MERITECH XBW User manual

XBW Sole Only

Installation and Operation Manual

XBW Sole Only • 2

XBW Sole Only

Automated Boot Scrubbing & Cleansing System

Installation and Operation Manual

Manufactured by:

Meritech Systems, LLC

720 Corporate Circle, Suite K

Golden, CO 80401 USA

Phone: (800) 932-7707

Fax: (303) 790-4859

www.meritech.com

E-mail: [email protected]

WARNING: The performance and effectiveness of CleanTech® systems have been extensively

tested when using solutions provided by Meritech Systems, LLC. Satisfactory performance or

effectiveness cannot be guaranteed when other solutions are used.

FAILURE TO USE MERITECH SYSTEMS, LLC SUPPLIED

CHEMICALS WILL VOID ANY AND ALL WARRANTIES

CAUTION: This equipment contains moving parts and starts automatically. DO NOT USE with

loose clothing that can be caught in the system. This includes, but is not limited to, long smocks,

frock ties, shoelaces and street shoes.

January 1, 2020

XBW Sole Only • 3

XBW Sole Only

Installation and Operation Manual

Index

3

Introduction

4

Overview

5

Facility Installation Instructions / Requirements

6

Operation

7

System Activation

8

Emergency Stop Button

8

Cycle Time / Calibration

9

Indicators

9

Maintenance

9 - 12

Motor Gear Box & Right Angle Drive

9

Drive Chains

10

Nozzle Cleaning

10

Brush Removal

11 - 12

Changing Solutions & Re-Priming System

13

Walking Grate Height Adjustment

14 - 15

System Cleaning

15

Cut Sheet / Specifications

16

System Drawings / Dimensions

17 - 18

If External Backflow Preventions is Needed

19

Spare Parts List

20

Contacting Meritech

21

Meritech Systems, LLC Warranty

22

Terms & Conditions of Sale

23

XBW Sole Only • 4

Introduction

Thank you for selecting the Meritech Boot Scrubber as a component of your sanitation regimen. We have

designed an entire family of Boot Scrubbing systems to be a convenient, reliable, and effective tool in your

food safety program.

Constructed of heavy-duty 304 stainless steel and hygienically designed to provide quick and highly effective

boot Scrubbing in the work place. For convenience and efficiency, the Meritech Boot Scrubber Family was

created to clean both boots simultaneously.

Shipped fully assembled with only one water and electrical connection required, the Meritech Boot Scrubber

is ideal for placement at all entrances in to production areas to minimize the risk of work place contamination.

Each Boot Scrubber is complete with handrails, emergency stop button, Photoeye operated, as well as long

lasting nylon brushes to scrub shoes or boot soles. The system is activated via a Photoeye beam conveniently

located in the handrails and timed per the electronics.

This manual contains all the information you will need to install, operate and maintain your Boot Scrubber.

XBW Sole Only shown below.

XBW Sole Only • 5

Overview

The Meritech Boot Scrubber provides a means of removing debris and bacteria from the shoes or boots of

your employees. The unit has a series of 2 sole brushes, which scour the soles of the boots. When the

Photoeye beam is broken, the brushes rotate and sanitizing solution is sprayed onto the brush bristles.

As you walk through the Boot Scrubber the boots contact the rotating brushes, which remove the particles

and transfer the sanitizing solution to the boot surface. The drain water and any removed soils or particles are

drained down into the catch basin at the bottom of the unit. The catch basin is sloped side to side and front to

back to keep the water and soils moving towards the drain of the system. The heavier particles may stay in the

catch basin and can be easily removed during shift cleanup. The Boot Scrubber is intended to be used in all

types of environments, bearing in mind that there will be some water that may be splashed out of the system

from use and tracking from the entrance and exit of the system.

Features:

• Sole Scrubbing

• Heavy Gauge 304 Stainless Steel

• 2” MNPT Drain Connection

• ¾” MGH Water Connection

• Bi-Directional Photoeye Operation

• Adjustable Sole Depth

• Ready Indicator Light

• Washing Indicator Light

• Soap Empty Indicator Light

• Soap Empty Audible Alarm

• Tool-Less Brush Removal

• Emergency Stop

• Electrical Disconnect Switch

• On Board 20 Liter Soap Container

• Wash-down Motor and Gearbox

• NEMA 4X Electronics Enclosure

• SLIPNOT® Upper Deck

• Auto shutoff if cover is opened

• 8 Adjustable Equipment Leg

SlipNot® is a registered trademark of SlipNot® Metal Safety Flooring, Detroit Michigan. Copyright W.S. Molnar Company

XBW Sole Only • 6

Facility Installation Instructions/Requirements

The Boot Scrubber unit requires 120 volt AC, single-phase power with a maximum current draw of 20

amps. Do not hardwire the system electrical cord without having a way to disconnect the system from

electrical source for future serviceability of the system.

The Boot Scrubber system requires a potable water source. Only cold water is required although warm or

hot water can be used as well depending on the types of soils being removed. Do not exceed 110⁰F water

temperature to prevent scalding. The supply line should supply at least be 4 gallons per minute at 50 PSI

minimum. Do not hard pipe directly to the system as this may prevent future serviceability to the

system. The unit comes from the factory with a ¾” male garden hose fitting for water hook up. The

system requires a floor drain. The sanitizing solution is automatically mixed with the incoming water

supply in the unit and is factory calibrated for 800 parts per million concentration when using Meritech Boot

Cleaner solution. The concentration and water flow rate can be adjusted easily if other settings are desired.

Please contact Meritech to have a qualified Service Technician make the adjustments.For additional

information, see the “Cut Sheet/Specification” of this manual.

Make certain that the system is sitting steady on floor and all 8 feet are touching. Verify that the system is

sloped towards the drain and is ¼bubble slope and is level side to side per the factory settings.

If these hook-ups are not readily available, you will need to consult with your commercial plumber or

electrician. Because of the different building codes and licensing regulations, Meritech cannot accept

responsibility for providing plumbing and electrical modifications to your facility; however, Meritech will be

happy to provide the necessary guidance to ensure a correct installation.

Consult local and national codes: conformity and compliance to local and national codes is the responsibility

of the installer.

IF YOU SHOULD EXPERIENCE ANY DIFFICULTY OR ARE UNSURE ABOUT THE

INSTALLATION PROCEDURE, WE ENCOURAGE YOU TO CONSULT

IMMEDIATELY WITH MERITECH SYSTEMS, LLC.

Meritech Systems, LLC

720 Corporate Circle, Suite K

Golden, CO 80401 USA

Phone: ( 800) 932-7707

Fax:( 303) 790-4859

www.meritech.com

E-mail: [email protected]

XBW Sole Only • 7

Operation

XBW Sole Only

The Meritech Boot Scrubber is easy to operate. As you approach the unit from the Photoeye end of the

system. The Green LED indicator light will be a solid. As you break the Photoeye beam the system will

automatically start. The Green LED indicator light will be flashing. The brushes will begin to rotate and the

sanitizing spray will wash each of the horizontal sole brushes. The system will run for approximately 8 seconds

and then shut off or when the person exits the opposite end. System run time is adjustable. Please contact

Meritech to have a qualified Service Technician make the adjustments.

While using the two side handles for support, walk slowly through the unit allowing time for the sole brush to

adequately clean the bottoms of the shoes or boots. When the entire boot surface is clean simply walk out of

the system. Boot cleaning should take approximately 4 - 8 seconds depending on the soil type. This may take

a few trial cycles to get the right length of time depending on the soil type.

The sanitizing solution is stored in the Blue 20 liter container located on the side of the system. When the

bottle is empty the system will stop rotating, the Red LED light will flash and an audible alarm will beep letting

you know the system needs a new solutions container. For further instructions on changing solutions,

please refer to the “Changing Solutions” in this manual.

CAUTION: This equipment contains moving parts and starts automatically. DO NOT USE with

loose clothing that can be caught in the system. This includes, but is not limited to, long smocks,

frock ties, shoelaces and street shoes.

XBW Sole Only • 8

System Activation

Photoeye

The system is bi-directional. Beaking the photeye beam on either end of the system will automatically start

the system and will run until the opposite photoeye beam has been broken and then it will shut off. The system

will automatically shut off if the system as run continuesly for 60 seconds.

USERS MUST HOLD BOTH HANDRAILS FOR PROPER SAFETY

Emergency Stop Button

In case of an emergency and to shut system down. Immediately depress the emergency stop button located

on the hand rail. To release the emergency stop button twist it clockwise to re-engage.

Photoeye

Photoeye

XBW Sole Only • 9

Cycle Time / Calibration

To adjust cycle time and calibration of the system please contact Meritech customer service for assistance.

Please refer to “Contacting Meritech” in this manual.

Indicators

The system is equipped with a 18 mm Multi-Color LED light and audible alarm. Please see photo below.

• Steady Green = System ready for use.

• Flashing Green = System is running

• Flashing Red/Alarm = System is out of soap / brushes will not rotate

XBW Sole Only • 10

Maintenance

MOTOR GEAR BOX & RIGHT-ANGLE DRIVE BOX

Only lubricate the motor gear box when fluid levels are below fill level.

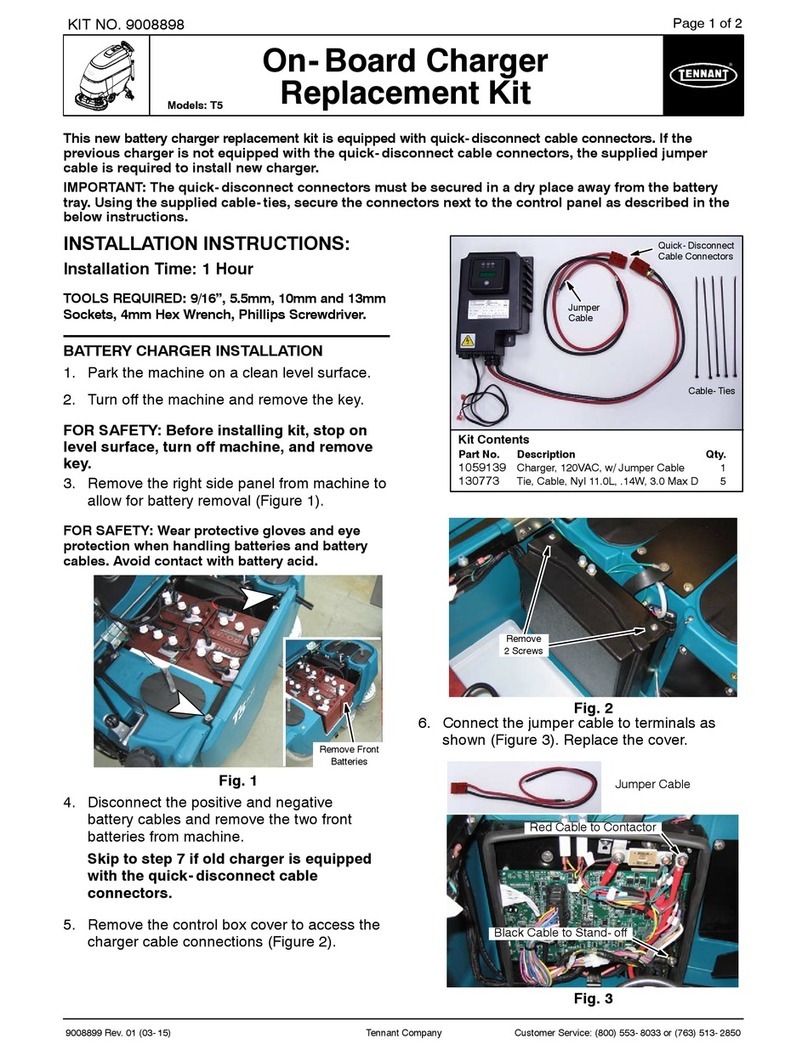

DRIVE CHAIN (every 12 months or as needed)

Always disconnect from electrical source and lockout and tag out before any chain adjustment. Check and

adjust chain tension to be no more than ½“ – 1” deflection of the chain at the midpoint between the sprockets.

Adjustment for the motor driven chain is accomplished by adjusting the auto spring chain tensioner up/down

on the 2 slots provided and in the photo below. Loosen the 2 – ¼”-20 hex nuts holding the auto spring

tensioner and either adjust up or down to so there is the proper chain deflection. Make certain that the chain

tensioner has spring adjustment available and is not bottomed out. See photo below. There should never be

more than ½”– 1” deflection of the chain at the midpoint of its longest run.

NOZZLE CLEANING (every 3 months or as needed)

With time and use the nozzles will become blocked with mineral deposits and soap build-up. We recommend

that you connect a gallon bottle of a mineral deposit remover (or similar item) in place of the boot cleaner

chemical and run the boot Scrubber for a period of 15 minutes by covering the Photoeye, to remove any build-

up that has accumulated in the nozzles. After cleaning the system with mineral deposit remover, replace the

mineral deposit remover with water and flush the system for 5 minutes. Replace with the boot cleaner

chemical and run the system for 1 minute to re-prime the system by holding your hand over one of the

photoeye’s.

For replacement nozzles refer to the spare parts list of this manual.

Auto Spring Chain

Tensioner

Slots to adjust Auto

Spring Chain Tensioner

(Qty. 2)

XBW Sole Only • 11

Maintenance - Continued

BRUSHES – HORIZONTAL (as needed)

Replace as required for effectiveness. Bristles will lose stiffness, fray with age and use. Refer to the “Parts

List” for the part number and contact Meritech for pricing and availability. The brushes are easily removed

from the system and do not require any tools. Follow the steps below and refer to photos for removing the

brushes.

1. Disconnect system from electrical source and lockout and tag out.

2. Open system covers by pulling up and away on the cover hold down strap on both ends of the

cover.

3. Swing open each brush cover allowing them to rest on the cover chains.

4. Remove the walking grate by removing the 6 wing nuts in each corner of the grate.

5. Lift the walking grate off of the 6 grate support bolts.

6. To remove the 2 sole horizontal brushes:

a. Pull the horizontal brush retainer pin with the ring at the end of the horizontal brush.

b. Pull the brush toward the direction of the pin was until it is no longer engaged on the drive

end.

c. Lift above the drive end and slide off holder shaft.

7. Replace brushes in reverse order.

Cover Hold Down Strap

XBW Sole Only • 12

Maintenance - Continued

BRUSHES – HORIZONTAL (as needed)

For replacements brushes part numbers refer to the spare parts list of this manual.

Grate Wing Nut – QTY. 6

Sole Horizontal Brush

Retainer Pin – QTY. 2

Drive End

Drive End

XBW Sole Only • 13

Changing Solutions & Re-Priming System

When the Red LED indicator light is flashing and the system alarm is sounding the solutions container needs

to be replaced on the system. Follow the steps below and refer to the photos for replacing the solutions

container and re-priming the system.

1. Remove dip tube assembly attached to the bottle cap with the hose attached from the empty

container.

2. Replace the empty container with a new container of Meritech Boot Cleaner.

3. Drop the dip tube assembly in the new container and screw on the container lid.

4. Hold your hand over one of the systems photoeye’s at the drain end of the system which is the priming

photoeye’s until the system begins to run water and consume soap.

5. Continue covering the Photoeye until the Boot Cleaner fluid is fully primed in the system & the green

LED light is flashing and the brushes are rotating.

Dip Tube Assembly w/ Cap

Priming Photoeye

note location or drain

end of system

XBW Sole Only • 14

Walking Grate Height Adjustment

Depending on the tread depth and design of the boot or as the horizontal brushes wear you may need to

adjust the height of the walking grate to expose more or less of the bristle for proper cleaning of the

boots. The grate is set at the factory with approximately 3/8” of the horizontal brush bristles above the

walking grate. Follow the steps below and refer to the photos to adjust the height of the walking grate.

• Caution – system is not designed for individuals over 300 lbs. in weight.

• Do not totally remove the black threaded spacer or use it alone for a height adjustment.

• The black threaded spacer must be on the nut shown below for proper grate support.

• The height adjustment can only be adjusted for 3/8”, ½”, or 5/8” bristle height.

• Modification of the system beyond manufacturer’s specifications could result in personal

injury, system malfunction, and will void warranty.

1. Disconnect system from electrical source and lockout and tag out.

2. Open system covers by pulling up and away on the cover hold down strap.

3. Swing open each brush cover allowing them to rest on the cover chains.

4. Remove the walking grate by removing the 6 wing nuts in each corner of the grate.

5. Lift the walking grate off of the 6 grate support bolts.

6. The following hardware stack up described below.

3/8-16 x 2 ½” SST Hex Bolt

3/8-16 SST Wing Nut

3/8 SST Split Lock Washer

Under Wing Nut

3 - 3/8 SST Flat

Washer

3/8-16 SST Hex Nut

3/8-16 Black Threaded Spacer

• 3 SST washers below

black spacer is: .325”

Bristle above grate

• 2 SST washers below

black spacer is: .425”

Bristle above grate.

• 1 SST washer below

black spacer is: .525

Bristle above grate.

• 0 washers below black

spacer is: .625 Bristle

above grate.

XBW Sole Only • 15

Walking Grate Height Adjustment - continued

• 3 stainless washers below black spacer is: .325” Bristle above grate per the picture above.

• 2 stainless washers below black spacer is: .425” Bristle above grate per the picture above.

• 1 stainless washer below black spacer is: .525 Bristle above grate per the picture above.

• 0 washers below black spacer is: .625 Bristle above grate per the picture above.

Caution make certain that all 6 of the grate hold down wings nuts are in place and tightened before system

is used.

System Cleaning

Depending on the environment that the system is installed, the type or frequency of use and or the types of

soils being removed from the boots will determine the frequency and the type of cleaning the system should

go through. The cleaning process should also be documented within your HAACAP or SSOP document or per

your company’s internal procedures.

Please contact Meritech customer service to receive a copy of the Meritech cleaning procedure and

recommendations.

CAUTION: Even though the electronics is contained in NEMA 4x enclosure, we DO NOT

recommend directly hosing down the electronics module of this system.

CAUTION: This equipment contains moving parts and starts automatically. DO NOT USE

with loose clothing that can be caught in the system. This includes, but is not limited to, long

smocks, frock ties, shoelaces and street shoes.

XBW Sole Only • 16

Cut Sheet/Specifications

XBW Sole Only

Specifications subject to change without notice.

Dimensions: 34” wide (without soap tray)

(See Drawing Next Page) 46.1” wide (with side mount soap tray)

82.1” long (including steps)

46.7” high (with 8 adjustable leveling feet)

Weight: 600 lbs.

Shipping Weight: 900 lbs.

Cycle Activation: Photoeye’s at each entrance and exit of the system.

Cycle Length: 8 Seconds (factory setting) Cycle Length Adjustable

Water Inlet: ¾” male garden hose fitting, maximum temperature 110°F

Water Supply Line: 3/8” ID line minimum - 4 GPM Minimum at 50 PSI Max.

Water Consumption: 2.6 GPM at 50 PSI

Electrical: 120-volt, single phase, 20 amps/NEMA 5-20 Power Cord

Drain: 2” male pipe thread in catch basin - to floor drain. (Floor drain required)

Warnings/Cautions:

• Do not hard pipe to the plumbing inlet as this will prevent future serviceability.

• Use a flexible water connection to the system.

• Always install facility water shut off valve near the system.

• Do not hardwire the systems electrical power cord without having a way to disconnect the system

from electrical source for future serviceability of the system.

• Always lockout & tag out when servicing the system or cleaning.

• This equipment contains moving parts and starts automatically. DO NOT USE with loose clothing

that can be caught in the system. This includes, but is not limited to, long smocks, frock ties,

shoelaces and street shoes.

• Use in Wet environments as there is water tracking from use of the system.

• Do not reduce or restrict the drain outlet.

• Make certain system is pitched towards drain.

• System has 3 overflow drains should main drain become clogged.

• System is not intended to be used with a macerator pump directly connected to the system drain.

Consult local and national codes: conformity and compliance to local and national codes is the responsibility

of the installer.

XBW Sole Only • 17

Cut Sheet/Specifications - Continued

2” NPT Drain Pipe

1 1/2” Overflow Safety

Drain Hole (2x)

XBW Sole Only • 18

Cut Sheet/Specifications - Continued

Water Inlet

XBW Sole Only • 19

If External Backflow Prevention is needed

If your local plumbing code requires or additional backflow prevention is required external to the handwash

system, the following backflow preventers are suitable and approved for use with our systems. Two units will

be required for each system, one on each the hot and cold inlets.

Consult local and national codes: conformity and compliance to local and nation codes is the responsibility

of the installer. Consult your local plumbing code for specific details for your location and use a certified

plumber for proper installation.

For ANSI/ASSE Standard 1024 applications:

Watts® Series 7C

Part Number: ¾H 7C

For ANSI/ASSE Standard 1012 applications:

Zurn/Wilkens Model 760

Part Number: 12-760

For ANSI/ASSE Standard 1056 applications:

Watt® Series 008PCQT-1/2”

For details or further assistance on these components, please contact Meritech Customer Service

800.932.7707

XBW Sole Only • 20

Spare Part List – None Warranty

XBW Sole Only

Part #

Part Description

Quantity

214-5023-001

Sole Horizontal Brush (standard)

2

214-5017-001

Sole Horizontal Brush HD

2

911-0013-058

Horizontal Spray Nozzle

10

For additional parts information or service contact Meritech Customer Service – see contact information in

this manual.

Table of contents

Popular Scrubber manuals by other brands

BETCO

BETCO Stealth ASD20BT Operator and parts manual

GoMax Electronics

GoMax Electronics CV-505Q user manual

Clemas & Co

Clemas & Co C110 55B Operator's manual

Advance acoustic

Advance acoustic ecoflex SC3000 26 Disc Charger Instructions for use

Kärcher

Kärcher BD 43/35 C Ep manual

Dustbane

Dustbane Hurricane 700 XTT quick guide