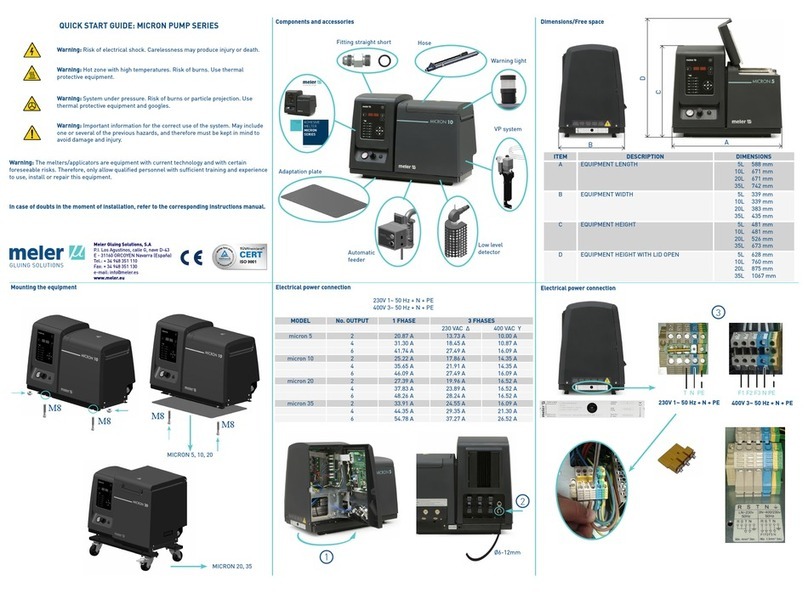

Control card Selecting the overheating value/ Standby

Temperature adjustment

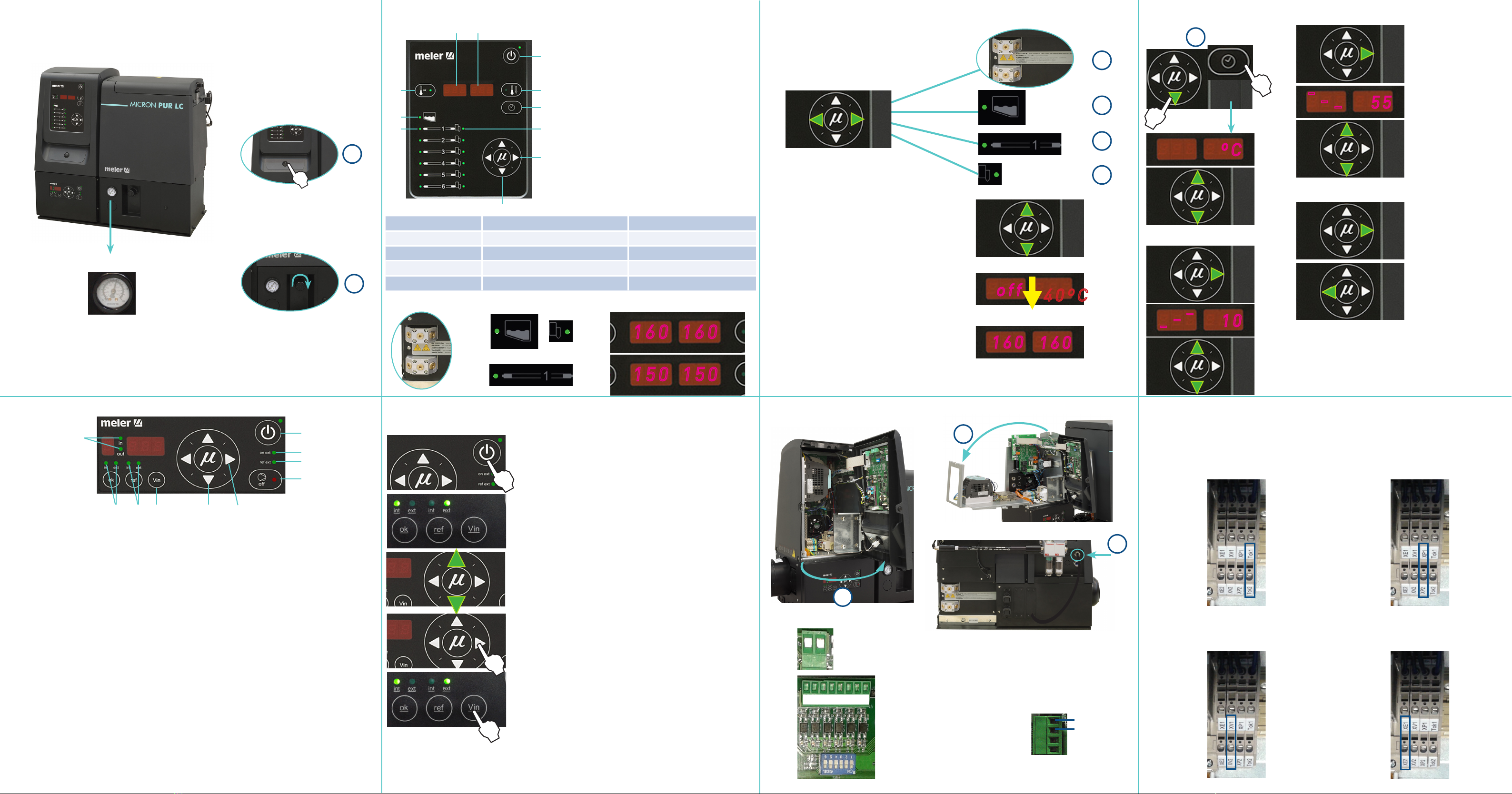

External I/O connections (optional) External I/O connections (optional)

For each following signals, connect each wire in the terminals indicated:

Starting up the melter equipment

8

1

2

11

9

3

10

7

6

4 5

1. Tank indicator LED

2. Hose indicator LED

3. Gun indicator LED

4. Temperature set point

5. Actual temperature

6. ON/OFF switch

7. Standby function

8. Temperature OK LED and active pump

9. Time scheduling

10. Left/right button - channel selection

11. Up/down button - temperature modification

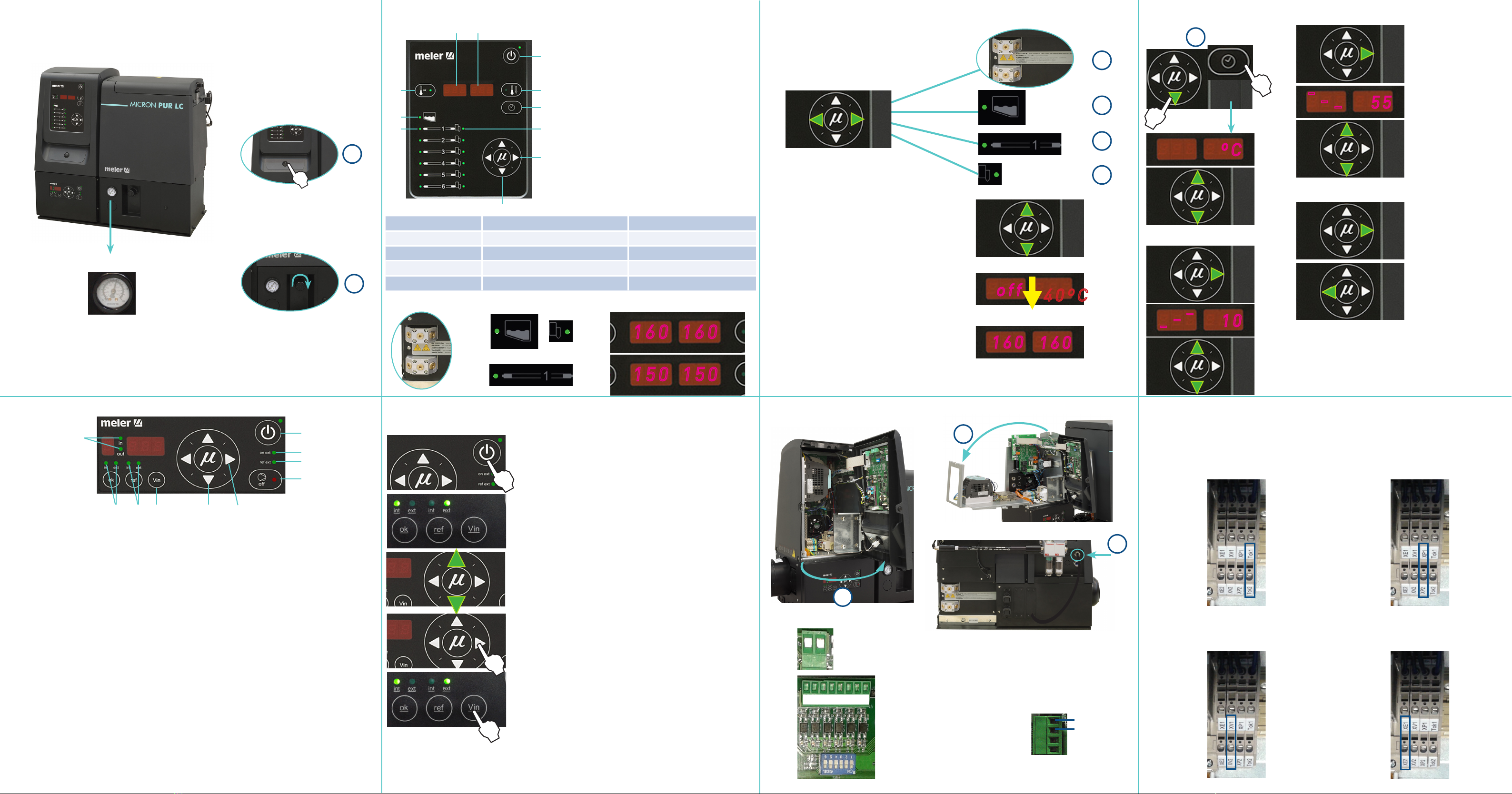

1. Control card ON/OFF LED.

2. Pumping ON/OFF LED.

3. Internal and external (ok) LEDs.

4. Internal and external (ref) LEDs.

5. On ext LED (external start-stop).

6. Ref ext LED (external reference).

7. In/Out LED to program the speed ramp.

8. Voltage value display.

9. Up/down arrow keys for selecting values.

10. Left/right arrow keys for selecting options.

To start working, select the appropriate mode of operation:

1. Internal pumping and speed control.

2. Internal pumping control and external speed control.

3. External pumping control and internal speed control.

4. External pumping and speed control.

To activate the start-up status, all of the following conditions must be met:

1. The equipment temperature is OK.

2. That pumping is enabled (red LED is turned off).

3. If the external ‘ok’ mode (start-stop) is selected, the external ‘ok’ input (E3) must be activated.

4. The failure input is not activated. For more information about the different functions of the pump control card, refer to the

corresponding instructions manual.

160160

150150

Select the element

Modify temperature

Below of 40ºC, temperature

display and heating OFF

Tank’s set point Tª value by default

3

1

2

4

off

40ºC

160

160

-

--

55

-

--

10

ºC

Return to initial

parameter

Next display to record the

value

Next display to record the

value:

1

OVERHEATING

10< Increase Tª < 25

STANDBY

25<Decrease Tª %< 55

CN 1

Power card

LOW LEVEL

1

2

1 contact NO

2 contact NO

Default values

1

2

Pump control card Speed working adjustment

Temperature OK

Since this contact is not under voltage, there is no

connection polarity.

Motor speed set point (ref ext)

The positive signal wire must be connected to point XV2 of

the terminal, while the negative wire must be connected

to point XV1.

Motor start up (ok ext)

Since this contact is not under voltage, there is no

connection polarity.

Failures output in pump control card

Since this contact is not under voltage, there is no

connection polarity.

1

5

6

2

4 8 9 103

71. Press the ON/OFF button to light up the control card.

2. Select the pumping mode ‘ok’ and the speed control ‘ref’.

In case of internal speed control, using the up/down arrows,

select the rotation speed.

3. The selected value is set pressing the right arrow key after

blinking three times.

In case of external speed control, the system will wait for the

speed signal from the main machine. Keeping the ‘Vin’ key

pressed will show the voltage sent by the main machine.

LED DISPLAY COMPONENT HEATING COMPONENT STATUS

constantly lit constant low temperature

blinking slowly as need (according to PID parameters) temperature near set point

blinking rapidly programming or display change in set point values

off not heating temperature reached

For more information about the different functions of the control card, refer to the

corresponding instructions manual.

On/ Off

1

2

P pneumatic P hydraulic

Ratio 1:15

3

Ø4-8mm

CN 5 CN 4

Control card

contact NO

contact NO

STANDBY

1 common and voltage out +

2 input for inhibitor output 1

3 input for inhibitor output 2

4 input for inhibitor output 3

5 input for inhibitor output 4

6 input for inhibitor output 5

7 input for inhibitor output 6

8 without connection

OUTPUT DISABLED

8 7 6 5 4 3 2 1