mcr-PROLIGHT VENTS,TYPE:DVP, DVPS

OPERATION AND MAINTENANCE MANUAL

Page 3 of 30

1. INTRODUCTION

This operation and maintenance manual (OMM) allows the user to learn the purpose, design,

principle of operation and correct installation of mcr-PROLIGHT smoke vents and smoke &

ventilation vents type DVP and DVPS. The documentation also covers additional information

on the conditions for use, maintenance and terms of the product's warranty.

Observing the guidelines contained herein will ensure the proper functioning of systems in

terms of their smoke exhausting and/or ventilation function, and the safety of system operators.

NOTE

Any works related with installation, operation, maintenance and servicing of the vents

and skylights may only be performed in compliance with SHE requirements, and with use

of appropriate personal protective equipment - including fall arresting devices. Any

works necessitating working at height in order to make electrical connections, etc. may

only be performed by duly licensed persons.

2. PURPOSE OF DEVICE

mcr-PROLIGHT smoke vents are automatic smoke venting devices. The principal function of

mcr-PROLIGHT smoke vents is the removal of heat energy, fire gases, and smoke from

enclosed spaces (production floors, storage rooms, public amenity buildings, etc.) outside the

building, contributing to the protection of life and property, through:

• maintaining escape routes in a state of moderate smoke intensity,

• facilitating fire fighting and rescue operations by providing a bottom corridor with

moderate smoking intensity,

• ensuring protection for the building structure and its equipment,

• limiting fire damage caused by smoke, hot burning fumes and thermal decomposition

byproducts

The smoke vents may also serve the purpose of ventilation vents, smoke & ventilation vents, or

roof skylights.

The use of smoke vents provides the following opportunities to the Investor:

• lowering the building's fire resistance grade

• extending permissible fire zones,

• elongating evacuation routes

mcr-PROLIGHT smoke vents are part of a smoke control system that comprises other

MERCOR SA products, including, among others: mcr-PROLIGHT smoke vents in continuous

skylights and single skylights, mcr-PROSMOKE smoke curtains, mcr 9705 and mcr 0204 control

units, and others.

mcr-PROLIGHT smoke vents have a Certificate of Conformity WE 1488-CPD-0151/W,

issued by the Institute for Building Technologies in Warsaw, certifying the conformance

of the vents design with the requirements of PN-EN12101-2:2005, and Certificate of

Conformity 1396-CPD-0040 issued by Fires s.r.o., NB 1396, Slovakia, certifying the

conformance of the vents design with the requirements of EN 12101-2:2003.

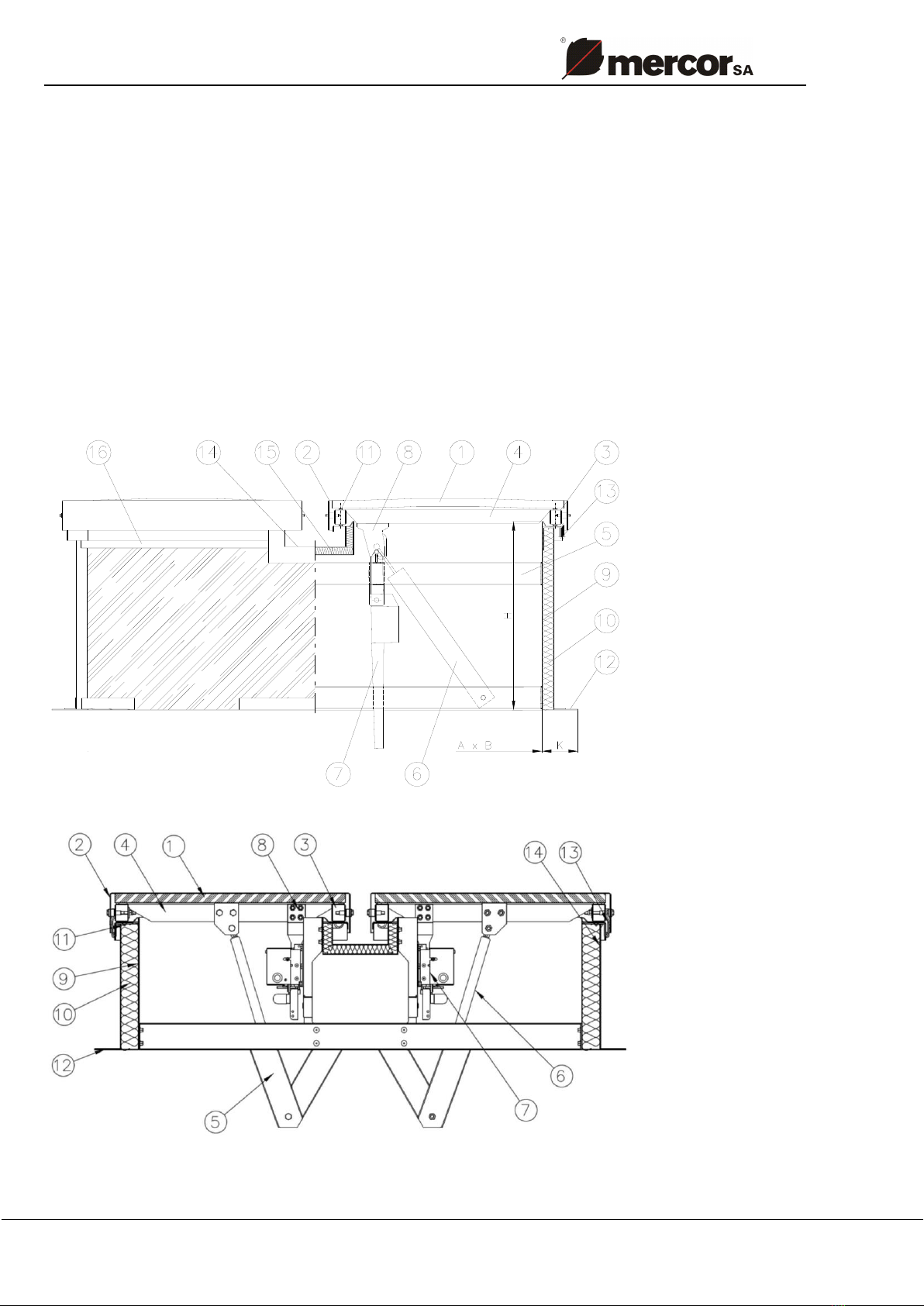

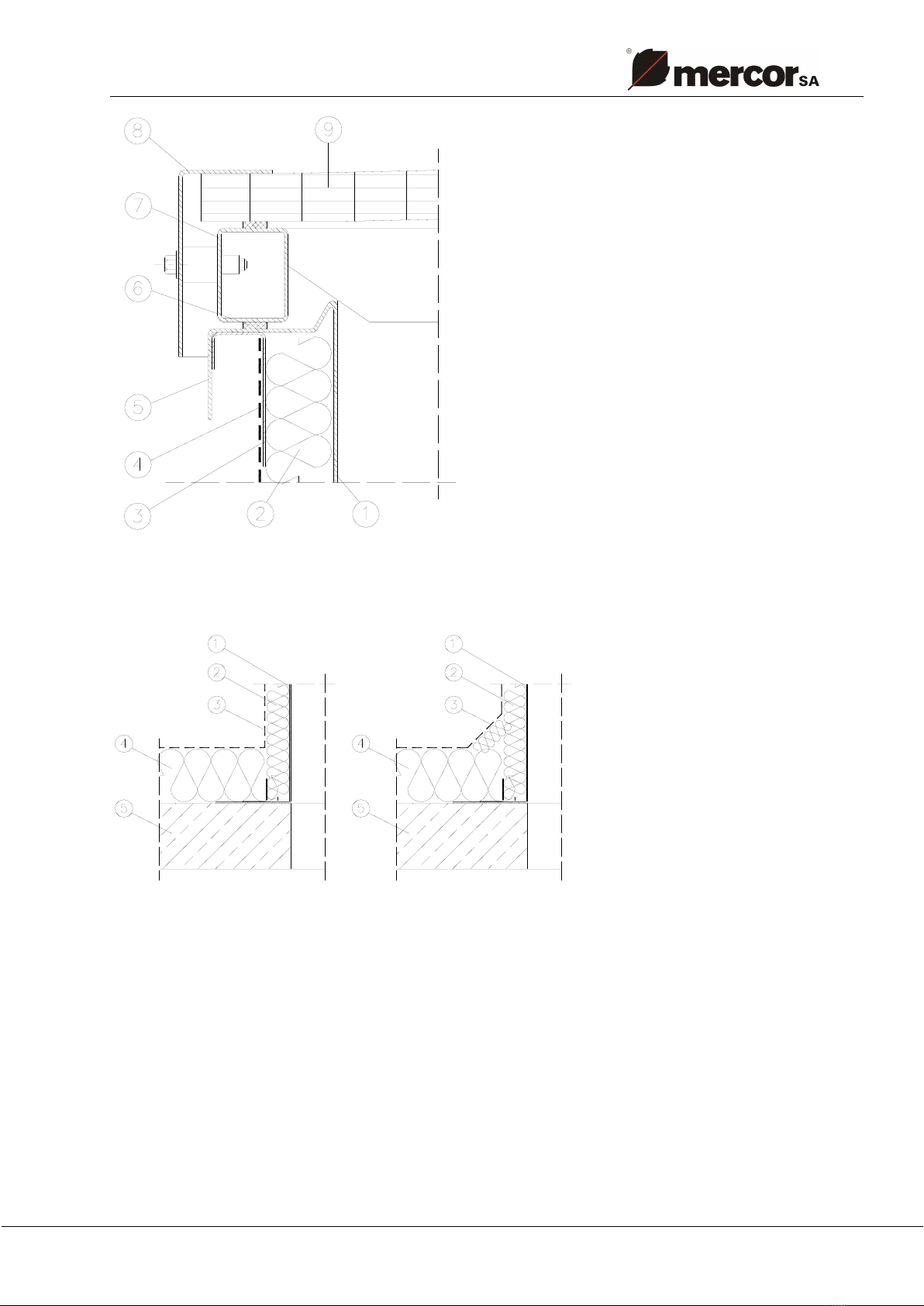

3. DEVICE DESIGN AND PRINCIPLE OF OPERATION

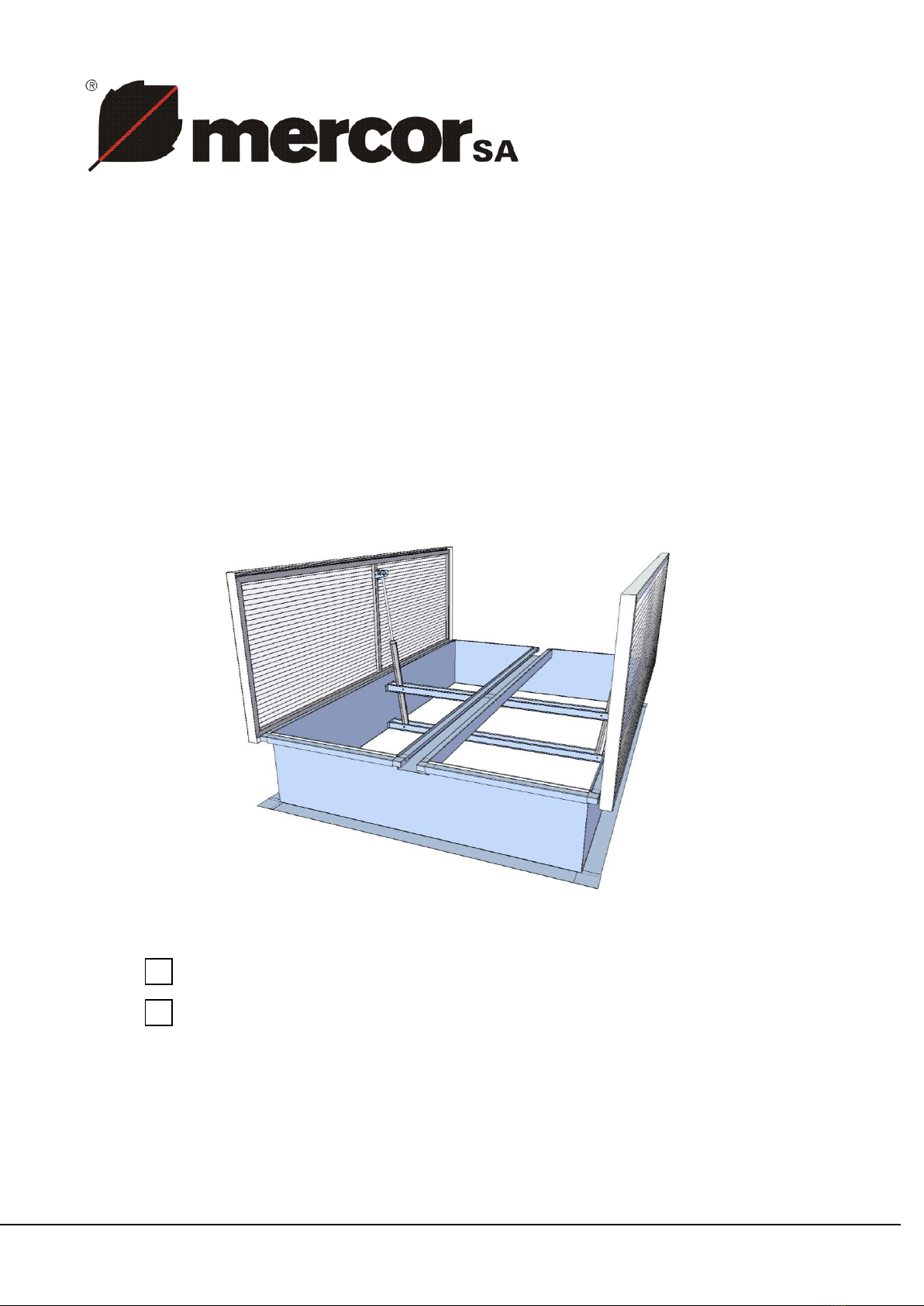

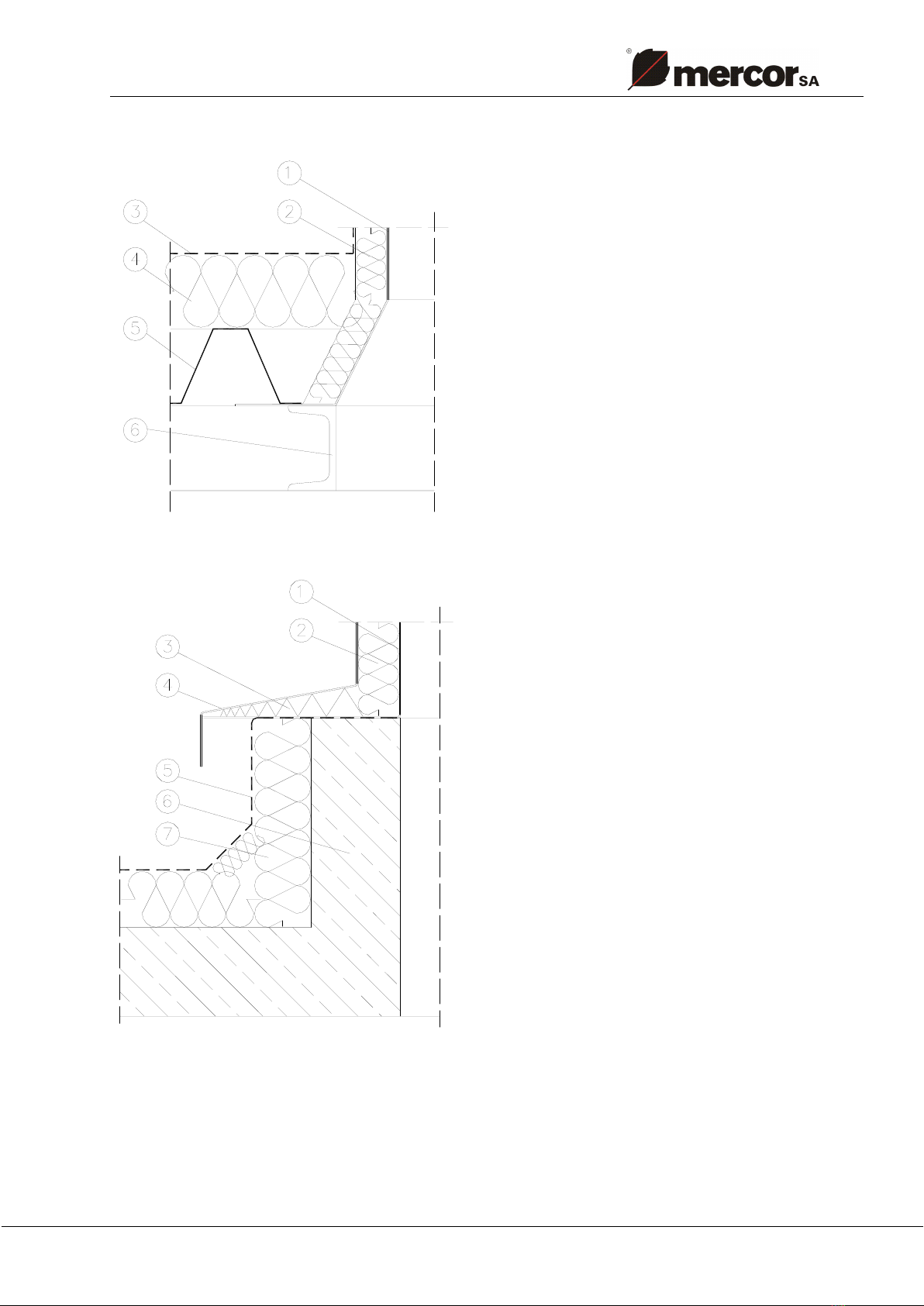

Depending on the customer's individual requirement, MERCOR offers double-leaf smoke vents

and fixed and opening skylights, on straight bases, in a broad range of clear dimensions and

base heights.

All steel elements of the vents are protected with a zinc coat, applied using hot-dip or galvanic

method.

In standard, the bases are supplied with thermal insulation of thickness 20 mm. Custom

thickness and thermal insulation type is possible.

The glazing options for the opening leaf are as follows: