3/15

CAUTION

All previous issues of this Technical Manual expire on the date of issue hereof.

This Technical Manual does not apply to any fans manufactured prior to this Manual's date of

issue.

1. FOREWORD__________________________________________________

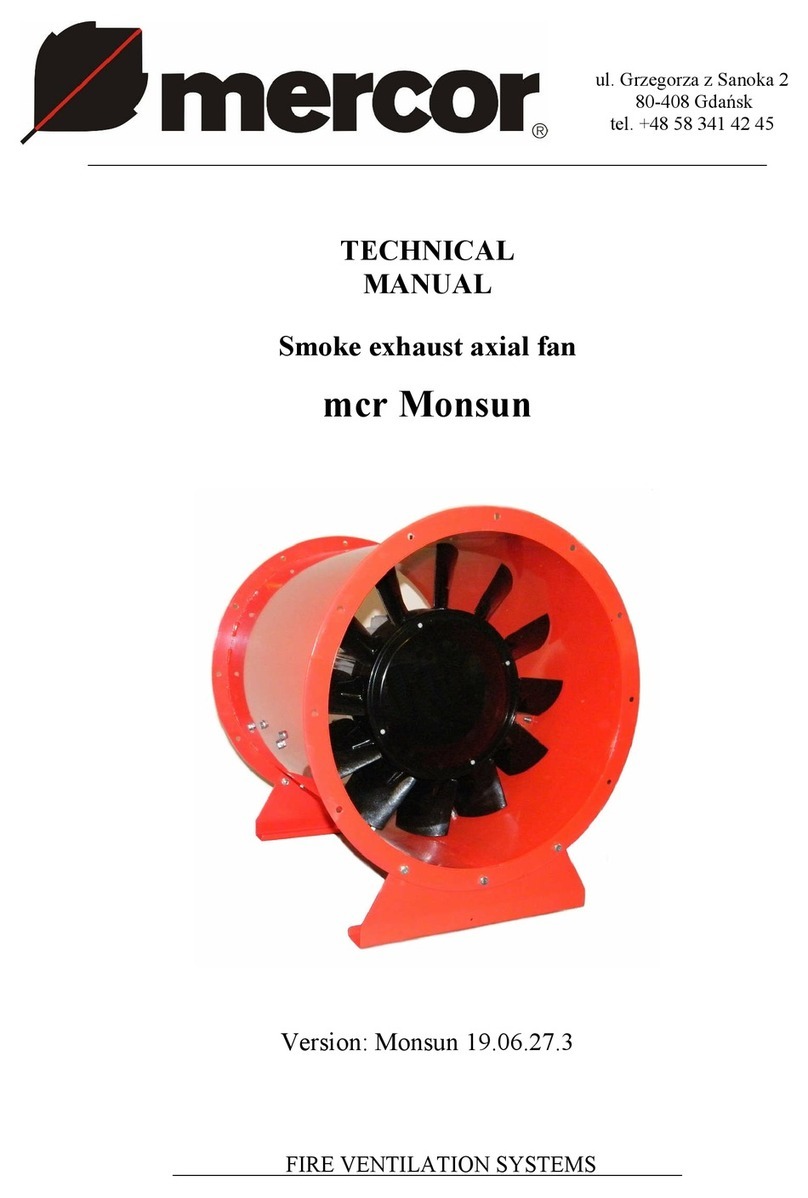

This Technical Manual is addressed to users/operators of type mcr Pasat roof smoke exhaust fans. This

document is intended to provide guidelines on the application, design, commissioning and operation of

the product.

Read this Technical Manual thoroughly before installing this equipment at its

operating site and commissioning.

If the equipment is found malfunctioning or defective, contact the manufacturer or

their Authorised Representative.

Due to the continuous product improvement policy, we reserve the right to change

the product design in order to improve its performance and safety.

This equipment has been designed and manufactured according to the following standards:

PN-EN 12101-3:2004 Smoke and heat control systems.

Part 3: Specification for powered smoke and heat exhaust fans.

PN-EN ISO 12100-1:2005 Safety of machinery. Basic concepts, general principles for design.

Part 1: Basic terminology, methodology.

PN-EN ISO 12100-2:2005 Safety of machinery. Basic concepts, general principles for design.

Part 2: Technical principles.

PN-EN 60204-1:2001 Safety of machinery. Electrical equipment of machines.

Part 1: General requirements.

The smoke exhaust fan design also meets the state of the art in technology, while assuring health and

safety protection.

2. MANUFACTURER'S DISCLAIMER_______________________________

The manufacturer shall not be liable for any consequences of non-intended use or misuse of the

equipment.

DO NOT install any components that are not included in the equipment composition or

accessories.

Unauthorised modifications or alteration of this equipment is strictly prohibited.

Protect the equipment enclosure (casing) from mechanical damage.

Before attempting to install this equipment, verify the load bearing capacity of the structural

elements to which the equipment is to be fastened. Unreliable fastening may result in damage or

failure of the equipment and/or be hazardous to all nearby personnel.

This fan is not intended for forcing air with viscous pollutants that may settle on the equipment,

and especially on its rotor.