C,

E,

NG-A

T

YPE

mcr-PROLIGHT

V

ENTS

O

PERATIONS AND

M

AINTENANCE

M

ANUAL

(DTR)

Page 3 of 26

1. INTRODUCTION.

The present Operations and Maintenance Manual describes the purpose, design, operating

principles, correct assembling, and support of spot smoke vents as well as smoke and

ventilation dampers: C, E, and NG-A type mcr-PROLIGHT units. Furthermore, the

documentation includes additional data on operations, maintenance, and warranty conditions.

Not only will the consistency with the recommendations contained in this Manual ensure regular

functioning of the systems designed for smoke evacuation and/or ventilation, but also guarantee

safety to the users.

WARNING

All the works connected with assembling, operations, maintenance, and service support

of vents and skylights should be conducted in compliance with occupational health and

safety rules. Applicable personal protections should be used, including mostly

protections from fall from a different level. High-rise works, works on electric systems,

etc., should be conducted by competent personnel only.

2. PURPOSE OF SMOKE EXHAUST VENTS.

Smoke exhaust vents mcr-PROLIGHT are automatic appliances the primary function of which

consists in evacuation of smoke, fire fumes, and thermal energy from closed spaces (production

buildings; warehouse buildings; public buildings, etc.) to the outside, thus contributing to

protection of life and property thanks to:

• Maintenance of low smoke level on the escape routes;

• Assistance in fire fighting and extinguishing procedures by means of a bottom layer

featuring low smoke level;

• Protection of structural elements and equipment inside the building, and

• Reduction in fire damages produced by smoke, hot fire gases, and thermal

decomposition products.

Smoke exhaust vents may be used also as ventilation systems, smoke and ventilation dampers,

as well as additional roof lights.

Installation of smoke exhaust vents means a number of benefits to the investors, such as e.g.:

• Reduced fire resistance class of the building,

• Expansion of admissible fire zones, and

• Extension of fire routes.

mcr-PROLIGHT smoke exhaust vents are integral parts of smoke control systems which include

other components manufactured by MERCOR SA, such as e.g.: smoke vents in mcr-

PROLIGHT roof skylights and skylights, mcr-PROSMOKE smoke curtains, mcr 9705 and mcr

0204 smoke control units, and many other products.

mcr-PROLIGHT smoke exhaust vents are delivered with Certificate of Conformity No. WE

1488-CPD-0151/W issued by Instytut Techniki Budowlanej w Warszawie (Building

Research Institute in Warsaw) and confirming that the vents are manufactured in

compliance with the requirements contained in PN-EN 12101-2:2005 Standard.

3. DESIGN AND OPERATING PRINCIPLES.

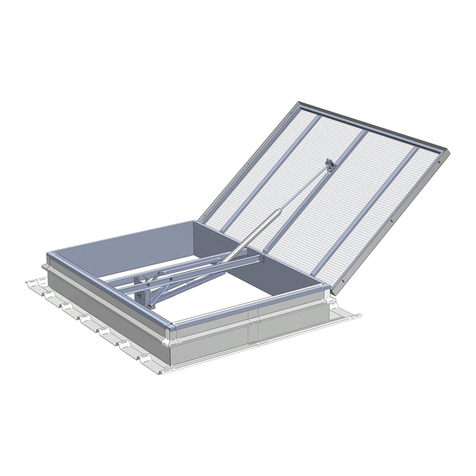

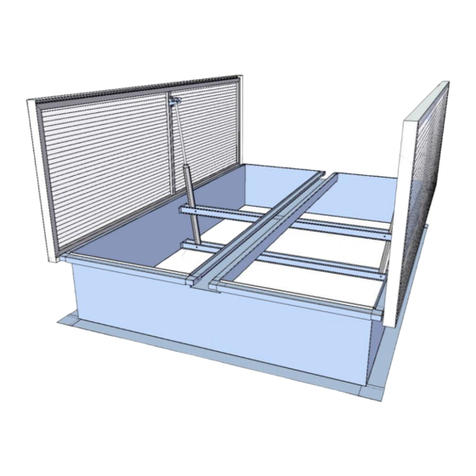

Depending on individual requirements, MERCOR offers smoke exhaust vents on simple and

diagonal bases with wide array of structural opening dimensions and base heights.

All the steel elements are protected by means of hot dip or electrolytic zinc coating.

Standard base models are delivered inclusive of 20 mm thick thermal insulation. Thickness and

type of thermal insulation may be individually selected on request.