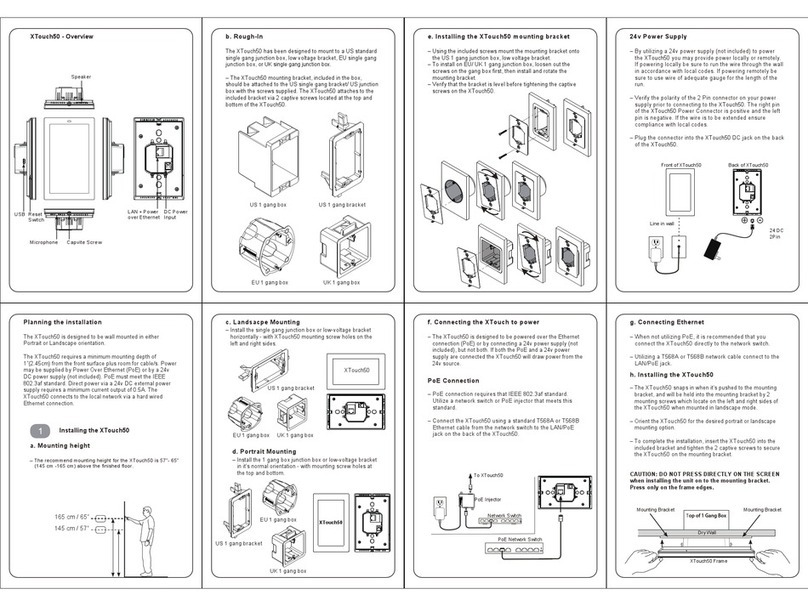

Xilica Audio Design

Xilica Audio Design XTouch Series: XTouch50 Quick install guide

IEI Technology

IEI Technology UPC-V315-QM77 user manual