Memtech AT3550 Wolverine User manual

AT3550 3.5” Wolverine

3.5” IDE Solid State Flash Drive

User Guide

80-03-00035

Revision 1.1

February 11, 2005

Memtech SSD Corporation

7628 Las Positas Road

Livermore, CA 94550

(925) 294-8483

(800) 445-5511

www.memtech.com

AT3550 User Guide V1.00 February 11, 2005 page 2 of 16

Table of Contents

1. HIGHLIGHTS...............................................................................3

2. INTRODUCTION..........................................................................3

3. INSTALLATION ...........................................................................4

3.1 PROCEDURE ...........................................................................................................4

3.2 JUMPERS................................................................................................................7

3.3 IDE INTERFACE.......................................................................................................9

4. OPERATION..............................................................................11

4.1 ACTIVE REMAP™ AND WRITE LIMITATIONS ..............................................................11

4.2 ECC......................................................................................................................11

4.3 POWER ................................................................................................................12

4.4 TROUBLE SHOOTING GUIDE ....................................................................................13

5. MAINTENANCE.........................................................................13

6. SPECIFICATIONS .....................................................................14

6.1 INTERFACE ...........................................................................................................14

6.2 PERFORMANCE .....................................................................................................14

6.3 ENVIRONMENTAL...................................................................................................14

6.4 POWER REQUIREMENTS ........................................................................................14

6.5 MECHANICAL.........................................................................................................15

6.6 RELIABILITY ..........................................................................................................15

7. APPENDIX.................................................................................16

7.1 CONTACT INFORMATION .........................................................................................16

7.2 ATA SPECIFICATION INFORMATION.........................................................................16

7.3 LIMITED LIFETIME WARRANTY ................................................................................16

AT3550 User Guide V1.00 February 11, 2005 page 3 of 16

1. HIGHLIGHTS

• 12 Gbyte capacity under 16mm (0.63”)

• 60 Gbyte maximum capacity

• Full -55oC to +125oC military temperature range

• 3.5” drive low profile form-factor

• UDMA-66 compliant IDE interface

• 16 byte CRC/ECC and Active Remap™ for exceptional data reliability

• Kicker™ Hold Up Circuit

• Active Remap™ Data Reliability Feature

• 5 volt, low power operation

• Completely solid state - no moving parts

• 2000G operating shock

• 20G operating vibration

• 0.1 millisecond random access time

• 26 Mbyte/sec cached Read performance

• 20 Mbyte/sec cached Write performance

• 8 year product warranty

• 8 million erase/write cycle endurance

2. INTRODUCTION

The AT3550 “Wolverine” is a series of IDE solid state drives available in a low-

profile 3.5-inch format. The drive is completely solid state, making it exceptionally

rugged and able to operate in extreme environmental conditions.

Sector Erasable NAND E2PROM (Flash) is used to provide over 60 Gbytes of

nonvolatile, solid state storage in an extremely small, rugged form factor. The

drive is 100% IDE compatible and requires no special drivers to operate. It is

essentially a drop in replacement for standard rotating media.

The IDE interface is implemented using a commercially available IDE controller. It

supports UDMA-66 transfers, LBA mode addressing, and incorporates a 1 Mbyte

buffer, and a 16-byte hardware error detection and correction logic. The

CRC/ECC circuitry, in conjunction with Memtech’s proprietary Active Remap™

technology, makes for a virtually bulletproof medium for data retention.

The drive is available in a number of standard capacities ranging from 1 to 60

Gbytes. Drives under 12 Gbytes are 16mm tall, while 60 Gbyte capacity drives

are under 35.5mm.

Each drive is fully tested under environmental extremes at the factory using

Memtech’s proprietary EnduroTest™ to guarantee data integrity in even the

harshest conditions. Full functionality of the product is guaranteed out of the box.

AT3550 User Guide V1.00 February 11, 2005 page 4 of 16

3. INSTALLATION

3.1 PROCEDURE

3.1.1 ESD PRECAUTIONS

The AT3550 is sensitive to static electricity. Before handling the AT3550, please

observe the following precautions to avoid ESD damage to the unit:

• Keep the drive in its shielded bag until ready to install.

• Ground yourself by touching a grounded chassis frame of the computer, or

use a grounded wrist strap before and during the installation process.

• Do not touch the exposed drive electronics or connectors. Always handle the

drive by the edges or mounting rails.

3.1.2 CONFIGURATION

Before applying power to the drive, configure the drive using the jumper diagrams

given in Section 3.2. The default configuration is for a single drive system or as

the master in a two-drive system. Change the configuration as required. Never

attempt to change the jumpers while the drive is plugged in and the computer is

on.

3.1.3 CABLE

With the computer off, attach the 40-pin, 0.1inch cable to the unitized IDE

connector on the drive. Note pin 1 orientation and alignment. Care should be

taken when installing the cable, as misalignment can permanently damage the

drive interface. Attach the separate power cable using the 4-pin AT Power

connector.

The AT3550 is UDMA66 compliant with the appropriate cable. If the host system

does not detect the correct cable type, the interface will restrict transfers to

UDMA33 speeds or slower. The type of cable is detected using the signal CBLID.

On UDMA66 compliant cables, this signal is grounded.

AT3550 User Guide V1.00 February 11, 2005 page 5 of 16

3.1.4 CONNECTOR

The drive may be interfaced directly to a standard 3.5”, 0.1in IDE socket connector

or a standard 40pin IDE ribbon and AT power cable. See drawing below for pin 1

location. Care should be taken when installing the AT3550 into the system, as

misalignment can permanently damage the drive interface connector or

electronics.

Figure 1 - Drive Connector

3.1.5 MOUNTING

The AT3550 may be mounted in any orientation. A total of four bottom and six

side mounting holes are available for installation. The mounting holes require 6-

32 screws with a maximum depth of 0.25 inch.

The diagram given below is valid for all capacities of the AT3550 drive. The

overall outside dimensions are 4 inches (101.7 mm) wide, 5.75 inch (146.05mm)

long, and 0.630 inch (16mm) tall. Please refer to the following drawing for

dimensions and mounting hole locations.

The diagram given below is for a 12 Gbyte drive. Drives with higher capacities will

be 0.760 inches (19.3mm) or taller. All other dimensions remain identical.

AT3550 User Guide V1.00 February 11, 2005 page 6 of 16

3.1.6 COMPUTER SETUP

To be recognized by the computer, the drive translation information must typically

be entered into the System Setup or CMOS Setup utility. For non-PC compatible

computers, this may not apply. The AT3550 supports automatic configuration if

offered by the BIOS. Automatic CHS translation and LBA mode is also supported.

3.1.7 PARTITION

The drive must be partitioned using the system’s FDISK utility. For operating

systems other than DOS, please refer to your OS operating guides. Note that

changing the partition information will erase all data currently on the drive. Refer

to your OS manual for information regarding partitioning a hard disk.

3.1.8 FORMAT

The AT3550 is low-level formatted at the factory, which establishes the 512-byte

sector size. A high-level format is required after the partition has been established

on the drive. Refer to your OS manual for information regarding hard disk drive

format procedures.

AT3550 User Guide V1.00 February 11, 2005 page 7 of 16

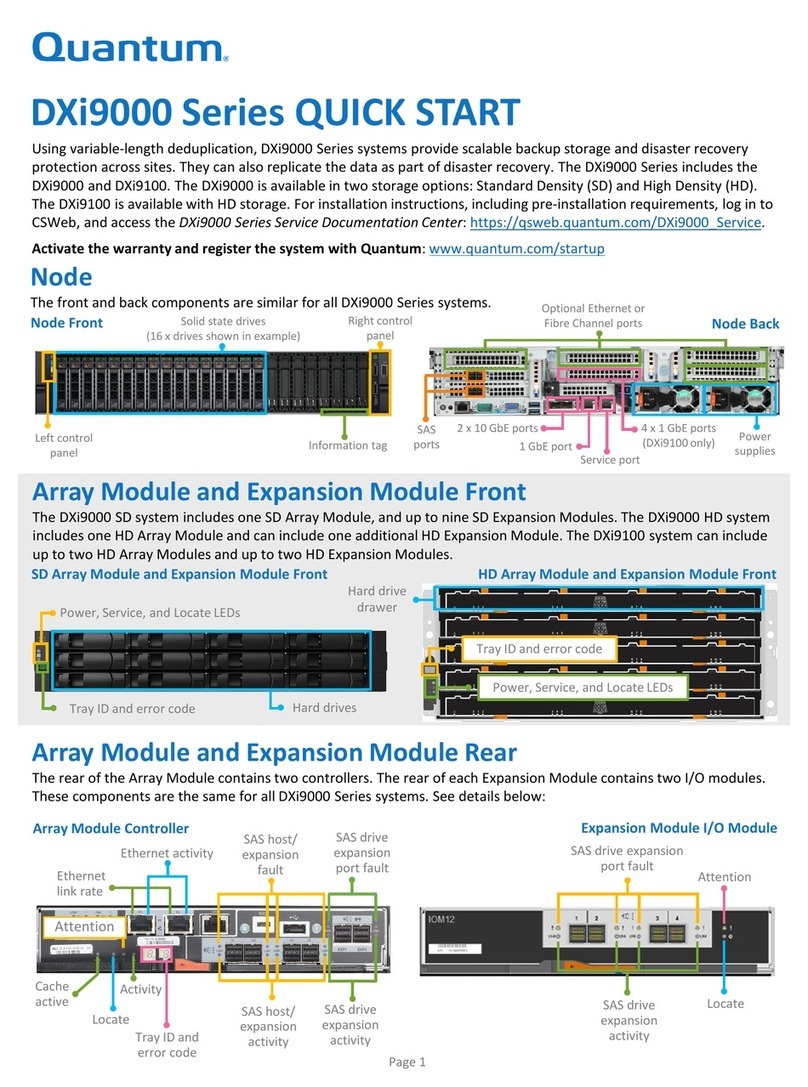

3.2 JUMPERS

The following diagram illustrates the locations of the jumpers on the AT3550

controller card. The jumpers are found on both the J1 interface header and the J2

jumper header. Refer to the illustration below. The option jumpers control the

master/slave configuration of the drive, the use of cable selection, drive write

protection, and other factory related functions. All headers are on 2mm centers.

3.2.1 MAIN HEADER (J1) JUMPERS

3.2.2 MASTER/SLAVE

If no jumper is installed or the MA jumper is in place, the drive is selected as the

C: or Master drive. If the drive is to be a Slave device (drive D), install the jumper

ion the SL location. This jumper is part of the unitized ATA interface header and is

on 0.1 inch centers. This location is factory shipped with no jumper or with the

jumper in the MA position, configuring the drive as the master drive.

3.2.3 CABLE SELECT

Jumper CS can be used to let the IDE Cable Select signal select the drive

configuration as either the master or slave device. Shorting the CS pins enables

the Cable Select feature. Leaving the pins unconnected disables the Cable Select

feature. The drive is factory shipped with these pins open.

3.2.4 WRITE PROTECT

The WP jumper is used to write protect the drive. Installing this jumper on either

the J1 or J2 header forces the drive to a write-protect condition, blocking any and

AT3550 User Guide V1.00 February 11, 2005 page 8 of 16

all writes from occurring. This jumper must be prior to the drive powering up to be

recognized.

3.2.5 OPTION HEADER J2

The Option Header is located on the LED-side of the drive, as illustrated below:

J2 Option Jumpers,

2x6, 2mm

WP

OPT1

OPT2

T

X

LED

R

X

XP

GND

Jumper Header – J2

3.2.6 WRITE PROTECT

The WP jumper on header J2 is used to write-protect the drive. The default

position of this jumper is OFF. Installing the WP jumper inhibits all further writes

to the drive, while read accesses occur as normal.

WP: Write Protect

configured for normal

operation --

j

umper off

3.2.7 OPTION JUMPERS

The OPT1 and OPT2 jumpers are used for factory test functions or special

functions only, and should always be left open.

AT3550 User Guide V1.00 February 11, 2005 page 9 of 16

OPT1,2: Option Jumpers

configured for normal

operation -- jumpers off

3.2.8 TX/RX CONNECTIONS

The TX and RX connections are for manufacturing use only.

TX/RX: RS232

Communications

GND

GND

RX

TX

3.2.9 EXTERNAL POWER

The XP pins on the Option Header are used to connect external standby power to

the drive. These pins are connected to the Kicker™ Holdup Circuit. Applied

power should be 5 volts +/- 10%. Do not exceed 6 volts on this line, as internal

damage to the drive may result.

The two outside pins on the header are used to connect power to the holdup

circuit. A third pin is needed to connect the grounds of the drive to the power

source.

Jumper Header – J2

XP

XP

GND

GND

GND

3.3 IDE INTERFACE

The AT3550 uses a unitized ATA connector that combines the 40-pin 0.1” IDE

header, the 4-pin AT Power connector, and an 8-pin option jumper header

mounted on the drives controller PCB. Maximum cable length is 18 inches.

Recommended cable length is 12 inches or less, especially if an advanced PIO or

UDMA transfer modes are being used. To achieve full drive performance, a

UDMA cable is required.

AT3550 User Guide V1.00 February 11, 2005 page 10 of 16

3.3.1 IDE CONNECTOR PHYSICAL ORIENTATION

The diagram below depicts connector orientation and location.

3.3.2 IDE CONNECTOR PINOUT

The following table depicts the 40-pin, 0.1 inch signal cable interface pin out.

PIN SIGNAL PIN SIGNAL

1 RESET- 2 GND

3 DATA7 4 DATA8

5 DATA6 6 DATA9

7 DATA5 8 DATA10

9 DATA4 10 DATA11

11 DATA3 12 DATA12

13 DATA2 14 DATA13

15 DATA1 16 DATA14

17 DATA0 18 DATA15

19 GND 20 KEY (NO PIN)

21 DRQ 22 GND

23 IOW- 24 GND

25 IOR- 26 GND

27 IOCHRDY 28 CSEL

29 DACK- 30 GND

31 IRQ 32 IOCS16-

33 ADDR1 34 PDIAG-

35 ADDR0 36 ADDR2

37 CS0- 38 CS1-

39 DASP- 40 GND

AT3550 User Guide V1.00 February 11, 2005 page 11 of 16

4. OPERATION

4.1 ACTIVE REMAP™ AND WRITE LIMITATIONS

Unlike mechanical drives, wherein the wear-out mechanism results from starting

and stopping the platters and the rotation of the spindle motors, the wear-out

mechanism for any solid state flash drive resides in writing to the non-volatile

memory, which in Memtech's case is NAND E2PROM. Writing the to the memory

devices requires that electrons be first removed from, and then trapped on the

floating gate in each cell using Fowler-Nordheim tunneling techniques. This

process is inherently harsh on the oxide layer isolating the floating gate from the

silicon substrate in the device, and establishes the write cycle endurance of each

cell in a device as specified by the device manufacturer.

To overcome this limitation, Memtech Solid State Flash Drives have been

designed with Active Remap™, which, on a detected cell failure, moves the

entire failing block to a reserved location and maps the failing block out of

active memory. This process is automatic and invisible to the user. It

extends the device's useful life almost 100 fold, and makes the Memtech

series of Solid State Drives suitable for both read mostly and read/write

applications.

In an ongoing effort to determine the durability of the flash components and

in turn extend the life of our products, Memtech has also conducted several

endurance tests using our flash drives. The results were very

encouraging. During testing, done under both benign and harsh operating

conditions, Memtech observed and documented an erase/write cycle

endurance of 8 to 30 million cycles. This is compared to the flash

manufacturer's test and report of only 100,000 to 250,000 erase/write

cycles for the flash devices.

Reading the NAND E2PROM has no adverse effects on the storage cells or

oxide layers, and is therefore unlimited.

4.2 ECC

The NRZ data interface used by the IDE controller implements a CRC/ECC

mechanism to detect and correct any errors in the data stored in the flash. This

polynomial is capable of correcting three 8-bit data bursts in a single sector, and

detecting up to six 8-bit error bursts per sector.

An extensive retry algorithm is implemented on the AT3550, so that single event

disturbances such as ESD can be readily overcome. Probability of miscorrection

is approximately 10-20 per bit corrected for a 512-byte field.

AT3550 User Guide V1.00 February 11, 2005 page 12 of 16

4.3 POWER

4.3.1 POWER DOWN

Whenever possible, do not power down the computer during a write command

sequence to any mass storage device. This includes during the normal operation

of the drive, and with the use of disk cache programs such as Microsft®

SmartDrive. If a write routine must interrupted, use the push button reset or a soft

reset. Powering down the AT3550 while it is being written may cause an

incomplete write sequence, and leave as many as 32 sectors with an Address

Mark Found Error or Uncorrectable Errors. DOS will report these with a message

“Error Reading Drive C:”.

4.3.2 POWER SUPPLY

The AT3550 voltage requirement is specified at +5 volts, +/- 5% on the drive itself.

Operation outside of these limits is not guaranteed. Note that the drive will

“operate” down to 4 volts, but reliability issues such as Uncorrectable Errors or

invalid data reads may occur. An on board voltage monitor will inhibit writes when

the supply voltage falls below 4.70 volts, thus preserving data integrity on the

drive.

4.3.3 POWER ROUTING

To avoid “glitches” or noise on the Vcc and ground lines, power in the system

should be routed so that all peripherals are sourced directly from the power supply

as opposed to routing a single continuous supply line to each device in the system

as in daisy chaining. Routing power in the star configuration, as is done on most

desktop PCs, will minimize the effect of one device’s current draw on another

device. This is key to maintaining data integrity on the AT3550. See diagrams

below.

Power Supply Power Supply

Floppy

Hard Disk

Main Board

Floppy

Hard Disk

Main Board

Star Topology Daisy Chain - Do Not Use

AT3550 User Guide V1.00 February 11, 2005 page 13 of 16

4.4 TROUBLE SHOOTING GUIDE

4.4.1 SELF-TEST DIAGNOSTIC CODES

The AT3550 has been designed to issue blink codes via the LED in the event of a

low-level or catastrophic failure. A blink code of five would be defined as five fast

blinks, a pause with no blinks, and a repeat of the process. The drive will not

respond to commands or a soft reset when in this state. Only powering down the

drive will clear the drive state and restart internal diagnostics.

Blink codes and their associated failure mechanisms are defined below. In the

event a blink code is encountered, contact the factory for further assistance.

Number of

Blinks Error

2 ROM Firmware Checksum error

3 ASIC initialization error

4 SRAM Test failed

5 IDE buffer failure

6 IDE controller error

7 NRZ data path error

4.4.2 UNCORRECTABLE ERRORS

If a drive has been subjected to a power down during a write command, or as

been run under marginal or dirty power conditions, uncorrectable errors may be

introduced into the media. This may result in data read errors, a corrupted FAT

table entry or directory, or an invalid boot partition or partition table. Microsoft®

Scandisk or Norton Disk Doctor™will successfully correct FAT table problems and

partition table errors, but should not be allowed to mark a sector in the data area

as bad. On a rewrite to a data sector with uncorrectable errors, all synchronization

and ECC codes will be rewritten and the error will be eliminated.

5. MAINTENANCE

No maintenance is required during the normal use of this drive.

If data is to be archived for long periods of time (> 10 years), it is recommended

that the data on the drive be refreshed every 5 to 10 years. The manufacturer of

the NAND E2PROM devices will only guarantee data integrity for a period of 10

years. Programs such as Norton Speedisk©, which reallocates all sectors on the

drive, or Microsoft®Scandisk, which writes and reads every sector on the disk

during its surface test, achieve this end very well.

AT3550 User Guide V1.00 February 11, 2005 page 14 of 16

6. SPECIFICATIONS

6.1 INTERFACE

IDE Compatibility ATA6 - T13/1410DR2A

IDE Drive Number Drive 0 or 1

Raw Physical Capacity 12288 Mbytes under 16mm

61440 Mbytes maximum

Physical Sector Size 512 bytes

6.2 PERFORMANCE

Average Access 0.1 ms

Track/Track Access 0.1 ms

Onboard Cache 16 Mbytes

Cached Read Transfer 26 Mbytes/sec

Cached Write Transfer 20 Mbytes/sec

Read Transfer Rate 9.5 Mbytes/sec sustained

Write Transfer Rate 5.0 Mbytes/sec sustained

Burst Transfers 66 Mbytes/sec

6.3 ENVIRONMENTAL

Commercial Temperature Range

Operating 0oto 70o C

Storage -65oC to 125oC

Extended Temperature Range (E)

Operating -20oC to 75oC

Storage -65oC to 125oC

Industrial Temperature Range (I)

Operating -40oto 85oC

Storage -65oto 125oC

Military Temperature Range (M)

Operating -55oto 125oC

Storage -65oto 125oC

Shock - operating 1000G, 0.5ms half sine, MIL-810F, method 516.5

Vibration - operating 15G Random, MIL-810F, method 514.5

Airflow None required

Humidity 5% to 95% NC (target)

6.4 POWER REQUIREMENTS

Voltage 5V +/- 5%

Current 4 Gbyte drive

Idle 160 mA

Read 350 mA

Write 320 mA

AT3550 User Guide V1.00 February 11, 2005 page 15 of 16

6.5 MECHANICAL

Length 5.750 inches (145.05 mm)

Width 4.006 inches (101.75 mm)

Height -

Up to 12288 Mbytes 0.630 inches (16.00 mm)

Add. 8192 Mbytes 0.130 inches (3.30 mm)

Cable Interface 40-pin, 0.1”

Max. Cable Length 18 inches (460 mm)

Rec. Cable Length 12 inches (305 mm)

Weight (4 Gbytes) 7.9oz (246g)

6.6 RELIABILITY

6.6.1 ERROR CORRECTION

A programmable 96-bit Reed-Solomon Error Correction and Detection capable of

correcting three random byte errors per sector.

6.6.2 MEMORY CELL ENDURANCE

8 million write/erase cycles (excluding ECC and Active Remap™).

6.6.3 DRIVE ENDURANCE

800 million write/erase cycles minimum with ECC and Active Remap™ enabled.

Read endurance is unlimited.

AT3550 User Guide V1.00 February 11, 2005 page 16 of 16

7. APPENDIX

7.1 CONTACT INFORMATION

For Technical Support or Warranty Repair information, please contact Memtech

at:

Memtech Technology

7628 Las Positas Road

Livermore, CA U.S.A. 94551

phone: (925) 294-8483

toll free: (800) 445-5511

7.2 ATA SPECIFICATION INFORMATION

Information regarding the ATA6 specification may be obtained from the following

locations:

AT-Attachment Document Distribution

Global Engineering

15 Inverness Way East

Englewood, Co. 80112-5704

Phone: (303) 792-2181 or (800) 854-7179

Fax: (303) 792-2192

ATA Anonymous FTP Site

http://fission.dt.wdc.com

7.3 LIMITED LIFETIME WARRANTY

Memtech warrants your AT3550 against defects in material and workmanship for

the life of the drive. The warranty is void in the case of misuse, accident,

alteration, improper installation, misapplication or the result of unauthorized

service or repair.

The implied warranties of merchantability and fitness for a particular purpose, and

all other warranties, expressed or implied, except as set forth in this warranty,

shall not apply to the products delivered.

In no event shall Memtech be liable for any lost profits, lost savings or other

incidental or consequential damages arising out of the use of, or inability to use,

this product.

BEFORE RETURNING PRODUCT, A RETURN MATERIAL AUTHORIZATION

(RMA) MUST BE OBTAINED FROM MEMTECH.

Product shall be returned to Memtech with shipping prepaid. If the product fails to

conform and warranty repair is necessary, Memtech will reimburse customer for

the transportation charges incurred.

Table of contents

Other Memtech Storage manuals

Popular Storage manuals by other brands

Fujitsu

Fujitsu ETERNUS DX100 S3 user guide

Spectra Logic

Spectra Logic Spectra 12K supplementary guide

IBM

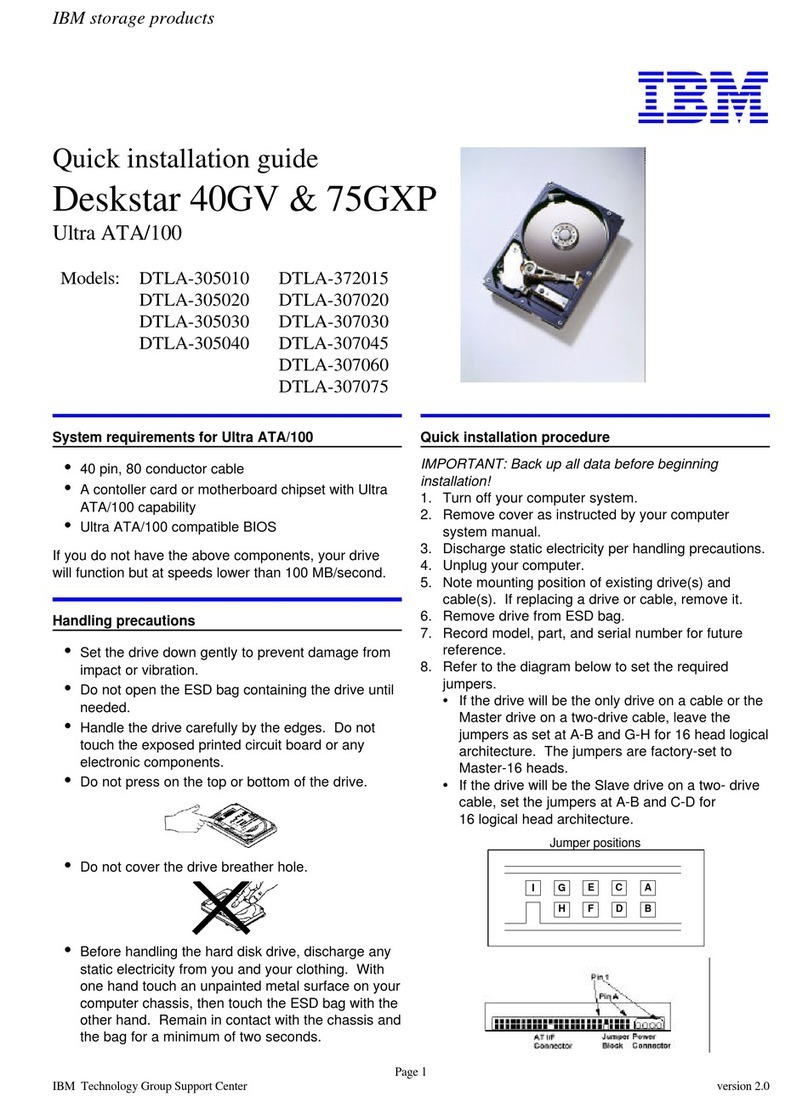

IBM Deskstar 40GV Quick installation guide

Buffalo

Buffalo LinkStation LS-LGL user manual

Rockler

Rockler Pack Rack BDL7878 instructions

Seagate

Seagate ST9500421AS - Momentus 7200 FDE 500 GB Hard... product manual