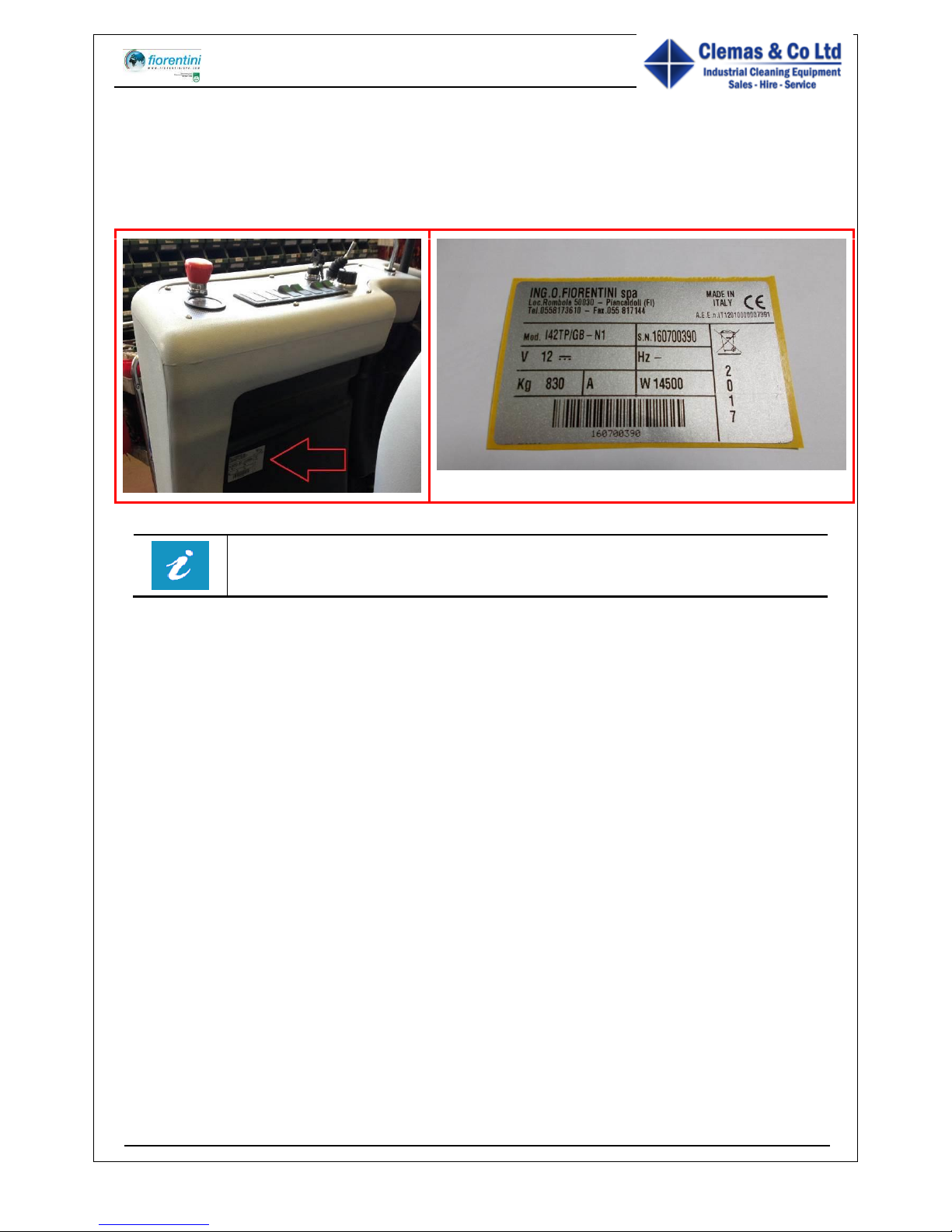

FIORENTINI 142TP-GB Operating instructions

This manual suits for next models

1

Table of contents

Other FIORENTINI Scrubber manuals

FIORENTINI

FIORENTINI I26PF User manual

FIORENTINI

FIORENTINI ECOPRO40 User manual

FIORENTINI

FIORENTINI ECOMINI 430 Specification sheet

FIORENTINI

FIORENTINI I 42/60 GAS User manual

FIORENTINI

FIORENTINI PINKY 26 Operating instructions

FIORENTINI

FIORENTINI ET 65-75 User manual

FIORENTINI

FIORENTINI TERMINATOR-1000 User manual

FIORENTINI

FIORENTINI SCOIATTOLO 75 User manual

FIORENTINI

FIORENTINI JOLLY 13 User manual

FIORENTINI

FIORENTINI ECOSMALL55-N1 Operating instructions

Popular Scrubber manuals by other brands

Tennant

Tennant Litter Hawk Operator's manual

Pacific

Pacific Tsunami operation & maintenance

Pacific Floorcare

Pacific Floorcare S-SERIES Parts & operating manual

Kärcher

Kärcher BD 50/70 R Bp Classic manual

Nilfisk-Advance

Nilfisk-Advance SR 1000S B Instructions for use

Tennant

Tennant CS16 Technical & service manual

U.S. Products

U.S. Products ADVANTAGE-200H Information & operating instructions

Magnum

Magnum 28'' DISK operating instructions

Teka

Teka Handycart DC operating instructions

lavina

lavina LA2000-115 user manual

Taski

Taski Diversey ULTIMAXX 1900 Instructions for use

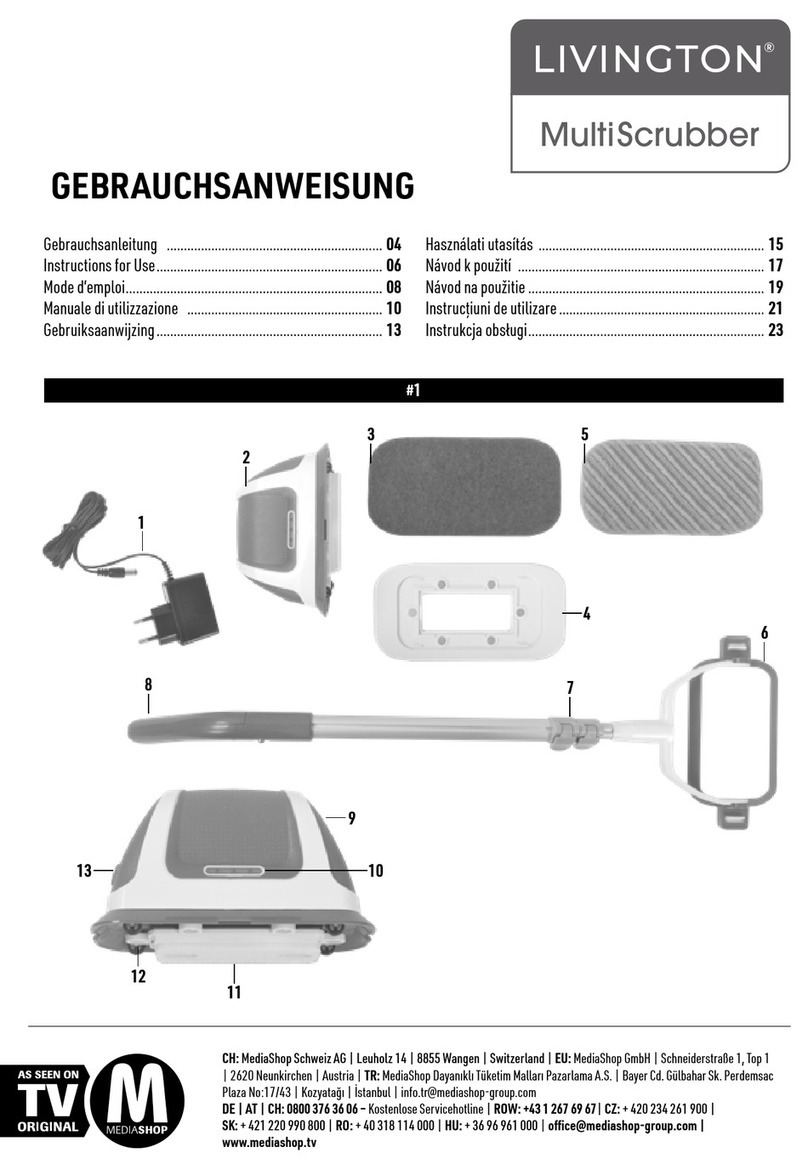

Livington

Livington MultiScrubber Instructions for use