MEP SHARK 282 User manual

USE AND MAINTENANCE MANUAL

YEAR OF MANUFACTURE: ______________

SHARK 282

EN

EN

”CE” CONFORMITY DECLARATION

(according to EEC MACHINES DIRECTIVE 2006/42/CE annex II A)

The manufacturer:

SPA

SEGATRICI

Via Enzo Magnani, 1

61045 Pergola (PU) ITALIA

Tel. 072173721--Fax 0721734533

Hereby declares that the bandsawing machine:

Machine model:

Serial number:

Year of manufacture:

SHARK 282

is in specification with the following directives:

•DIRECTIVE EEC MACHINES DIRECTIVE 2006/42/CE

•DIRECTIVE 2006/95/CE ”LVD”

•DIRECTIVE 2004/108/CE ”EMC”

Managing Director

(William Giacometti)

Introduction and technical specifications 1---1......................

Foreword 1---1..........................................................

Machine presentation 1---2...............................................

Machine specification 1--- 2...............................................

N a m e p l a t e 1 --- 2........................................................

Dimensions 1---6........................................................

Functional parts 2---1............................................

SHARK 282 model 2---1.................................................

Cutting head 2---2.......................................................

Vice 2 --- 2..............................................................

C o n t r o l Pa n e l 2 --- 3......................................................

Tu r n t a b l e 2 --- 3..........................................................

Base 2 --- 4..............................................................

Safety and accident prevention 3---1................................

U s e o f t h e m a c h i n e 3 --- 1.................................................

General recommendations 3---2...........................................

Recommendations to the operator 3---3....................................

Machine safety devices 3---5..............................................

Reference standards 3---5................................................

Protection against accidental contact with the blade 3---6......................

Electrical equipment 3---6................................................

Emergency devices 3---7..................................................

Noise level of the machine 3---8...........................................

Noise level measurement 3---8............................................

Noise level values 3---8...................................................

Vibration emission 3---9..................................................

Electromagnetic compatibility 3---9........................................

Machine installation 4---1........................................

Packaging and storage 4---1...............................................

Anchoring the machine 4---4..............................................

Minimum requirements 4--- 4..............................................

C h e c k l i s t 4 --- 5..........................................................

Balancing the cutting head 4---6...........................................

Connection to the compressed---air supply (MA version) 4---6..................

Connection to the power supply 4---7.......................................

Description of machine operation 5---1.............................

Description of the control panel 5---1......................................

Basic instructions for carrying out a cutting operation cycle 5---4................

Manoeuvring the cutting head 5---4........................................

Clamping the work piece in the vice 5---5...................................

Clamping the work piece in the Automatic Vice (MA version) 5---5.............

Rapid vice positioning 5---6...............................................

Rapid translation of the vice 5---6..........................................

Wi d t h o f c u t 5 --- 7.......................................................

Preliminary check list for cutting operation 5---8.............................

Manual operating cycle 5---8..............................................

CCS (Cut Control System) functioning cycle 5---11............................

A n g l e d c u t s 5 --- 1 3........................................................

Angled cuts 45° to the left 5---13...........................................

Angled cuts 60° to the left 5---14...........................................

Angled cuts 45° to the right 5---16..........................................

Diagrams, exploded views and replacement parts 6---1................

Pneumatic diagram (MA version) 6---1.....................................

How to read the wiring diagrams 6---2......................................

D2---Letter codes used to designate the type of component 6---4................

Standardised Wiring Diagrams (CENELEC Standard) 6---7...................

Exploded views 6---22.....................................................

Motor assembly 6---22....................................................

Front flywheel assembly 6---24..............................................

Motor flywheel assembly 6---26.............................................

Cutting head cover 6---28..................................................

Vice assembly 6---30......................................................

Base assembly 6---32......................................................

C o n t r o l p a n e l 6 --- 3 4......................................................

H a n d g r i p 6 --- 3 6..........................................................

Fixed work table and turntable 6---38........................................

Optional Cut Control System 6---40.........................................

Supplementary pneumatic vice 6---42........................................

Adjustments 7---1...............................................

Air treatment unit (MA version) 7---1......................................

Topping up and bleeding the cylinder (Cut Control System optional) 7---2........

Topping up the head cylinder 7---2.........................................

Bleeding the head cylinder 7---3...........................................

Vice 7 --- 4..............................................................

Vice play adjustment 7---4................................................

Cutting head 7---5.......................................................

Blade tensioner slide play adjustment 7---5..................................

B l a d e t e n s i o n i n g u n i t 7 --- 6................................................

Adjusting operating head travel 7---8.......................................

Blade guide parts 7---9...................................................

Blade guide heads 7---9..................................................

Blade steady buttons 7---9................................................

Blade guide plates 7---9..................................................

Blade 7 --- 1 2.............................................................

Tool change 7---12........................................................

Blade perpendicularity 7---14..............................................

Orthogonality of the blade 7---15...........................................

Front flywheel 7---19......................................................

Motor flywheel 7---20.....................................................

Maintenance and choice of consumables 8---1.......................

The role of the operator 8---1.............................................

Maintenance requirements 8---2...........................................

General maintenance 8---2...............................................

Daily 8 --- 2.............................................................

Weekly 8 --- 2............................................................

Monthly 8 --- 3...........................................................

Maintenance of working parts 8---3........................................

Consumable materials 8---3...............................................

Oil for blade tensioner cylinder 8---3.......................................

Oils for Cut Control System hydraulic circuit 8---4............................

Oil for transmission box 8---4.............................................

Oil for lubricant/coolant fluid 8---4.........................................

Oils for spray mist system (optional) 8---4...................................

Cutting speed and choice of tools 9---1..............................

Cutting speed 9---1......................................................

Standard machine 9---1..................................................

Machine with 4/8 pole motor (optional) 9---1................................

Machine with Inverter (optional) 9---2......................................

Choice of blade 9---3....................................................

Saw tooth pitch 9---3.....................................................

Cutting speed and downstroke speed 9---4..................................

Ty p e s o f s w a r f : 9 --- 4.....................................................

Lubricant/coolant fluid 9---5..............................................

Blade structure 9---6.....................................................

B l a d e t y p e s 9 --- 6........................................................

C o n v e n t i o n a l r a k e 9 --- 7..................................................

Po s i t i v e r a k e 9 --- 7.......................................................

Va r i a b l e p i t c h 9 --- 7......................................................

Variable pitch blades with 0° cutting angle 9---8..............................

Variable pitch with positive rake (from 9 to 10 degrees) 9---8...................

Set: 9 --- 8...............................................................

Standard or splayed set 9---8..............................................

U n d u l a t e d s e t 9 --- 9......................................................

Alternating grouped sets 9---9.............................................

A l t e r n a t i n g s e t 9 --- 9.....................................................

Blade selection table relating to cutting speed and downstroke speed 9---10.......

Classification of steels 9---11...............................................

Classification of steels 9---12...............................................

Troubleshooting 10---1............................................

Troubleshooting blade and cutting problems 10---1............................

Troubleshooting machine faults 10---8.......................................

Accessory Installation 11---1.......................................

Automatic vice kit 11---1..................................................

Blade 1 1 --- 2.............................................................

Cut Control System 11---2.................................................

Electronic rpm variator (inverter) 11---3.....................................

Rodmarkedoffinmillimetres 11---5........................................

Roller table 11---6........................................................

Support for the roller platform on the feeding/discharging side 11---7.............

Discharge side roller table adaptorAdattatore pianale a rulli lato scarico 11---8....

1--1

Introduction and

technical

specifications

Foreword

MEP S.p.A.,in response to modern production techniques, has developed the new

SHARK 282.

This work tool has been designed to satisfy the wide range of cutting needs of a

modern workshop with simplicity and reliability, while at the same time

complying with all EEC safety standards.

The SHARK 282 is structurally rigid, silent and safe: it produces a minimum of

waste (1.2 mm) while its great versatility makes it suitable for cutting various

materials such as stainless steel light alloys, aluminium, copper and bronze at

high speed and with high precision.

Its high cutting capacity, combined with the possibility of making inclined cuts

from 60° left to 45° right, make this model the ideal solution for satisfying the

wide strange of cutting needs of machine shops, turneries, structural steel shops

and engineering workshops.

We congratulate our clients on having chosen this product, which will give

effective and faithful service for many years, especially if the instructions

contained in this use and maintenance manual are carefully followed.

This cutting machine has been designed and made specifically for cutting

metallic materials.

Warning

1

MEP S.p.A.

1--2 2

Use and maintenance manual SHARK 282

Machine presentation

Functioning is completely manual: the operator, after having checked the

workpiece in the vice, grips the control lever and presses the bandsaw start

microswitch; with a downwards movement, the material is cut to the preset

length; the cutting head returns up at the end of the cutting operation, ready to

start a new work cycle.

In the MA version (Automatic Vice), a pneumatic cylinder applied on the vice

blocks the material between the jaws: the open/close control is located on the

base of the machine.

With the CCS accessory (Cut Control System), the machine can also perform a

semi---automatic work cycle. The operator, after using the selector located on the

control panel to choose the semi---automatic work cycle, clamps the material in

the vice and presses the button on the cutting head handgrip to start up the

bandsaw; the saw begins turning and the head commences its downstroke, the

speed of which can be adjusted using the control valve (head downstroke speed

regulator) located on the control panel. The head performs the cutting operation;

once the cut has been made, a limiter stops the cutting cycle, after which the head

is manually returned to its upper position so that, when a new workpiece is in

place, a new cycle can be started using once more the handgrip button.

Both the Automatic Vice and the Cut Control System are optional for the

SHARK 282 model; they can be factory installed on request made during the

ordering procedure, or may be installed by the user after the machine has

been bought.

Machine specification

Name plate

Theanodisedaluminiumnameplateisrivetedonthesideofthemachine;the

same data are reproduced on the declaration of conformity included with this use

and maintenance manual.

MODELLO SHARK 282

MATRICOLA

ANNO DI COSTRUZIONE

MEP SPA Via Enzo Magnani, 1

61045 Pergola (PU) Italy

tel: 0721/73721

When communicating with the Technical Service department, the model, serial

number and year of manufacture of the machine must be quoted.

Warning

N.B.

1--3

3Introduction and technical specifications

CUTTING SPEEDS

1st Slow Speed mt/min 36

2nd Fast Speed mt/min 72

All models can be equipped with the Inverter, an optional device, which offers

a range of speeds comprised between 20 and 90 mt/min As the machine is

predisposed for the Inverter, it can be installed by the client or factory

pre--installed on request made during the ordering procedure.

BAND SAW

Rated size mm 2950 x 27 x 0,9

Max/min blade length mm 2960÷2940

Blade height mm 27

Blade width mm 0,9

Band saw tension bar/kg 70 / 900

When choosing the cutting tool, if its dimensions do not correspond to those

included in the “Rated size” section, check that the dimensions at least fall

within the admissible max/min specifications.

RATED ELECTRICAL POWER

Head spindle motor kW 1,8/1,5

Electric coolant pump motor kW 0,06

Max installed power kW 1,86

WORKING PRESSURE MODEL MA (Automatic Vice)

Max. working pressure for opening/closing vice Bar 6

Air consumption for a complete cycle Nl/min 1,34

The “air consumption” value refers to standard conditions (temperature 0°and

pressure 1.013 bar, i.e. density 1.3 x 10-- 3 Kg/l) where 1 Kg/min. = 772 Nl/min.

LUBRICANT/COOLANT FLUID AND OIL

Oil for blade tensioner unit VL 0,5

Oil for transmission box capacità Kg 0,32

Oil for optional Cut Control System cylinder capacità Lt. 0,7

Lubricant/coolant fluid (oil concentration 5---6%) capacità Lt 13

VICE

Vice max. opening mm 285

Warning

Attention

N.B.

MEP S.p.A.

1--4 4

Use and maintenance manual SHARK 282

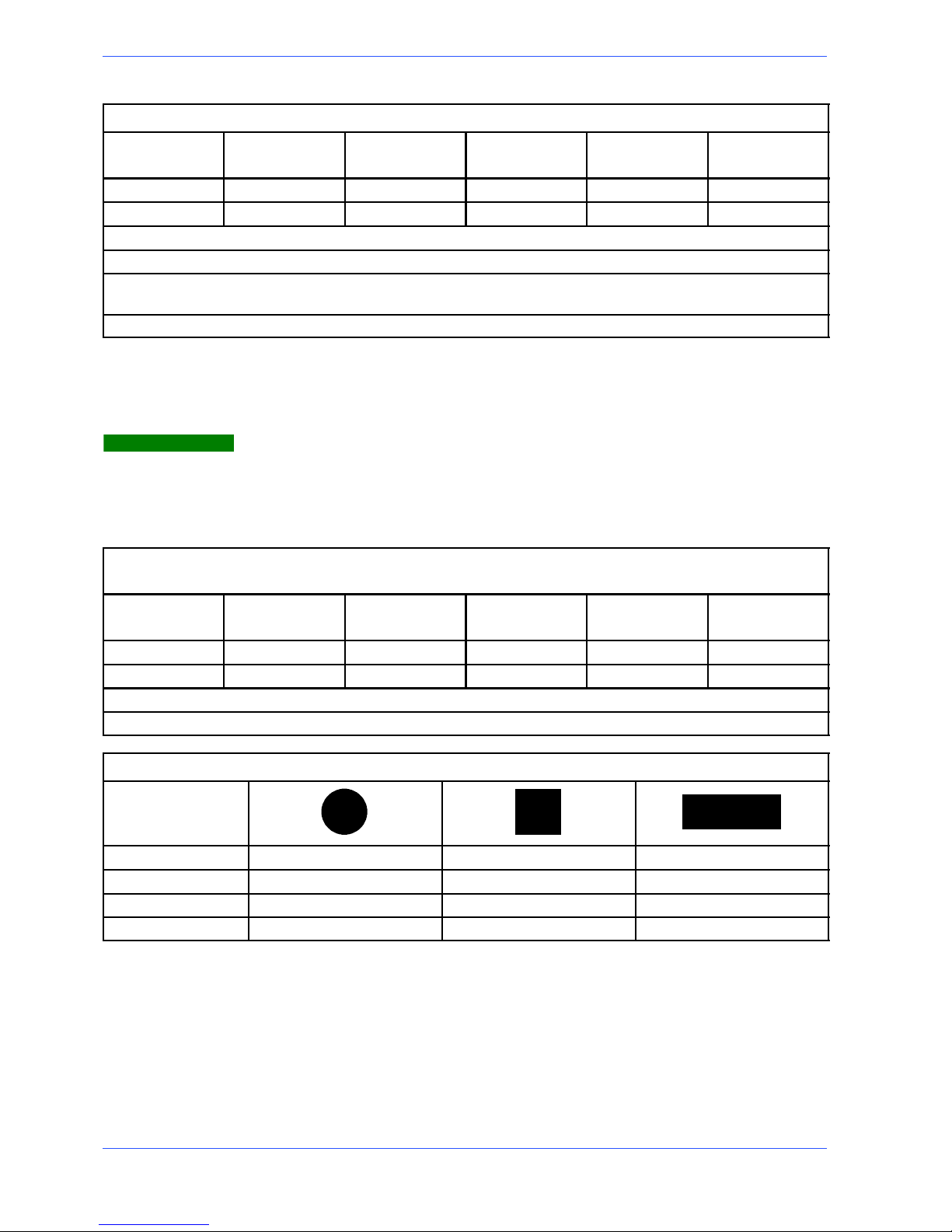

SPINDLE MOTOR

No.of poles Current (Volts) Absorption

(Amps)

Power (Kw) rpm Band saw

speed

2/4 400 5,6/4 1,8/1,5 2.860/1400 72/36 mt/min

4/8 optional 400 3,1/2,7 1,1/0,55 680/1330 36/18 mt/min

Stator wound with enamelled copper wire, class H 200° C.

Class F insulation (limit temperature TL 155° C).

IP 55 protection rating (total against contact with live parts, water sprayed from all directions, with shaft oil

seal).

Conforming to CEI norms, publication: IEC 34 of 01/07/1985.

Example of class F insulation: in air--cooled machines at an ambient

temperature of 40°C (according to CEI 2--3 and IEC 85), the allowable

overtemperature is 100°C (where ٛ

100 C represents the allowable DT).

The machine is supplied with a 2/4 pole three phase motor giving 2 band saw

speeds:

-- 1ª speed (4 poles) = 36 mt/min

--- 2ª speed (2 poles)= 72 mt/min;

The OPTIONAL 4/8 pole motor gives speeds of 36/18 mt./min.

ELECTROPUMP MOTOR

Single phase; Frequency 50 Hz.

Voltage (Volts) Absorption

(Amps)

Power (Kw) rpm Delivery rate

lt/min

Head (mt.)

230 0,40 0,06 2800 11 1,5

400 0,20 0,06 2800 11 1,5

Protection rating IP 55.

Conforming to CEI norms, publication: IEC 34 of 01/07/1985.

CUTTING CAPACITY

Section

0° 250 220 280 x 220

45° a230 200 220 x 200

60° a120 80 140 x 80

45° '200 170 200 x 140

N.B.

Warning

1--5

5Introduction and technical specifications

PACKED WEIGHT

Wooden cage and pallet kg 70

Wooden pallet kg 20

1700

1000

1900

MEP S.p.A.

1--6 6

Use and maintenance manual SHARK 282

Dimensions

MACHINE INSTALLED

Work table height mm 870

Weight kg 440

900 700470 410 550

170

1800

1830

870

1315

2--1

Functional parts

SHARK 282 model

In order for the user to move towards a full understanding of how the machine

works, which is described in detail in the chapter 5, this chapter deals with the

main units and their locations.

CUTTING HEAD

CONTROL

PANEL

VICE

TURNTABLE

BASE

2

MEP S.p.A.

2--2 8

Use and maintenance manual SHARK 282

Cutting head

The cutting head is the unit that cuts the material. It consists of a cast iron head

on which the following are mounted: the band saw, the blade guide components,

the blade tensioner components, the transmission box and the spindle motor. The

cutting head is limited in its movements by the joint on the work table, and its

cutting stroke is manually guided by the operator.

Motor

Head joint pivot

Blade guide

heads

Blade guide head

plate

Handgrip

Handwheel

Transmission box

Vice

The vice is the unit that clamps the workpiece in place during cutting; it consists

ofavicesupport,commonlyknownasaleadnut,fixedtotheworktable,anda

lead screw with a slideway on which the mobile jaw is mounted. The vice is

operated manually by a handwheel, or by a pneumatic cylinder in the MA version

(optional).

TurntableSlidewa

y

Handwheel

Fixed platform

Vice support (lead nut)

2--3

9Functional parts

Control Panel

The control panel has a protection rating of IP 54 and contains the electrical

equipment. Access is gained by removing the screws fastening a safety panel,

while the operator’s safety is guaranteed by a key---operated safety switch,

designed to prevent any intentional interference with the unit. In order to remove

the panel from its mounting, the main switch has to be shifted to 0 (OFF), which

automatically cuts off the electrical supply.

Control panel

Main switch

Panel fastened by

screws

Turntable

A cast iron casting forms the fulcrum for the cutting head, and the support for the

work table and the control panel. Releasing the locking lever on the slideway

allows the cutting head to be rotated to the right and to the left.

Cutting head mechanical limiting

switch

MEP S.p.A.

2--4 10

Use and maintenance manual SHARK 282

Base

On opening the door in the base, you will find the air treatment unit (optional

extra only on versions with MA automatic vice) and the drawer with the coolant,

complete with electric pump.

Lubricant/coolant tank

Electric pump

3--1

Safety and accident

prevention

The SHARK 282 has been designed and produced in accordance with European

standards. For the correct use of the machine we recommend that the

instructions contained in this chapter are carefully followed.

Use of the machine

The SHARK 282 band saw cutting machine is intended exclusively for cutting

metallic materials, ferrous or non---ferrous, in section or solid.

Other types of material and machining are not compatible with the specific

characteristics of the saw.

The employer is responsible for instructing the personnel who, in turn, are

obliged to inform the operator of any accident risks, safety devices, noise

emission and accident prevention regulations provided for by international

standards and national laws regarding the use of the machine. The operator must

be perfectly aware of the position and function of all the machine’s controls.The

instructions, warnings and accident prevention standards in this manual must be

respected without question by all those concerned.The following definitions are

those provided for by EEC MACHINES DIRECTIVE 2006/42/CE :

H“Danger zone”: any zone in and/or around a machine in which the presence of a

person constitutes a risk for the safety and health of that person.

H“Person exposed”: any person finding himself either completely or partly in a

danger zone.

H“Operator”: the person or persons given the responsibility of installing, operating,

adjusting, maintaining, cleaning, repairing or transporting the machine.

The manufacturer declines any responsibility whatsoever, either civil or

criminal, should there be unauthorised interference or replacement of one or

more parts or assemblies on the machine, or if accessories, tools and

consumable materials are used that are different from those recommended by

the manufacturer itself or if the machine is employed in a plant system and its

proper function is thereby altered.

Attention

3

MEP S.p.A.

3--2 12

Use and maintenance manual SHARK 282

General recommendations

LIGHTING

Insufficient lighting for the types of operation envisaged could constitute a safety

hazard for the persons concerned. For this reason, the machine user must provide

lighting in the working area sufficient to eliminate all shadowy areas while also

avoiding any blinding light concentrations. (Reference standard ISO 8995---89

“Lighting in work environments”).

CONNECTIONS

Check that the power supply cables and pneumatic feed systems comply with the

maximum machine absorption values listed in the “Machine Specification” tables;

replace if necessary.

EARTHING

The installation of the earthing system must comply with the requirements set out

in IEC STANDARD 204.

OPERATOR POSITION

The position of the operator controlling machine operations must be as shown in

the diagram below.

Table of contents

Other MEP Saw manuals

Popular Saw manuals by other brands

Craftsman

Craftsman 351.268500 Operator's manual

Hafco

Hafco BP-305 instruction manual

Elektra Beckum

Elektra Beckum TKHS 315 E/P 2.2 W operating instructions

Scheppach

Scheppach HM110T Translation of the original operating instructions

Wen

Wen 20630 instruction manual

Husqvarna

Husqvarna FSA 8400 D Operator's manual