Mercury Floor Machines BOSS-II Guide

© 2013 Copy Rights Reserved Mercury Floor Machines, Inc.

Important Information and Safety Instructions

Register your Machine at mercuryoormachines.com/registration.aspx

Serial No:

BOSS-II Floor machine

Heavy-Duty

Safe & Easy to Use

Fully Adjustable

Powerful Motor

Super Value

Three Apron Sizes

REGISTER

YOUR

MACHINE

ONLINE!

Safety, Operation and Maintenance

Manual with Parts List

Please read before use!

175/300 RPM, 1.5 HP

Make a copy of this card for future reference.

© 2013 All Rights Reserved Mercury Floor Machines, Inc.

New Equipment Warranty

Limited Warranty

Mercury Floor Machines, Inc. warrants new equipment against defects in material and

workmanship under normal use and service to the original purchaser. Any statutory implied

warranties, including any warranty of merchantability or tness for a particular purpose, are

expressly limited to the duration of this written warranty. Mercury Floor Machines, Inc. will not

be liable for any other damages, including but not limited to indirect or special consequential

damages arising out of or in connection with the furnishing, performance, use or inability to

use the machine. This remedy shall be the exclusive remedy of the purchaser. The warranty

period is subject to the conditions stated below.

5 Years - Motor and Gearbox, 1 Year - Service Labor

Mercury Floor Machines, Inc. warrants electric motors and transmission gearboxes on

all Mercury Floor Machines, Inc. oor machines to be free from defects in material and

workmanship, under normal use and service for ve (5) years to the original purchaser.

Parts replaced or repaired under this warranty are warranted for the remainder of the

original warranty period. Service labor charges are covered for one (1) year from the date of

purchase, when performed by a Mercury Floor Machines, Inc.-authorized service provider.

Freight charges to and from this service provider will be covered for ninety (90) days from

the purchase date. After this ninety (90) day period, these freight charges will be paid by the

equipment owner. Travel expenses are not covered.

Wear Items on all Machines

Critical Wear Items - bearings, capacitors, clutches, pulleys, rectiers, relays, switches, wheels,

tires and casters are warranted for manufacturing defects for one (1) year from the purchase

date.

Normal Wear Items - belts, brushes, bumpers carbon brushes, cords, nishes, squeegees,

actuating cables and gaskets are warranted for manufacturing defects for ninety (90) days

from the purchase date.

All warranties of motors and associated components will be voided: if the machine is used

as a oor sander; if the machine is serviced by anyone other than a Mercury Floor Machines,

Inc.-authorized service provider; if the machine is mechanically modied; or if the machine is

misused or abused.

The warranty starts on the purchase date by the original purchaser from an authorized

Mercury Floor Machines, Inc. distributor, subject to proof of purchase. The machine

registration card must be completed and returned immediately at the time of purchase. If

proof of purchase cannot be identied, the warranty start date is ninety (90) days after the

date of sale to an authorized Mercury Floor Machines, Inc. inventory.

Mercury Floor Machines, Inc.

110 South Van Brunt Street

Englewood, NJ 07631

Phone: 201-568-4606

Toll Free: 888-568-4606

www.mercuryoormachines.com

Model BOSS-II

Five

Interchangeable

Aprons Available:

13”, 15”, 17”, 19”

and 21”

(2) BOSS-II Floor Machine BOSS Multi-Tasker Floor Machine (13)

Warranty

Registration

Mail to:

Mercury Floor Machines, Inc.

110 South Van Brunt Street

Englewood, NJ 07631

See reverse side for warranty information.

Make a copy of this card for future reference.

© 2013 All Rights Reserved Mercury Floor Machines, Inc.

Please take a moment to register your machine. Fill out the

information below and mail back to Mercury immediately.

The warranty starts on the purchase date by the original purchaser, subject to

proof of purchase. Please immediately register your machine online at www.

mercuryoormachines.com/registration.aspx or return this Machine Registration Card

at the time of purchase. If proof of purchase cannot be identied, the warranty start

date is ninety (90) days after the inventory stocking date at the distributor’s warehouse.

Machine Model Purchase Date

Motor Type Serial No.

Place of Purchase

Shipped To

Your Name Phone

E-mail Fax

Address Line 1

Address Line 2

City State Zip

Comments:

Dear Valued Customer,

Congratulations on the purchase of your BOSS-II Floor Machine! The world of oor care

is becoming more high-tech and competitive and we strive to provide you with the most

innovative products. Our BOSS-II machine is yet another example of this, bringing a new

dimension to oor care and maintenance with its cutting-edge features, quality and value.

Please review this manual paying careful attention to the Safety Instructions section.

Keep in mind that any unnecessary damage, neglect or abuse of this machine will void

your warranty. You can be condent that simple maintenance will ensure that your Floor

Machine provides quality performance for many years to come.

If warranty questions arise, please consult your manual or contact your distributor.

Should you have any questions regarding maintenance, replacing parts or ordering parts,

please call an authorized distributor.

Before you begin using your Floor Machine, thoroughly review the Owner’s Manual.

Again, congratulations on the purchase of your BOSS-II Floor Machine!

Questions or Comments?

Phone: 201-568-4606

Toll Free: 888-568-4606

Fax: 201-568-7962

info@mercuryoormachines.com

Mailing Address:

110 South Van Brunt Street, Englewood, NJ 07631

Visit our Web site at www.mercuryoormachines.com

Register your Machine at www.mercuryoormachines.com/registration.aspx

BOSS-II Floor Machine (3)

© 2013 Copy Rights Reserved Mercury Floor Machines, Inc.

110 South Van Brunt Street, Englewood, NJ 07631

Phone: 201-568-4606 | Toll Free: 888-568-4606 | Fax: 201-568-7962

info@mercuryoormachines.com | www.mercuryoormachines.com

Please ll out the following information:

Model No:

Serial No:

Distributor Name:

Distributor Phone No:

Date of Purchase:

BOSS-II Floor Machine

By Mercury Floor Machines

Table of Contents

New Equipment Warranty...................................................................................................4

1.0 Safety Instructions .......................................................................................................5

2.0 Grounding Instructions ................................................................................................6

3.0 Assembly Instructions..................................................................................................7

4.0 Operating Tips..............................................................................................................9

5.0 Trouble Shooting Guide.............................................................................................10

6.0 Brush Construction ....................................................................................................11

7.0 Machine Schematic Drawing.....................................................................................13

8.0 Machine Parts List .....................................................................................................14

(4) BOSS-II Floor Machine BOSS-II Floor Machine (17)

New Equipment Warranty

5-year warranty on motor and gearbox. 1-year warranty on service labor.

Mercury Floor Machines, Inc. warrants electric motors and transmission gearboxes on all Mercury

Floor Machines, Inc. oor machines to be free from defects in material and workmanship, under

normal use and service for ve (5) years to the original purchaser. Parts replaced or repaired under

this warranty are warranted for the remainder of the original warranty period. Service labor charges

are covered for one (1) year from the date of purchase, when performed by a Mercury Floor

Machines, Inc.-authorized service provider. Freight charges to and from this service provider will

be covered for ninety (90) days from the purchase date. After this ninety (90) day period, these

freight charges will be paid by the equipment owner. Travel expenses are not covered.

Wear Items on all Machines

Critical Wear Items - bearings, capacitors, clutches, pulleys, rectiers, relays, switches, wheels,

tires and casters are warranted for manufacturing defects for one (1) year from the purchase date.

Normal Wear Items - belts, brushes, bumpers carbon brushes, cords, nishes, squeegees, actuating

cables and gaskets are warranted for manufacturing defects for ninety (90) days from the purchase

date.

All warranties of motors and associated components will be voided: if the machine is used as a

oor sander; if the machine is serviced by anyone other than a Mercury Floor Machines, Inc.-

authorized service provider; if the machine is mechanically modied; or if the machine is misused

or abused.

Warranty Policy

All equipment is inspected and tested before shipping from the manufacturer. All parts are

warranted to be new and free from defects in workmanship and material, under normal use to the

original retail purchaser. This warranty limits manufacturer’s liability for defects in workmanship

or materials for replacement of defective parts only. Manufacturer accepts no liability for incidental

or consequential damages arisen from the use of any equipment, defective or not. This warranty is

in lieu of all expressed or implied warranties and is extended only to the original retail purchaser.

Manufacturer sales and service representatives are not authorized to waive or alter the terms of this

warranty, or to increase the obligations of the manufacturer under the warranty. Parts replaced or

repaired under warranty are warranted for the remainder of the original warranty period.

Freight charges and travel charges to and from the service provider shall be covered for ninety (90)

days from the original purchase date. After this ninety (90) day period, freight charges shall be paid

by the equipment owner, subject to manufacturer discretion. Certain circumstances may require

additional consideration. No travel charges shall be covered after ninety (90) days.

Manufacturer covers up to 1-year (365 days) of service labor at manufacturer’s calculated hourly

labor rate/repair time when performed by a manufacturer’s authorized-service provider. Ultimately,

labor reimbursement costs are at the discretion of the manufacturer. After 1-year, the original retail

purchaser is responsible for all labor costs with no manufacturer reimbursement.

Manufacturer charges a 15% restocking fee for any items that are being returned to stock. Items

must be new, unused and free of damage. Only good for up to 1-year (365 days). After 1-year,

manufacturer does not accept the return of any item(s) for a reimbursed price. Authorized warranty

replacement parts need to come directly from the manufacturer. Use of any other parts will void

warranty. Manufacturer does not reimburse for parts used by the customer that were not supplied

directly for the machine under warranty.

(16) BOSS-II Floor Machine BOSS-II Floor Machine (5)

1.0 Safety Instructions

READ THIS MANUAL BEFORE USING FLOOR MACHINE. KNOW THE

PROPER OPERATION, CORRECT APPLICATIONS AND THE LIMITATIONS OF

THIS EQUIPMENT BEFORE USE.

Reduce the Risk of Fire, Electric Shock or

Injury:

• Thisoormachineisdesignedforindooruseonly.Do

notuseoutdoors.Donotexposetorain.

• Donotwashthemotorwithowingwater.Ifthemotor

getswet,seekauthorizedservice.

• Keeptheventsonthisair-cooledmotorfreefromdebris.

Donotoperatewiththemotorcoveredorwithvents

blocked.Donotusethismachineasaoorsander.

• Neveroperatethisoormachinenearammabledusts,

liquidsorvapors.Neveruseammablesolventsasa

cleaningagent.Enginesparksandoperatingheatcan

causere.

• Neverhandleelectricalequipmentwithwethands.Never

operatethisoormachinewithbarefeet.

• Unplugtheoormachinewhennotinuseandwhen

servicingtheequipment.Tounplug,grasptheplugnot

thecord.

• Donotoperateaoormachinewithdamagedhandle

controls,cordorplug.Iftheequipmentisnotperforming

properly,seekrepairfromaqualiedservicesupplier.

• Thisoormachineisconstructedwithelectrical

groundingattheplug.Operateonlywhenconnectedtoa

properlygroundedoutlet.Seesection1.2forgrounding

details.

• Preventelectricalcordabuse.Donotcloseadoor

uponthecord,driveequipmentoverit,orruntheoor

machineoverit.Donotexposethecordtohotsurfaces.

Donotlift,pullorcarrythisoormachinebythecord.

• Neveroperatetheoormachineoversharpobjectsthat

canbethrownoutandharmtheoperatoranddamage

theoor.Sweephardoorsbeforescrubbingorbufng.

Vacuumcleancarpetsbeforeshampooingorbonnet

cleaning.

• Trainyourstaffinproperuseofthisoormachine.

Notes:

(6) BOSS-II Floor Machine BOSS-II Floor Machine (15)

2.0 Grounding Instructions

DANGER: IMPROPER GROUNDING METHOD CAN RESULT IN A RISK OF

ELECTRIC SHOCK.

Electrical equipment must be grounded. If it should malfunction or breakdown,

grounding provides a path of least resistance for electrical current and reduces the risk

of electric shock. The vacuum is equipped with a cord containing a grounding conductor

and grounding plug. The plug must be inserted into an appropriate outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

If repair or replacement of the cord or plug is necessary, DO NOT connect the grounded

wire to a at bed terminal. The green insulated wire, with or without yellow stripes, is the

grounding wire.

This oor machine operates on a 15 amp nominal 115V, 60 Hz, A.C. power circuit

(motors may be custom wired at the factory 220V, 50 Hz international operation). The,

amp, hertz and voltage ratings are listed on the motor spec label found on each oor

machine. Using voltages above or below those indicated on the spec label will damage

the motor. Always check your local voltage requirements.

The electric vacuum is for use on a normal 120 volt circuit. It has a grounded plug that

ts the outlet illustrated in Figure A. If a properly grounded outlet is not available, a

temporary adapter, such as the adapter illustrated in Figure B and C, may be used to

connect the plug into a 2-pole outlet, as shown in Figure C.

The temporary adapter should be used only until a properly grounded outlet, Figure A,

can be installed by a qualied electrician. The green color rigid ear lug or grounding

means extending from the adapter must be connected to a permanent ground, such as

a properly grounded outlet box cover. Whenever the adapter is used, it must be held in

place by its grounding means and a metal screw, as shown in Figure C.

WARNING:

Improper connection of the equipment grounding conductor can result in a risk of electric

shock. Check with a qualied electrician or service person if you are in doubt as to

whether the outlet is properly grounded. DO NOT modify the plug provided with the

equipment. If it will not t into the outlet, have a proper outlet installed by a qualied

electrician.

The oor machine is built with a 50 foot (15 M) safety cord which plugs directly into an

approved outlet. Use of any extension cords is NOT RECOMMENDED.

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian

Electrical Code.

8.0 Machine Parts List Continued

Item Description Part No. Qty.

62A Bumper 13” - Yellow M-232-13/Y 1

62B Bumper 15” - Yellow M-232-15/Y 1

62C Bumper 17” - Yellow M-232-17/Y 1

62D Bumper 19” - Yellow M-232-19/Y 1

62E Bumper 21” - Yellow M-232-21/Y 1

63A Apron 13” A-163 1

63B Apron 15” A-167 1

63C Apron 17” A-169 1

63D Apron 19” A-171 1

63E Apron 21” A-172 1

64 Scrubber Plug B-50 1

65 Base Casting Screw B-31 4

66 Flag Wire Connector G48 3

67 Slotted Hex Head B-3 2

(14) BOSS-II Floor Machine BOSS-II Floor Machine (7)

3.0 Assembly Instructions

3.1 Handle Installation

Thismachinehandle(1)hasbeencustomttoits

mountingyoke(2)atthefactoryandthentakenapartfor

shipping.Foreasyassembly,makesurethatthehandle

numberonthetag(seeright)matchedtheserialnumber

stampedonthechassis.

You will need 7/16” wrenches to complete the assembly:

1. Remove the handle and mounting hardware from the

carton. Bolts, nuts, washers and the locking lever

assembly are in the plastic bag attached to the handle.

2. Position the handle (1) over the mounting yoke

(2) with the power cord (3) facing away from the

motor. Push the tube down until the bolt holes are

lined up.

3. Insert the mounting bolts (4) into the bolt holes

from the back of the machine. Secure each bolt

with a locking nut (5). The locking nuts will face

the motor.

4. The handle mounting collar (6) is designed to slide

freely up and down the handle tube. This feature

allows the handle to be adjusted for the comfortable

operation of all users. Align the mounting collar (6)

and the two bent handle braces (7).

5. Remove the lever assembly parts from the plastic

bag.

• Place the thick spacer with a rectangular hole (9)

onto the locking lever shaft (8). The spacer must

t onto the rectangular neck of the lever.

• Insert the shaft through the mounting hole in the

right handle brace, the mounting collar and the left

handle brace.

• Place the spacer (10) on the shaft.

• Place the split washer (11) on the shaft.

• Adjust the wing nut for tightness. When correctly

installed, the collar slides easily when the cam-

engineered locking lever is “up,” but is rmly

xed when the lever is “down.”

8.0 Machine Parts List

Item Description Part No. Qty.

1 Switch Box Back A-104 1

2 Handle Tube Screw B-23 2

3 Switch Box Closing Screw B-21 4

4 Strain Relief Clip M-213 1

5 Ground Wire Screw B-68 2

6 Rubber Spacer - Yellow M-218-Y 2

7 Hand Grip M-218 2

8 Handle Tube Insert M-247 1

9 Handle Tube Assembly M-206 1

10 Cable Hook Screw B-2 2

11 Cable Hook A-164 1

12 Sliding Collar A-111 1

13 Cam Washer B-37 1

14 Cam Lock Wing Nut B-25 1

15 Cam Split Washer B-39 1

16 Bent Brace M-216 2

17 Yoke Bolt B-18A 2

18 Yoke Nut B-19 2

19 Handle Tube Cable G-16 1

20 Black Rubber Cable Connector M-249 1

21 Cable Grommet B-63 1

22 Rectangular Hole Cam Washer B-67 1

23 A Cam Assembly C-100 1

23B Complete Cam Assembly Kit (Includes 1 each of CCA 1

Drawing Items #13, 14, 15, 22, 23)

24 50-Foot Cable, 14/3-Gauge - Yellow G-14-15-Y 1

25 Switch Mounting Plate G-30-B 1

26 Switch Plate Screw B-1 2

27 Int. Tooth Lock Washer (for Switch) B-35 1

28 Insulated Flag Wire Connector G-48 2

29 On-Off Switch and Plate Assembly G-30-AB 1

30 Lock Washer B-33 1

31 Trigger Return Spring G-30-CT057 4

32 Label for Switch Box 1

33 Switch Box Front A-103 1

34 Wire Connector G-47 1

35 Trigger A-105 2

36 16” Crossbar M-211-A 1

37 Safety Interlock Assembly SIA-1 1

38 Trigger Pin B-70 2

39 Crossbar Screw B-22 2

40 Acorn Nut for Yoke Pin B-8 2

41 Rubber Yoke Spacer B-5 2

42 Yoke Pin B-7 1

43 Yoke A-1001 1

44 Drip Cap Mounting Screw B-151 3

45 66 Frame Drip Cap Cover M-242 1

46 66 Frame Drip Cap Cover Bumper - Yellow M-239-Y 1

47 Two-Speed Motor Screen SCR-02 1

48 Two-Speed Motor Screen Bumper - Yellow M-238-Y 1

49 Cork Drip Cap Gasket M-248 1

50 Two-Speed Motor, 66 Frame, 1.5 HP w/ Gearbox 115V MOTOR/GB-TS 1

51 Gear Box, 11:1, Triple Planetary GB96008 1

52 Two-Speed Hi-Lo Switch Box SCAP-2 1

53 Two-Speed Hi-Lo Switch HILO-TS 1

54 Hub Caps V0038 2

55 Spring Washer B-51 4

56 6” Wheels M-250 2

57 ½” Flat Washer B-29 2

58 Spring B-30 2

59 Axel M-240 1

60 Main Machine Frame A-166 1

61 Thumb Screw B-96 3

(8) BOSS-II Floor Machine BOSS-II Floor Machine (13)

3.2 Install / Change the Apron

If you’ve purchased more than one apron, you can easily

change aprons for different cleaning jobs.

• Lock the handle in the “up: position and tip the oor

machine back.

• If you’re changing the apron, give the brush a quick ip

counterclockwise to unlock and remove the brush.

• Remove the 3 knurled thumb nuts that hold the apron to

the machine chassis.

• Remove the existing apron.

• Align the new apron.

• Re-install the three bolts and tighten.

• Install a brush that is 2” smaller than the apron.

3.3 Attach the Power Cord

The triple-wire grounded power cord has been factory-

installed into the handle tube. A exible rubber cable

connector (11) is used to secure the plug-in connections.

The oor machine ships with this connector mounted on the

cord coming out of the handle (10). Stretch the connector

and slip the male connector (9) (coming out of the motor

housing) through the connector hole and then into the

female connector.

Now, plug the end of the 50 foot cord into a grounded power

outlet. Squeeze the triggers on the handle and check for

power to the motor.

3.4 Brush or Pad Driver Installation

A brush or pad driver mounts onto your oor machine with

a “B” style Universal clutch plate.

Unplug the oor machine. Lock the machine handle in

the “up” position and tip the oor machine back onto the

handle.

Slide the brush or pad driver clutch plate (11) over the drive

plug (12).

Quickly spin the brush counter-clockwise to lock the brush

onto the drive plug.

Now, lower the machine back onto the brush. You’re ready

to go to work.

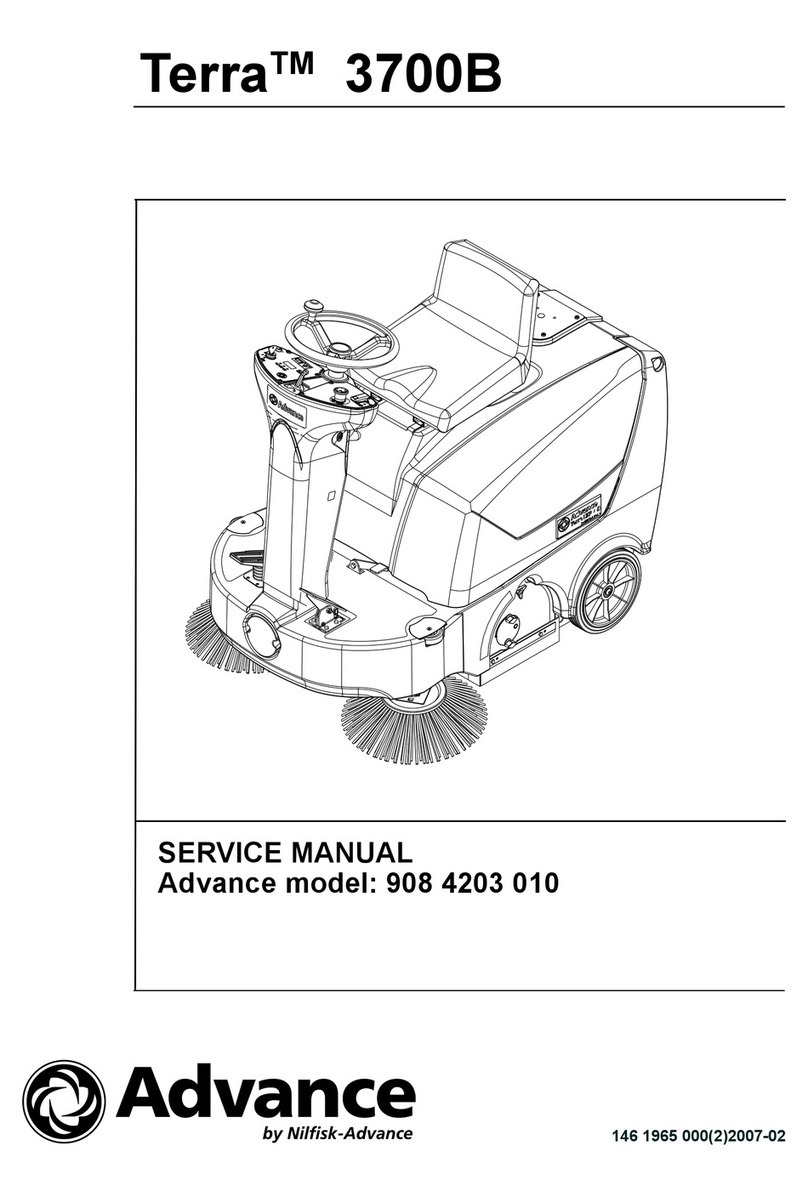

7.0 Machine Schematic Drawing

(12) BOSS-II Floor Machine BOSS-II Floor Machine (9)

4.0 Operating Tips

• For indoor use only. Sweep abrasive soils before

scrubbing.

• While the brush or pad driver is spinning, keep the oor

machine moving to avoid “donut” burns on the oor.

ToStartOperation:

• Unlock the handle by raising the locking lever.

• Lower the handle to a comfortable position, typically

waist height.

• Relock the handle by pushing the lever down. NEVER

OPERATE THE MACHINE WITH THE HANDLE

UNLOCKED.

• This oor machine is a high torque motor. Hold the

machine rmly with both hands when starting up.

• Push the red safety interlock switch forward to unlock the

dual triggers.

• Squeeze the dual triggers to release power to the motor.

Once power is on, either trigger will keep power to the

motor.

• To stop the oor machine release both triggers.

• The spinning brush helps move the oor machine. (Lift the

handle slightly to work to the right. Push the handle down

slightly to work to the left.)

4.1 To Store your Machine

• Lock the handle in the “up” position. Tilt the machine

back and remove the pad driver or brush.

• Wind the cord around the handles and the bottom cord

hook.

• Wash brushes or pads and hang to dry. Never store

machine standing on the brush.

• Inspect and maintain equipment on a regular schedule for

best results.

• Check and clean pads after each operation. Remove soil

and chemical buildup. Replace worn or damaged pads.

• Check the triggers and switches for proper operation.

• Repair or replace damaged skirts and dumpers.

• Use air pressure or vacuum to remove dust and debris

from the motor vents.

• Report problems and repair promptly.

6.2 Scrubbing Brush Filaments

Scrubbing brushes are available with a range of bristle types - from the softest for

high-gloss oors, to the most aggressive for heavy soils. Match your brush to the

oor as you match a detergent with the soils.

Nylon isusedforgeneralscrubbing.Becausenylonsoftenswhen

wet,itisgreatforgentlescrubbing,moppingandpolishingof

decorativeoors.Nylonwillnotscratchtile,terrazzoorcoated

surfaces.Nylonbrushesaredurableandlonglasting.

Polypropyleneisacommonchoiceforgeneralpurpose

scrubbingandworkswellonbothconcreteandoncoatedoors.

Polypropylenebrushestypicallycostlessthannylon,butdonot

lastaslong.

Non-scuff poly isanerdiameter(0.015-0.018”)lamentused

forlighterdutyscrubbingconditionsandonwaxedornished

oors.

Bassineisasoft,naturalber.Theendofthebristlesplitsor

“ags”tobuildapolishingsurface.

Union mixisamixtureofbassineandtampico(anothernatural

ber).Themixtureisstifferthanbassinealoneandisusedby

moretraditionalcleanersforscrubbing.Itisoftenreplacedby

poly.

Soft abrasive bristleisa0.018”nylonlamentextrudedwitha

500gradegrit.Itisusedforgentlescrubbingandisasaggressive

asawhitescrubpad.

Daily abrasive bristleisa0.035”nylonlamentwith180grade

grit.Itisusedfordailyscrubbingofresilienttileandnished

oorsandisasaggressiveasaredscrubpad.

Stripper abrasive bristleisa0.022”nylonlamentwith120

gradegrit.Itisusedforaggressivescrubbingandlightstripping

ofresilientoors,terrazzoandconcrete.Itisasaggressiveasa

bluescrubpad.

Heavy-duty stripper abrasive bristle isa0.050”nylonlament

with80gradegrit.Itisusedforveryaggressivescrubbingand

strippingofconcrete,brickandquarryle.Itisasaggressiveasa

blackscrub/strippad.

(10) BOSS-II Floor Machine BOSS-II Floor Machine (11)

5.0 Troubleshooting Guide

Neveroperatethisoormachinewhentheequipmentisnotperformingasexpected

orwhenanypartisvisiblydamaged.Thecauseandsolutionforsomebasicproblems

aredescribedbelow.Whenrepairisneeded,taketheequipmenttoanauthorizedrepair

servicecenter.

5.1 The Floor Machine will not Run

• Circuit breakers are tripped in the building. Check and reset.

• Equipment is unplugged. Check plug, wall and at machine base. Plug in.

• Power cord failure. Test with a working power cord. Lock the handle up and tip the

motor back. Unplug the cord at the motor and plug the motor into your working

power cord.

• IMPORTANT! THIS IS JUST FOR TESTING. When you do this, you have

removed the safety handle controls from the circuit and you are sending power

directly to the motor. If the motor now spins, the problem is in the cord of the

handle assembly. Seek authorized repair services.

• If the motor still does not spin, the problem is either in the male connection at the

motor base or in the motor. Seek authorized repair service.

• Motor sparks or smokes. Seek authorized repair service.

5.2 Electrical Shock to Operator

• Equipment wiring failure or electrical short in the machine. Seek authorized service.

• Poor grounding or no grounding. Test the outlet with a ground fault interrupter.

Retaincertiedelectriciantoinspectandrepairgrounding.NEVERclipoffthe

ground plug on your cord.

• Repeated circuit breaking. High amp draw and circuit breaking can be an electrical

or mechanical problem. Seek authorized repair service.

5.3 High Vibration

• Pads are not centered on the pad driver. Tip machine back and re-center the pad.

• Uneven wear or warp of pads, pad drivers or brushes. Replace.

• Machine chassis is damaged by dropping. Replace.

4.2 Transport

Totransportthisoormachinefromthejanitor’scloset

totheworkarea:

• Lock the handle in the “up” position. Wid the cord

around the handles and the bottom cord hook.

• Tip the machine back onto the transport wheels. Push

or pull the machine by the handle, not by the cord or

any other part of the machine. Travel carefully.

6.0 Brush Construction

Yournewoormachineprovidesreliable,efcient,

safepowertoyourscrubbingbrush.Togetthebest

results,youneedtouseabrushofthebestdesignand

construction.

Youroormachineisbuiltwitha“B”styledrive

plug(1).Theheightandwidthoftheearsontheplug

willmatcha“B”styleor“Universal”clutchplate(2)

mountedonthebrushblock.

Thebrushblock(3)isconstructedofmoldedplastic

orthisplywood.Useabrushwithablockdiameter2”

lessthanyourmachineapronsize.

Thebristlematerial(4)thatactuallydoesthe

scrubbingistypically1-1/2”to2”long.Holesare

drilledintheblockandbundlesofbristlesarefolded

inhalf,forcedintotheholeandstapledinplace

(staple-set).

Whenthebristlesweardowntolessthan1/2”long,

theyhavelittleexibilityandit’stimetoreplace.

Bristlematerialsaredescribedonpage11.

6.1 Pad Driver Construction

If you scrub or polish with a non-woven pad, use a

pad driver to connect the pad to the machine.

The brush block (3) is constructed of molded plastic,

t with shorter, stiffer, pad-holding bristles (5) or

“velcro-like” pad-holding hooks (6) and use a riser

(7) to create extra clearance between the block and

the machine apron. With this construction, use a pad

driver with block diameter 1” less than your machine

apron size.

A complete machine includes (1) base unit with (1) or more aprons.

MachineApronSize 13” 15” 17” 19” 21”

PadDriver-with3/4”Riser 12” 14” 16” 18” 19”

Brush-withNORISER 11” 12” 15” 17” 18”

Table of contents

Other Mercury Floor Machines Floor Machine manuals

Popular Floor Machine manuals by other brands

Bartell

Bartell SPE DFG280 Owner's manual and parts book

BETCO

BETCO STEALTH DRS21BT MicroRider Parts and maintenance manual

Sure Sweep

Sure Sweep ST1000 operating manual

Carpet Care Systems

Carpet Care Systems Trinity OP owner's manual

comoc

comoc CS700 Use and maintenance manual

Tennant

Tennant ATLV 4300 Instruction bulletin