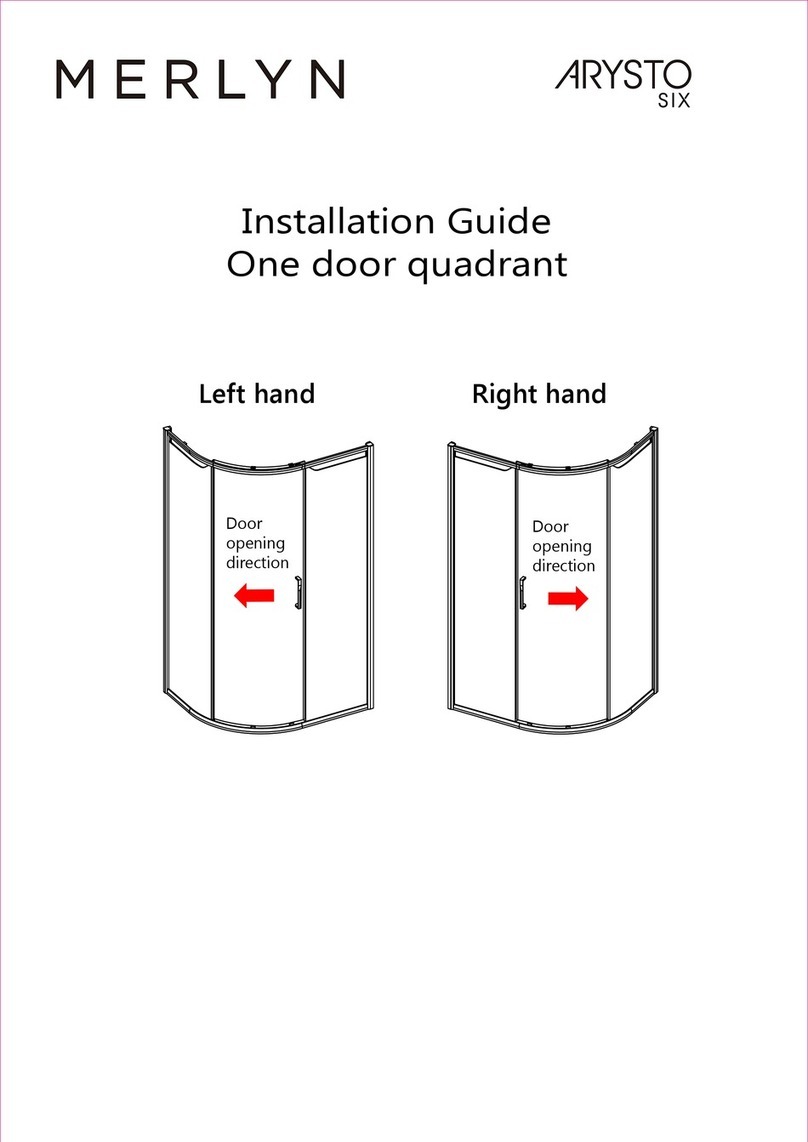

MERLYN ARYSTO COLOUR GHB1100 User manual

Other MERLYN Plumbing Product manuals

Popular Plumbing Product manuals by other brands

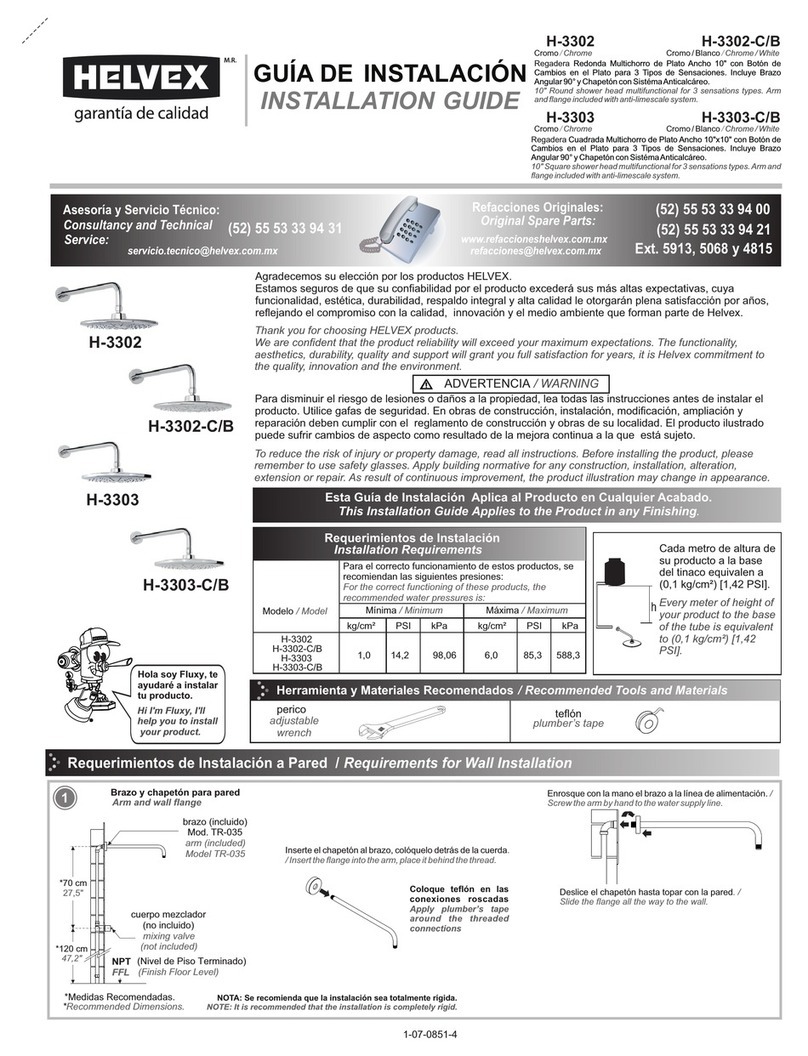

Helvex

Helvex H-3302-C/B installation guide

Hans Grohe

Hans Grohe Metropol S 14020Series Assembly instructions

Lefroy Brooks

Lefroy Brooks R1-4006 Installation, operating, & maintenance instructions

Zline

Zline FFCC-CH Installation guide and user's manual

Moen

Moen ELECTRONIC FAUCET 8301 user manual

American Standard

American Standard Colony Soft 4275.550 Specification sheet

ESS

ESS Easy Drain Easy Turn ET-1300 Installation advice

CRISTINA

CRISTINA CRICS800 installation instructions

newform

newform 28157 instructions

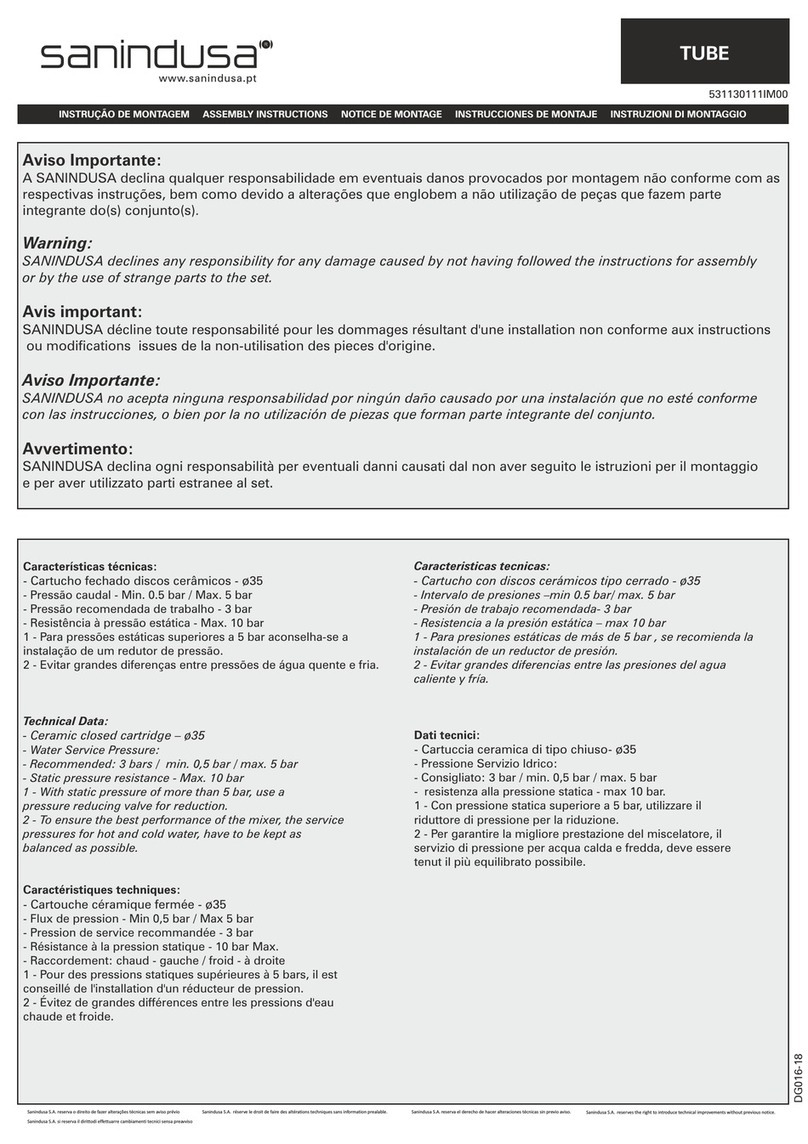

sanindusa

sanindusa TUBE 5311301 Assembly instructions

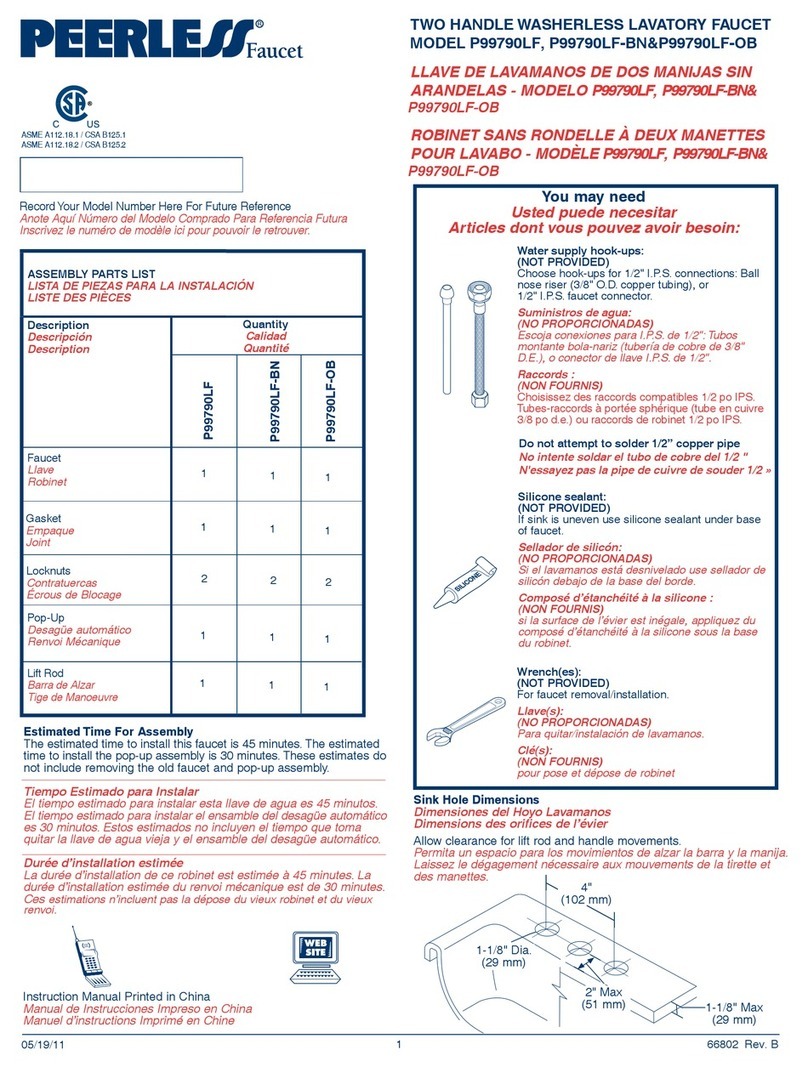

Peerless Faucet

Peerless Faucet P99790LF Assembly instructions

BELLOSTA

BELLOSTA j-q 7821 Installation instruction