mensor CPC3000 User manual

Calibration Technology

Pneumatic High-Speed Pressure Controller

Model CPC3000

Applications

Industry (laboratory, workshop and production)

Pressure transmitter manufacture

Calibration service companies

Research and development laboratories

Special features

Pressure ranges:

Gauge: 0 ... 5 up to 0 ... 1500 psig

Absolute: 0 ... 15 to 0 ... 1515 psia

Bi-directional: 5 ≤ span ≤ 1515

Control speed

: < 3 seconds.

Uncertainty: 0.025% FS (365 day calibration interval)

Optional Uncertainty 0.025% IS-50 (365 day calibration

interval)

Bezel and Handle

Includes A2LA/NIST Calibration Certicate

Description

Overview

The CPC3000 has a compact, light weight design, a reliable

high speed pressure regulator, gauge / absolute / bi-directional

ranges and an optional barometric reference for emulation.These

qualities make the CPC3000 suitable for a variety of applications.

Applications

With an uncertainty of 0.025% FS and a high speed regulator,

the CPC3000 is well suited for use in the production of pressure

sensors, transmitters, transducers, and pressure switches or as

a working standard for the control and calibration of all types of

pressure gauges.

Functionality

A color touch-screen, combined with user-friendly menus, guaran-

tees high productivity in a calibration lab or production facility; all

screens can be viewed in several dierent languages.

To enter the pressure setpoint, the operator can choose between

four input modes which can be selected using the corresponding

tab. The input modes are:

1. The numeric key menu provides a way to enter a specic

pressure set point value to be controlled.

2. The step keypad menu provides dened steps programmed

in pressure increments or percent of a user dened span to

move the pressure setpoint across the range of the instru-

ment under test.

3. The jog key menu provides a way for the operator to dene

small pressure steps up or down to reach a cardinal point on

a dial gauge. The jog buttons increment the least signicant

digit by 1, 10 or 100 counts.

4. The user dened Jog menu provides a way for the operator

to dene any step within the span to increase or decrease

the setpoint.

Software

Customers can create their own test programs using the Mensor

communication command set, the SCPI command set or the

emulation command set used when replacing other calibrators.

Complete testing and calibration systems

Communication with other instruments is made easy with an

IEEE-488.2, an Ethernet and a USB interface. The CPC3000

can be integrated into an existing system, or our Custom Systems

group can design a system to meet a specic need.

Data Sheet CPC3000 • 02/2014

Page 1 of 8Data Sheet CPC3000 • 02/2014

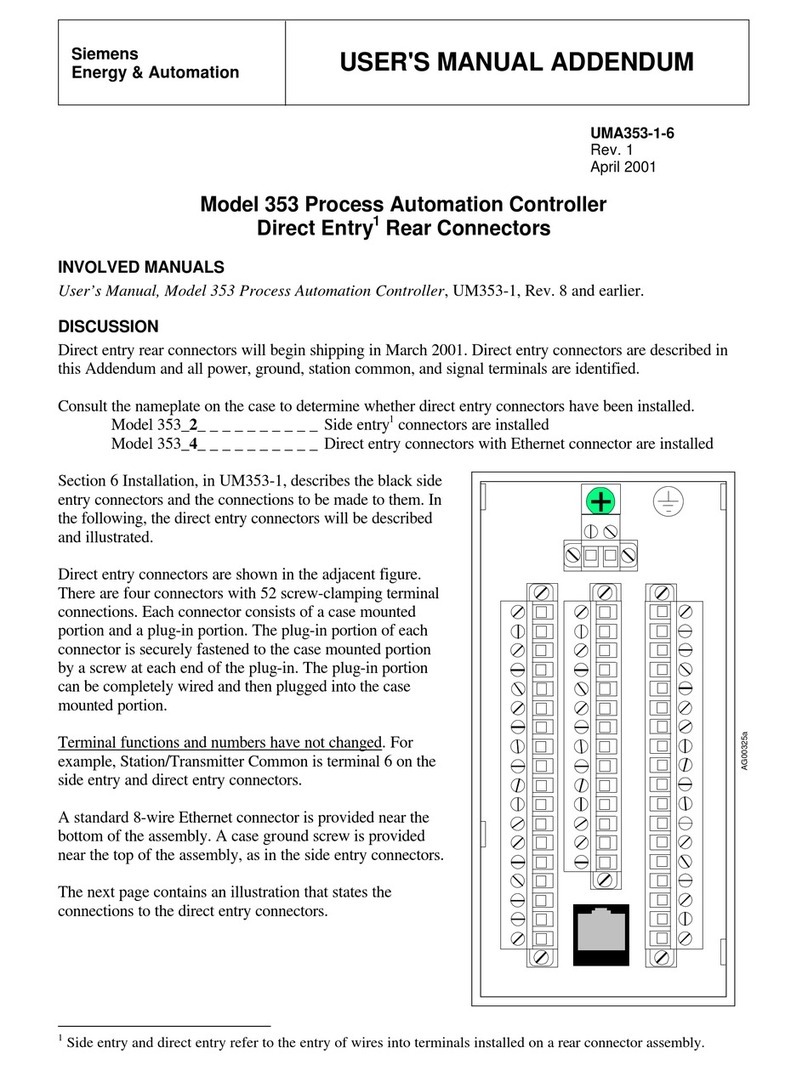

High-Speed Pneumatic Pressure Controller Model CPC3000

Supply

Measure / Control

Sensor Ref. Port

Vent

Exhaust/Vacuum

Barometer Port

Exhaust Relief Port

12.3125

Page 2 of 8 Data Sheet CPC3000

Dimensions in inches

Rear view

Front view Side view

Fan

On/O switch

Fuse

Power supply

Electrical connections and pressure ports - rear view

10.1875

8.6875

5.5

7.375

Ethernet IEEE-488 USB

Page 3 of 8

Data Sheet CPC3000

Specications CPC 3000

Pressure ranges Gauge: 0 ... 5 up to 0 ... 1500 psig (0 ... 0.35 to 0 ... 103 bar)

Absolute: 0 ... 14.5 to 0 ... 1515 psia (0 ... 1 to 0 ... 104 bar)

Bi-directional: 5 ≤ span ≤ 1515

Pressure types Absolute, gauge or bi-directional ranges

Uncertainty 0.025% full span for all standard pressure ranges specied above. Uncertainty (k=2) includes

hysteresis, linearity, repeatability, reference standard, drift and temperature eects over the calibrated

range for the calibration interval specied, with periodic re-zeroing.

Optional Intelliscale Uncertainty

Gauge

Transducer Range (psig) Total Uncertainty (1) (cal interval)

0 ... 14.5 to 0 ... 1500 0.025% IS-50 (1) (365 days)

Absolute

Transducer Range (psia) Total Uncertainty (1) (cal interval)

0 ... 14.5 to 0 ... 1515 0.025% IS-50 (1) (365 days)

Bi-directional

Transducer Range (psi) Total Uncertainty (1) (cal interval)

-15 ... 145 to -15 ... 1500 0.025% IS-50 (1) (365 days)

5 ≤ span < 145 0.025% of Full Span (365 days)

(1) 0.025% IntelliScale-50 (0.025% IS-50): Uncertainty from Min to 50% of Max = (0.025% x 50%

x Max) or 0.025% of Reading from 50% to 100% of Max.

Optional barometer uncertainty 0.02% R from 8.5 to 17 psia for 365 days

Compensated temperature range 15 to 45 °C

Calibration interval 365 days

Pressure units: English psi, psf, oz/si, tons/sq in, tons/sq ft, atm, inHg @0C, inHg @60F, mTorr, Torr, inSW, ftSW, inH2O @4C,

inH2O @20C, inH2O @60F, ftH2O @4C, ftH2O @20C, ftH2O @60F

Pressure units: Metric mbar, bar, g/sq cm, kg/sq cm, dyn/sq cm, pascal, hPa, kPa, MPa,

mmHg @0C, cmHg @0C, mHg 0C, mSW, mmH2O @4C, cmH2O @4C, mH2O @4C, mmH2O @20C,

cmH2O @20C, mH2O @20C

Pressure units user dened 2 (multiplier from psi or Pascal)

Slew rate 3 seconds to stable ag (+/-0.025% full scale pressure) for a 10% pressure change typical into

150cc volume at pressures greater than 5 PSI. Larger volumes can lengthen this time. Controlling to

pressures less than atmosphere can lengthen this time.

Overshoot <1 % FS, in high speed mode

Control stability 0.003% of range

Pressure ports 7/16-20 Female SAE threaded ports for Measure/Control, Exhaust, Reference, and Supply.

Barometric Reference port is a hose barb.

Filter elements 40 micron lter element included in each pressure port (excluding the optional barometer and the

reference port on a gauge sensor)

Permissible pressure media Clean, dry, non-corrosive gases

Parts exposed to pressure media 6000 series aluminum, 316 SS, brass, Teon, Urethane, Silicone, RTV, Silicone grease, PVC, Epoxy, Ceramics

Overpressure protection Pressure relief valves

Instrument mounting Desk top with bezel and handle, or optional rack mount kit.

Display 7.0" color LCD

Resolution Six signicant digits

Warm-up time approx. 15 min

Digital interface IEEE-488, Ethernet, USB

Power supply 100 - 240 VAC, 50/60 Hz, 700 mA max

Maximum pressure, supply port 110 … 120 %FS

Pneumatic overpressure protection internal relief valves

Operating temperature 0 … 50 °C

Storage temperature 0 ... 70 °C

Air humidity 0 … 95 (% relative humidity without moisture condensation)

Operating position Negligible, can be removed with re-zeroing

Weight <20 lbs.(<9.1 kg) with all internal options

Dimensions 5¼ h x 8⅜ w x 12 d in (133 x 213 x 305 mm)

CE-mark Conformity certicate

Calibration NIST traceable calibration certicate included, A2LA certication

Page 4 of 8 Data Sheet CPC3000

Touch screen operation

Main screen

The CPC3000 main operation screen appears after powering up the unit. This screen contains all of the controls needed to

navigate within the menus and to operate the instrument. The setup icon button opens up a menu that provides navigation to all

the set up screens, limits indication, tab selectable input menu, set point display and selection, pressure value indication, pressure

units indication and selection and measure / control / vent mode selection.

MEASURE

Measure mode pneumatically connects

the pressure sensor directly to the device

under test. In measure mode pressure

regulation is inactive.

CONTROL

In the control mode, the device

regulates the pressure output

according to the set point value,

providing a precise pressure at

the test port.

VENT

Vent mode vents the system and the

device under test to atmospheric

pressure.

Optional information can be displayed in the main menu by selecting the option in the setup menu

User dened DUT / control range limits

(congurable via SETUP)

* optional display element

Numeric keypad

Delete selected set point

Delete last entered digit

Accept selected set point

Setup Icon Button

Entered set point

Stable indication

Current pressure value

Pressure unit and mode

Bar graph

Mode

SETUP menu

The SETUP menu allows conguration

of the following points:

Language (17 currently available)

Maximum control range

Step and Jog functions

Interface setting

Display of additional information

SETUP

menu

Communication status*

Optional barometric refer-

ence display*

Jog key pad selection tab

User dened Jog

Step key pad selection tab

Numeric key pad selection tab

Note: See the following page for detailed information on

each set point entry screen.

Page 5 of 8

Data Sheet CPC3000

The jog keypad

Application: Fine adjustment of the pressure value to reach a cardinal value on a pressure gauge or similar device under test.

The step keypad

Application: Calibration of incremental user dened pressure points or percent of full span of the device under test.

The pressure set point can be changed using one of three input modes

The numeric keypad

Application: Direct input of set point value.

Operation

The desired pressure set point value is entered using the numeric

keypad and then acknowledged by pressing the check mark key.

In control mode the controller will regulate the output pressure to

the entered value.

Operation

Each step on the step keypad can indicate user dened pressure

values or percent of span values for the device under test. For

example: the step keypad shown to the left is set for 10% steps

going from 0% to 100%. These steps are a percent of the user

dened device under test full span. In control mode, when a step

is touched, the controller will regulate the output to the associ-

ated set point.

Operation

The triangles on the Jog keypad have values which correspond

to the 3 last digits of the pressure reading and are used to incre-

ment the set point. Triangles pointing up will increase the value

and those pointing down will decrease it. The smallest triangle

increments the least signicant digit by one, the medium size

triangle increments the least signicant digit by ten and The large

triangle increments the least signicant digit by one hundred. The

values will change accordingly if the resolution of the indication

is changed.

Congurable via SETUP

% of span of limit value

User dened pressure steps

Step keypad

Delete input, delete last character,

input acknowledgement

Numeric keypad

Jog keypad

Set point

increased

by:

Least signicant digit x 100

Least signicant digit x 10

Least signicant digit

Set point

decreased

by:

Least signicant digit

Least signicant digit x 10

Least signicant digit x 100

The user dened jog keypad

Application: User dened quick pressure adjustment.

Increase by user dened amount.

User dened amount key.

Decrease by user dened amount.

Operation

Pressing the “User Dened Amount” key will open a numeric

entry screen where a user dened amount can be entered. This

value will be shown in the key indication. Pressing the triangles

will increase or decrease the set point by this value.

0

10

20

30

40 50 60

70

80

90

100

PSI

Clean, dry

pressure supply

Device Under Test

0

50

100

150

200 250 300

350

400

450

500

PSI

Range : 0 ... 500 psig S/N: 811000

Application — Typical Setup

Page 6 of 8 Data Sheet CPC3000

Application — Setpoint entry options and function

012345

0

20

40

60

80

100

Percent of Setpoint

Time (s)

Direct entry of setpoint using the numeric

keypad: enter the setpoint value and press

. The controller will then ramp up the

setpoint.

0

20

40

60

80

100

Percent of Setpoint

Steps changed at operator discretion

Setpoint entry using the step keypad:step

changes, automatically calculated as a

percent of the user dened full scale limit,

and indicated in percent FS or pressure

units can be entered by pressing step keys

( ) in any sequence.

Setpoint entry using jog keypads:

setpoint can be increased or decreased

in small or large steps using the jog

keys to reach a cardinal point on

a dial gauge or step through a calibra-

tion sequence.

Communications

Page 7 of 8

The variety of communications modes and command sets make the CPC3000 a good choice to replace older pressure controllers

that communicate remotely via IEEE-488.The Mensor command set will integrate seamlessly with other Mensor controllers and the

SCPI command set provides integration in areas where the SCPI command structure has been used.The CPC3000 even understands

commands and automation programs that have been written previously for non-Mensor / non-WIKA controllers. Within the setup

menu, under the remote tab, communication emulation selections are available to switch between the various command structures.

In addition to IEEE-488, the CPC3000 has Ethernet and USB communications making it remotely accessible to today’s modern

automation systems. Trouble shooting the initial remote setup is made easy by viewing the remote monitor which displays the most

recent commands sent and responses from the CPC3000 plus any error messages.

Options and accessories

Barometric reference

An optional barometric reference is available for emulation of gauge pressure when the internal sensor is absolute and emulation

of absolute pressure when the internal sensor is gauge. The internal gauge sensors must include a negative gauge range of one

atmosphere in order to be able to emulate sub atmospheric absolute pressures.

Rack mount kit

A 19” x 3U rack mounted tray is available.

Pressure adaptor ttings

Customized calibration systems

Mensor

201 Barnes Drive

San Marcos, Texas 78666

Toll Free: 800-984-4200

Tel: 512-396-4200

Fax: 512-396-1820

Email: sales@mensor.com

Specications and dimensions given in this leaet represent the state of engineering at the time of printing.

Modications may take place and materials specied may be replaced by others without prior notice.

Page 8 of 8 Data Sheet CPC3000 • 02/2014

Scope of supply

CPC3000 High-Speed Pressure Controller

(Desk top version with bezel and handle)

Power cable (6 ft.) with plug

Operating instructions

NIST traceable calibration certicate

Pressure adaptor ttings

A2LA certicate

Options

Barometric reference

19" rack mounting kit

Customized calibration system

Accessories

Additional pressure adaptor ttings

All standard Mensor products are provided with a calibration

certificate traceable to NIST. The calibration program at

Mensor is accredited to both ISO/IEC 17025:2005 and

Z540-1-1994 by A2LA. Mensor is certied to ISO9001:2008.

©2007 Mensor.

Represented by:

Table of contents

Other mensor Controllers manuals

Popular Controllers manuals by other brands

Mitsubishi

Mitsubishi Q2ACPU user manual

Dell

Dell H310 user guide

Faller

Faller 180725 instruction manual

LSI

LSI MegaRAID SCSI 320-0 Zero-Channel RAID Controller Series... Hardware guide

Spirax Sarco

Spirax Sarco IP2AM Installation and maintenance instructions

KELD

KELD KLT11IB Specification and operating instructions