Installation manual of mcr PROLIGHT continuous rooflight with smoke vents

Page 2 of 104

Table of Contents

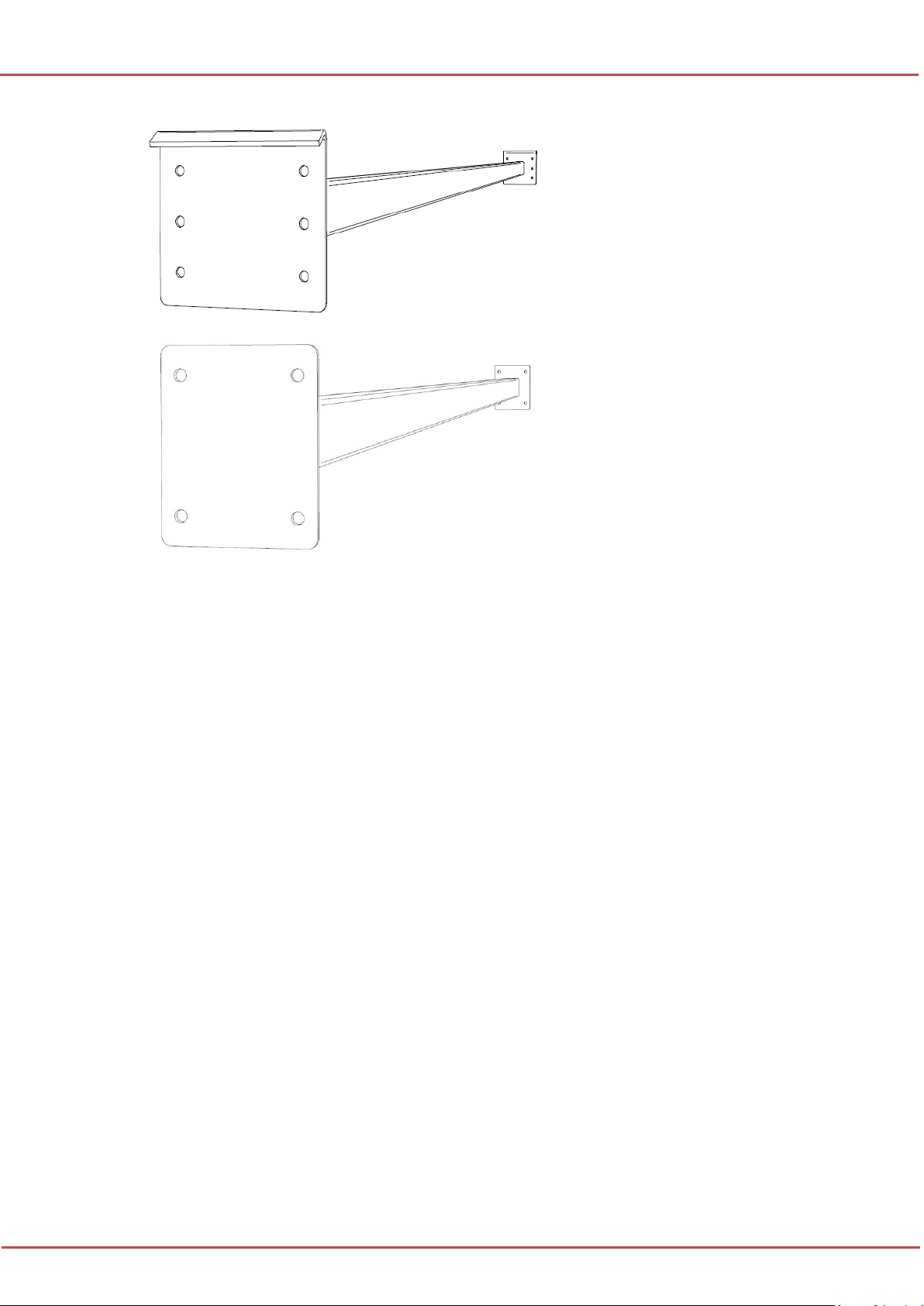

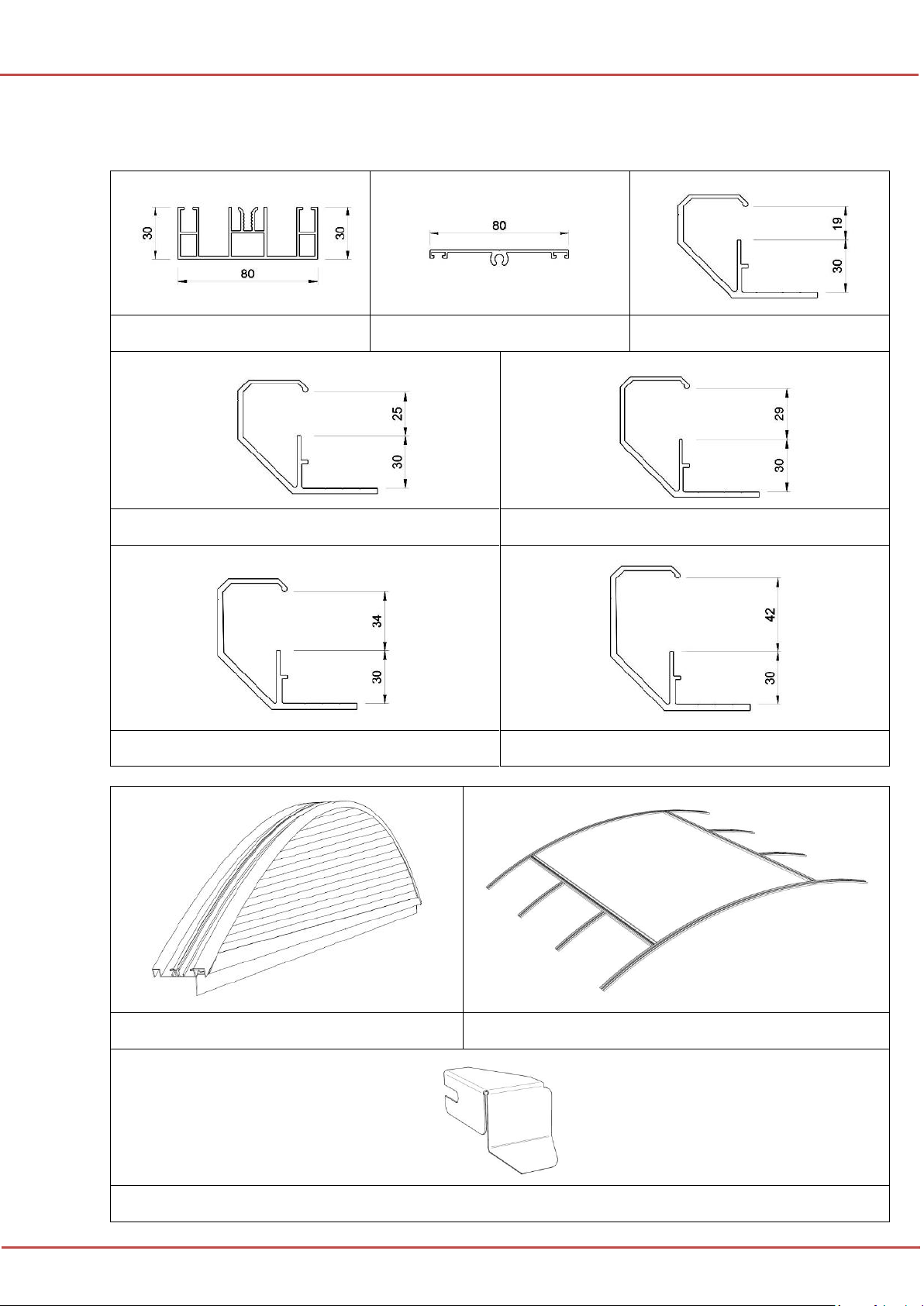

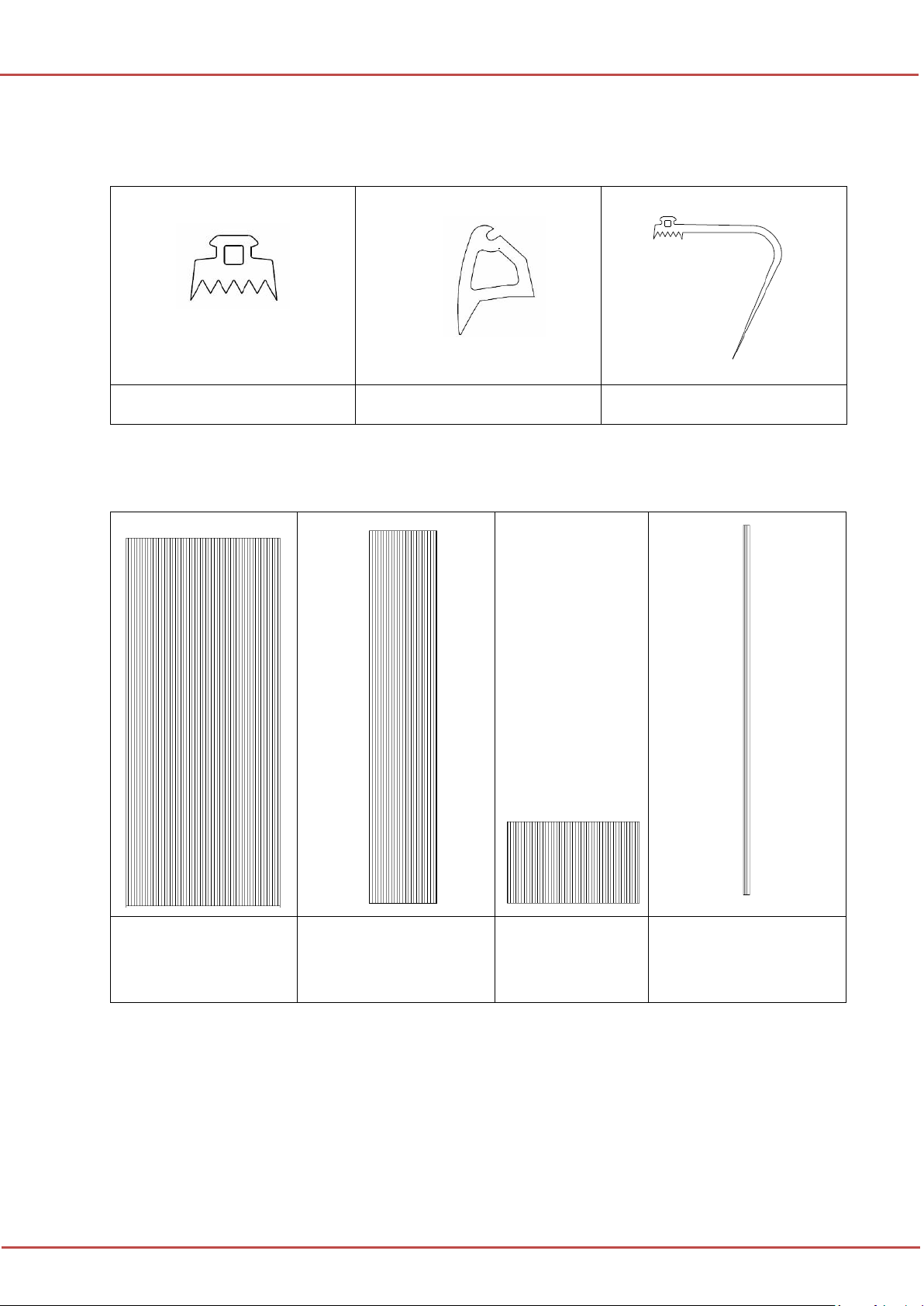

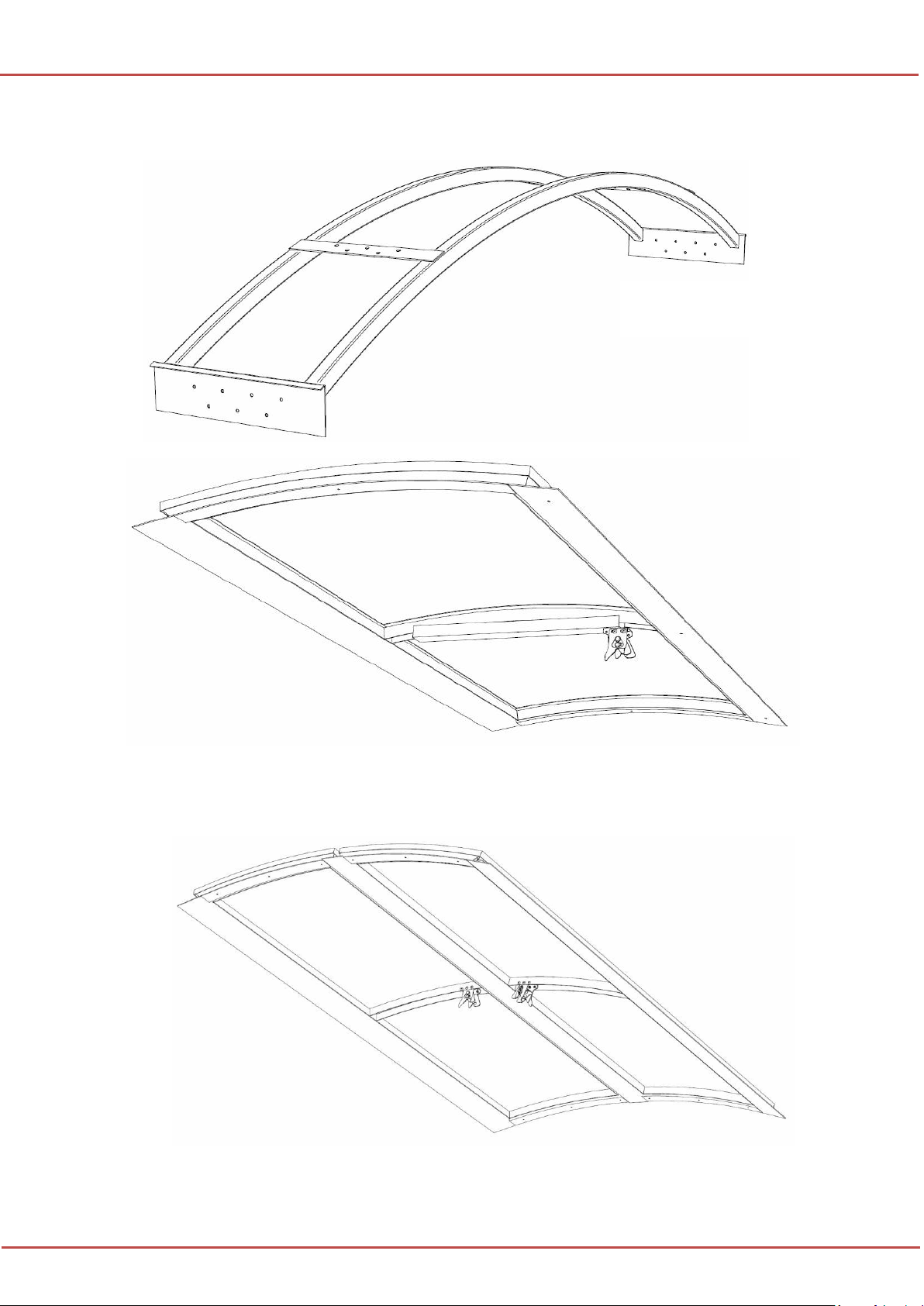

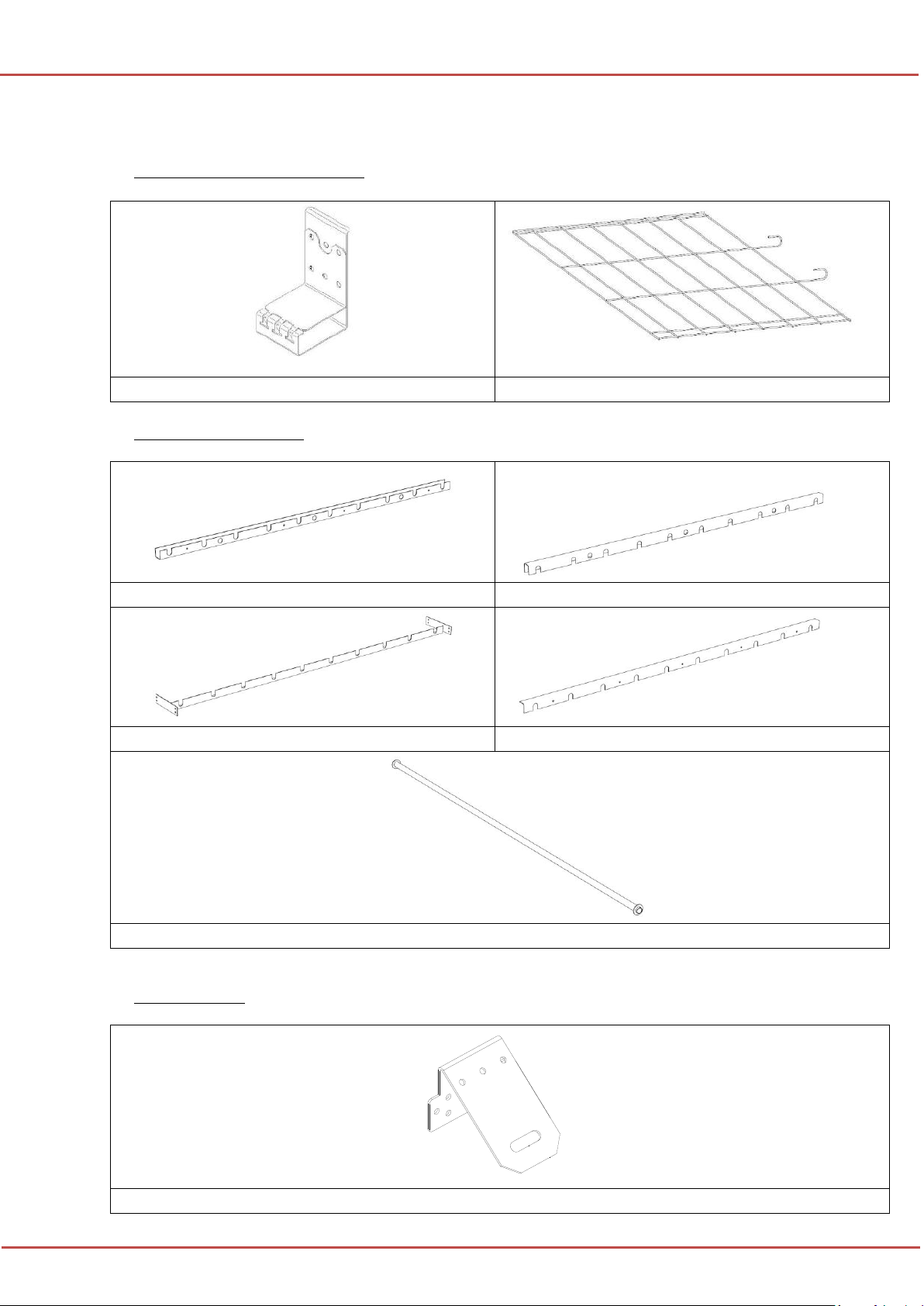

I. Components of continuous rooflight and components of continuous rooflights

with sandwich panels........................................................................................................3

II. Installation of the rooflight base.....................................................................................13

III. Installation of an overlay base ........................................................................................18

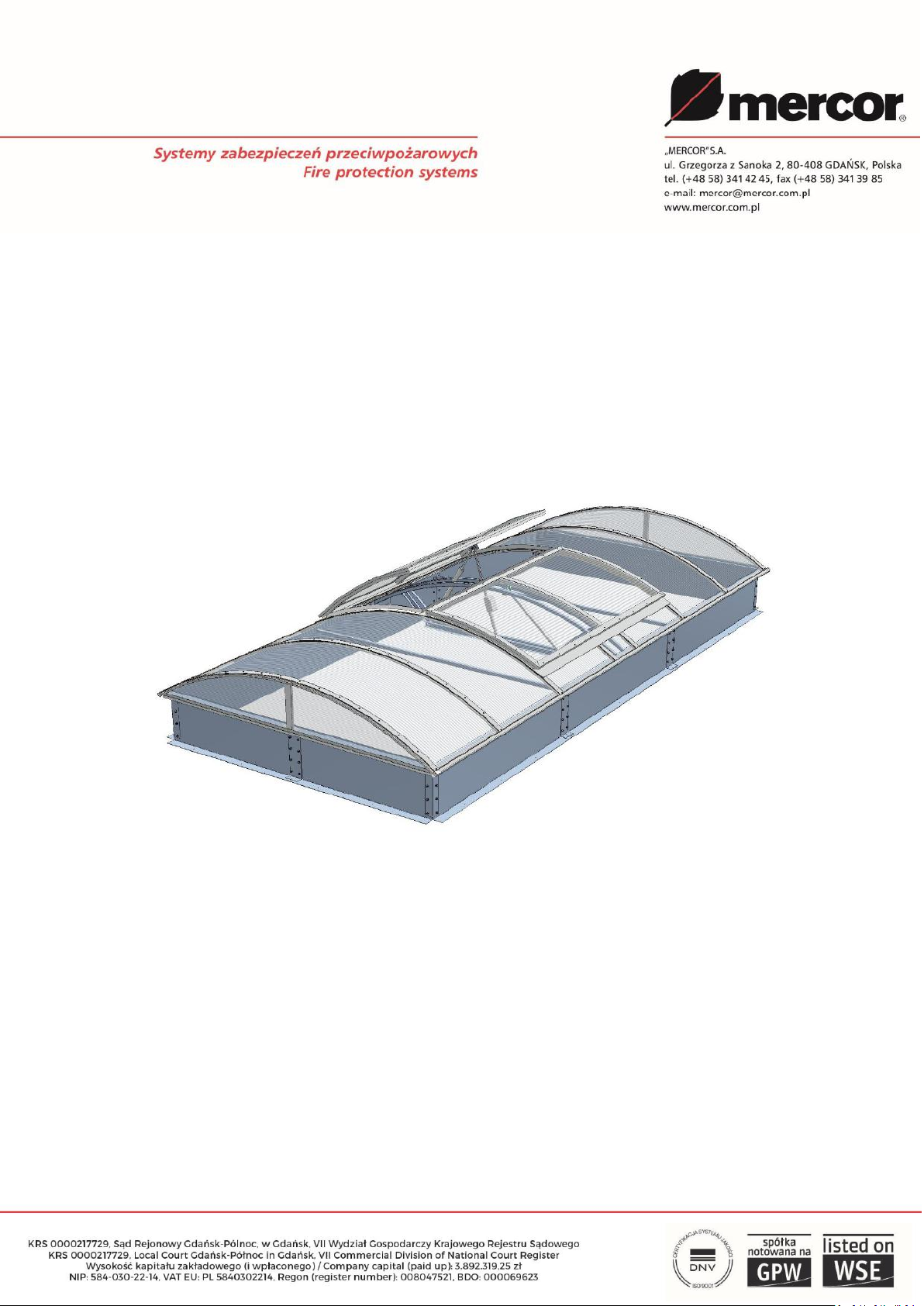

IV. Installation of a safety nets / an anti-burglar grids..........................................................20

A. Installation of a safety net...............................................................................................20

B. Installation of the anti-burglar grid.................................................................................23

C. Installation of PAS anchorage points..............................................................................25

V. Double glazings –possible configurations and installation sequence............................27

VI. Assembly of the top section of the continuous rooflight................................................37

VII. Additional operations limiting errors in roofing works at the tympanum panel ............54

VIII. 1200 J reinforcements to the top section structure..........................................................55

A. Types of 1200J reinforcements.......................................................................................55

B. Spacing of 1200 J braces ................................................................................................56

C. Installation of 1200 J reinforcements..............................................................................58

IX. Assembly of triangular rooflight.....................................................................................61

X. Installation of a double-leaf vent integrated into a continuous rooflight........................67

XI. Installation of a single-leaf vent in a continuous rooflight.............................................74

XII. Installation of wind deflectors ........................................................................................78

XIII. Instruction for the installation of the continuous rooflight crossing the roof ridge........80

XIV. Roof ridge crossing: how to install the 1200 J reinforcements.......................................98