mensor 9424 User manual

Operation Manual –PN 0040032001CS

Mensor Model 9424

Special Application Pressure Controller

Mensor Model 9424

Special Application Pressure Controller

Version 2.04.00 To 2.04.02

Mensor Model 9424 Special Application Pressure Controller

Manual PN 0040032001CS

Table of Contents

General Description.......................................................................................................... 1

Precautions ........................................................................................................................ 2

Unpacking and Initial Setup............................................................................................ 3

Pressure Connections...................................................................................................... 3

Electrical Connections.................................................................................................... 4

Operation........................................................................................................................... 4

Front Panel Operation.................................................................................................. 5

Keypad Entry Function............................................................................................... 5

Jog Functions.............................................................................................................. 6

Control Output Drivers............................................................................................... 6

Mode Selection and Display....................................................................................... 7

Unit Selection and Display ......................................................................................... 7

Control Stable Display................................................................................................ 7

Setup Button…………………………………………………………………………8

Setup - Jog (Small)………………….………………………………………………..8

Setup –Transducer Offset (Cal Zero)………………………………………………..8

Setup –Transducer Multiplier (Cal Span)…………………………………………...8

Pressure Setting Display……………………………………………………………..9

Pressure Reading Display……………………………………………………………9

Set Point Display......................................................................................................... 9

Info Display ................................................................................................................ 9

Remote Computer Controlled Operation................................................................... 9

Command Set.............................................................................................................. 9

Typical Operating Processes...................................................................................... 15

Calibration....................................................................................................................... 16

Tuning…………………………………………………………………………………. 17

Storage and Transportation........................................................................................... 19

Maintenance .................................................................................................................... 19

Specifications................................................................................................................... 20

Measurement Specifications ...................................................................................... 20

Control Specifications................................................................................................. 20

General Specifications................................................................................................ 21

Appendix.......................................................................................................................... 23

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 1

Mensor Model 9424

Special Application Pressure Controller

General Description:

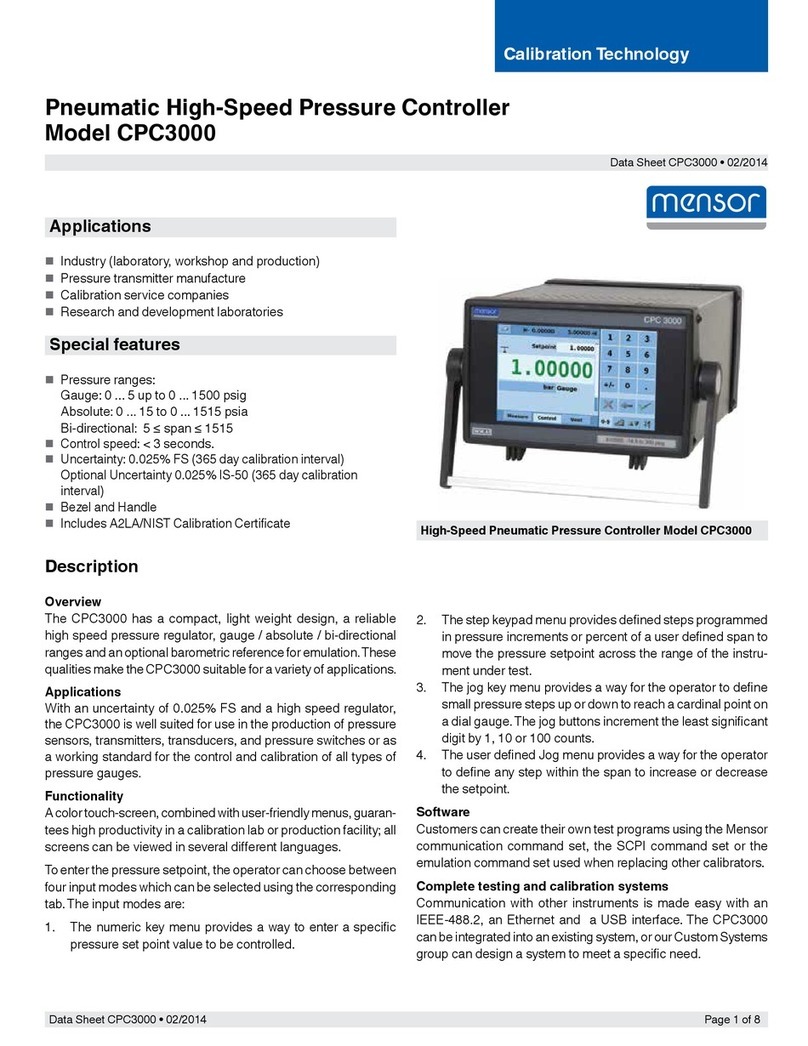

The Mensor Model 9424 Special

Application Pressure Controller is a

single-channel pneumatic pressure

monitor/controller/calibrator. The range

of the instrument is preset by the

customer and can be up to 1500 psi

gauge or absolute pressure. The unit is

optimized for high-speed pressure tests

into volumes from near zero to 11 liters

or more. The instrument utilizes the

Mensor Series 6100 Digital Pressure Transducer for measurements. The transducer can

be mounted in a special design allowing rapid exchange of the transducer from the front

panel to facilitate external calibration. The standard Series 6100 transducers have an

accuracy of 0.010 % of span and a precision of 0.003 % of span with a 180-day

recommended calibration interval. (The Series 6180 can be offered in certain ranges with

higher accuracy and a 365-day recommended calibration interval.) The 9424 is housed in

an aluminum chassis having dimensions of 14.02” (35.61 cm) wide, 7.55” (19.2 cm)

high, and 12.42” (35.61 cm) deep. All porting extends from the rear of the chassis and

adds additional depth depending on fittings and connections to the unit. An optional rack

mount configuration is available for a standard 19” instrumentation rack, 4U height.

The front panel contains a color LCD monitor with a touch screen. Manual operation of

the 9424 is through the front panel. External pressure porting and electrical signal

connections are provided on the rear of the unit. Pressure ports include a supply input

port for clean dry inert media (air or nitrogen

preferred), a vacuum or exhaust port, and either a

single measure/control port or separate measure input

and control output ports. If separate measure and

control ports are installed, a pneumatic connection

manifold is provided (designated as the Remote

Pressure Sense Manifold, PN: 0017905001) to connect

the measuring port to the pressure output port near the

test volume. The advantage of this configuration is to

improve control speed with long hoses and large

volumes. Electrical connections consist of an RS-232

Serial Port for connection to a user computer and four

individual driver outputs to control external devices using 12 volt DC, 1 Amp drive.

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 2

The instrument accepts

universal AC power (90 to

260 Volts AC, 50 or 60 Hz,

100 Watts). Power is

brought into the 9424 on a

standard IEC 320 power

entry module on the rear

panel. A power switch is

contained on the module

along with fuses and line

filters. Power is fused on

both the hot and neutral AC

lines entering the unit. No

switching or adjustments

are required.

Internally all components are powered by 5 Volt and 12 Volt DC supplies.

The Mensor 9424 communicates with a user-provided computer over a 3-wire RS-232

serial connection at a Baud of 57600, 8 data bits, 1 stop bit, and no parity.

Precautions:

1. The 9424 has a maximum supply pressure rating of 165 psi gauge for low-

pressure instruments and 1500 psi gauge for high-pressure instruments and a

recommended supply input of 110 % of the maximum installed transducer range.

The internal transducer has a burst rating of approximately 1.5x the full-scale

pressure.

2. The 9424 can operate in system configurations containing large pressure

storage tanks. Large vessels even at fairly low pressures can hold large amounts

of kinetic energy. Users should safely bleed all pressure stored in the tanks before

servicing, removing pressure hoses, or removing instruments. For units

configured below 400 psi, powering down the instrument should start the venting

process to relieve pressure from both internally and externally connected vessels,

but due to the size of the tanks and the desire to maintain a safe discharge rate;

this operation can take an extended period of time to achieve. Units configured

above 400 psi may require manual venting prior to powering down to discharge

pressure. If the exhaust port is connected to a vacuum device, a relief valve may

be required to protect the vacuum device from overpressure. If the exhaust port is

unconnected a muffler may be required to reduce noise on higher pressure

systems.

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 3

3. In control mode pressure is discharged through the exhaust port on the rear

panel. In vent mode pressure is discharged through an internal port. On units

configured above 400 psi, the internal vent port will be fitted with a muffler.

4. The system uses normal power line AC voltages. The user should remove the

AC power cord from the mains

when servicing inside the 9424

chassis.

5. Any maintenance or

troubleshooting should be

performed by users knowledgeable

in pneumatic pressure

instrumentation and electronic

equipment.

Unpacking and Initial Setup:

The initial installation should include removing any packing material used in shipment

and inspecting that fittings and screws are snug, and that hoses and electrical cords are

not chaffed or cut. The Model 9424 should be installed on a level surface with adequate

airflow to keep the system within its 15 to 45 C optimum operating temperature range.

The system operates on line voltages between 90 and 260 VAC, 47 to 63 Hz. A source of

dry inert gas media is required for operation. This supply for full operation should be

approximately 110 percent of the range of the instrument, but should not exceed 165 psi

for low-pressure instruments (or 1500 psi gauge for high-pressure instruments.) Mensor

recommends that the gas supplied should be instrument quality. If compressed air is used

it should be a quality class of 1.2.1 or better as defined by ISO Standard 8573.1. This

limits dirt particles to less than 0.1 microns, a water pressure dew point of -40 C or lower

at 100 psig, and oil vapor of less than 0.008 ppm.

Pressure Connections:

The supply pressure should be connected to the rear panel lower left port labeled as

SUPPLY. The pressure should be approximately 110 % of range. For sub-atmospheric

pressure control, a vacuum pump is required and should be connected to the pressure port

labeled EXHAUST. If only pressures above barometric pressure are required, no vacuum

pump is needed and the EXHAUST port should be left open. If a pump is not used and

exhaust noise is excessive, a pressure muffler can be installed on the exhaust port.

Mensor can provide recommendations on a suitable muffler. Porting on the rear of the

9424 are female 7/16-20 SAE straight thread. Adapters are provided to convert to ¼”

tube fittings or optionally 6 mm metric fittings on the exhaust or supply ports.

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 4

For units with individual measure and control ports,

connection to the user’s device under test (DUT)

should be made with the Remote Pressure Sense

Manifold provided and shown to the right. This

manifold connects the MEASURE INPUT port and

the CONTROL OUT port of the 9424 closer to the

actual test device. Mensor provides two 2-meter

hoses to connect the two ports on the 9424 to the

two ports on the Remote Pressure Sense Manifold.

The DUT output port on the manifold should

connect to the DUT or near the DUT. The Remote

Pressure Sense Manifold ports are 7/16-20 SAE

straight thread. An adapter is provided to convert to ¼” tube fitting or optionally 6 mm

metric fitting on the “To DUT” output.

On units with a single measure/control port, connection to the user’s device under test

should be made directly. Long hose lengths or small hose diameters serving large

volume loads may require a 9424 with separate measure and control ports and the use of

a Remote Pressure Sense Manifold. (Consult the factory if the unit has difficulty

controlling large volumes.)

Electrical Connections:

The communication port on the rear of the instrument is provided for connection to a

user's computer. A short 9-pin male to 9-pin female D-Sub cable is provided to connect

to a PC serial port. The length of this cable can be extended if desired by the user.

Mensor recommends that a shielded cable be used and conform to local EMI standards.

On the rear panel, four Control Signals are available to drive external loads/devices.

Each of the four drives is capable of driving 1 Amp loads at 12 volt DC. Wiring is done

through a removable terminal block labeled from left to right as OUT1, OUT2, OUT3,

and OUT4. Front panel touchscreen buttons and remote commands allow user control of

these drive lines.

Operation:

Generally, the system once configured requires power, clean dry pressure media, and

possibly a vacuum source for sub-atmospheric control and near-atmospheric control.

Start-up operation commences when power is applied. The internal normally open vent

valve(s) should immediately energize to seal the system to prepare for operation. The

processor and display should go through internal self-tests and display the operating

screen within approximately 45 seconds.

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 5

Front Panel Operation:

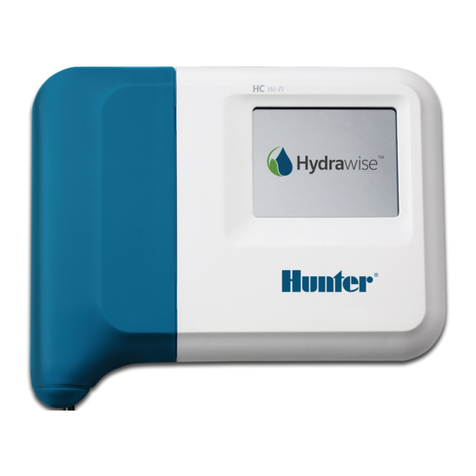

The 9424 powers up into the default

operating screen in the default mode of

measure and with the control set point

equal to the first pressure measured.

The screen is subdivided into functional

sections. The top row identifies the

instrument type. On the far right is the

numeric keypad, below the keypad are

the control jog functions, and below the

jog functions are the toggle buttons for

the external control signals. On the far

left of the screen is a large window

displaying the control set point value

near the top and the current measured

pressure reading below the set point value. The measured pressure reading also acts as

the pressure stable indicator. The reading is green if the pressure is stable and yellow if

the pressure is driving to a new control point. Below this window are 6 buttons labeled

Meas Mode, Ctrl Mode, Vent Mode, Unit Chg, Setup Scrn, and Edit Setup. The first

three buttons change the mode of operation from measure to control to vent. The Unit

change button brings up 4 menus of pressure units that can be selected. Pressing one of

the unit buttons immediately changes the set point value and the reading value to the new

units of measure. On initial power-up, the setup/status window is normally displayed

below the 6 buttons. The window can be called up if the SETUP SCRN, or EDIT

SETUP button is pressed. This window displays the model, serial number, pressure

range, stable window(stable tolerance), jog values, and transducer zero and span.

Keypad Entry Function:

The keypad (light blue in color)

normally found on the right side of

the screen is used for multiple

numeric data entries. Normally at

power up and whenever the set

point window is pressed, the

keypad is used for entering a

control set point value. This is

designated at the top of the keypad

with the word “SETPT:”. As

numeric values are entered they are

displayed in the window next to

“SETPT:”. The ‘CE’ key can be

used to clear the last keystroke and the ‘X’ key deletes the entire entry. Once the correct

value is entered, the ‘=’ key is used to accept the value and display it in the actual

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 6

Pressure Setting window. If the ‘=’ key is pressed with no new value entered, no changes

will be made to the value and the last value will be retained.

The EDIT SETUP function also uses

the keypad to change instrument

values such as Jog values and Stable

window values. The top bar of the

keypad window will indicate the

function and allow the user to enter

the value. Pressing the EDIT

SETUP button will sequence through

all editable values. Values are saved

on exit.

The last keypad function (SETPT or

SETUP) remains in effect until

changed. This allows new set points

to be entered one after another

without pressing inside the set point

window every time.

Jog Functions:

Below the keypad box are the control pressure jog buttons. These 4 buttons are labeled

“+++” for large positive pressure change, “+” for small positive pressure change, “-“ for

small negative pressure change, and “---“ for large negative pressure change. If the

current set point was 100 mbar and the large jog value was10 and the small jog value was

1, pressing the “+++” button would change the control set point to 110 mbar, and the “-“

would change the 100 mbar to 99 mbar. If the units were changed to psi, the 10 mbar jog

value would be converted to psi and the large jog would change the set point to .145 psi

(10 mbar equivalent). If a new jog value exceeds the range of the unit, it is ignored.

Both the large jog and the small jog can be changed using the EDIT SETUP button.

Control Output Drivers:

Below the keypad and Jog function buttons,

the control output (OUT1, OUT2, OUT3,

and OUT4) buttons can be found. Each of

the buttons controls the state of an output

line on the rear of the instrument. The

buttons function as on and off signal

toggles. The 9424 powers up with all

outputs in the OFF state. Pressing the

appropriate button will energize the output

and toggle the state to ON. When ON, the

output provides 12 volts DC between the +

and –pins on the rear panel. The maximum

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 7

load is 1 Amp current (sink or source). Mensor can provide attachments that allow the

12-volt dc drive signals to switch larger AC power loads such as vacuum pumps,

compressors, and AC enunciators up to 20 amps.

Mode Selection and Display:

In the center of the screen near the left side are the mode selection buttons. Three modes

consisting of measure (MEAS), control (CTRL), and vent (VENT) are available. The

mode that is currently active is displayed in green letters just above and to the right of the

buttons. The MEAS mode shuts off all control functions and reads the pressure applied

at the measuring port on the rear of the instrument, displaying the reading in the current

units of measurement in the reading window. The CTRL mode controls the pressure on

the CONTROL OUT port based on the pressure measured on the MEASURE INPUT

port. Both ports need to be connected together using the remote sensor manifold

provided. The VENT mode shuts off all control functions, opens the vent valve, and

vents internal and external pressure to atmosphere. The pressure is continuously

monitored and displayed in the pressure reading window area.

Unit Selection and Display:

Just to the right of the three mode

selection buttons is the UNITS CHG

button. This button brings up the unit

selection screen just below the button.

There are four screens each showing 10

different units of measurement. To

change the current unit, find and press

the desired unit button. If the selection

is not available, press either the

PREVious or NEXT button to display

the next 10 selections. Once a unit is

selected, it will be displayed in the

green pressure setting/pressure reading

window at the bottom. Both the unit

name and the unit number will be

listed.

Control Stable Display:

The color of the pressure reading is used to indicate the pressure's stable status. It will

turn green if the pressure difference between the measured pressure and the set point

value is less than the tolerance specified by the STABLE WINDOW value. Outside this

+ and –tolerance, the pressure reading value will be yellow. The default tolerance is

0.01% of full scale. This tolerance may be changed over the serial communications port

using the “STABLEWINDOW=” command or read back with the

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 8

“STABLEWINDOW?” query. The stable window value can be modified from the front

panel by pressing the EDIT SETUP button until STABLE WINDOW is highlighted in

blue and the keypad shows STABLE WINDOW above the numeric keys.

Setup Button:

The SETUP button displays the user's changeable values and other instrument-specific

information. These values can only be changed when the EDIT SETUP button is

pressed and the value is highlighted in blue. At this point, changes can be made using

the numeric keypad. Once the enter key is pressed, the setup screen will re-appear.

Changes are stored in the instrument or transducer and are retained through power-down

cycles.

Setup - Jog (Big)

This function allows the large positive and negative jog values to be set. Acceptable

values must be positive and within the range of the instrument in the current displayed

units of measurement. The same absolute value is used for both the ‘+++’ button (added

to the current set point value) and the ‘---‘button (subtracted from the current set point

value). No check is made to determine if the large jog is bigger than the small jog. The

user can use the buttons as desired.

Setup - Jog (Small)

This function allows the small positive and negative jog values to be set. Acceptable

values must be positive and within the range of the instrument in the current displayed

units of measurement. The same absolute value is used for both the ‘+’ button (added to

the current set point value) and the ‘-‘ button (subtracted from the current set point

value). No check is made to determine if the large jog is bigger than the small jog. The

user can use the buttons as desired.

Setup –Transducer Offset (Cal Zero)

This entry allows the calibration offset (in the transducer units only) to be monitored and

changed. The zero offset is a fixed value that is added to each pressure reading. It is

normally zero to start with and can be changed to adjust the pressure reading. This field

is a display-only field and must be adjusted on the transducer by qualified calibration

technicians. (See CPT6100 manual for more information.)

Setup –Transducer Multiplier (Cal Span)

This entry displays the transducer calibration span factor. The span is a multiplier

(normally a non-dimensional value of 1.0000) that adjusts each reading. This field must

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 9

be adjusted by a qualified calibration technician using proper equipment. (See CPT6100

manual for more information.)

Pressure Setting Display:

The pressure setting window displays the current control set point in the current units of

measurement. Pressing anywhere within the window sets the keypad function to accept

new set point values.

Pressure Reading Display:

The reading display window shows the current pressure value in the current units of

measurement. It is always active.

Info Display:

The info window is used for displaying user information. The displays vary based on

modes and conditions encountered.

Remote Computer Controlled Operation

Functions available from the front panel are also available remotely using the command

set found below. Communications between the user’s external computer and the Model

9424 use standard RS-232 serial communications. The protocol is 19200 baud, 8 data

bits, 1 stop bit, and no parity. The 9424 will accept upper, lower, and mixed-case ASCII

commands. All commands should be terminated with a linefeed character or a carriage

return character.

Responses to queries will terminate with a carriage return and a line feed.

A complete command set can be found below.

Command Set:

The following command set applies to software version V1.00. All commands should

terminate with a line feed or a carriage return. Responses are terminated with a carriage

return followed by a line feed. Commands are accepted in uppercase, lowercase, or

mixed-case characters. Commands should not be concatenated together and must be

separated with a linefeed or carriage return. The user should accept query responses prior

to sending additional commands.

Command

Description

Example

rdg?

Returns the pressure reading of

the internal measurement

transducer in the current units

of measurement. Returns 8

Send: "RDG?" Return:

"123.456"

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 10

characters with decimal point.

setpt=

Commands the instrument to a

new set point in the current

units of measurement.

Command takes effect

immediately if in the control

mode or prepares the unit to

control at this point when

placed in the control mode.

Command will be ignored if it

is less than minimum range of

instrument or greater than

range of instrument.

Send:

“SETPT=23.400”

Returns:

setpt?

Returns the current set point in

the current units of

measurement. Returns 8

characters with decimal point.

Send: “Setpt?”

Returns:“ 23.400”

mode=

Sets the mode of operation to

measure (MEAS), control

(CTRL), vent (VENT)

Send: “MODE=ctrl”

Returns:

mode?

Returns the current mode of

operation measure (MEAS),

control (CTRL), vent (VENT)

Send: “Mode?”

Returns: “MEAS”

unit=

Sets the displayed units to any

of the built in units. (See

UNITS? Query to obtain a list

of those built in.) Instrument

will accept either the unit

number (1,2 3,4…) or the unit

name (PSI, inHG, mBar, kPa,

Bar, mmHG, ATM, inH2o)

Send: “UNIT=mbar”

Returns: “mbar, 15”

Send: “UNIT=15”

Returns: “mbar, 15”

unit?

Returns the current units of

measurement

Send: “Unit?”

Returns: “mBar, 15 ”

units?

Returns a list of available units

of measurement by both the

unit number and the unit name.

The actual multiplier from PSI

to the units is also provided.

Send: “Units?”

Returns: “1 psi

1.000000

2 inHg@0C 2.036020

…

id?

Returns the unit identification

of the 9424.

Send: “ID?”

Returns: “Mensor

Model 9424 Spec App

Controller”

sn?

Returns the serial number of

the 9424.

Send: “SN?”

Returns: “990354”

stable?

Returns the control stable flag,

an indication of control value

Send: “Stable?”

Returns: “HI”,

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 11

being within the stablewindow

setting. A returned value of HI

indicates that the pressure

reading is above the stable

window setting, A returned

value of LO indicates that the

pressure reading is below the

stable window setting , and a

returned value of OK indicates

that the pressure reading is

within the window.

“LO”,

Or “OK”

stablewindow=

Sets the allowed pressure

difference (control set point

and measured pressure reading)

to indicate a stable setting. The

setting is in the current units of

measurement.

Send:

“stablewindow=0.12”

Returns:

stablewindow?

Returns the allowable stable

error setting. This is the

allowed pressure difference

between the control set point

and the measured reading in the

current units of measure

Send: “Stablewindow?”

Returns: “0.12”

zero=

With the proper password,

allows the current zero offset

value to be changed on the

internal transducer. See CPW=

command to enter the

password. The value sent

should be in the current units of

displayed measurement.

To make a 760 mmHg

read 770 mmHg, send

“zero=10.000”

To make a 300 psi unit

read 295, send

“zero=-5.0”

zero?

Returns the current zero offset

value on the internal

transducer. It is an offset in the

current units of measurement

and the base transducer unit of

measurement. All changes

should be made in the

displayed units of

measurement.

Send: "zero?"

Returns: "5.0 mmHg"

span=

With the proper password,

allows the current span

multiplier value to be changed

on the internal transducer. See

CPW= command to enter the

password.

Send: “span= 1.0”

Returns:

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 12

span?

Returns the current span

multiplier value on the internal

transducer. The Span is

typically a number around 1.00

Send: “span?”

Returns: "1.000"

pass=

Allows commands and queries

to be passed directly to the

internal Mensor 6100

transducer. Commands can be

found in the Mensor Model

6100 Operation Manual

included in the appendix. Since

the passed commands can

change the calibration of the

transducer, they are password

protected like the zero and span

commands. See CPW=

command for details.

PASS=#1?

To read the pressure

reading directly from

the internal transducer.

lockpanel

Disables the front panel touch

screen to force only remote

communications and ignore

manual front panel operations.

Turning the power off and back

on resets the unit to allow

touch screen events or the

Unlockpanel command can be

sent.

Send: “LOCKPANEL”

Returns:

unlockpanel

Enables operation from the

front panel or over the serial

communication port.

Send:

“UNLOCKPANEL”

Return:

panelstate?

Returns the panel lock

condition.

Send: "Panelstate?"

Returns: "Panel Lock

ON"

Or "Panel Lock OFF"

version?

Returns the software version in

the instrument.

Send: "version?"

Returns: "V2.04.02"

echoon

Turns on command echo for

the remote serial

communications port. Can be

turned off with the EchoOFF

command. Unit defaults to

EchoOn at power up.

Send:“ECHOON”

Returns:

echooff

Turns off command echo for

remote serial communications

port. Can be turned on with the

EchoOn command or by

cycling the unit power.

Send: “ECHOOFF”

Returns:

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 13

cpw=

Calibration password required

to change the zero offset or

span multiplier on the internal

transducer. The calibration

password if accepted (correct)

will return “CPW”. A correct

password will allow the zero,

span and pass= commands to

be used within the next four

commands before it is disabled

and the password must be

entered again.

Send: “cpw=123456”

Returns:"CPW"

out1on

Turn on output 1

out1off

Turns off output 1

out2on

Turn on output 2

out2off

Turns off output 2

out3on

Turn on output 3

out3off

Turns off output 3

out4on

Turn on output 4

out4off

Turns off output 4

outon

Turns all outputs on

outoff

Turns all outputs off

jogbig=

Sets the jog value from a

typical value of 10 to a new

value. After entry, the value is

used any time the JOG+++ or

JOG--- keys are pressed. This

value is saved through power

cycles.

Send: “jogbig=20”

Returns:

jogsmall=

Sets the jog value from a

typical value of 1 to the new

value. After entry, the value is

used any time the JOG+ or

JOG- keys are pressed. This

value is saved through power

cycles.

Send: “jogsmall=2”

Returns:

setrate?

Returns the control rate.

Send: “setrate?”

Returns: "25.0000"

setrate=

Assigns the control rate.

Send: “setrate=25”

Returns:

rate?

Returns the current rate of

change in pressure in displayed

units/second.

Send: “rate?”

Returns: "12.3456"

rateon

Turns on rate control

Send: “rateon”

Returns:

rateoff

Turns off rate control

Send: “rateoff”

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 14

Returns:

ratestat?

Returns the current rate control

setting.

Send: “ratestat?”

Returns: "Rate control

is ON" or "Rate control

is OFF"

kp?

This is how much gain is given

to the rate position error

(Default value = .5). Too much

and it will overshoot or

oscillate around the setpoint.

Too little and it will be

sluggish at the rate setpoint.

Send: “kp?”

Returns: ".5000"

kp=

Assigns the position gain value.

Send: “kp=1”

Returns:

ki?

Integrator gain (default value =

80). This is how much gain is

given to the integrator

error.Globally applied without

regard to how much postion

error there is.

The control algorithm mainly

controls with the integrator

term, hence the higher gain, the

more rapid rate of correction.

Send: “ki?”

Returns: "80"

ki=

Assigns the integrator gain

value.

Send: “ki=100”

Returns:

itime?

This is the integrator time

constant (Default value = .01)

The amount of error transferred

to the integrator each cycle

If you make this value too big,

the unit will oscillate around

the rate setpoint

It can also cause oscillations at

the pressure setpoint.

if you make it too small, it wiil

not track the control rate

Send: “itime?”

Returns: ".0100"

itime=

Assigns the value for the

Integrator time constant.

Send: “itime=.0050”

Returns:

decaytime?

This is the number of seconds

before reaching the setpoint

that the control rate will start to

decay (Default Value= 4).

To speed up control make this

number smaller.

To reduce overshoot or

Send: “decaytime?”

Returns: "4.0000"

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 15

oscillations at the pressure

setpoint, make this number

larger.

decaytime=

Assigns the value for the Decay

Time.

Send: “decaytime=3”

Returns:

Added in versions 1.10

JogBig=

Sets the jog value from a

typical value of 10 to a new

value. After entry, the value is

used any time the JOG+++ or

JOG--- keys are pressed. This

value is saved through power

cycles.

Jogbig=20.000

JogSmall=

Sets the jog value from a

typical value of 1 to the new

value. After entry, the value is

used any time the JOG+ or

JOG- keys are pressed. This

value is saved through power

cycles.

Jogsmall=.001

Typical Operating Processes:

A typical operation would consist of setting up the supply, measure, and control hoses to

the appropriate ports. If power is not applied to the 9424, it should be powered up. The

unit will initialize into the measure mode with the initial control set point equal to the

first measured pressure reading. If pressure control is desired, the incoming supply

pressure should be adjusted to the recommended pressure in the Unpacking and Initial

Setup section, but not more than 165 psi gauge for low-pressure units or 1500 psi for

high-pressure units.

To control pressure, verify the control setting is within an acceptable value with respect

to any connected devices and then select the control mode button CTRL MODE. Once in

the control mode, new control points can be entered from the numeric keypad and

pressing the ‘=’ key. Also, the jog functions can be used to jump in uniform steps

through the useable pressure range. At the end of the process, the VENT mode can be

used to vent internal pressure. The unit should be left in the measure mode when not

being utilized or can be powered off if the unit is not needed for an extended period of

time to reduce energy consumption.

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 16

Calibration:

Calibration of the pressure equipment should be done periodically.

Mensor CPT6100 Digital Pressure Transducers have a

recommended calibration interval of 180 days. Units equipped

with Mensor 6180 Digital Pressure Transducers have a

recommended calibration interval of 365 days. This interval can

be extended or shortened depending on the requirements of the

intended application and historical calibration data.

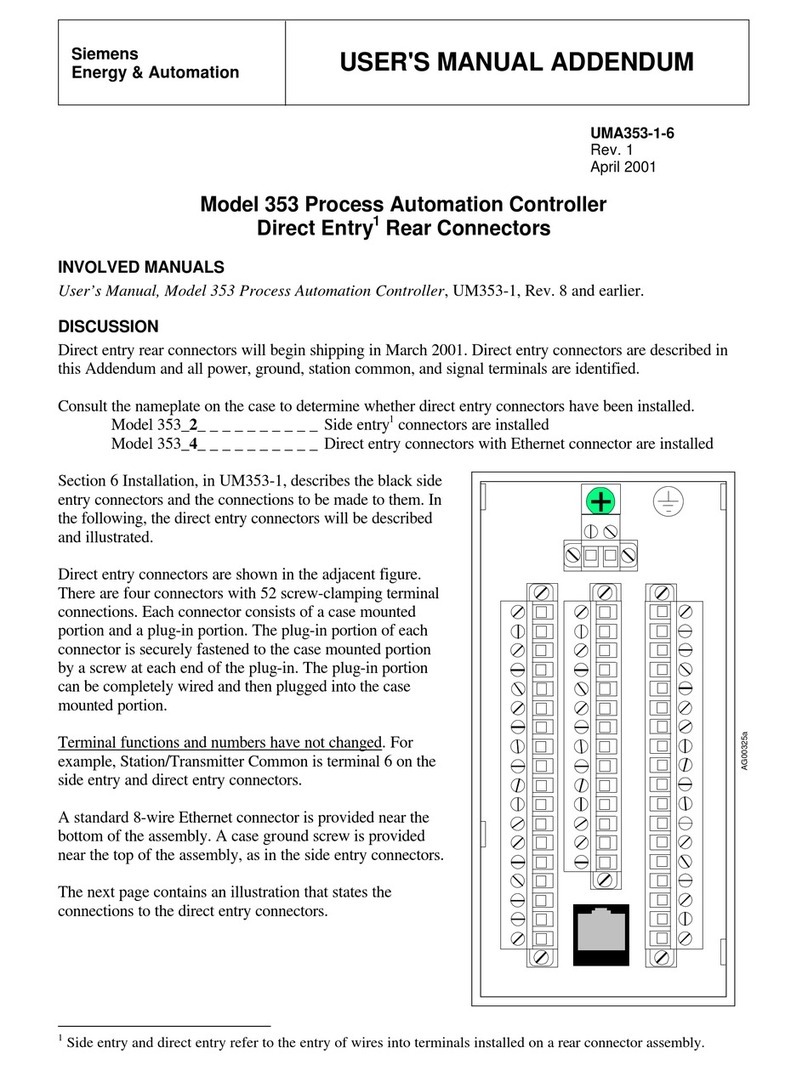

The transducer in the Model 9424 can be removed from the unit for calibration. If the

transducer is removed from the unit, an optional power supply, cable, and software are

required to perform the remote calibration. (Contact

Mensor if this option is preferred.) To remove the

transducer when removable options are chosen, turn the

power off and allow time for the unit to vent any

pressure externally and internally. Loosen the two

screws on the right side of the front panel to open the

panel door. The transducer should be in the front on the

right side of the chassis. Two screws (highlighted in red

in the photo to the right) near the bottom of the

transducer toward the back should be removed. The

transducer should be pulled out sufficiently to remove

the 9-pin d-sub connector on the top. A CPT 6100

Operation Manual describing the calibration process is

included in the appendix. The transducer is set for an

address of ‘A’ and a protocol of 19200 baud, 8 data bits,

1 stop bit, and no parity. The transducer is set up for

standard RS-232 communications. Utilize instructions

and connection recommendations found in the CPT 6100

Manual section 4.

To calibrate the Mensor 6100 transducer(s) when mounted inside the Model 9424

chassis, an external pressure standard needs to be connected to the MEASURE Port on

the rear of the instrument and the 9424 needs to be powered up and left in the

MEASURE mode of operation. Calibration checks can be performed with a precision

pressure standard. See CPT 6100 Operation Manual in the appendix for typical

calibration setup and instructions.

Adjustments to the calibration are done by changing the zero offsets and span multiplier

on the transducer. This can be done over the communication bus or through the front

panel.

Mensor Model 9424 Special Application Pressure Controller 0040032001CS May 25,2023 17

Tuning the Model 9424 Pressure Controller

When tuning the Model 9424, there are several variables to consider such as the DUT

volume, pressure range and control rate from one setpoint to the next. To operate the

Model 9424 efficiently, users must tune the machine to match their performance

requirements. Ideally, when the Model 9424 has been tuned correctly, there will be little

or no overshoot when controlling to a given setpoint and the pressure will be stable once

it reaches the desired setpoint.

No Overshoot when controlling and stable at setpoint

Overshoot when controlling up and down to a setpoint

Unstable at setpoint

Other mensor Controllers manuals

Popular Controllers manuals by other brands

Mitsubishi

Mitsubishi Q2ACPU user manual

Dell

Dell H310 user guide

Faller

Faller 180725 instruction manual

LSI

LSI MegaRAID SCSI 320-0 Zero-Channel RAID Controller Series... Hardware guide

Spirax Sarco

Spirax Sarco IP2AM Installation and maintenance instructions

KELD

KELD KLT11IB Specification and operating instructions