Melco EP 1 User manual

Installation, Operation, and

Maintenance manual

for the EP 1

embroidery peripheral

• Single head, single needle

• Easy to operate

• Low power consumption

• High-quality results

Part Number 11034, Revision A

1575 West 124th Avenue

Denver, Colorado 80234

United States of America

© Copyright 1998 by Melco Embroidery Systems

ALL RIGHTS RESERVED No part of this publication may be reproduced, stored in a retrieval system,

or transmitted in any form or by any means (electronic, mechanical, photocopying, recording, or

otherwise) without prior written approval of Melco Embroidery Systems. Melco reserves the right

to revise this publication and to make changes in it at any time without obligation of Melco to

notify any person or organization of such revisions or changes.

All precautions have been taken to avoid errors or misrepresentations of facts, equipment, or

products. However, Melco does not assume any liability to any party for loss or damage caused by

errors or omissions.

Printed in the United States of America

Revision A, May 1998

Table of Contents

1. Setup

2. Needles, Bobbins, and Threads

Threading the EP1 2 - 1

Drawing Out the Bobbin Thread 2 - 3

The Bobbin Case 2 - 3

Removal 2 - 3

Winding Thread Onto The Bobbin Reel 2 - 4

Setting the Bobbin 2 - 4

Installation 2 - 5

Setting Thread Tensions 2 - 5

Upper Thread Tension 2 - 5

Bobbin Thread Tension 2 - 5

How to Select a Needle 2 - 6

Needle Replacement 2 - 6

3. Embroidery Hoops

Loading Garments 3 - 1

Round Hoops 3 - 1

Rectangular Hoops 3 - 1

Attaching The Hoop To The Pantagraph 3 - 2

4. Detailed Operation

The Control Panel 4 - 1

The Liquid Crystal Display (LCD) 4 - 1

Start Key 4 - 1

Stop Key 4 - 1

Arrow Keys 4 - 1

Hoop Center Key 4 - 1

Spool Key 4 - 1

Menu Key 4 - 1

Enter Key 4 - 1

Alt Key 4 - 2

The Light Emitting Diodes (LED) 4 - 2

The Operation Menus 4 - 2

Design Menu 4 - 2

Table of Contents

i

Run Design 4 - 2

Frame Menu 4 - 3

Trace Menu 4 - 3

Hoop Selection 4 - 3

Move Menu 4 - 3

Moving The Hoop Numerically 4 - 3

Seeing The Hoop’s Physical Location 4 - 3

Reset Menu 4 - 4

System Reset 4 - 4

Hard Reset 4 - 4

Other Functions 4 - 4

Thread Break 4 - 4

Bobbin Thread Low 4 - 4

Dust Accumulation 4 - 4

Upper Shaft Lock 4 - 4

Hoop Limits 4 - 4

5. Configuration

Unit Number 5 - 1

Display Brightness 5 - 1

Key Click Volume 5 - 2

Error Beep Volume 5 - 2

6. Operator Maintenance

Cleaning 6 - 1

Disassembling the Hook Area 6 - 1

Assembling the Hook Area 6 - 1

General Cleaning 6 - 2

Lubrication 6 - 2

Lubricating the Hook Area 6 - 2

General Lubrication 6 - 2

7. Troubleshooting Guide

Table of Contents

ii

iii

Single-Head Embroidery Peripheral

EP 1 Specifications

Maximum embroidery speed

1000 stitches per minute

Number of Heads

1

Number of needles

1

Dimensions

46cm W x 36cm H x 52cm D

18" W x 14" H x 20.5" D

Weight

26kg

58 lbs

Shipping weight

31kg

68 lbs

Power consumption

60 W; wired for 200V to 250V 50 or 60Hz

2 fuses, 800mA Fast Blow (FB)

Noise level and test conditions

Equivalent continuous A weighted sound pres-

sure level at 1 meter from the machine is 66db.

The peak C weighted instantaneous sound

pressure level is 71db.

The noise level was measured sewing a test

design at 600 spm.

Recommended power conditioning equip-

ment

LC 1800 Line stabilizer (available from

Accessory Resource Corporation)

Embroidering field size

24 x 14cm (9.5 x 5.5")

Compatibility

Premier, EDS-EZ, and EDS III

Intended use

The EP 1 is designed to embroider on textile

products which are placed easily in a Melco

embroidery hoop. The machine should not be

used on thick leather, wood, plastic, or other

dense material.

Table of Contents

iv

Explanation of Symbols

Caution!

Indicates a machine component will move. Keep clear!

Shock hazard. No user replaceable parts behind this label. Do not open!

Pinch point, Keep clear!

Pinch point, Keep clear!

Pinch points, Keep clear!

Needle pinch point, Keep clear!

1-1

1. Setup

The setup procedure for the EP 1 Embroidery Peripheral is easy and will only take a few minutes.

1. Carefully remove the machine from the shipping container, using care not to drop or damage

any other items packed around it. The machine is heavy, so be careful. Place the machine on a

sturdy table or work bench.

NOTE: Be sure to save the shipping container and packing supplies that your embroidery periph-

eral came in. If your machine should ever require factory service, it should be returned in

the original (or other equally suitable) shipping container.

2. Make certain the machine’s power switch is turned to the OFF position.

3. Plug one end of the power cord into a wall outlet. A

surge protector is recommended but not required.

Plug the other end into the machine.

4. Connect the peripheral to your controller or host

computer using the network cable. Plug the net-

work cable into either of the network ports, as

shown in Figure 1-1. Plug the terminator cable into

the other network connector. It does not matter

which cable is plugged into which connector.

5. Your machine may have come with a needle already

installed, but it is a good idea to start your sewing

with a new needle.

6. Locate the thread guide bar and gently pull it

upward until it reaches its maximum height. It will

extend like a car antenna. Rotate the guide bar until

the ends are aligned over the thread cones on the

base below (see Figure 1-2).

7. Your machine may have come with thread already

loaded on the bobbin, but check to make certain.

8. Load a spool of thread onto the thread stand and

thread the machine as required.

At this point your EP 1 should be ready to begin sewing.

If you should encounter any problems during this procedure, contact your local Melco representa-

tive for assistance, or call Melco’s Technical Support line.

11034 Rev. A 1. Setup

Figure 1-1

Network cable

Terminator cable

Figure 1-2

1-2

EP 1 Operation Manual Melco Embroidery Systems

Hazards of operation

Caution! Below are risk areas or danger points encountered dur-

ing operation. Always wear eye protection while operating the

machine to prevent injury in the event of a needle break. Do not

wear loose or baggy clothing when operating the machine.

Take-up Lever Oscillation

Do not touch the take-up levers during operation.

Exposed Needles During Operation

Do not place body parts or other foreign objects under the needles

during operation.

Rotary Hook Rotation

Do not attempt to change bobbin thread during operation. Do not

place hands or other objects in the rotary hook area during operation.

Do not operate the machine without the hook guards in place.

1-3

Dangers de service

Attention! Ci-dessous vous trouverez les descriptions de diverses zones

de risque ou points dangereux lors du service de la machine. Il faut tou-

jours porter des lunettes protectrices pendant le service de la machine

afin d'éviter des blessures en cas d'une casse d'aiguille.

11034 Rev. A 1. Setup

Oscillation du releveur de fil

Ne pas toucher les releveurs de fil pendant le service.

Aiguilles exposées pendant le service.

Ne mettre ni de parties du corps ni d'autres objets au-dessous

des aiguilles pendant le service.

Rotation de la navette rotative

Ne pas essayer de changer la canette pendant le service. Ne

pas mettre ni les mains ni d'autres objets dans la zone de la

navette rotative pendant le service. Ne pas mettre la machine

en marche sans avoir mis en place les gardes du ramasseur.

1-4

EP 1 Operation Manual Melco Embroidery Systems

Betriebsgefahren

Vorsicht! Nachfolgend sind Risikobereiche und Gefahrenpunkte genannt,

die während des Betriebs auftreten können. Tragen Sie immer einen

Augenschutz, wenn die Maschine in Betrieb ist, um Verletzungen im Falle

eines Nadelbruchs vorzubeugen. Tragen Sie keine weite oder lockere

Kleidung, wenn Sie die Maschine bedienen.

Hin- und Herbewegung des Fadengebers

Die Fadengeber nicht berühren, wenn die Maschine in Betrieb

ist.

Offenliegende Nadeln während des Betriebs

Körperteile fernhalten und keine fremden Gegenstände unter

die Nadeln legen, wenn die Maschine in Betrieb ist.

Umdrehung des Umlaufgreifers

Die Garnspule nicht austauschen, während die Maschine in

Betrieb ist. Die Hände vom Umlaufgreifer fernhalten oder

andere Gegenstände nicht in den Bereich des Umlaufgreifers

bringen, wenn die Maschine läuft. Die Maschine nicht bedi-

enen, wenn der Greiferschutz nicht an seinem Platz ist.

1-5

Pericoli nel funzionamento

Attenzione! Di sotto vengono descrite le zone di rischio o i punti peri-

colosi che potreste incontrare durante il funzionamento. Portate sempre

degli occhiali prottetivi mentre comandate la macchina, per pervenire il

ferimento in caso di rottura di ago.

11034 Rev. A 1. Setup

Oscillazione delle leve d'avvolgimento

Non toccate le leve durante il funzionamento

Aghi esposti durante il funzionamento

Non mettete delle parti del corpo o altri oggetti stranieri sotto

gli aghi durante il funzionamento.

Rotazione del perno girevole della bobina

Non provate a ricambiare la bobina di filo durante il funziona-

mento. Non mettete le mani o altri oggetti sul perno girevole

della bobina durante il funzionamento.

1-6

EP 1 Operation Manual Melco Embroidery Systems

Risco de funcionamento

Atenção! São a seguir indicadas áreas de risco ou zonas perigosas encon-

tradas durante o funcionamento. Usar sempre protecção para os olhos ao

comandar a máquina para evitar ferimentos no caso de quebra de agulhas.

Não use vestuário solto ou desapertado quando trabalhar com a máquina.

Oscilação da alavanca de enrolamento

Não toque nas alavancas de enrolamento durante o seu fun-

cionamento.

Agulhas à vista durante o funcionamento

Não coloque partes do corpo ou objectos estranhos por baixo

das agulhas durante o funcionamento.

Rotação do gancho rotativo

Não tente mudar fios das bobinas durante o funcionamento.

Não ponha as mãos ou outros objectos na área do gancho rota-

tivo durante o funcionamento. Não trabalhe com a máquina

sem os resguardos dos ganchos estarem instalados.

1-7

Peligros durante el funcionamiento

¡Atención! A continuación se mencionan las zonas de riesgo o los puntos

de peligro con los que se podrían encontrar Vds. durante la maniobra.

Utilicen siempre gafas protectoras cuando operen la máquina a fin de pre-

venir heridas en caso de rotura de la aguja. No lleven vestidos holgados

mientras están operando la máquina.

11034 Rev. A 1. Setup

Oscilación de la palanca de compensación (entrega-hilo)

Eviten tocar las palancas de compensación (entrega-hilo)

durante el funcionamiento.

Agujas al descubierto durante el funcionamiento

Eviten colocar partes del cuerpo u otros objetos debajo de las

agujas durante el funcionamiento.

Rotación del gancho giratorio

No traten de cambiar el hilo inferior de bobina durante la

operación. Eviten colocar las manos u otros objetos en la área

del gancho giratorio durante el funcionamiento. No accionen la

máquina sin el dispositivo de protección del gancho en su sitio.

1-8

EP 1 Operation Manual Melco Embroidery Systems

2-1

2. Needles, Bobbins, and Threads

This chapter covers how to thread your machine, select and install needles, wind the bobbin reels,

and properly set the upper and lower thread tensions.

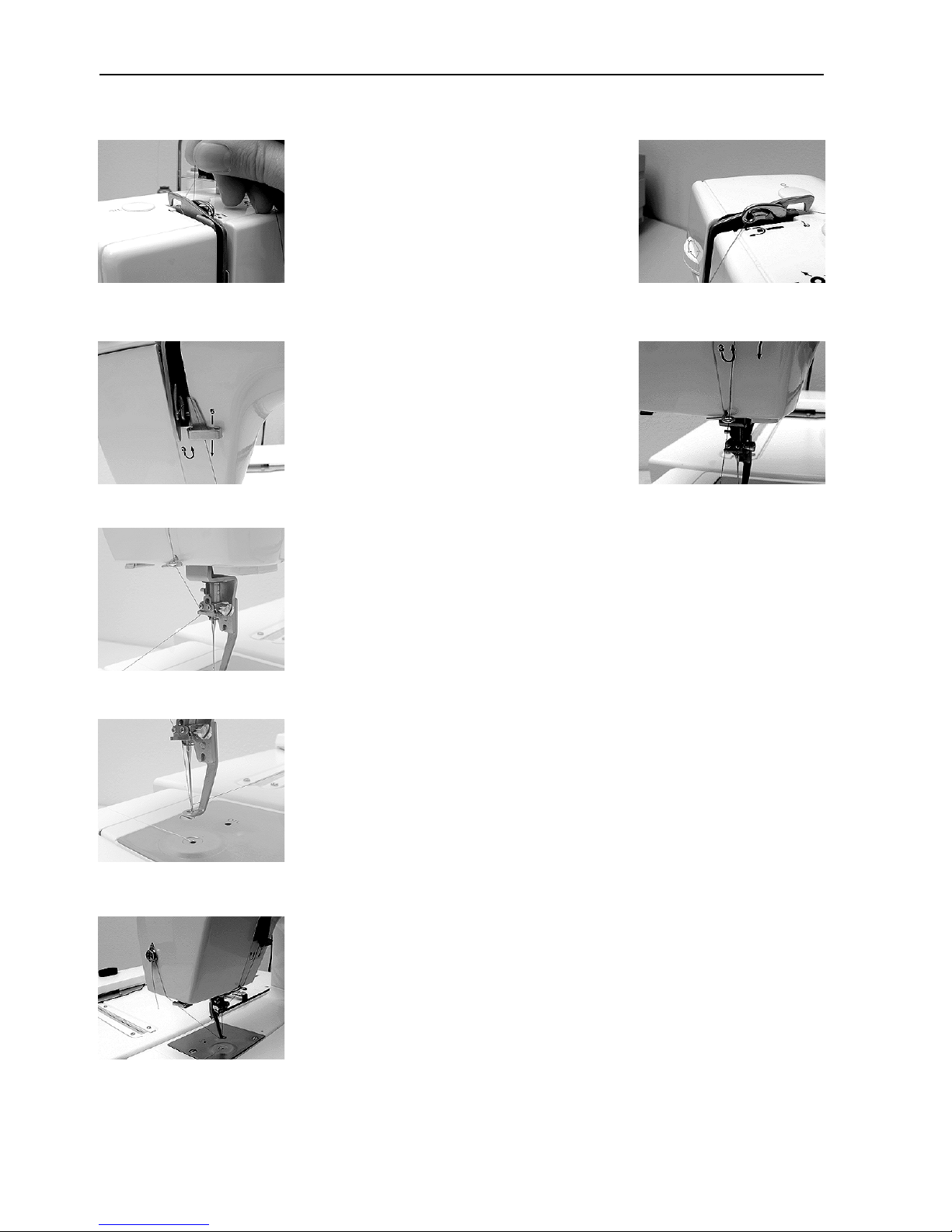

Threading the EP 1

1. When routing the thread, apply a

small amount of pressure on the

supply spool to prevent the thread

from unwinding too quickly .

2. Hook the thread onto the thread

guide mounted above the supply

spool.

3. Pass the thread into the right hole

of the top plate thread guide from

the front to the back. Bring the

thread over the top of the same

thread guide and pass it into the left hole, again from the front to the back (refer to Figure 2-

1).

4. Hook it around the back of the tension disc (A) 1/2 turn in a counter-clockwise rotation (refer

to Figure 2-1). Use the rear tension disk (B) instead of (A) only when the Isacord thread is

used.

11034 Rev. A 2. Needles, Bobbins, and Threads

Figure 2-1

Threading

diagram

Thread

guide

Thread B

A

Figure 2-2

5. Pass the thread into the rear hole of the thread tension unit, with

the thread between the thin metal piece and the bar.

Figure 2-3

6. Pull the thread under the take-up spring and up the right side of

the thread tension unit, passing it under the take-up spring.

2-2

EP 1 Operation Manual Melco Embroidery Systems

Figure 2-4

7. Pass the thread through the embroidery

thread take-up lever from the left to the

right; and then pull it downward toward

the first lower thread guide.

Figure 2-5

Figure 2-6

8. Hook the thread into the two lower

thread guides as you continue to pull it

downward.

Figure 2-7

Figure 2-8

9. Hook the thread into the needle bar thread guide from the left

side.

Figure 2-9

10. Pass the thread into the needle from the front to the rear (use a

threader if desired).

Figure 2-10

11. After threading the needle, position the embroidery thread through

the presser foot hole. You may do this now by threading it as you

would the eye of a needle or in the following procedure while

drawing out the bobbin thread.

2-3

The Bobbin Case

Removal

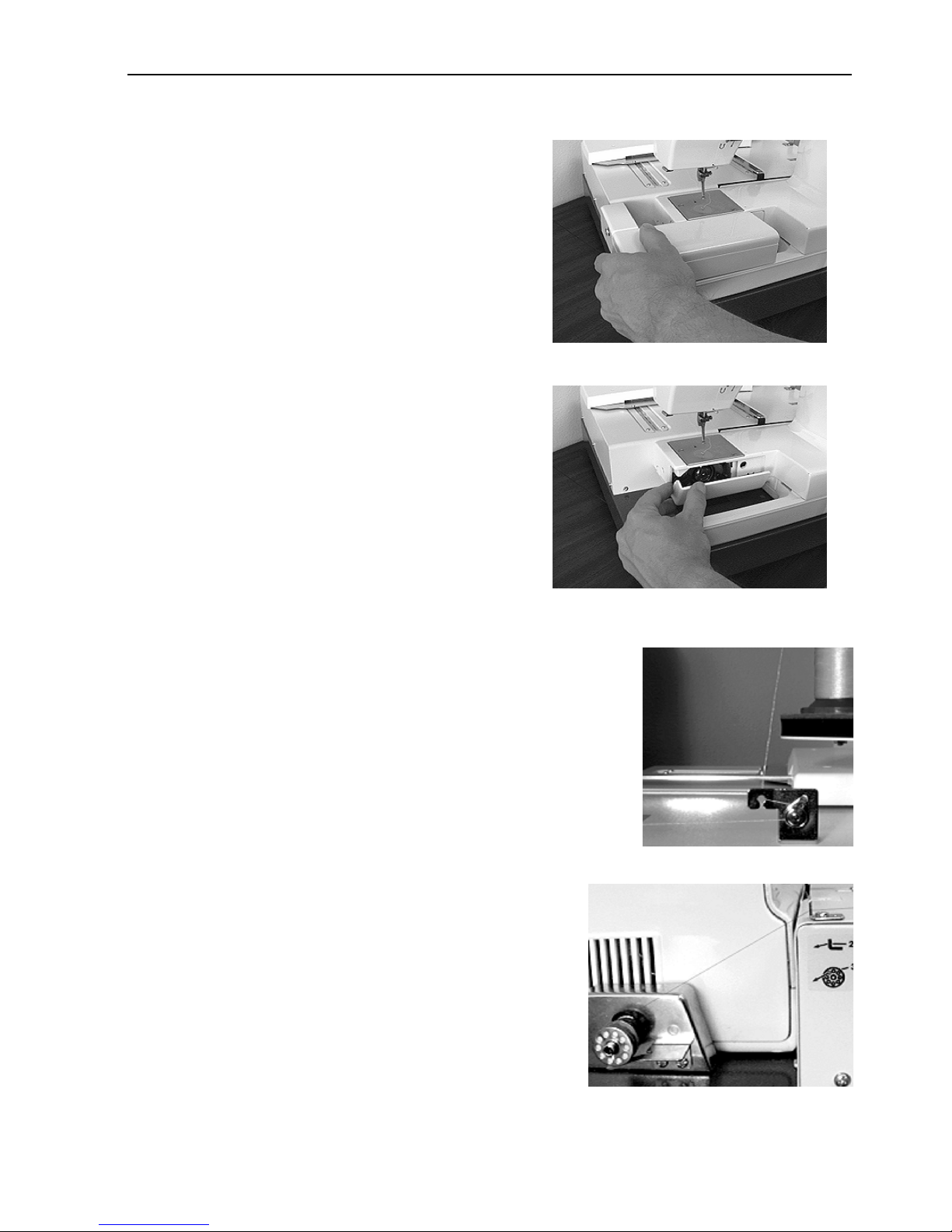

1. After turning off the power switch, lift the needle

above the throat plate by rotating the flywheel.

2. Remove the auxiliary table by lifting slightly at its

left front and sliding it off to the left.

3. Open the bed cover by placing your finger at the

left rear of the cover and flipping it forward and

down to its opened position.

4. Pull out the bobbin case lever and remove the

bobbin case from

NOTE: The hook area must be kept clean to avoid

thread breakage problems! If you find any

thread debris at this time, clean it out.

Winding Thread Onto The Bobbin Reel

The bobbin winder can wind bobbin thread anytime, even while

embroidering, because the bobbin winder is an independent part of

the embroidery machine.

1. Attach the bobbin reel onto the bobbin winding shaft, and push

the bobbin winding shaft downward.

2. After hooking the bobbin thread onto the thread guide above the

bobbin thread cone, route the thread through the first thread

guide, and then the second guide, in this order. Each thread

guide features a thread path diagram, as shown in Figures 2-13

and 2-14.

3. Pass the thread through a bobbin reel hole from the inside

of the wall to the outside.

4. Press and hold the [SPOOL] key until the bobbin begins

turning.

NOTE: If the [SPOOL] key is not held down long enough, the

bobbin will not turn.

11034 Rev. A 2. Needles, Bobbins, and Threads

Figure 2-11

Figure 2-12

Figure 2-14

Figure 2-13

2-4

EP 1 Operation Manual Melco Embroidery Systems

5. After the thread has been wound completely, the bobbin reel will continue to spin for a few

moments before stopping.

6. After the bobbin reel has stopped turning, cut the thread and remove the bobbin reel from

the bobbin winding shaft.

7. If the thread was cut or if thread cannot be wound on the bobbin reel normally during thread

winding, the thread winding can be stopped by pressing the [SPOOL] key again.

Setting the Bobbin

After thread has been wound onto the bobbin reel and the bobbin reel is placed into the bobbin

case, install the bobbin case into the hook body.

NOTE: Turn the power switch OFF when putting the bobbin case into the hook body.

1. Hold the bobbin case in your left hand so the open side is facing toward you.

2. Hold the bobbin reel in your right hand.

NOTE: It is recommended that you orient the bobbin reel so the thread is coming off in a clock-

wise direction. However, some users feel that orienting it with the thread coming off in a

counter-clockwise direction is better. Either way is acceptable.

3. Place the bobbin reel into the bobbin case.

4. Grasp the end of the thread, and pass the thread into the bobbin case slit.

5. Draw the thread under the tension plate and out the opening in the bobbin case, then pass

the thread into the hole of the bobbin case horn (use the aid of the threader if desired).

6. Draw out the thread about 4 inches (10cm).

7. Set the bobbin thread tension.

Installation

1. To install the bobbin case into the hook body, pull out the bobbin case lever as you do when

you remove the bobbin case (the bobbin does not

fall out of the case when the lever is held out).

2. Position the bobbin case horn so it points

upward. Set the horn into the concave portion of

the hook body as you insert the bobbin case onto

the post in the middle of the hook body.

3. Release the bobbin case lever and check that the

lever has grasped the end of the post, thus secur-

ing the bobbin case in the hook body. Figure 2-15

2-5

Drawing Out the Bobbin Thread

After setting the bobbin thread and threading the embroidery thread, draw the bobbin thread out

of the needle plate hole as follows:

1. Hold the end of the embroidery thread by the left hand. Do not stretch it so tightly that the

needle tip is deflected.

2. Lower the needle once, and lift it again by rotating the flywheel toward you (counterclock-

wise) with your right hand.

3. After the embroidery thread take-up lever has reached the top, pull slightly on the embroidery

thread, and the bobbin thread will come through the needle plate hole.

4. Pull the drawn bobbin thread to the left, and hook it to the thread holder of the auxiliary

table.

5. Pull the embroidery thread loop to the left from below the Presser Foot, thus allowing it to

pass through the bottom hole.

6. Hook the embroidery thread to the thread holder on the left side of the faceplate. Take up any

looseness, and hang it down about 1 1/4 inches (3cm).

7. Use the face plate thread cutter to cut any surplus thread to a suitable length.Setting Thread

Tensions

Setting Thread Tensions

Upper Thread Tension

The upper thread tension wheel works best when set between 4 and 5 on the numbered dial. A

higher number on the dial will increase the tension and a lower number will decrease the tension.

Experimentation with different threads and fabrics will give you experience on how to set the

upper thread tension to best suit your needs.

Bobbin Thread Tension

For the best possible results, it is important to use the bobbin reels and bobbin thread that was

furnished with your machine. Most pre-wound bobbins do not work well with the EP 1. Melco

recommends the use of Rasant bobbin thread, which is available from Accessory Resource

Corporation.

1. Put the filled bobbin reel into the bobbin case. Make certain the thread goes through the slit

in the side of the case and under the tension plate.

2. Support the bobbin case with one hand and lift the thread with the other hand.

3. Dangle the case by the thread. The tension should be tight enough that the case is supported

by the thread. If the thread unwinds from the reel too easily, the tension must be increased.

Tighten the setscrew (clockwise) on the outside of the case.

11034 Rev. A 2. Needles, Bobbins, and Threads

2-6

EP 1 Operation Manual Melco Embroidery Systems

4. Gently jiggle the case like a yo-yo. The tension should be loose enough that a small amount of

thread (about an inch) unwinds from the reel, then stops. If no thread comes out, the tension

must be decreased. Loosen the setscrew slightly (counter-clockwise), then jiggle the case

again.

5. Once the tension has been set properly, put the thread through the hole in the horn that is

attached to the bobbin case, then install the case into the machine.

How to Select a Needle

The EP 1 embroidery machine uses a Class 15 household sewing machine needle. The following

needle types are given to help guide you in selecting the proper needle for your various embroi-

dering situations. This is only a suggestion, and you should choose your needles in the future

through experience you gain while embroidering.

HA x 1 65/9 sharp: for embroidering a thin material, like a pocket in the lining of a coat.

HA x 1 75/11 sharp: standard, applicable to almost all embroidering.

HA x 1 90/14 sharp: for embroidering a thick material, like a canvas bag.

65/9 ball point, 75/11 ball point, & 90/14 ball point: for knits, sweaters, & other delicate gar-

ments.

Needle Replacement

1. With the power switch turned OFF, raise the needle above the needle plate by turning the fly-

wheel counter-clockwise.

2. Loosen the needle clamp screw with a screwdriver.

3. Remove the needle by pulling it down and out of the needle clamp.

4. Check the new needle for a flat portion on the shank. If there is a flat, rotate the needle so

the flat is facing to the rear of the machine. This automatically positions the needle properly

for installation. If no flat is on the shank of the new needle you must orient the needle with

the “scarf’ facing to the rear of the machine. This will leave the ”thread groove" of the needle

in the front. (You can easily feel the groove by rubbing your finger nail across the front of the

needle.)

5. Insert the new needle fully into the needle clamp until it touches the pin.

6. Tighten the needle clamp screw securely.

Table of contents

Other Melco Sewing Machine manuals