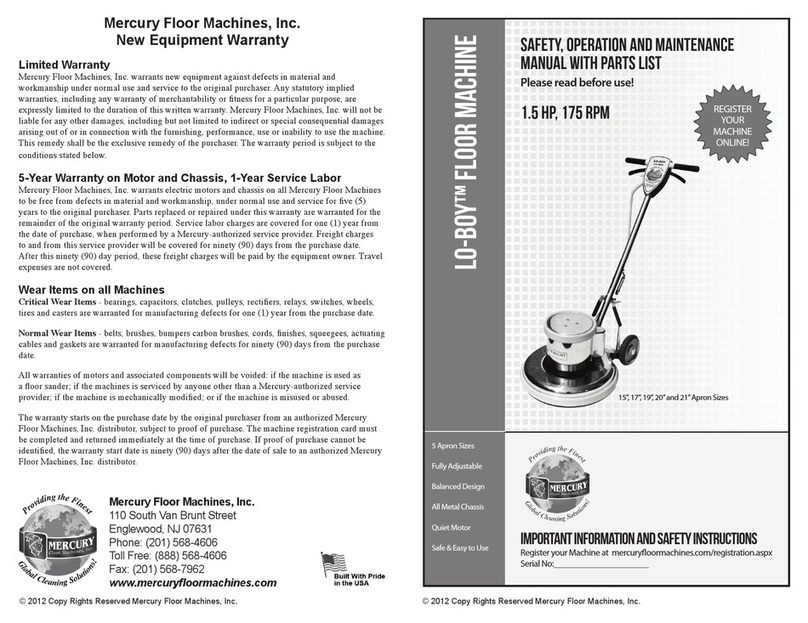

Mercury Floor Machines L-15E User manual

110 South Van Brunt Street

Englewood, NJ 07631

Phone (201) 568-4606

Toll Free (888) 568-4606

FAX (201) 568-7962

www.mercuryfloormachines.com

Mercury Floor Machines, Inc

New Equipment Warranty

Limited Warranty

Mercury Floor Machines, Inc. warrants new equipment against defects in material and

workmanship under normal use and service to the original purchaser. Any statutory implied

warranties, including any warranty of merchantability or fitness for a particular purpose, are

expressly limited to the duration of this written warranty. Mercury Floor Machines, Inc. will not be

liable for any other damages, including but not limited to indirect or special consequential damages

arising out of or in connection with the furnishing, performance, use or inability to use the machine.

This remedy shall be the exclusive remedy of the purchaser. The warranty period is subject to the

conditions stated below.

5 Years - Motor and Gearbox. 1 Year- Service Labor

Mercury Floor Machines Inc. warrants electric motors and transmission gearboxes on all Mercury

floor machines to be free from defects in material and workmanship, under normal use and service

for five (5) years to the original purchaser. Parts replaced or repaired under this warranty are

warrantied for the remainder of the original warranty period. Service labor charges are covered for

one (1) year from the date of purchase, when performed by a Mercury authorized-service provider.

Freight charges to and from this service providers will be covered for 90 days from the purchase

date. After this 90 day period, these freight charges will be paid by the equipment owner. Travel

expenses are not covered.

Wear Items on All Machines

Critical Wear Items - bearings, capacitors, clutches, pulleys, rectifiers, relays, switches, wheels,

tires and casters are warranted for manufacturing defects for one (1) year from the purchase date.

Normal Wear Items - belts, brushes, bumpers, carbon brushes, cords, finishes, squeegees,

actuating cables, and gaskets are warranted for manufacturing defects for ninety (90) days from

the purchase date.

All warrantees of motors and associated components will be voided; if the machine is used as a

floor sander; if the machine is serviced by anyone other than a Mercury-authorized service

provider; if the machine is mechanically modified; or if the machine is misused or abused.

The warranty starts on the purchase date by the original purchaser from an authorized Mercury

Floor Machines, Inc. distributor, subject to proof of purchase. The Machine Registration Card must

be completed and returned immediately at the time of purchase. If proof of purchase cannot be

identified, the warranty start date is 90 days after the date of sale to an authorized Mercury Floor

Machines, Inc. Distributor.

ISSA

The Experts

on Cleaning and Maintenance

®

MEMBER

MEMBER

SINCE 1958

©2009 Mercury Floor Machines, Inc.

MERCURY LoBoy

175 RPM Super Heavy Duty Floor Machine

1.5 HP / 15”, 17”, 19”, 20” and 21”

YES

NO

NO

NO

NO

NO

(2) LO-BOY Super Heavy-Duty Floor Machine

Scrubbing brushes are available with a range of bristle types - - from the

softest for the highest gloss floors, to the most aggressive for the heaviest

soils. Match your brush to the floor as you match a detergent with the soils.

Nylon is used for general scrubbing. Because Nylon

softens when wet, it is great for gentle scrubbing,

mopping, and polishing of decorative floors. Nylon will

not scratch tile, terrazzo or coated surfaces.

Nylon brushes are durable and long lasting.

Polypropylene is a common choice for general

purpose scrubbing and works well on both concrete

and on coated floors. Polypropylene brushes typically

cost less than nylon, but do not last as long.

Non-Scuff Poly is a finer diameter (0.015-0.018")

filament used for lighter duty scrubbing conditions and

on waxed or finished floors.

Bassine is a soft natural fiber. The end of the bristle

splits or “flags” to build a polishing surface.

Union Mix is a mixture of Bassine and Tampico

(another natural fiber). The mixture is stiffer than

bassine alone and is used by more traditional

cleaners for scrubbing. Often replaced by poly.

Soft Abrasive Bristle is a 0.018” Nylon filament

extruded with a 500 grade grit. For gentle scrubbing.

As aggressive as a white scrub pad.

Daily Abrasive Bristle is a 0.035” Nylon filament with

180 grade grit. For daily scrubbing of resilient tile and

finished floors. As aggressive as a red scrub pad.

Stripper Abrasive Bristle is a 0.022” Nylon filament

with 120 grade grit. For aggressive scrubbing and light

stripping of resilient floors, terrazzo, and concrete.

As aggressive as a blue scrub pad.

Heavy Duty Stripper Abrasive Bristle is a 0.050”

Nylon filament with 80 grade grit. For very aggressive

scrubbing and stripping of concrete, brick, and quarry

tile. As aggressive as a black scrub / strip pad.

5.2 Scrubbing Brush Filaments

LO-BOY Super Heavy-Duty Floor Machine (11)

1.0 Safe Operating Conditions

READ THIS MANUAL BEFORE USING THIS FLOOR MACHINE.

KNOW THE PROPER OPERATION, CORRECT APPLICATIONS

AND THE LIMITATIONS OF THIS EQUIPMENT BEFORE USE.

Reduce the risk of fire, electric shock, or injury:

!This floor machine is designed for indoor use only.

Do not use outdoors. Do not expose to rain.

!Do not wash motor with flowing water. If motor

gets wet, seek authorized service.

!Keep the vents on this air-cooled motor free of

debris. Do not operate with the motor covered or

with vents blocked.

!Never operate this floor machine near flammable dusts, liquids

or vapors. Never use flammable solvents as a cleaning agent.

Engine sparks and operating heat can cause a fire.

!Never handle electrical equipment with wet hands.

Never operate this floor machine with bare feet.

!Unplug the floor machine when not in use

and when servicing the equipment. To

unplug, grasp the plug, not the cord.

!Do not operate a floor machine with damaged

handle controls, cord, or plug. If the equipment

is not performing properly, seek repair from a

qualified service supplier.

!This floor machine is constructed with electrical

grounding at the plug. Operate only when

connected to a properly grounded outlet.

See section 1.2 for grounding details.

!Prevent electrical cord abuse. Do not close a

door upon the cord, drive equipment over it,

or run the floor machine over it. Do not

expose the cord to hot surfaces. Do not lift,

pull or carry this floor machine by the cord.

!Never operate the floor machine over sharp

objects that can be thrown out and harm the

operator and damage the floor. Sweep hard-

floors before scrubbing or buffing. Vacuum

clean carpets before shampooing or bonnet

cleaning.

!Train your staff in the proper use of this floor machine.

Figure 1

Figure 2

1.1 Electric Power

This floor machine operates on a 15 amp nominal 115V,

60 HZ, A.C. power circuit. (Motors may be custom wired

at the factory for 220 V, 50 Hz international operation.)

The amp, hertz, and voltage ratings are listed on the

motor spec label found on each machine. Using

voltages above or below those indicated on the spec

label will damage the motor. Always check your local

voltage requirements.

This floor machine must be grounded while in use to

protect the operator from electrical shock. This floor

machine is built with a 3-wire cord and a 3-prong

grounding type plug (Figure 1) to fit the properly

grounded receptacle.

Before using this floor machine, make sure a

properly grounded, 3-hole electrical outlet is

available. If not, as in some older facilities, use an

adapter for connecting a 3-prong plug to a 2-prong

receptacle (Figure 2) to ground to the outlet

chassis.

IMPORTANT!! This adaptor may not be

used in Canada.

IMPORTANT!! Never cut off the grounding prong for use

in a 2-prong outlet. By doing so, you have cut off your

protection from electrical shock.

Never assume that all 3-hole outlets are properly grounded.

Never assume that an adaptor connection (as in Figure 2) is

properly grounded. Check the outlet with a ground fault

interrupter device which quickly indicates if a ground is

connected. Correct a faulty grounding before proceeding.

This floor machine is shipped with a 50 foot (15 M) long safety

cord which plugs directly into an approved outlet. The use of an

extension cord is not recommended.

1.2 Grounding Instruction

1.3 Extension Cords

SIZE

2

1

3

4

3

6

5

7

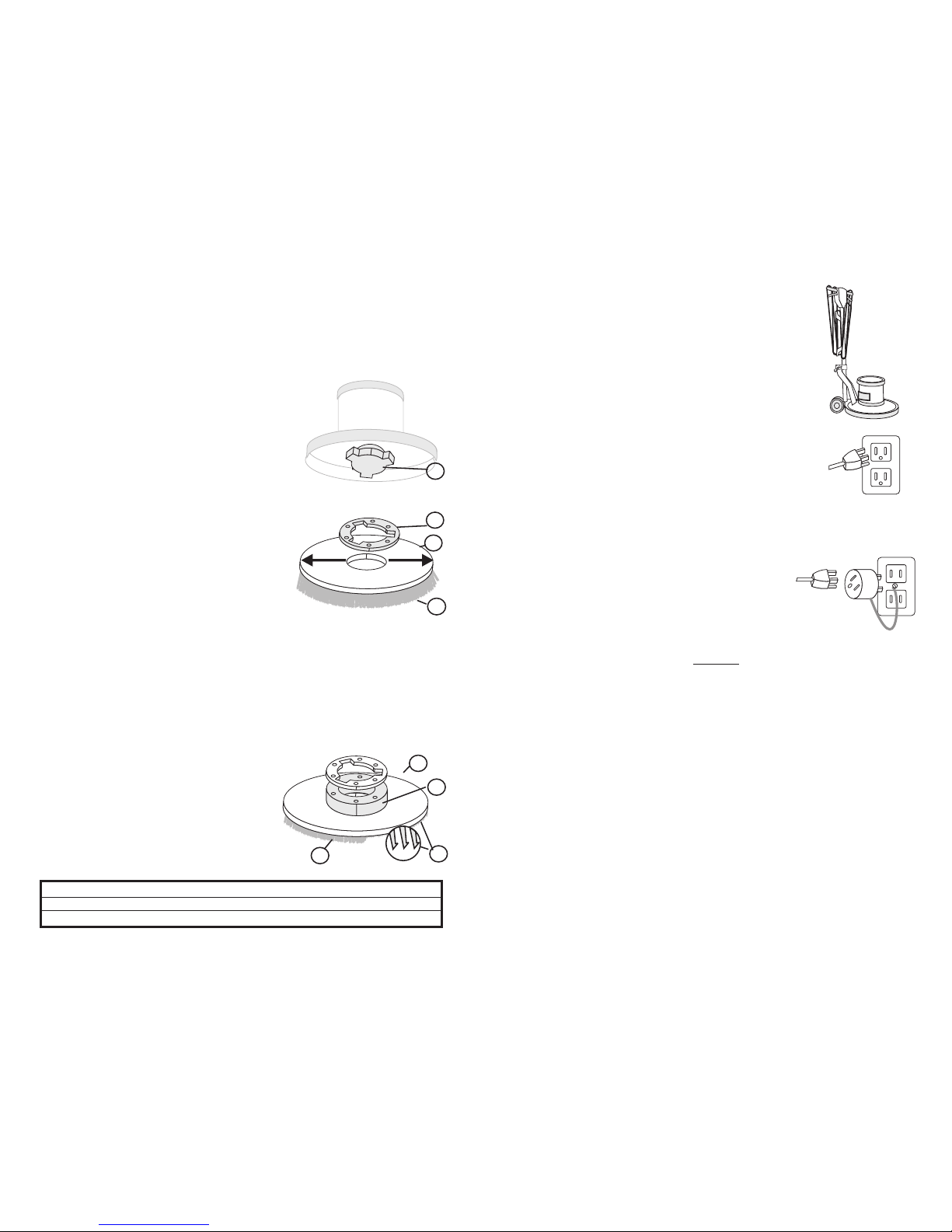

5.0 Brush Construction

Your new floor machine provides reliable, efficient, safe power to your

scrubbing brush. To get the best results, you need to use

a brush of the best design and construction.

Your floor machine is built with a “B” style

drive plug (1). The height and width of the ears

on the plug will match a “B”-style or a “Universal”

clutch plate (2) mounted on the brush block.

The brush block (3) is constructed

of molded plastic or thick plywood.

Use a brush with a block diameter

2” less than your machine apron size.

The bristle material (4) that actually

does the scrubbing is typically 1-1/2” to 2” long.

Holes are drilled in the block and bundles of

bristles are folded in half, forced into the

hole and stapled in place (staple-set).

When the bristles wear down to

less than 1/2” long, they have little

flexibility and it’s time to replace. Bristle

materials are described on page 11.

5.1 Pad Driver Construction

If you scrub or polish with a non-woven pad,

use a pad driver to connect the pad to the

machine.

The brush block (3) is constructed of molded

plastic, fit with shorter, stiffer, pad-holding

bristles (5) or “velcro-like” pad-holding

hooks (6) and use a riser (7) to create

extra clearance between the block and the

machine apron. With this construction use

a pad driver with block diameter 1” less

than your machine apron size.

Machine Apron Size 15” 17” 19” 20” 21”

Pad Driver - with 3/4” Riser 14” 16” 18” 20” 20”

Brush - with NO RISER 13” 15” 17” 19” 19”

(10) LO-BOY Super Heavy-Duty Floor Machine

LO-BOY Super Heavy-Duty Floor Machine (3)

To transport this floor machine from the janitor’s closet to the work area:

!Lock the handle in the “up” position. Wind the cord around the

handles and the bottom cord hook.

!Tip the machine back onto the transport wheels.

Push or pull the machine by the handle,

not by the cord or any other part of the

machine. Travel carefully.

4.0 Troubleshooting

Never operate this floor machine when the equipment is not performing as

expected or when any part is visibly damaged. The cause and solution for

some basic problems are described below. When repair is needed, take

the equipment to an authorized repair service center.

4.1 Floor machine will not run

- Circuit breaker tripped in building. Check and reset.

-Equipment unplugged. Check plug at wall and at machine base.

Plug in.

- Power cord failure. Test with a working power cord. Lock the

handle up and tip the motor back. Unplug the cord at the motor

and plug the motor into your working power cord.

IMPORTANT! THIS IS JUST FOR TESTING. When you do this, you

have removed the safety handle controls from the circuit and you

are sending power directly to the motor. If the motor now spins,

the problem is in the cord or the handle assembly. Seek

authorized repair service.

If the motor still does not spin, the problem is either in the male

connection at the motor base or in the motor. Seek authorized

repair service.

- Motor sparks or smokes. Seek authorized repair service.

4.2 Electrical shock to operator

-Equipment wiring failure or electrical short in the machine. Seek

authorized service.

- Poor grounding or no grounding. Test the outlet with a ground fault

interrupter. Retain a certified electrician to inspect and repair

grounding. NEVER clip off the ground plug on your cord.

- Repeated circuit breaking. High amp draw and circuit breaking can

be an electrical or mechanical problem. Seek authorized repair

service.

4.3 High Vibration

- Pad not centered. Tip machine back and re-center the pad.

- Unevenly wear or warp to pad or brushes. Replace.

- Machine chassis damaged by dropping. Replace.

3.2 Transport

(4) LO-BOY Super Heavy-Duty Floor Machine

LO-BOY Super Heavy-Duty Floor Machine (9)

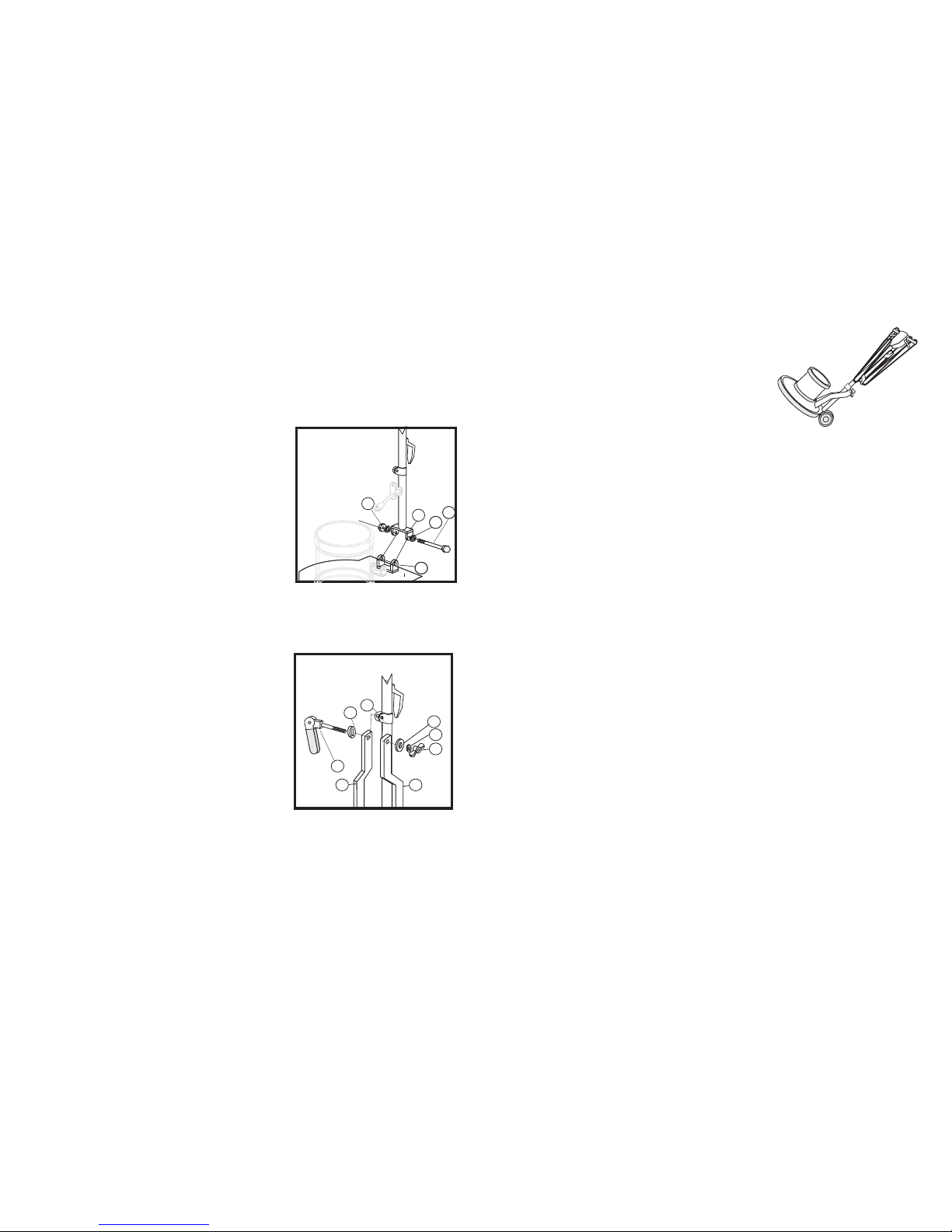

2.0 Mount the Handle

This floor machine is shipped from the factory with the handle

unattached. You will need two 7/16” wrenches to complete the

assembly.

Remove the handle and mounting hardware from its carton. Bolts,

nuts, washers and the locking lever assembly are in the plastic bag

attached to the handle.

1. Mount the handle on the chassis.

Align the handle with the yoke (1) over

the mount (2) on the buffer chassis.

The power cord will be facing the motor.

Place a flat washer (4) on a 3” bolt (3),

then place the bolt through the holes in

the yoke and the mount. Place another

washer on the bolt and secure with the

locking nut (5).

2. Connect the support braces to

the handle.

Tip the handle “up”. The handle

mounting collar (7) is designed to slide

freely up and down the handle tube,

allowing the handle to be adjusted for

the comfortable operation of all users.

Line up the mounting collar with the

upper holes in the two bent handle

braces (6).

!Place the spacer with the rectangular

hole (12) onto the locking lever shaft

(11). The spacer must fit completely

onto the rectangular neck of the lever

shaft.

!Insert the shaft through the hole in the

left handle brace (6), mounting collar

(7), and right handle brace (8).

!Place a spacer (9) on the shaft.

!Place the split washer (10) on the shaft

!Place the locking wing nut (13) on the shaft.

!Tighten and adjust the wing nut. When correctly installed, the

collar slides easily when the cam-engineered locking lever is “up”,

but is firmly fixed when the lever is “down”.

3

11 44

22

5

13

10

7

11

68

9

12

2.1 Attach the Power Cord

The triple-wire grounded power cord has been

factory-installed into the handle tube. Plug the male

connector (9) coming out of the motor housing into

the female connector (10) coming out of the end of

the handle tube.

Now, plug the end of the 50 foot cord into a

grounded power outlet. Squeeze the triggers on the

handle and check for power to the motor.

2.2 Install the Brush or Pad Driver

A brush or pad driver mounts onto your floor

machine with a “B” style Universal clutch plate.

Lock the machine handle in the “up” position

and tip the floor machine back fully.

Slide the brush or pad driver clutch

plate (11)over the drive plug (12).

Quickly spin the brush counter-clockwise to

lock the brush onto the drive plug.

Now, lower the machine back onto the brush.

You’re ready to go to work.

10

12

11

9

LO-BOY Super Heavy-Duty Floor Machine (5)

LIFT

RIGHT

(8) LO-BOY Super Heavy-Duty Floor Machine

3.0 Operating Tips

!For indoor use only.

!Sweep abrasive soils before scrubbing.

!While the brush or pad driver is spinning, keep the floor

machine moving to avoid “donut” burns on the floor.

!To start operation:

- Unlock the handle by raising the locking lever.

- Lower the handle to a comfortable position,

typically waist height.

- Relock the handle by pushing the lever down.

NEVER OPERATE THE MACHINE WITH THE

HANDLE UNLOCKED.

- This floor machine has a

high torque motor. Hold the

machine firmly with both

hands when starting up.

- Push the red safety interlock

switch forward to unlock the

dual triggers.

- Squeeze the dual triggers to

release power to the motor.

Once power is on, either trigger will keep

power to the motor.

- To stop the floor machine, release both triggers.

!The spinning brush helps move the floor machine.

(Lift the handle slightly to work to the right. Push

the handle down slightly to work to the left.)

3.1 To store your machine

!Lock the handle in the “up” position. Tilt the machine

back and remove the pad driver or brush.

!Wind the cord around the handles and the bottom

cord hook.

!Wash brushes or pads and hang to dry.

!Never store machine standing on the brush.

!Inspect and maintain equipment on a regular schedule

for best results.

]Check and clean pads after each operation. Remove soil

and chemical buildup. Replace worn or damaged pads.

]Check the triggers and switches for proper operation.

]Repair or replace damaged skirts and bumpers.

]Use air pressure or vacuum to remove dust and debris

from the motor vents.

Lift

SET HANDLE

HEIGHT

PUSH LOCK

FORWARD

SQUEEZE BOTH

TRIGGERS

Providing the Finest Global Floor Care Solutions

61 60 59

62

65

64

63

50

52

47

48

56

54

51

53

57

58

49

51

50

52

51

51

51

51

40

41

42

54

55

53

30

12

11

22

10

23

3

4

5

2

7

36 37 1

38 39

6

7

6

8

9

32

33

26 28

29

30

24

25

27

34

18

19

17

16

20

21

31

35

45

46

43

44

LO-BOY

Super Heavy-Duty Floor Machine

175 RPM - 1 HP or 1.5 HP

15”, 17”, 19”, 20” and 21”

(6) LO-BOY Super Heavy-Duty Floor Machine

13

15

16

14

ITEM DESCRIPTION PART # #REQUIRED

1 Switch Box Back A-104 1

2 Handle Tube Screw B-23 2

3 Switch Box Closing Screw B-21 4

4 Strain Relief Clip M-213 1

5 Ground Wire Screw B-68 2

6 Rubber Spacer M-218 Y 2

7 Hand Grip M-218 2

8 Handle Tube Insert M-247 1

9 Handle Tube Assembly M-206 1

10 Cable Hook Screw B-2 2

11 Cable Hook A-164 1

12 Sliding Collar A-111 1

13 Oval Hole Cam Washer B-37 1

14 Cam Lock Wing Nut B-25 1

15 Cam Split Washer B-39 1

16 Bent Brace M-216 2

17 Yoke Bolt B-18A 2

18 Yoke Nut B-19 2

19 Handle Tube Cable G-16 1

20 Black Rubber Cable Connector M-249 1

21 Cable Grommet B-63 1

22 Rectangular Hole Cam Washer B-67 1

23 Cam Assembly C-100 1

23A Complete Cam Assembly Kit (Includes 1 each of CCA 1

Drawing Items #13, 14, 15, 22, 23)

24 50 Foot Cable 14/3 Yellow G-14-50-Y 1

25 Switch Mounting Plate G-30-B 1

26 Switch Plate Screw B-1 2

27 Int. Tooth Lock Washer (For Switch) B-35 1

28 Insulated Flag Wire Connector G-48 2

29 On-Off Switch And Plate Assembly G-30-AB 1

30 Lock Washer B-33 1

31 Trigger Return Spring G-30-CT057 1

32 Label For Switch Box CALL FOR # 1

33 Switch Box Front A-103 1

34 Wire Connector G-47 1

35 Trigger A-105 2

36 16" Crossbar M-211-A 1

37 Safety Interlock Assembly SIA-1 1

38 Trigger Pin B-70 2

39 Crossbar Screw B-22 2

40 Yoke Bolt B-14 1

41 Yoke A-1001 1

42 Acorn Nut For Yoke Bolt B-10 1

43 Drip Cap Mounting Screw B-151 3

44 66 Frame Drip Cap Cover M-241 1

45 66 Frame Drip Cap Cover Bumper M-239 1

46 Cork Drip Cap Gasket M-248 1

47 Split Washer B-32 4

48 Motor 66 Frame 1.5 HP With Gearbox, 115V MOTOR /GB-LH/E 1

49 Gear Box, 11:1, Triple Planetary GB96008 1

50 Wheel Axel Bolt B-15, BDP 2

51 Spring Washer B-51 12

52 6" Wheel M-245 2

53 Wheel Carriage A-117 2

54 Spring B-30 2

55 9” Axel M-217 1

56B Base Casting 15" A-124 1

56C Base Casting 17" A-134 1

56D Base Casting 19" A-127 1

56E Base Casting 20" A-129 1

56F Base Casting 21" A-129 1

57 Axel Pin B-45 2

58 Wheel Axel Pin B-46 2

59 Bumper Screw B-68 2

60 Bumper Strap 15” (order 43” of Bumper Strap) Bumper Strap 2

61A Bumper 15" (order 37” of Bumper Stock) Bumper Stock 1

61B Bumper 17" M-232-17 1

61C Bumper 19" M-232-19 1

61D Bumper 20" M-232-21 1

61D Bumper 21" M-232-21 1

62 1/4” Medium Split Washer B-32 3

63 Cap Screw B-31 3

64 Scrubber Plug B-50 1

65 Label for Motor CALL FOR # 1

LO-BOY Super Heavy-Duty Floor Machine (7)

This manual suits for next models

4

Table of contents

Other Mercury Floor Machines Floor Machine manuals