Mercury MerCruiser Alpha User manual

2002-06 APRIL 2002 Printed in U.S.A. - 2002, Mercury Marine Page 1 of 16

This document is provided for the sole and exclusive use of the original recipient as prescribed by Mercury Marine and may not be distributed or

copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Bulletin No. 2002-06

WARRANTY INFORMATION SERVICE INFORMATION

PARTS INFORMATION

Sales ManagerCirculate to: Accounting Service Manager Technician Parts Manager

Corrosion Prevention and Maintenance

Models

ALL MerCruiser, Outboard and Jet Drive Products

Drive Corrosion

The prevention of marine corrosion can be a challenge for boat owners. However, corrosion

damage is almost always controllable; it just requires knowledge of what causes corrosion,

and the proper maintenance steps that must be taken to protect the product.

Over the years, Mercury has published several guides and manuals to educate dealers and

boat owners about corrosion, and what steps should be taken to prevent corrosion from

causing significant and costly damage to submerged drive components. All Mercury dealers

should be familiar with these publications, understand the primary causes of corrosion, and

what to do to prevent marine corrosion in all types of boating environments. During the pre-

delivery inspection process with the boat owner, review the proper maintenance activities

that are needed to ensure that the boat and sterndrive are properly protected from corrosion.

Also, we encourage you to review the contents of the Mercury Corrosion Protection Guide

with them, and give them a copy to take home. This guide is available to you at no charge

by ordering 90-881813 01 (Mercury branding) or 90-809844 01 (Quicksilver branding).

If a boat owner has a complaint about corrosion damage, please perform the necessary in-

spection and testing procedures to identify the source of the corrosion (see enclosed 3 page

Corrosion Test Data Sheet that can assist you in this effort). As always, our dealer technical

support team is available to provide technical assistance in the diagnosis and correction of

corrosion. Contact MerCruiser technical support at 405-743-6555 or outboard technical

support at 920-929-5884.

CORROSION PREVENTION AND MAINTENANCE

Page 2 of 16 APRIL 2002 2002-06

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

What is Corrosion

Types of Marine Corrosion; Metal parts under water are primarily subjected to two basic

types of corrosion: 1) Galvanic Corrosion 2) Stray Current Corrosion.

1) Galvanic corrosion: Galvanic Corrosion is an electrochemical reaction between two

or more different (or “dissimilar”) metals. The metals must be different because one must

be more chemically active (or less stable) than the other(s) for a reaction to take place.

Galvanic Corrosion is an electrical exchange that occurs.

All metals have an electrical potential because all atoms have electrons, which are

electricity.

Galvanic corrosion of the more chemically active metal can occur whenever two or more

dissimilar metals that are “grounded” (connected either by actually touching each other, or

through a wire or metal part) are immersed in a conductive solution (any liquid that can trans-

fer electricity). Anything but pure water is conductive. Salt water, fresh water with a high min-

eral content, and polluted fresh water are very conductive, and conductivity goes up with

water temperature. (That’s one reason why boats in Florida experience more corrosion than

boats in Maine.)

The simplest example of galvanic corrosion, and the most applicable, is an aluminum lower

unit with a stainless steel propeller. The aluminum is the more chemically active metal (the

“anode”), and the stainless steel is the less chemically active metal (the “cathode”). Several

things happen at the same time.

2) Stray Current Corrosion: is corrosion caused by a leakage of current into and through

the metal drive components, exiting for a water path to ground. Stray current corrosion

is commonly a result of connecting a boat to shore power; as it is regular galvanic corro-

sion greatly accelerated by the addition of electricity.

CORROSION PREVENTION AND MAINTENANCE

2002-06 APRIL 2002 Page 3 of 16

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Corrosion Protection Offered to Address Galvanic and or Stray Current Corrosion

1. Sacrificial Anodes: Come in both aluminum (for use in fresh, Brackish and saltwater)

and magnesium (for use in fresh water only).

2. MerCathode: Comes standard on all Bravo product and is available in a kit for Alpha

product.

3. Transom Mounted Anode: Connected to the current MerCathode for additional anodic

protection.

4. Transom Mounted MerCathode Kit: For use with Outboards, Jet Drive and non-cur-

rent MerCruiser product where the transom Gimbal housing has no access for mounting

a current style MerCathode system.

5. Defender Anode: Connects to either the negative terminal on the battery or a good en-

gine ground, for additional protection while the boat is moored.

6. Galvanic Isolator: This device is connected in series into the boat’s green safety

grounding lead ahead of all grounding connections on the boat. This device functions

as a filter, blocking the flow of destructive low voltage galvanic (DC) currents, but still

maintaining the integrity of the safety grounding circuit.

CORROSION PREVENTION AND MAINTENANCE

Page 4 of 16 APRIL 2002 2002-06

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

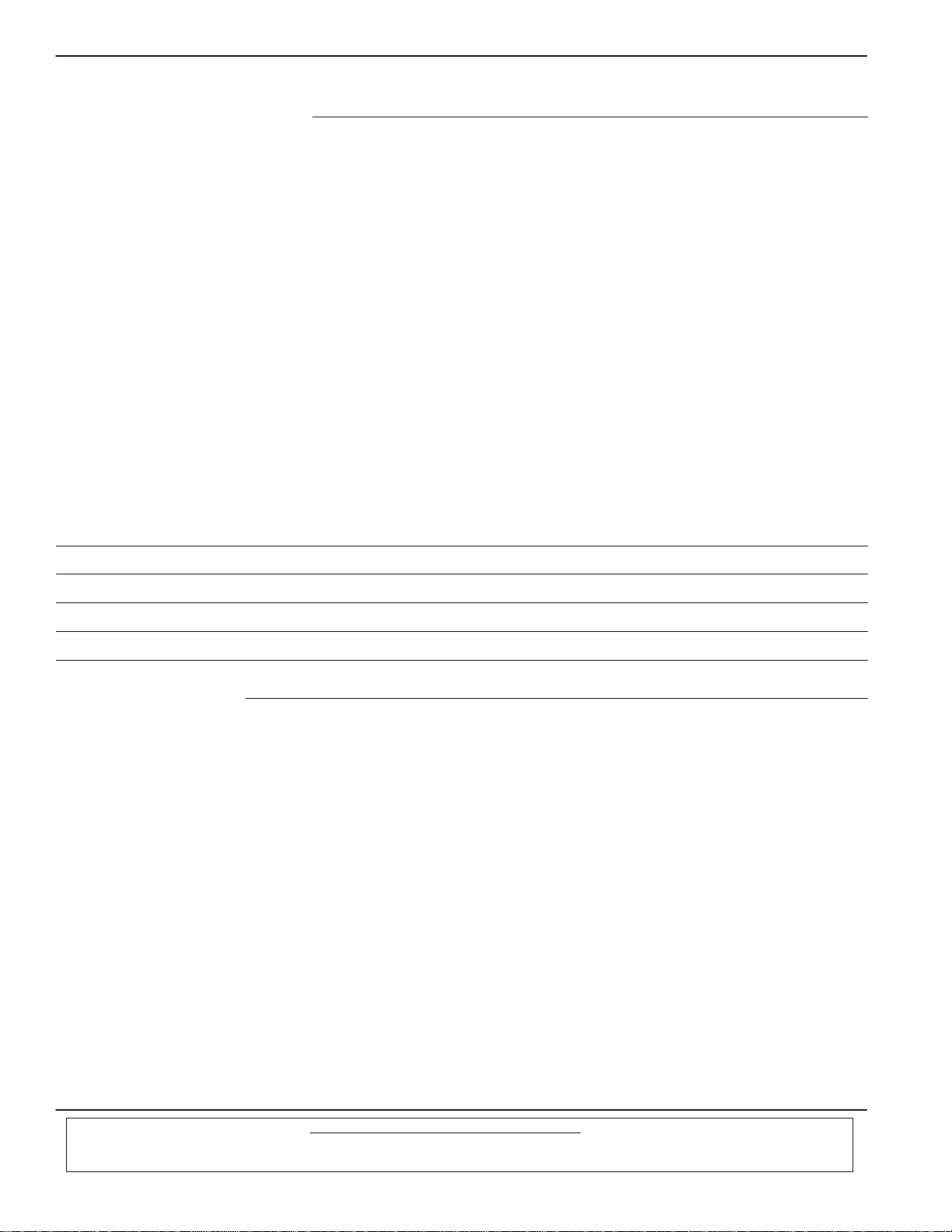

Test Equipment

In fresh water, brackish water or salt water conditions the dealer must perform a hull po-

tential check, by using a Digital Multi-meter, such as the Mercury DMT200A

(91-854009A3) along with the Quicksilver Reference Electrode (91-76675T1).A copy

of the 3 page corrosion data sheet is included with this bulletin to be completed and re-

turned to the appropriate service group.

Alpha Bravo I, II Bravo III

Fresh Water Conditions

with a hull potential

reading between 750 to

1050 millivolts

standard alumi-

num anodes are

sufficient

The factory

installed

MerCathode

system is

normally sufficient

The factory

installed

MerCathode

system is

normally sufficient

with a hull potential be-

low 750 millivolts and

heavily silted water

additional anodes

and / or a MerCa-

thode system

should be recom-

mended

The factory

installed MerCa-

thode system plus

additional anodes

and / or two tran-

som mounted but-

ton anodes may

be required

The factory

installed MerCa-

thode system plus

additional anodes

and / or two tran-

som mounted but-

ton anodes may

be required

Alpha Bravo I, II Bravo III

Salt Water Conditions

with a hull potential

reading between 850 to

1100 millivolts

standard alumi-

num anodes are

sufficient

The factory

installed

MerCathode

system is

normally sufficient

The factory

installed

MerCathode

system is

normally sufficient

with a hull potential

reading below

850 millivolts

additional anodes

should be

recommended

The factory

installed

MerCathode

system plus addi-

tional anodes will

be required

The factory

installed

MerCathode

system and two

transom mounted

anodes will be

required

CORROSION PREVENTION AND MAINTENANCE

2002-06 APRIL 2002 Page 5 of 16

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

The procedures listed below will be located in the publications following.

1. Corrosion Protection, Testing and Trouble Shooting

2. Drive Unit Continuity Test

3. Hull Potential Testing

4. Stray Current Corrosion

5. Crevice Corrosion

6. The effect of water velocity on corrosion rates

7. Methods of increasing the protection provided by a MerCathode system

8. Anti-fouling paints on drives

Corrosion information publications

Marine Corrosion Protection Guide (90-881813 01)

MerCruiser Service Manual 6, Section 7

MerCruiser Service Manual 11, Section 7

MerCruiser Service Manual 14, Section 7

MerCruiser Service Manual 28, Section 7

Owner’s Manuals (All)

Outboard Service Manuals (All) Section 1

Jet Drive Service Manuals (All)

CORROSION PREVENTION AND MAINTENANCE

Page 6 of 16 APRIL 2002 2002-06

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Step by Step Procedures when checking a boat for a

Corrosion Problem at the Location where the boat is normally moored

Tools Required:

1) Digital Multi-meter (VOA)(volt/ohm/amp) (91-854009A 3)

2) Quicksilver Reference Electrode tester (91-76675T1)

The first five things to check before performing any test:

1) If equipped with shore power, unplug the shore power.

2) Check the fuse in the positive (+) battery lead.

3) Check the battery voltage, the voltage must be 12.6 volts or higher.

4) Check for loose connections at the controller and at the battery. All connections must be

tight.

5) Check the ground between the drive and the controller.

Step 1) Before performing corrosion testing.

The boat should be moored (without being operated) for at least eight hours before perform-

ing the test. This is necessary to allow the MerCathode System and/or the sacrificial anodes

to polarize the water molecules in direct contact with the drive. Be careful not to rock the boat

excessively while performing the test, as this will alter the test readings.

Step 2) Checking for conductivity, using the following method.

1) The boat must be moored in the water when performing this test.

2) Using a digital volt/ohm/amp multi-meter set on DC volt scale set the meter on 0-2 volt

(0-2000 millivolt) scale.

3) Connect the negative (black) (–) meter lead to the multi-meter, then connect the lead to

the negative (–) battery terminal.

4) Connect the (red) positive (+) meter lead to the multi-meter, then suspend the lead in the

water within (152mm) 6” in. of the aft end of the drive unit. (Do not allow it to make con-

tact with the drive unit or the propeller) for this test. The reading should be above 3milli-

volts.

5) Next connect the end of the positive meter lead to each metallic component on the stern

drive and transom, making sure that there is good electrical contact to each surface. The

reading should drop below 2millivolts.

6) A reading higher than 2millivolts indicates an improper grounding circuit.

CORROSION PREVENTION AND MAINTENANCE

2002-06 APRIL 2002 Page 7 of 16

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Step 3) Measuring Hull Potential

1) The boat must be in the water where the boat is moored when performing this test (with-

out being operated) for at least 8hours before performing the test. This is necessary to

allow the MerCathode System and/or the sacrificial anodes to polarize the water mole-

cules in direct contact with the drive unit.

Be careful not to rock the boat excessively while performing the test, as this will alter the

test readings.

2) Using a digital volt/ohm/amp multi-meter set on the DC volt scale, set on 0-2 volt (0-2000

millivolt) scale.

3) Connect the negative (black) (–) meter lead to the multi-meter, then connect it to the

negative (–) battery terminal, the engine ground stud on the flywheel housing for Mer-

Cruiser or the engine ground where the negative battery cable is connected to the

powerhead for Outboards and Jet Drive’s.

4) Connect the red Reference Electrode lead with the (silver/silver chloride wire) to the

multi-meter, and then suspend the end of the Reference Electrode in the water within

(152mm)6in. of the aft end of the drive unit behind the propeller. (Do not allow the Elec-

trode to make contact with either the drive unit or the propeller).

5) Record hull potential readings at this time.

Step 4) Hull potential readings

Hull potential reading too Low

a) Hull potential below:850 millivolts for salt water = Drive corrosion happening.

b) Hull potential below: 750 millivolts for fresh water = Drive corrosion happening.

Hull potential reading too High

a) Hull potential above: 1100 millivolts for salt water = Drive is over protected.

b) Hull potential above: 1050 millivolts for fresh water = Drive is over protected.

Hull potential reading Proper

a) Hull potential between 850 to 1100 millivolts for salt water = Drive is protected.

b) Hull potential between 750 to 1050 millivolts for fresh water = Drive is protected.

CORROSION PREVENTION AND MAINTENANCE

Page 8 of 16 APRIL 2002 2002-06

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Step 5) Symptoms of hull potential reading too low are:

a) Too much (cathode) such as stainless steel.

b) Loss of continuity between drive components and ground.

c) Sacrificial anodes more than 50% consumed or painted or inactive.

d) MerCathode reference wire or anode plate painted over.

e) No power to the MerCathode controller.

1) Blown fuse.

2) Shut off at the battery switch, wired to the wrong side of the switch.

f) Poor connection between the reference electrode (brown) lead or the anode (orange)

lead at the MerCathode controller.

g) Faulty MerCathode reference electrode.

1) Test by disconnecting the reference electrode (brown) lead from the “R” terminal on

the controller. Then connect the (brown) lead to the positive (+) lead from the digital

multi-meter (set on 0-2000 millivolt scale). Connect the negative (–) lead of the multi-

meter to either the negative battery lead or the engine grounding stud at the flywheel

housing, (note the meter reading), then repeat the test with the Quicksilver reference

electrode (91-76675T1) held behind the drive. The same reading should be ob-

tained with both tests. If not replace the unit on the Transom Gimbal housing on Mer-

Cruiser or on the transom for Outboard and Jet Drive.

h) Faulty MerCathode controller.

1) With the anode and the reference electrode leads connected to the controller, con-

nect a jumper wire between the “R” terminal and the negative (–) terminal on the

controller. Set the multi-meter on the 0-20 volt DC scale, now connect the Red Posi-

tive (+) lead of the multi-meter to the “A” terminal on the controller, connect the Black

Negative (–) lead from the multi-meter to the Negative terminal on the controller.

2) The readings should be:

•Fresh water areas = 11.5 volts minimum

•Salt water areas = 3.55 volts minimum

If the readings are low, replace the controller.

CORROSION PREVENTION AND MAINTENANCE

2002-06 APRIL 2002 Page 9 of 16

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Step 6) Symptoms of hull potential reading too high are:

a) Paint blistering and falling off.

b) Pitting of aluminum on the drive.

•Excessive voltage causes hydrogen to be formed at the surface of the metal “blow-

ing” the paint off.

•This also creates an alkaline condition at the surface which dissolves the aluminum.

c) Stray Current Corrosion.

•Any electrical current flowing along or through a metal conductor leaves the metal for

a water path to ground will cause ionization of the metal, and an area of rapid

corrosion.

•If the source is internal, observe the readings while disconnecting the electrical com-

ponents (one at a time) until high the reading is eliminated.

That is the immediate source of the stray current. If external, install a Galvanic

Isolator.

d) Poor connection between MerCathode Reference Electrode (brown) lead and the “R”

terminal on the controller.

•Clean and/or tighten the connections, repair wiring as required.

Clean off any and all salt deposits.

e) Faulty MerCathode Reference Electrode.

•Test by disconnecting the reference electrode (brown) lead from the “R” terminal on

the controller. Then connect the (brown) lead to the positive (+) lead from the digital

multi-meter (set on the 0-2000 millivolt scale). Connect the negative (–) lead of the

multi-meter to either the negative battery terminal or the engine grounding stud at the

flywheel housing, for MerCruiser or the engine ground where the negative battery

cable is connected to the powerhead on Outboard and Jet Drive. (Note meter read-

ing), then repeat the test with the Quicksilver Reference Electrode (91-76675T1)

held (152mm)6 in. behind the propeller. The same reading should be obtained with

both tests. If not replace the MerCathode unit on the Transom Gimbal Housing on

MerCruiser or the unit on the boat Transom for Outboard and Jet Drive.

CORROSION PREVENTION AND MAINTENANCE

Page 10 of 16 APRIL 2002 2002-06

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

f) Faulty MerCathode Controller.

•Check output of the controller.

•If the hull potential indicates overprotection, remove the reference electrode lead

from the controller. If the controller is “off” (no impressed current called for) the volt-

age between the negative (black) and the anode should be less than (one volt). If your

digital multi-meter can read amperage, with the reference electrode disconnected,

the amperage between the negative on the controller and the anode terminal should

be less than one milliamp.

•If your multi-meter can measure amperage, you can measure the output of the Mer-

Cathode. Disconnect the orange anode lead from the controller, set your multi-meter

to the 2000 milliamp scale and connect between the orange anode lead and the

anode terminal. If the MerCathode is fully on, the output should be about (200 mil-

liamps) in salt water or (20-25 milliamps) in fresh water. If you now disconnect the

brown reference electrode lead the output should drop to Zero. If there is any current

output, with the brown reference lead disconnected, the controller is faulty and

should be replaced.

Step 7) Checking the MerCathode Anode for output:

If your multi-meter can measure amperage, you can measure the output of the MerCathode.

Disconnect the orange anode lead from the controller, set your multi-meter to the 2000

milliamp scale and connect between the anode lead and the anode terminal. If the

MerCathode is fully on, the output should be about 200 milliamps in salt water or 20-25

milliamps in fresh water. If the reading is zero the MerCathode assembly on the gimbal

housing must be replaced.

CORROSION PREVENTION AND MAINTENANCE

2002-06 APRIL 2002 Page 11 of 16

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Out of Water Resistance Check

A Digital Multi-Meter such as the Mercury DMT2000A (91-854009A 3), a Fluke Digital Multi-

Meter or a Radio Shack Digital Multi-Meter or equivalent must be used for this test.

(a) Meter setting on low ohm range (2 ohm).

(b) Connect the Black meter lead from the (COM) port on the meter to the drive unit Trim

Tab or the drive shaft housing Cavitation Plate Anode.

(c) Connect the Red meter lead into the (OHM) location on the meter and set it to the low

ohm scale.

(d) Using the other end of the RED lead, connect to an exposed area of any component of

the power package to be tested.

The reading should be no higher than 150 Milliohms or 0.15 ohms between all

components.

(e) Connect the Black meter lead to the battery negative terminal or a good ground on the

engine such as the ground stud at the flywheel housing on MerCruiser or the engine

ground where the negative battery cable is connected to the powerhead on Outboard

and Jet Drive.

(f) Connect the RED meter lead, plugged into the low range ohms location on the meter,

to the ground strap on the inner transom plate. Reading should be no higher than 150

Milliohms or 0.15 ohms.

NOTE: If a higher reading than specified exists, poor continuity is indicated. The high resist-

ance area must be located and its cause must be corrected.

CORROSION PREVENTION AND MAINTENANCE

Page 12 of 16 APRIL 2002 2002-06

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Galvanic Isolator Testing Procedure

Using a VOA Meter that has the Diode test capability such as the Mercury DMT2000A

(91-854009A 3), or a Fluke Digital Multi-Meter or Radio Shack’s Digital Multi-Meter or

equivalent.

1.) Connect the Red test lead to the meter at the (Com) connection per the instruction book-

let from the meter being used.

2.) Connect the Black test lead to the (Volt/Ohm/Hz) connection per the instruction booklet

from the meter being used.

3.) Connect the leads between the ends of the (Green leads) on the Galvanic Isolator.

4.) The meter reading should start out at the low end of the scale and gradually build up

until the meter reaches a point to where it levels out depending on the size of the

diode being used.

5.) Next reverse the leads from end to end. The reading should again start out low and reach

a point to where it levels out. The two readings should be about the same.

6.) If the readings are not close to the same (one readings is high when the leads are

switched the reading stays at “0” the Diode is bad and the Galvanic Isolator requires

replacement.

7.) If the reading goes to infinity the diode is shorted and the Galvanic Isolator requires

replacement.

Newly developed Anode kits for Current MerCruiser Sterndrives

The following kits include all anodes required to replace every anode on the Alpha and Bra-

vo drives and transoms.

888756A 1 Alpha Aluminum Anode Kit

888755A 1 Alpha Magnesium Anode Kit

888758A 1 Bravo I Aluminum Anode Kit

888757A 1 Bravo I Magnesium Anode Kit

888761A 1 Bravo II/III Aluminum Anode Kit

888760A 1 Bravo II/III Magnesium Anode Kit

CORROSION PREVENTION AND MAINTENANCE

2002-06 APRIL 2002 Page 13 of 16

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Corrosion Test Data Sheet

Initial Test Data Form

Date of Test : Day Month Year

Dealer Name Dealer Number

Customer Name

Address

Telephone Number (____)____________________________

Address where the boat is Moored

Boat Manufacturer Boat Model

Type of Installation: Single ( ) Dual ( ) Triple ( )

Engine Package Model

Serial Numbers: Starboard Engine

Starboard Transom

Starboard Drive

Center Engine

Center Transom

Center Drive

Port Engine

Port Transom

Port Drive

CORROSION PREVENTION AND MAINTENANCE

Page 14 of 16 APRIL 2002 2002-06

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

MerCathode System Type: Boat Transom Mounted ( ) or Gimbal Housing Mounted ( )

Water Type: Fresh ( ) Brackish ( ) Salt ( )

Water Velocity: (speed of movement) ( ____ mph)

Propeller Type: Aluminum ( ) Stainless ( )

Boat Equipped with Trim Tabs: Yes ( ) No ( )

If so what type: Aluminum ( ) Stainless Steel ( )

If Yes, Are the Trim Tabs Grounded to the Power Package: Yes ( ) No ( )

Does the boat have an attached swim platform with mounting hardware: Yes ( ) No ( )

If so what type of Mounting Hardware is used: Aluminum ( ) Stainless Steel ( )

If yes is the Swim Platform grounded to the Power Package: Yes ( ) No ( )

Is there a Battery Switch in use: Yes ( ) No ( )

If yes, can the switch turn off the power to the MerCathode Controller: Yes ( ) No ( )

Is there Shore Power to the Boat: Yes ( ) No ( )

If yes, does the boat have a Shore Power Isolator or an Isolation Transformer installed: Yes ( ) No ( )

If yes, what Brand:

Does the Hull Potential Voltage Rise with the shore power unplugged: Yes ( ) No ( )

Has an Anti-Fouling Paint been applied to: Drive: Yes ( ) No ( ) Transom: Yes ( ) No ( )

If yes, list the type of Anti-Fouling Fouling Paint used:

If applied to the boat hull, is there 1” to 1 1/2” of unpainted Boat transom around the Gimbal Housing:

Yes ( ) No ( )

Date of Test:

Technical Service Representatives Name:

Test Results for the Following:

Battery Voltage Test: Volts

Anode Output Test: Milliamps

Hull Potential Voltage Test: Volts

CORROSION PREVENTION AND MAINTENANCE

2002-06 APRIL 2002 Page 15 of 16

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Continuity Test: Millivolt Reading, the boat must be in the water for this test.

1. Set the Digital Multimeter on the 0-2 volt (0-2000 millivolts) scale.

2. Connect the negative (black) meter lead to the negative (–) battery terminal.

3. Suspend the end of the positive (red) meter lead in the Water within (152 mm) 6 in. of the drive unit. Do

not allow it to make contact with the drive unit. The reading should be above 3 millivolts.

4. Connect the end of the positive meter lead to each metallic component on the stern drive unit, making sure

that there is good contact to each metallic surface. The reading should drop below 2 millivolts.

5. A reading higher than 2 millivolts indicates an improper grounding.

If the above readings were higher than 2 millivolts the following should be performed: Milliohms Reading set

the Digital Multimeter on the low ohm range (2 ohm) scale or (X1) on the meter.

Gear housing Milliohms Drive Shaft Housing Milliohms

Bell Housing Milliohms Gimbal Ring Milliohms

Trim Cylinders Milliohms Propeller Milliohms

If the Continuity reading was too high, What was the cause for the high reading?

What was the: Water Temperature Degrees

Air Temperature Degrees

Type of Dock Construction: Metal Yes ( ) No ( ) Wood Yes ( ) No ( )

Shore Line Type:

Docking Area: 1. Number of Boats

2. Type of Boats

3. Is Shore Power Present on other Boats? Yes ( ) No ( )

CORROSION PREVENTION AND MAINTENANCE

Page 16 of 16 APRIL 2002 2002-06

This document is provided to be used for solely and exclusively by the original recipient and as prescribed by Mercury Marine and may not be

distributed or copied, digitally or otherwise, without the prior written consent of Mercury Marine.

Has a Stray Current Check been done? Yes ( ) No ( )

If so, what was the reading taken:

Have pictures been taken? Yes ( ) No ( )

The Locality of the Corrosion: ( ) All under water power package components.

( ) Gear Housing ( ) Drive Shaft Housing ( ) Bell Housing

( ) Gimbal Ring ( ) Gimbal Housing ( ) Trim Cylinders

( ) Propeller ( ) All Anodes ( ) Other

If the unit has Paint Blistering what is the Locality: ( ) All under water power package components

( ) Gear Housing ( ) Drive Shaft Housing ( ) Bell Housing

( ) Gimbal Ring ( ) Gimbal Housing ( ) Trim Cylinders

( ) Propeller ( ) All Anodes ( ) Other

What is the severity of the Paint Blistering: ( ) None ( ) Slight ( ) Moderate ( ) Severe

What is the severity of the corrosion: ( ) None ( ) Slight ( ) Moderate ( ) Severe

What is the condition of the Boat Hull?

Inspection performed by:

This manual suits for next models

2

Table of contents

Popular Outboard Motor manuals by other brands

Side-Power

Side-Power SRV 285 TC Installation & user guide

Lewmar

Lewmar TT 140 Owners installation, operation & basic servicing manual

TOHATSU

TOHATSU MFS 9.9E Series owner's manual

Mariner

Mariner 30 JET 40 (4 CYL) Service manual

TOHATSU

TOHATSU MFS 9.9E Series owner's manual

Yamaha

Yamaha F6C owner's manual