Merach MR-526 User manual

MR-526

ELLIPTICAL TRAINER

INSTRUCTION MANUAL

Email:service@merach.com

Official Website: www.merach.com

Company: Zhejiang Yulu Electronic Technology Co., Ltd.

Address: 298 Weiye Road, Binjiang District, Hangzhou,

Zhejiang Province, China

MR-526 ELLIPTICAL TRAINER

INSTRUCTION MANUAL

Dear Customers,

We want to thank you for having chosen an Elliptical trainer and wish you a lot of

fun and success during training.

Please note and follow the enclosed safety and assembly instructions carefully.

If you have questions please do not hesitate to contact us.

Support email:[email protected].

Safety Instruction ...................................2-3

Exploded Drawing ....................................4

Parts List .........................................5-7

Installation Steps ...................................8-13

Operation instruction of multifunctional sports monitor ......14-16

Table of Content as below

2

Before you start training on your home Elliptical trainer, please read the instructions

carefully. Be sure to keep the instructions for information, in case of repair and for

spare part delivery.

This elliptical trainer is made for home use only and tested up to a maximum body

weight of 350lb.

Follow the steps of the assembly instructions carefully.

For assembly use only suitable tools and asks for assistance with assembly if

necessary.

Check before the first training and every 1-2 months that all connecting elements

are tight fitting and are in the correct condition. Replace defective components

immediately and/or keep the equipment out of use until repair. For repairs, use only

original parts.

In case of repair, please ask your dealer for advice.

Avoid the use of aggressive detergents when cleaning the home exerciser.

Ensure that training starts only after correct assembly and inspection of the item.

For all adjustable parts be aware of the maximum positions to which they can be

adjusted/tightened to.

The home exerciser is designed for adults. Please ensure that children use it only

under the supervision of an adult.

SAFETY INSTRUCTION

■Ensure that those present are aware of possible hazards, e.g.

movable parts during training.

■Consult your physician before staring with any exercise program.

He or she can advise on the kind of training and which impact is

suitable.

WARNING!INCORRECT/EXCESSIVE

TRAINING CAN

CAUSE HEALTH INJURIES.

■Please follow the advice for correct training as detailed in training

instructions.

■The load/work level can be adjusted by turning the adjustment

knob on the handle bar stem.

■The safety level of this equipment can be maintained only if it is

check regularly for all assembly procedure mentioned in the

assembly instruction sheet.

■Please check regularly for the tightening knobs to notice any

irregular wear.

3

EXPLODED DRAWING

4

16

9L

10

11 12 13

15

14

17

21

22 23 24

26 27

9R

25L

34R

36R

40

18

41

89

90

91L

92

74 75 76 58 57 56

86

88

87

85

84

32

31

30

Item.99*2

Item.100*1

28

29

44R 45

42

43

46

20

48

49

50

53

64

65

67 68 69 70

63

71 72 73

77 78 79

80

81

82

83

91R

95

94

60

61 62

47

55

51

54

19

33

34L

35

36L

39

38

37

1

2

3

4

5

6

8

7

25R

59

66

93

96

99

100

44L

52

98

97

MR-526 Components and Parts List

No

Product name

Specification

Material

Quantity

1 Electronic meter

JS-10327 outgoing line 120MM, two heartbeat outgoing line

100MM

1

2

Hand-held heartbeat

sheet

Flexible rubber 2

3

Handle weld

∅

25

FE

1

4

Cup head self-tapping

screw

M4*20 BK 2

5

Semi-round end cover

∅

25

PP

2

6

Foam

∅

25*3T*500mml

HDR

2

7

End cover

∅

50*32 upper swing pipe with a small top ring

PP

2

8

Foam

32*3t*570MML upper swing pipe

HDR

2

9R

Upper swing right

∅

32*1.5T*752MML

FE

1

9L

Upper swing left

∅

32*1.5T*752MML

FE

1

10

Umbrella-head

inner-hexagon screw

M8*20 Nylonpatch 360°, 5MM handle 2 + central axis 2 +

crank spindle 2

Plating black

6

11

Spring washer

∅

8 pedal spindle 2 + central axis 2 + handlebar 6

Plating black

10

12

Spring washer

8*36*3 central axis

Plating black

2

13

Nylon bush

18.8*38 outer ring without groove

PA+MnS2

4

14

Curved washer

8*19*1.5T upper swing pipe 4+ handlebar 6+ handle 2

Plating black

12

15

Umbrella-head

inner-hexagon screw

M

8*20 5mm Upper swing with hexagon hole 4 + handlebar 6

Plating black

10

16

Spring washer

∅

19.5*

∅

38*0.5

BK

2

17

Big flat head screw

M5*12

BK

4

18

Line clamping plug

∅

12 Hardness 55-60 degree

PVC

1

19

Nylon bush A

19*38 outer ring with groove

PA+MnS2

2

20

Heartbeat line

650MM

2

21

Central axis

∅

18. 8*354. 2MML extrusion tap on both sides M8*25

UCP

1

22

Umbrella-head

inner-hexagon screw

M10*78 part-thread lower swing pipe type A 5-leg hexagon

hole

Plating black

2

23

Lower swing casing

pipe

∅14*59 UCP 2

24

Bush

32*14

PA+MnS2

4

25L

Lowe swing weld left

∅

32*1.5T*580MML

FE

1

25R

Lower swing welding

right

∅32*1.5T*580MML FE 1

26

Spring washer

10*19*2 lower swing pipe

Plating black

2

27

Nylon nut

M10 lower swing pipe

Plating black

2

28

Bottle holder

TC-F01

Black

1

29

Big head thread cutting

screws

M5*15 Bottle holder

Electrophoresis

black

2

30

Handlebar pipe weld

∅

60*1.5T*985MML cut 51°

FE

1

31

Upper line

1100MML

1

32

Fine tuning lower

section

Lower section of 1300mm outgoing line 34MM straight pipe

screw

1

33

Elliptical tube plug

30*60 pedal tube

PP

2

34L

Pedal welding left

30*60*1.5T*780MML Ellipse

FE

1

34R

Pedal welding right

30*60*1.5T*780MML Ellipse

FE

1

35

Carriage bolts

M6*50 pedal plate

Plating black

4

36L

Pedal left

8001 All Black

PP

1

36R

Pedal right

8001 All Black

PP

1

37

Spring washer

6*14*2 pedal plate

Plating black

4

38

Spring washer

∅

6

Plating black

4

39

Small round flower

rotary knob

M6 internal thread ABS 4

40

Spring washer

8*24*2 pedal mandrel

Plating black

2

5

41

Nylon powder

∅

16.3*022.4 Crank connecting pipe

PA+MnS2

4

42

Umbrella-head

inner-hexagon screw

M8*50A type, tooth length 12MM

Electrophoresis

black

2

43

Powder metallurgy

11.5*8*15 (pedal tube)

4

44L

M piece welding left

3T, no M5 hole in the middle

FE

1

44R

M piece welding right

3T, no M5 hole in the middle

FE

1

45

Spring washer

8* office 16*1.5

Plating black

2

46

Nylon nut

M8 opposite side with 14

Plating black

2

47

spring washer out-plane

hexagonal nut

M10*1.25 opposite 15MM*7T magnetic control wheel ucp 2

48

Wave spring washer

∅

17.5*22*0.5

BK

1

49

Magnetic control wheel

∅

250*345kg

1

50

Bearing

6000-2RS

2

51

Nut

M10*1.25 opposite 17MM*3T magnetic control wheel

ucp

2

52

Drill screw

M5*20 Housing 2 + Sensor 1

BK

3

53

Magnetic control wheel

spindle

M10*1.25 teeth pitch *112MM Blacking 1

54

Chain adjuster

BK

2

55

Axis protector

opposite side 15

PP

1

56

Sensor

1100MML Sensor bar 25MML

1

57

Spring washer

17*22*2 Tianxin

BK

2

58

C-type buckle (jump

ring)

∅15(axle 17) BK 1

59

welded frame

1

60

C type buckle

For 10 axis

BK

3

61

Pressing wheel

∅

37 * 20.5 L black surface double bearings(PB3851)

1

62

Compression wheel

arbor

∅10*42mml BK 1

63

Magnet

40*25*10MM

Indication S/N

10

64

Nut

M6 opposite side 10

ucp

2

65

Double-thread screw

∅

6 * 80 denticulate hinge on both sides M6*25

BK

1

66

Silica spring washer

8*16*1.5

1

67

Spring washer

∅

6*14*1.5

ucp

3

68

Nylon nut

M6 opposite side 10

ucp

1

69

Spring

∅1 * 12 circle taper, big head 15, small head 9, total length 60

ucp

1

70

Magnet set fixing seat

4T

FE

1

71

Rotating mandrel

∅

12*33.2

ucp

1

72

Spring washer

∅

6

ucp

2

73

Umbrella-head

inner-hexagon screw

M6*15 ucp 2

74

Flange nut

BK

2

75

Cross welding

FE

2

76

Large flat head

self-tapping screw belt

M4.5*15 disc BK 8

77

Bearing

60032RS

2

78

Spring washer

17*22*1 Tianxin

BK

3

79

Wave spring washer

∅

17.5*22*0.5

BK

1

80 Belt pulley 260*17.1 hole 4 holes

Aluminium

tray

1

81

Belt

460J6

1

82

Tianxin welding

∅

17*134MML

FE

1

83

Outer hexagonal screw

M8*12(Tianxin)

BK

4

84

Front foot pad

∅

60 (inner wheel)

ABS

2

85

Front foot pipe

∅

60*1.2T*380MML

FE

1

86

Back foot pad

∅

60 dodecagon

ABS

2

87

Hind foot pipe

∅

60 * 1.2t * 485mml for bumping

FE

1

88

Umbrella-head

inner-hexagon screw

Medium carbon steel 8.8/5mm hexagonal hole in M8*70

front and rear bottom pipe

Plating black

4

89

Crank plug

Black hardness 55-60 °

PVC

2

6

90

Disc

8509 black

HIPS

2

91L

Housing Left

KS-8007

ABS

1

91R

Housing Right

KS-8007

ABS

1

92

Drill screw

M5*15 shell 6

BK

6

93

Sealing ring

∅

60( Hardness 55-60 degrees)

Black

1

94

Ornament cover of front

pipe

KS-8007 ABS 1

95

Self-tapping screw

M4.5*25

BK

6

96

Fine tuning upper

section

The upper section is 540mm and the outgoing line is 30MM

1

97 Round head screw M5*55

Plating

black

1

98 Curved washer 5*16*1.5T

Plating

black

1

99

Hexagon socket wrench

5mm with cross

UCP

2

100

Open spanner

10.17.14.19 heat treatment

UCP

1

7

I

nstallation Steps

S

tep 1

1

. After assembling the foot pad (86) and rear foot pipe(87)

2

. Fixing the front foot pipe (85) with screws, and aligning hole sites from the lower foot pipe with two carriage screw

s

In the same way, Fixing the rear foot pipe(87) with screws, and aligning hole sites from the lower foot pine wit

h

carriage screws(88) Screwing with an Allen wrench (99).

S

tep 2

1

. Firstly, inserting the front pipe ornament cover (94 ) into the handlebar stand pipe(30), and then the connecting line (31

)

is connected with the induction line (56) in the figure.

2

. Firstly, turning the fine adjustment to the maximum value (level 8). Connecting the fine-tuning wire (32) of th

e

platform and fining the upper end (96). Inserting the handlebar stand pipe(30) into the platform (59).

STEP 2

32

94

31

30

96

32

56

96

59

STEP 1

88

85

87

86

59

8

S

tep 3 M piece installation

P

utting the M piece (44R) through the pedal core shaft (75) of the platform (59) parts, and fixing the M piece (44R) on th

e

p

edal core shaft (75) with the inner hexagon screw (10), cushions (11) and gasket (40). Screwing with an Allen wrench (99)

.

(

Note that the M pieces are divided into left (L) and right (R), which are marked on the package)

S

tep 4 Installation of center shaft and lower swing

F

irstly, installing the pre-assembled (34R) + (25R) on the handlebar stand pipe (30) (firstly installing the position shown i

n

t

he figure below), then successively penetrating into the lower swing (25R) with the central shaft (21), after that, puttin

g

t

hem into the spring washer (16), penetrating into the handlebar stand pipe(30), the details are shown in the correspondin

g

p

osition. The other side can be installed as above. Finally, the two ends of the central shaft (21) are fixed with screws (10)

,

c

ushions (11) and spring washers(12), fastening with two inner allen wrench(99).

STEP 3

44L

11

40

10

59

75

44R

40 11

10

STEP 4

21

10 11 12

16

34R

25L

25R

34L

30

44R

44L

59

12

11

10

16

9

S

tep 5 Installation of upper armrest, pedal tube and M piece

1

. Placing the upper armrest (9R) into the position corresponding to the lower swing (25R), and fastening the other sid

e

with screws (15) and spring washer(14) as in the previous step. (Refer to the following figure for installation)

2

. Putting the rear end of the pedal tube (34R) into the U-shaped opening of the M piece (44R), and then successivel

y

penetrating into the corresponding hole position with the inner hexagon screws (42), after that, screwing into inne

r

hexagon screw pumps with the gasket (45) and the nylon cap (46). Locking it with an inner allen wrench (99) and a

n

open end wrench (100) until it cannot be shaken. The other side is the same as the previous step.

STEP 5

15

14

9R

9L

25L25L

25R

34L

34R

44R

44L

42

45

46

59

44R42

45

46

14

15

10

Step 6 Installation of pedal plate

P

utting the pedal plate(36R) into the pedal tube (34R) and aligning its hole, then inserting into the hole corresponding of th

e

p

edal plate(36R) and the pedal tube (34R) in turn with the screw pump (35), then installing the plum blossom knob (39),

s

pring washer (38) and spring washer (37) on the screw pump(35) and tightening them up. The other side can be installed a

s

a

bove.

S

tep 7

L

ocking the screws (15), the cushions (11), and the washers (14) into the driver's stand pipes(30),Other screws are operate

d

in the same step, and tightening and fixing them with an Allen wrench (99). (See the figure for detailed operation)

STEP 7

11

14

15

30

94

59

11

15

14

STEP 6

35

36L

36R

37

38

39

34R

34L

59

35 37 38 39

11

12

Step 8: Installation of kettle holder/fixed handle/electronic meter

1

. Firstly, removing the screws (29) from the handlebar stand pipe(30), aligning the hole and fixing the kettle holder (28)

on the handlebar stand pipe with the screws (29) according to the figure.

2

. Fixing the fixed handle (3) on the handlebar stand pipe(30) with screws (10) and spring washers (14), tightening it with

an Allen wrench (99). Passing the hand-held heartbeat line (20) into the corresponding position of the handlebar stan

d

pipe(30), and fixing it with the line clamping plug (18).

3

. Removing the fixed screws (17) on the back of the electronic meter(1) in advance, connecting the upper flat cable (31

)

with the flat cable corresponding to the electronic meter (1), and the hand-held heartbeat line(20) with the hand-hel

d

heartbeat line corresponding to the electronic watch (1). In the end, fixing the electronic meter(1) on the handlebar

stand pipe frame (31) with the previously removed screws (17). See the figure for details.

4

. Loading batteries into the battery box behind the electronic meter(1). Installation is done.

STEP 8

1

17

20

10

14

31

28

29

3

30

18

18

14

10

17

13

N

ow, your machine is ready to use.

N

ote:

M

ake sure all the screws are tightened before using

14

Operation instruction of multifunctional sports monitor

VER.01

NO.0004

4

1

. Instrument Function Buttons

M

ODE Status Key ---Selecting the display window to be set or reset;

R

ECOVERY/UP ---In the setting state, setting up the countdown interval, distance, calorie value an

d

temperature (°C or °F) on the corresponding flashing window.

---Pressing this button to enter/exit the heart rate recovery function test when there i

s

heart rate signal input in the stopped movement and non-set state.

D

OWN ---In the setting state, setting down the countdown interval, distance, calorie valu

e

and temperature (°C or °F) on the corresponding flashing window.

R

ESET/GO ---In the setting state, resetting the countdown interval, distance value, calorie valu

e

on the corresponding flashing window.

---In the meter state, pressing and holding the RESET key for 3 seconds to clear al

l

window display values. --In the body parameter setstate, pressing this button to star

t

the body fat level.

B

ODYFAT ---In the stopping setstate, entering/exiting the lipid measurement parameters.

2

. Meter Function

1

. Speed, rpm, fat percentage: Window A display

(1) It measures the instantaneous speed, showing the speed of movement, and the measurement range is 0.0 ~ 99.

9

km/h

(2) Revolutions per minute (RPM) measures the pedal speed, showing the speed of the treadwheel. Measuremen

t

range 0 ~ 1500 rpm

(3) It measures the percentage of body fat

2

. Time/body mass index BMI: Window B display

(1) Measuring the cumulative time of exercise

Measuring the time from start doing exercise to stop, ranging from 0 to 99 minutes and 59 seconds

(2) Time alarm function

Firstly setting the exercise time, after the exercise starts, the time will be counted backwards, counting to zero alarm 1

0

seconds, the maximum setting time is 99 minutes.

(3) Measuring BMI value

3

. Distance/basal metabolic rate BMR: Window C display

(1) Measuring the cumulative distance of motion

Measuring the distance from the start to the stop of movement, with the measuring range of 0.00~9.99~99.9 km, it wil

l

automatically display with one decimal after counting 9.99 km.

(2) Distance alarm function

Setting the movement distance first, the time will be counted backwards after the movement starts, counting to zer

o

alarm 10 seconds. The maximum setting value is 99.9 kilometers.

(3) Measuring BMR value

4

. Calories/temperature: Window D display

15

(1) Measuring the accumulated heat consumption of exercise

Measuring the heat (i.e., calories) consumed from the start to the stop of exercise, with the measuring range o

f

0.0~99.9~999 kcal, it will automatically turn to integer display after counting 99.9 kcal.

(2) Calorie alarm function

Firstly, setting the calories consumed by exercise, after the exercise starts, the time counts down to zero, then alarmin

g

for 10 seconds. the maximum setting value is 999 kcal.

(3) Measuring temperature (℃or F)

5

. Heart rate: Window E display

Measuring the number of heartbeats per minute, ranging from 40 to 240 beats per minute. If there is no heartbeat signa

l

for 60 seconds, and then automatically showing the symbol "P", indicating that the heart rate test is suspended

;

Pressing the UP or DOWN key for once, if the symbol "P" changes to "□", indicating that the heart rate can be tested.

6

. Wheel circumference

Setting it to a certain size according to the matching requirements of fitness equipment.

7

.

There are key tones when operating the MODE status key, RECOVERY/UP key, DOWN key, RESET/GO key or

BODYFAT key.

8

. Standing still for 8 minutes (no key operation and no movement), the instrument will automatically shut down an

d

clear all data except human body parameters and temperature, at the same time, it will automatically switches t

o

display only the temperature value, and the operation button or the start of the movement will automatically display.

3

. Instrument installation method

1

.

Removing the battery door on the rear housing, loading two new No.5 with 1.5 volt (size SIZE AA UM3 R6) or No.

7

(size SIZE AAA UM4 R03) batteries according to the positive and negative directions on the battery box and the battery

model indicated in the battery box. The meter with MP3 needs to load 4 batteries.

2

. Fixing the meter on the dashboard in front of the fitness equipment with silk.

3

. Installing the magnet base and the sensor at the designated positions of the fitness equipment, and keeping parallel

,

with the distance between them being 2~15mm and the axial separation being 7 ~ 10 mm.

4

. Connecting the sensor wire plug with the connector of the outgoing line on the back of the instrument or inserting i

t

into the signal input jack on the back of the instrument.

5

. When stepping on the fitness machine, the displayed speed changes, indicating that the installation is qualified

.

Otherwise, check whether the magnet seat and the sensor are installed correctly and whether the connection betwee

n

the sensor wire plug and the meter head lead is reliable.

4

. Instrument usage method

1

. Pressing the MODE status key to select the display window to be set or cleared, the value on the correspondin

g

window flashes, pressing the UP/DOWN key to set the alarm time or alarm distance or alarm calories you need, an

d

pressing and holding the UP/DOWN key without moving, which can be set quickly; Pressing the RESET key to clea

r

the value displayed in the corresponding window.

2

. Stepping on the fitness machine to start measuring, and observing your exercise parameters according to the content

s

displayed in different windows.

3

. Heart rate measurement: Click the UP or DOWN key, and then grasping the metal plate of the heart rate sensor at th

e

corresponding position with the left and right palms respectively

(Note: each palm should touch two metal plates at the same time). After 3~4 seconds, the heart rate display windo

w

displays your current heart rate in beats/minute. When the heartbeat signal is received during the measurement, th

e

heartbeat symbol "zero" flashes. In order to prevent palm movements from affecting heart rate measurement an

d

ensure accurate heart rate measurement, it is suggested that heart rate measurement should be carried out after pause o

r

stop, and heart umbrella should not be measured when running.

16

Tips: As signal interference sometimes occurs when the palm catches the metal sheet, the heart rate value displayed i

n

the first 2-3 seconds may be inaccurate and on the high side, which is a normal phenomenon, and then the heart rat

e

will return to normal measurement. Monitoring heart rate in this way is mainly helpful to determine your exercise, an

d

cannot be used as a basis for disease treatment.

Note: For an instrument equipped with a wireless heart rate receiving device for chest strap, the chest strap shall b

e

properly worn first, and the heart rate signal shall be sent to the instrument within the signal range of chest strap.

4

. Measuring heart rate recovery ability: In the unset state after stopping exercise (speed is 0), the heart rate should b

e

measured by the above heart r

ate measurement method, pressing RECOVERY/UP key to enter the heart rate recovery

function test, and then keeping holding hands or wearing chest strap (when this function is available) to measure th

e

heart rate. At this time, the time window displays a 1-minute countdown, and the value in the heart rate displa

y

window will decrease because the heartbeat gradually returns to calm after stopping exercise, When the time is counte

d

down to 0, your heart rate recovery status (F1 ~ F6) will be displayed, where F1 means the fastest heart rate recovery

,

followed by fast to slow, and F6 means the slowest. Pressing the RECOVERY/UP again to exit the heart rate recovery

function test.

5

. Measuring fat percentage, BMI and BMR: In the non-movement (speed is 0) state, pressing m) DYFAT key to enter th

e

lipid measurement parameter setting state, first setting the individual NO. At this time, the corresponding No. value

flashes, pressing RECOVERY/UP key, DOWN key to select the setting (1 ~ 8) up to 8 human body data. Pressing th

e

MODE key to enter the weight setting, pressing the RECOVERY/UP key or the DOWN key to set the weight value,

and so on: Setting weight KG, height CM, age YEAR and gender in turn. Pressing RESET/GO key after setting, then

holding the heart rate sensin

g metal sheet with both hands, displaying the results after 6 seconds. Pressing BODYFAT

again to exit the lipid measurement state.

Note: (1) In the human body data setting state, if there is no operation within 10 seconds, it will automatically exit th

e

setting state of lipid measurement parameters

(2) In the process of fat measurement, if the measured body is not sensed for 10 seconds, [ER.1] will be displayed.

5

. Comparison Table of Fat Content and Obesity

Gender/age Relatively

thin Normal Slightly fat Overweight Obesity

Male /<30

<14%

14%~20%

20.1%~25%

25.1%~35%

>35%

Male /> 30

<17%

17%~23%

23.1%~28%

28.1%~38%

>38%

Female /<30

<17%

17%~24%

24,1%~30%

30.1%~40%

>40%

Female />30

<20%

20%~27%

27.1%~33%

33.1%~43%

>43%

6

. Audio Amplification and Output [If this function is available]

C

onnecting the audio input line to the output port of the audio player, and turning on the audio switch on the right side o

f

t

his table to play the music output by the audio player.

7

. Battery Replacement

W

hen the display dims or there is no display, removing the battery door, install 2 new No. 5 with 1.5 V(AA, UM3) or No.

7

(

AAA, UM4) batteries (4 batteries with MP3) according to the direction of the positive and negative electrodes of th

e

b

attery and the battery model indicated in the battery box, and install it back.

Maintenance Service Description:

User Name:

Purchase

Date:

Name of

Commodity:

Product

Model:

Purchase

Place:

Tel.:

Repair Date Failure and

Inspection Record

Maintenance

Date Technician

Warranty Card

Maintenance Records

MERACH, Global Family Fitness Expert

1.Installation of goods shall be carried out in

accordance with the instructions of the product

drawings. Damage or accident caused by wrong

installation or improper use shall not be included

in the scope of free maintenance.

2.If the goods need to be repaired, this card

and purchase certificate should be attached to

the designated repair center for repair.

3.Maintenance fee will be charged for items

beyond the free range.

Warranty Period:

The whole machine is guaranteed free of

charge for one year from the date of

purchase (man-made damage is not within

the warranty scope). Please keep the shop-

ping voucher and warranty card properly.

Email:service@merach.com

Official Website: www.merach.com

Company: Zhejiang Yulu Electronic Technology Co., Ltd.

Address: 298 Weiye Road, Binjiang District, Hangzhou,

Zhejiang Province, China

Table of contents

Other Merach Elliptical Trainer manuals

Popular Elliptical Trainer manuals by other brands

Precor

Precor EFX EFX 821 Assembling and maintaining

Align-Pilates

Align-Pilates A2RII Reformer Assembly guide & user's manual

Deltech Fitness

Deltech Fitness DF935 Assembly instructions

Horizon Fitness

Horizon Fitness Andes 3 owner's manual

Kettler

Kettler NOVA M CT1019-300 manual

Matrix

Matrix Stepper owner's manual

Dyaco

Dyaco XE569s Service manual

Sunny

Sunny SF-E3803 user manual

NordicTrack

NordicTrack E 11.6 Elliptical Manual Del Usuario

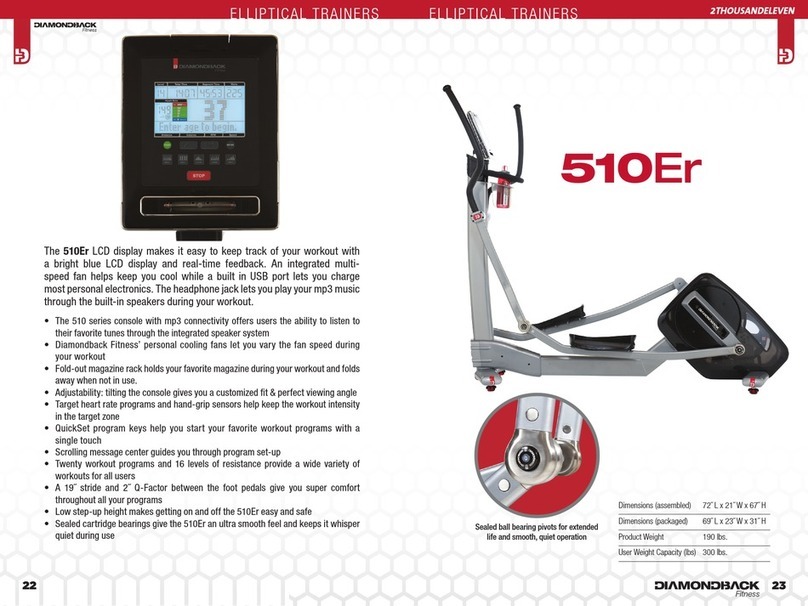

Diamondback

Diamondback ELLIPTICAL TRAINERS 510ER user manual

ICON Health & Fitness

ICON Health & Fitness NordicTrack FREESTRIDE TRAINER FS7I user manual

Reebok

Reebok SL8.0 user manual