Melco Bravo User manual

Technical Manual

Rev 082115

2 of 271

Contents

Copyright Notice 9

About This Manual 10

Scope of Manual 11

Standard Conventions and Denition of Terms 12

Regulatory Notices 13

Best Maintenance Repair Practices 14

Maintenance Philosophy: 14

Grounding and Static Electricity 17

Machine Orientation 19

Safety Issues 20

Warranty Considerations 21

Explanation of Machine Symbols 22

Keypad Operations 23

Keypad Buttons 26

Trace Button 26

Arrow Up Key (Y-Axis Back) 26

Color Change/Needle Case 26

Arrow Left Key (X-Axis Left) 26

Arrow Right Key (X-Axis Left) 27

Center Key 27

Adjustment Key 27

Arrow Down Key (Y-Axis Forward) 27

Hoop Key 28

Step Back Key 28

Step Forward Key 28

Laser Key 28

Start Button 28

Stop Button 29

Emergency Stop Button 29

LED Indicator 30

Specications 31

Technical Specications 33

Torque Specications 34

Table of Contents

3 of 271

Software Maintenance Menus 36

Special Tools and Fixtures 37

General Maintenance 38

Cleaning 38

Lubrication Schedule and Specications 40

Maintenance Schedule 40

Daily Maintenance 42

Weekly Maintenance 43

Monthly Maintenance 45

Quarterly Maintenance 51

Thread Cutter Blade Replacement 61

Centering The Needle Plate 62

Head Up Position Adjustment 63

Mechanical Head-Up Position 63

Adjusting Head-Up (Z-Home) Position: 64

Hook Timing Inspection/Adjustment 65

Rotational Hook Timing Inspection Procedure 65

Needle To Hook Gap Inspection Procedure 67

Adjustment Procedure 67

Thread Clamp Replacement 71

Thread Clamp PCB Replacement 72

Thread Clamp Harness Replacement 72

Laser Light - Adjustment 74

Needle Depth 76

Setting the Needle Depth by Eye 76

Presser Foot Height 77

X/Y Home Adjustment 78

Home Adjustment Procedures: 78

X-Cable Tension 81

Determining if an X-Cable is Set to Required Specications 81

Adjusting an X-Cable that is Tensioned Outside the Required Specications 82

Y-Axis Timing Belt Tensioning 84

Y-Axis Belt Tension Inspection 84

Y-Axis Belt Tension Adjustment 85

When Belt Tensions are Correct 85

Y-Motor Timing Belt Tensioning 86

Inspection and Adjustment 86

Table of Contents

4 of 271

Z-TIMING: Bottom Center & Head-Up 87

Bottom Center (Z Timing) 87

Z-Drive Belt Tensioning 92

Inspection and Adjustment 92

Z-Home Adjustment 94

Procedure to Identify the Closest Needle 95

Needle Case Calibration 98

Fine calibration procedure: 98

Rough Calibration Process: 99

Rotary Hook Support Adjustment 101

Inspection Procedure 101

Adjustment Procedure 103

Color Change, Take-Up, Feeder Housing Assembly 105

Replacement Procedure for Entire Color Change/Take-Up/Feeder Assembly: 105

Color Change Linear Actuator Replacement 107

Replacement Procedures: 107

Thread Feeder Gear Replacement 110

Replacement Procedures: 110

Thread Feeder Optical Sensor PCB Replacement 112

Replacement Procedure: 112

Thread Feeder Radial Bearing Replacement 113

Replacement Procedures: 113

Thread Feeder Stepper Motor Assembly 114

Replacement Procedure: 114

Laser Pointer Assembly 116

Replacing the laser assembly: 116

LED Cluster PCB Replacement 118

Presser Foot Assembly Replacement 119

Reciprocator 122

Replacement Procedure 122

Take-Up Lever Cam Replacement 124

Replacement Procedure 124

Z-Drive Repair and Adjustment 127

Z-Drive Belt Replacement and Tensioning 127

Z-Home Sensor PCB Replacement 129

Table of Contents

5 of 271

Z-Belt Idler Assembly Replacement 131

Z-Motor Assembly 132

Clearing Thread from Thread Feeder Roller 135

Color Change Spindle Mounting Bracket Replacement 137

Grabber Blade Replacement 139

Needle Case Removal 142

Needlecase Installation 144

Grabber Stepper Motor Replacement 146

Take Up Lever Replacement 147

Thread Feeder (replacement and adjustment) 149

Thread Sensor Assembly Replacement 152

Bobbin Shaft Overhaul 154

Rotary Hook Replacement 156

Main PCB 158

Power Input Assembly Replacement 160

Power Input Assembly Removal: 160

Power Input Assembly Component Replacement: 161

Power Input Assembly Installation: 166

User Interface Assembly Replacement 167

Harnesses 170

Color Change Motor Harness 171

Ethernet Harness 174

Grabber/Threadfeed Motor Harness 176

Grabber/Threadfeed/CC Home Harness 179

Laser Harness 182

LED Cluster Harness 184

Replacement Procedures: 184

Thread Break Harness 188

Z Home Harness 191

Table of Contents

6 of 271

User Interface Harness 193

X/Y Home Harness 195

Bearing Block Assemblies 197

X-Beam Assembly 199

X-Carriage Assembly 201

X-Drive Cable Removal 203

X-Drive Cable Installation 205

X-Drive Motor Replacement 209

X-Home Optical Switch Assembly Replacement 212

X/Y Home PCB Replacement 214

Y-Drive Belt Replacement 216

Y-Motor Assembly 218

Troubleshooting 220

Grabber Function Test 221

Final Functional Tests 223

Optical Sensors Test 225

Power Supply Test 226

Servo Motor Resistance Test 229

Stepper Motor Resistance Test 230

Servo Motor Resistance Test 231

Troubleshooting Stepper Motors 232

Table of Contents

7 of 271

Test Designs 235

Thread Tension Test 236

Belt Tension Test 237

Long Stitch Test 237

Looping Test 237

Orientation Test 238

Registration Test 238

Small Alphabet Test 238

Thread Break Sensor Test 239

Thread Break Test 239

Trimmer Test 240

Electrical Failures 241

AC Power Failure 241

Color Change Failures 241

LED Cluster Assembly Failures 242

Machine Initialization Failure 242

Mechanical Failures 244

False Thread Breaks 244

Loose/Looping Stitches 244

Needle Breaks 244

Skipped Stitches 245

Thread Breaks 246

Miss-Starts 250

Cap Frame Issues 250

Miscellaneous Problems 251

X-Axis Failures 252

Y-Axis Failures 253

Z-Axis Failures 254

Software Error Messages 255

DSP Command Errors 256

Can’t Initialize Stepper Motors 256

No Trace Data 256

XY Home Not Set 256

Goto Func Error 257

Hoop Center Error 257

Stepper Motor Time Out and Index Errors 257

E-Stop Engaged 258

Servo Motor Errors (Move Time Out, Tracking, and Over Current Errors) 260

Table of Contents

8 of 271

Critical Measurements 262

Introduction 262

Needle Drive Stud to Reciprocator Fit 263

Hook Timing 263

Upper Arm to Lower Bed Alignment 263

Needle to Hook Gap 264

Hook to Rotary Support Gap 264

Take-Up Lever Stroke 264

Take-Up Lever Fit to Shaft 265

Take-Up Lever Endplay 265

Cam Follower Preload 265

Pull Force on Take-Up Lever 266

Color Change Lead Screw 266

Color Change Housing Location 267

Bobbin Tension 267

Presser Foot Adjustment at Bottom Dead Center 268

Thread Feed Forward 200 269

Needles 269

Thread Clean Thread Path 270

Z-Belt Tension 270

X-Cable Tension 271

Y-Axis Timing Belt Tension 271

Proper Lubrication of Moving Parts 271

Table of Contents

9 of 271

Copyright Notice

© Copyright Melco, 2014

ALL RIGHTS RESERVED. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means (electronic, mechanical, photocopying, recording or otherwise)

without prior written approval from the author. The author reserves the right to revise this publication

and to make changes in it at any time without obligation of the author to notify any person or organiza-

tion of such revisions or changes.

All precautions have been taken to avoid errors or misrepresentations of facts, equipment, or products.

However, the manufacturer does not assume any liability to any party for loss or damage caused by errors

or omissions.

The machine technology is protected by - but not limited to - the following patents:

• U.S. 4,955,305

• U.S. 6,823,807

• U.S. 5,603,462

• U.S. 5,832,853

• U.S. 6,445,970 B1

• U.S. 6,732,668 B2

• U.S. 6,729,255

• U.S. 6,871,605

• U.S. D 474,785 S

• U.S. 6,736,077 B2

• CH 693569 A5

• EP 0 666 351 B1

• more patents pending

Table of Contents

10 of 271

About This Manual

This manual contains instructions on repairs and adjustments to the embroidery machine, in addition to

other technical information.

If you do not fully understand any information in this manual, you are advised to contact your local au-

thorized technical support provider for assistance.

Table of Contents

11 of 271

Scope of Manual

This technical manual is a guide to performing repairs and adjustments that go beyond routine operator

maintenance.

Although these procedures are best understood and performed by professional service technicians in

conjunction with specic factory technical training, much of the information in this manual is a useful

reference for others who might possess appropriate technical aptitude and skills.

•

Note: This manual is written for individuals with adequate knowledge, Melco certied training

or equivalent and experience in the use of tools required. No attempt is made to explain how

to use tools required to make repairs to the machine other than graphical depictions within the

procedures involved.

This technical manual species that certain functions are to be performed only by authorized service tech-

nicians. This is because specialized training and/or special tools or xtures are required in order to per-

form the function correctly. Performing repairs to the machine may result in damaged components, poor

machine performance, and potential injury to the technician or operator.

If you do not fully understand any information in this manual, contact technical support for assistance

before performing the procedure. The technical support staff are professional service technicians trained

on this equipment. They have acquired technical expertise through experience and technical training.

Additionally, certied equipment technicians routinely receive up to date servicing information to further

enhance their product knowledge.

This technical manual is presented in six sections:

1. Introduction to the manual and various service requirements

2. General information and specications containing all of the engineering settings and specications

you need to know when adjusting the machine

3. Lubrication schedules and procedures

4. Service and repair - detailed instructions to service and repair the machine

5. Options - maintenance and repair of optional equipment

6. Troubleshooting - a troubleshooting guide for problems commonly encountered with the machine.

Table of Contents

12 of 271

Standard Conventions and Denition of Terms

Throughout this manual abbreviations and specic terms may be used. When abbreviations or techni-

cal terms are used, they are dened through the use of pop-up hot spots, which opens a dialog box to

explain their meaning. Hot spot text is green and underlined. To access a pop-up hot spot simply click the

underlined word to read its explanation.

Certain procedures in the manual require actions such as pressing a certain key, or typing some letters on

the computer keyboard. The following is a list of some of the more commonly used conventions found in

this manual:

• To indicate a key on the computer keyboard, the key in question is enclosed in brackets, for exam-

ple: Press the [Enter] key to initiate the application.

• A key on the interface keyboard is represented by a picture of that key.

Attention Styles:

Occasionally in the manual, special attention is required. In these situations, certain images and text styles

are used to attract your attention to a particular message. The following styles are used to denote certain

types of messages.

•

WARNING!! Situations which may result in personal injury if not performed correctly.

•

CAUTION!! Situations that might result in damage to equipment or property but is not likely to

result in personal injury.

•

IMPORTANT: Situations critical to correct machine operation that is not likely to result in damage

to the machine or personal injury.

•

NOTE: Important information that is signicant, but not likely to result in interference to correct

machine operation.

•

TIP: Helpful information that might make a procedure easier or more efcient.

When a reference to a part description is in bold type, that reference is the actual part description as

listed in the machine parts manual. The parts manuals are unique for each machine depending on serial

number and date of build. For part numbers, pictures, and assembly diagrams, refer to the parts manual

issued for that particular machine.

Table of Contents

13 of 271

Regulatory Notices

(U.S.) The FCC (Federal Communications Commission) mandates that if a user makes changes or modi-

cations to the machine not expressly approved by the manufacturer, the user’s authority to operate the

machine may be voided.

Table of Contents

14 of 271

Best Maintenance Repair Practices

The procedures presented in this manual are to be considered best maintenance repair practices. These

procedures are intended to optimize the performance and durability of your machine. Best maintenance

repair practices are to be performed using the correct tools and xtures while adhering to all safety pre-

cautions appropriate for each job.

•

WARNING!! Personal injury may result if proper precautions are not observed. Remove rings,

watches, and any other metallic objects from hands and wrists before servicing the machine.

Remove metallic articles from shirt pockets to prevent them from falling into the machine. Do

not allow loose clothing or long hair contact moving parts of the machine. Under certain con-

ditions of machine failure, the moving parts of the machine may not be controllable by normal

means. At these times, the machine may operate without notice.

•

CAUTION!! Use extreme care not to drop metallic objects, tools, or other conductive material on

the main Printed Circuit Board (PCB) when you have the base cover removed. If you drop such

objects on the main PCB, it can severely damage the electronics which will be very expensive to

repair.

Maintenance Philosophy:

The maintenance philosophy used in this manual is to isolate potential problems within the system to the

smallest practical replacement assembly. Therefore, components are typically not repaired, but rather, a

circuit board or mechanical subassembly may be replaced.

In the process of isolating problems in the machine, the person performing the troubleshooting must also

practice good troubleshooting techniques. Good troubleshooting techniques include, but are not limited

to, guarding against static electricity that can result in further damage to machine components, and only

replacing one part at a time to enable identication of the defective part after the machine is repaired.

•

WARNING!! Failure to practice Best Maintenance Repair Practices may result in injury to person-

nel performing the work and/or damage to the equipment. The warranty is exclusive of, and

may be VOID if poor maintenance practices have caused damage to the equipment.

Dust:

As with any electronics, the worst source for contamination for the PCBs and the Control PCB is dust.

Although great care has been made during the design of the electronics in the machine, dust accumula-

tion may cause failure of the machine if it is allowed to accumulate.

•

CAUTION!! DO NOT use solvents of any type on the printed circuit boards (PCBs) or sensors.

Solvents will damage the electronic components. Use only compressed air to clean these items.

Table of Contents

15 of 271

Using compressed air, blow the dust away from sensors and off the PCB’s in the machine. In addition,

minimize dust accumulation cleaned on all exposed surfaces. Excessive dust will reduce the useful life

span of the machine.

Sensors should be cleaned with dry, compressed air during each of the lubrication cycles. Dust accumula-

tion in the base around the control PCB should be blown out every month or whenever the base cover is

removed for any type of maintenance.

Liquid Cleaning Compounds:

Never spray liquid cleaning compounds directly onto the machine, especially if it is turned on or connect-

ed to an electrical supply outlet. Always spray cleaning compounds onto a rag and wipe the machine

clean. Liquid cleaners can, if sprayed directly on the machine, get onto electrical components and short

them out. Optical sensors are very sensitive and may be damaged by liquid cleaning compounds.

Obstructions:

Obstructions of machine movements can cause severe damage. Obstructions include things like fabric

getting caught in the gears, loose hardware left inside the machine, thread accumulation around the

grabber blade, Velcro, and anything that hinders the machine’s moving parts. It is very important to clear

obstructions from any subsystem immediately before damage or excessive wear occurs.

Use Proper Parts For The Job

It is very important that you use the proper parts for the job, especially needles. Refer to the Operator

Manual for information on needle selection. Using the wrong needle will increase the frequency of frays

and thread breaks and will decrease performance of the machine.

Avoid using substandard substitute parts on the machine. Always use manufacturer distributed parts or

better to ensure superior quality output of your machine. When considering buying substitute parts, i.e.,

hardware, it is strongly recommended that you consult Technical Support and obtain the specications to

ensure that you get the equivalent grade or better parts.

Use The Correct Tools When Making Repairs

Always use the correct tools when making repairs or performing maintenance on the machine. No at-

tempt has been made in this Manual to explain what tools to use. It is assumed that the person who

makes repairs or performs maintenance on the machine has the proper technical aptitude and training to

allow them to do so. Using tools incorrectly or using the wrong tools can cause damage to the machine

and result in personal injury.

The use of poor quality tools such as multimeters and mechanical measuring devices can produce unpre-

dictable and often unsatisfactory results. Always purchase tools for repair or maintenance on the machine

that are of standard design and professional quality. You may if desired, consult Technical Support for

assistance in recommending such tools as multimeters and measuring devices before you purchase them.

Table of Contents

16 of 271

Drive Belt Tensions:

•

CAUTION! Damage to the machine may result if belt tensions are improperly adjusted. All drive

belts require special procedures and tools for setting the proper tensions. If the tension adjust-

ments are made without using the proper procedures and tools (and without training in some

cases), poor performance, excessive wear, damaged components, personal injury, and voided

warranty may result.

Scheduled Maintenance:

Scheduled maintenance is lubrication, cleaning, measurements, and inspections that are specied on a

periodic schedule.

Scheduled maintenance is prescribed in the operator manual for the machine. Failure to perform sched-

uled maintenance will result in poor performance and eventual failure of the machine. In addition, failure

to perform the maintenance prescribed in the operator manual can affect warranty protections.

Lubrication:

Lubrication should be done whenever a part is replaced or repaired and as prescribed according to the

Lubrication Specications. When applying lubricants to any parts, use only the approved lubricants and

application methods specied in the Lubrication Specications.

•

CAUTION! Damage to the machine will result if inadequate or excessive lubrication is applied

to machine parts. Failure to adhere to lubrication specications will result in premature wear,

poor performance, and potential warranty issues.

Torque Measurements:

Apply proper torque to all screws, bolts, and nuts or similar parts used in the machine. Torque speci-

cations are provided for a reason. They have been developed from years of experience with the parts

involved. Avoid guessing at the torque applied to a part and measure it, especially where measurement is

specied.

•

CAUTION!! Inadequate torque can result in premature failure of the part involved, usually

causing it to come loose. Excessive torque usually results in stress to the part that will not al-

ways be detectable. The part can fail later during machine operation and can cause catastroph-

ic machine failure.

Table of Contents

17 of 271

Grounding and Static Electricity

•

WARNING!! It is very important that the power cord is plugged into a properly wired electri-

cal outlet. Failure to have a properly wired outlet may result in damage to the equipment and

personal injury. It is recommended that a licensed electrician be consulted to ensure that the

electrical outlet is properly wired and grounded. If a properly wired electrical outlet is not used

for the source supply voltage to the system, electrical failures may result.

Static Electricity:

As with all computerized equipment, your machine is sensitive to static electricity. Any time work is

performed inside covered areas of the embroidery machine, the person performing the work must use

a static grounding strap or take adequate steps to dissipate static build-up prior to touching electronic

components.

•

WARNING!! Failure to use a grounding strap, or failure to practice other good maintenance/

repair techniques may cause damage to the machine and possible personal injury.

•

CAUTION!! Unless otherwise specied within these procedures, DO NOT disconnect the

electrical supply input cord from the machine or the electrical input source outlet. Doing so will

remove the ground connection needed to dissipate the electrical static build-up prior to work-

ing on the internal components in the machine. Always make contact with the exterior metal

portion of the machine for about one minute to dissipate any electrical static build-up in your

body before touching any electronic component of the machine, especially the main board.

Grounding Strap Use:

A grounding strap should be connected properly to ensure that static charge on the person’s body is neu-

tralized to the chassis ground of the embroidery machine when working in the electronic areas under the

covers. Proper connection is provided at any bare (unpainted) metal surface or any other surface (such as

a ground screw head) that is known to be an earth ground. If a ground strap is not used or is not avail-

able, touch the chassis for about a minute to dissipate any static build-up before you touch any electronic

component inside the machine (with the machine turned off and the power input cord connected to an

electrical outlet).

•

WARNING!! DO NOT attempt to use any grounding strap that is not specically designed for

static use. A “straight-wire” grounding device (one without built-in resistance) will place the

operator in danger of exposure to dangerous voltages. It is recommended that the static strap

be checked during daily use for proper resistance protection.

Table of Contents

18 of 271

•

CAUTION !! Use extreme care not to damage the cable and protective coating during assem-

bly. If the protective coating is damaged, the cable will wear out very fast impacting the quality

of the sew outs.

Table of Contents

19 of 271

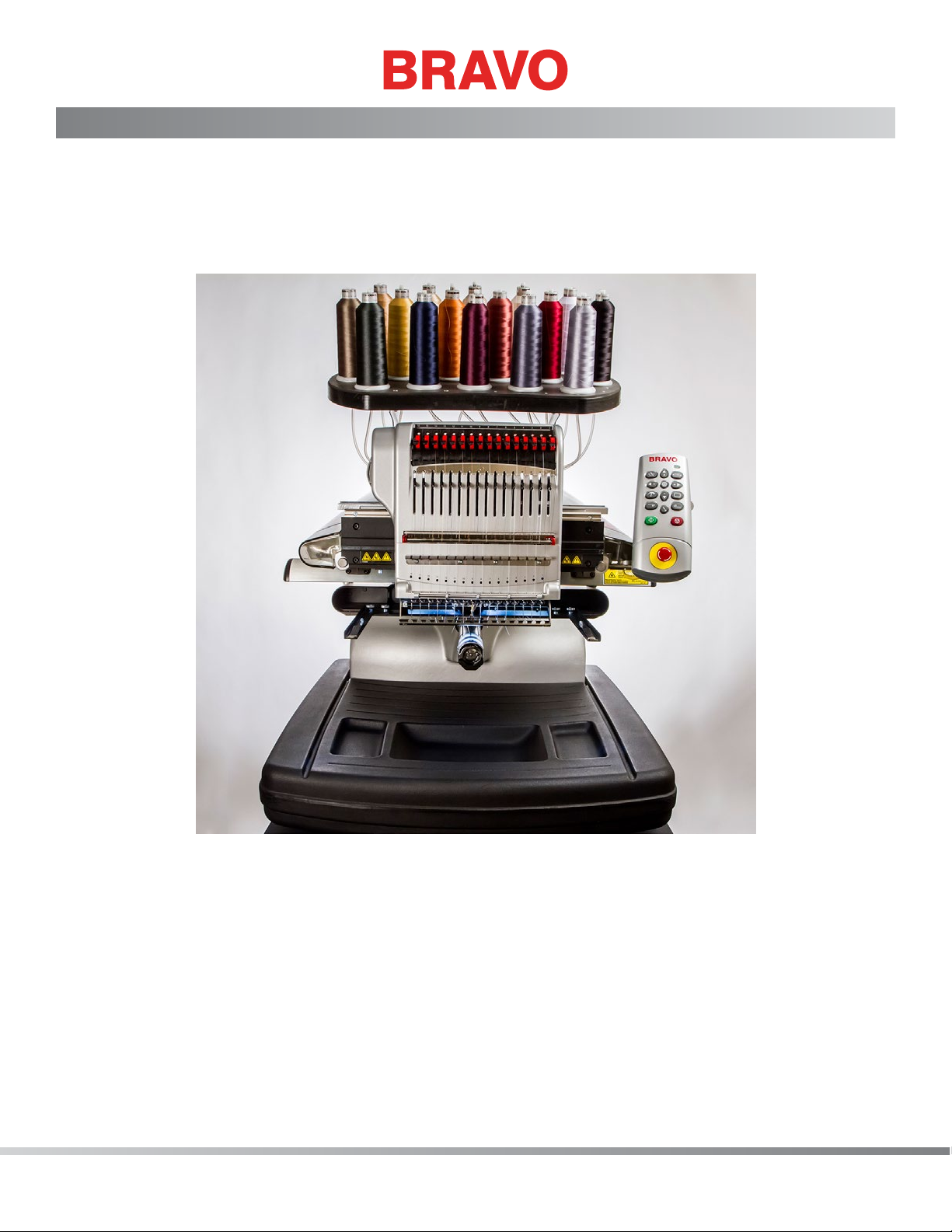

Machine Orientation

The references in the manual to certain sections of the machine are oriented as if you were facing the

front of the machine as shown below. Example: The “left” arm cover is on the left side of the machine

when you face it from the front, but is on the right side if you face it from the rear. The part however, is

called the “left” arm cover since it is installed on the left side, oriented as you face the machine from the

front.

Left Side Right Side

The left and right sides of the machine are oriented just as if you were facing it from the front side of the

machine directly.

The rear of the machine refers to the entire back side of the machine.

The front part of the machine refers to the entire front section of the machine.

The upper arm assembly, lower arm assembly, needlecase, user interface, and thread tree refer to the

entire individual assembly and associated components.

Table of Contents

20 of 271

Safety Issues

Voltages

•

WARNING!! Lethal voltages exist inside the power supply unit, at the back side of the electrical

supply input connector, and in the wires between the two. If you plan to do any work with any

of these components, turn the power switch off and disconnect the electrical input supply cord

from the machine.

•

WARNING!! DO NOT disassemble the power supply unit. It contains no customer or eld ser-

viceable parts. The internal components in the power supply unit may contain dangerous volt-

ages even when the power is disconnected. Disassembling the power supply can cause severe

injury resulting from electrical shock, and may void the warranty.

•

WARNING!! DO NOT operate the machine with the lower rear cover removed, except when

indicated by the instructions in this manual. Operating the machine without the covers creates

a risk of severe electrical related injury.

Hazardous Material Notices:

•

WARNING!! The lubricants specied in this Manual contain known carcinogens. Do not allow

lubricants to come into contact with your eyes, mouth, or nose. Always wash your hands thor-

oughly after performing lubrication procedures.

•

WARNING!! When using solvents to clean components in the machine, always ensure adequate

ventilation. Allow all solvents to completely evaporate before turning the machine back on to

prevent shorting out electrical components. Vapors from most solvents are both toxic and am-

mable. Dispose of rags soaked with solvent properly.

Moving Parts:

•

WARNING!! Do not operate the machine without the covers being installed. Moving parts can

cause crushing and pinching injuries. In addition, fabric and other materials can get caught in

the moving belts and gears and damage the machine.

•

WARNING!! Do not attempt to pull on or trim threads near moving needles. This can result in

painful injury.

Table of Contents

Table of contents

Other Melco Sewing Machine manuals