Mersen CL-Profiler User manual

Safety Instructions

This device is safe and complies with the current regulations. If, however

the device is used for purposes other than those intended or operated by

unskilled personnel, risk of serious/life threatening injury may occur!

The below instructions must be strictly followed

1. Read the enclosed documentation before using the device for the

first time. All safety regulations included in the enclosed manual

must be complied with.

2. This device may only be operated by specially trained personnel.

The customer must ensure that unauthorised personnel do not ap-

proach the machine on which the device is being used.

3. This device may only be used for the intended purposes.

4. The customer is not allowed to make any modifications on the de-

vice unless prior written approval given by Mersen France Amiens.

5. The device must not be used in case of deterioration or in case of

lack of maintenance. Mersen France Amiens may not be held re-

sponsible of any damage and/or injury if the customer does not fully

comply with these safety instructions.

MEASURING TOOLS

CL-Profiler Operating

Instructions

CL-Profiler operating instructions page 2 of 15

www.cl-profiler.com

CL-Profiler operating instructions

Table of contents

I) Introduction.................................................................................. 3

II) Computer Installation ................................................................... 3

1) Computer requirements .............................................................. 3

2) Software installation................................................................... 3

III) Registration................................................................................ 4

IV) Software use............................................................................... 5

1) Language selection..................................................................... 5

2) Settings .................................................................................... 5

a - General ................................................................................. 5

b - Own logo............................................................................... 6

c – ViRoTi................................................................................... 6

d – CL-profiler software update ..................................................... 6

3) Linear measurement................................................................... 7

a - Slider.................................................................................... 7

b - Y-scale.................................................................................. 7

c - Recording .............................................................................. 7

d - Save data.............................................................................. 8

e - Printing ................................................................................. 8

f

- Graph ................................................................................... 8

g - Cursors ................................................................................. 9

4) Bar to bar measurement ............................................................. 9

5) Open saved files ...................................................................... 10

6) Measuring Analysing................................................................. 10

a - Add Curves.......................................................................... 11

b - Curve’s position ................................................................... 11

d - X-Scale ............................................................................... 11

e - Export to Excel..................................................................... 11

f

- Other buttons ...................................................................... 12

7) ViRoTi tool .............................................................................. 12

a – How to use.......................................................................... 13

V) Maintenance .............................................................................. 14

VI) Warranty .................................................................................. 14

VII) Technical data.......................................................................... 15

VIII) Contact information ................................................................. 15

CL-Profiler operating instructions page 3 of 15

www.cl-profiler.com

I) Introduction

CL-Profiler is an instrument that must be used in combination with a PC,

laptop or mini-PC. The instrument records movements of a probe as a

function of time. CL-Profiler is usable for different profile applications but

is specially developed for commutators and slip rings profiling.

II) Computer Installation

1) Computer requirements

- Computer with Windows 2000, XP, VISTA or Windows 7.

- Minimum 100MB free disk space.

- Minimum 512MB RAM memory.

- One or two free USB ports. We strongly recommend not to use a USB

hub, since it will decrease the sensor performance (add noise).

2) Software installation

Only connect the device to the USB port AFTER software installation. The

reason is that the USB driver must be installed first.

Run the setup file which is provided on CD or downloaded it on

www.cl-profiler.com (see downloads). After installing, the computer must

be restarted.

The device is ready to be used.

For users with administrator limitations;

-the USB plug of CL-Profiler must now be connected to the USB

port of the PC to activate the USB driver.

-Let Windows search for a driver.

-CL-profiler is now ready to be used.

-The file “CL-profiler” on C drive should not be limited.

CL-Profiler operating instructions page 4 of 15

www.cl-profiler.com

III) egistration

To start the CL-

Profiler software, click on the Windows start menu, go to

“programs” and select “CL-

Profiler”. You can also use a shortcut on the

desktop. If the software is unregistered a pop-up will appear for registra-

tion

For registration, one needs to have access to the internet to obtain an in-

stallation code, this can be done on any computer. If you are unable to

register at this time, you can click on the button “cancel after xx sec” at

the moment that it changes to “Register later”.

To obtain an installation code, click on the button “Register software” and

go to http //www.cl-profiler.com/registration.aspx

Enter all your information on the web page. The registration site will send

the installation code to your e-mail address.

Once you receive the installation code by e-mail, click on the button “Reg-

ister software…”, a new window will appear

Enter all your personal information, exact the same as on the web page,

and make sure the CL-

Profiler is connected to the computer. Now click on

“Register”.

Note: the registration is based on your personal information and the CL-

Profiler serial number.

When connecting a different CL-

Profiler, registration must be done again.

CL-Profiler operating instructions page 5 of 15

www.cl-profiler.com

IV) Software use

To start the CL-Profiler software, click on the Windows start menu, go to

“Programs” and select “CL-

Profiler”. If installed, You can also use the

shortcut on the desktop.

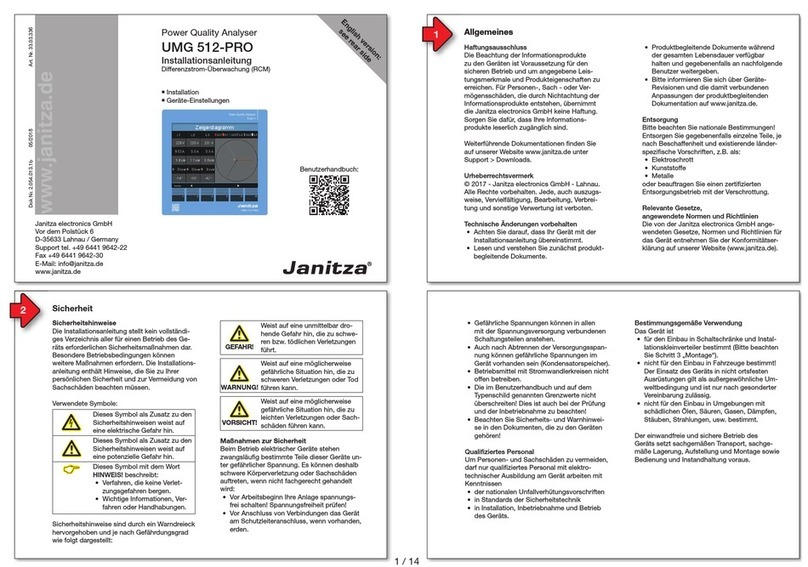

The main screen looks as follows

1) Language selection

First select your language via menu (1). If your language is not listed,

contact Mersen France Amiens to check if it can be made available.

2) Settings

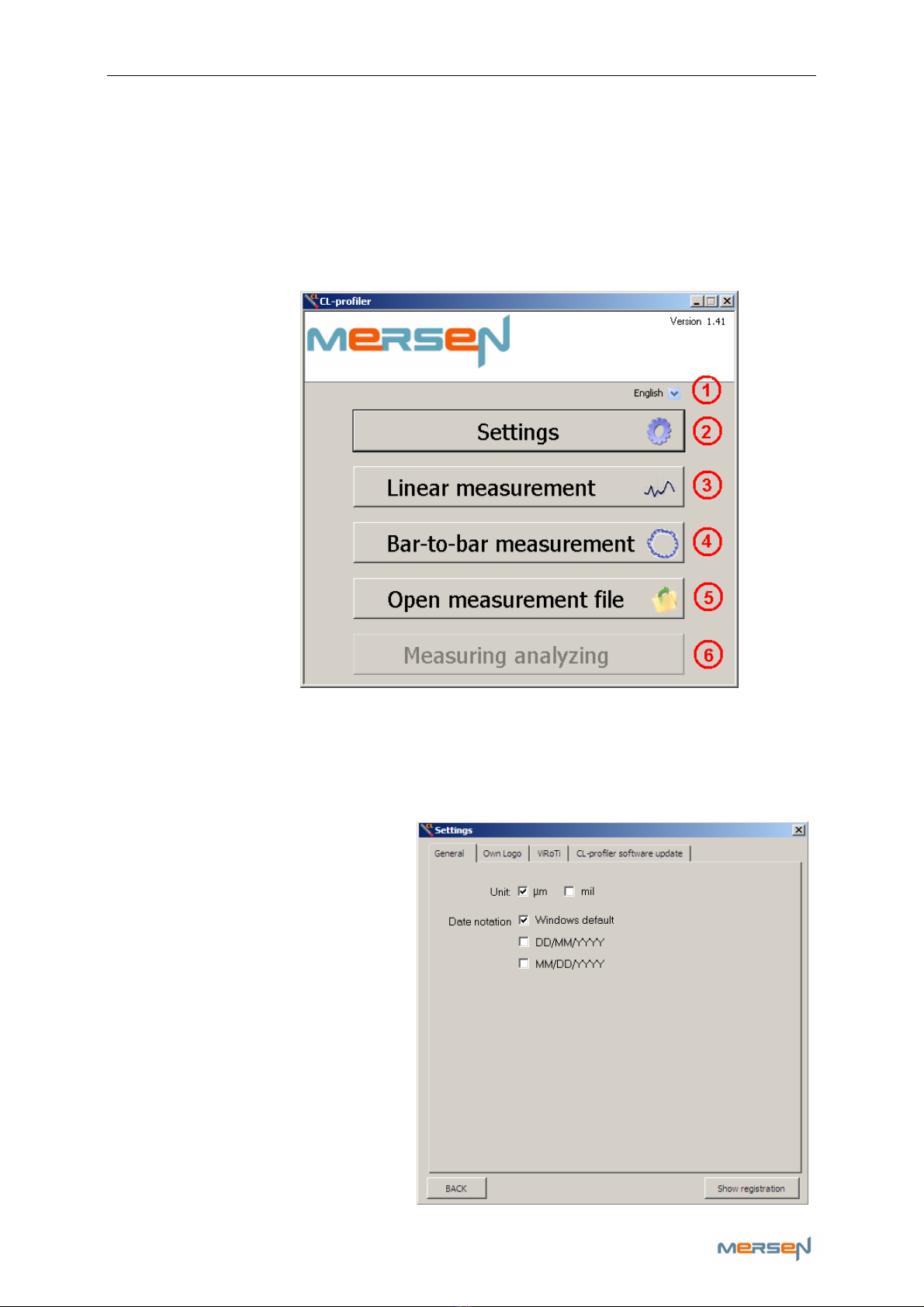

Click on button (2) to open the

settings screen, a new window

pops up

a - General

Adjust the various settings to

your preferences. Click on the

“BACK” button to close the

window.

Click on “Show registration” to

confirm who’s name the soft-

ware is registered to.

CL-Profiler operating instructions page 6 of 15

www.cl-profiler.com

b - Own logo

Click the tab ‘Own Logo’.

In here you have the possibility

to personalize the software with

your own logo.

This logo appears on the main

menu and the reports.

Wink the box ‘Activate Own

Logo’

You can load your logo by click-

ing the ‘Load own logo image

(JPG,BMP,PNG)- button’ and

browsing for your image.

Make sure the image of your

logo does not exceed the measurements 320x75 pixels, in order to get a

complete view of your image.

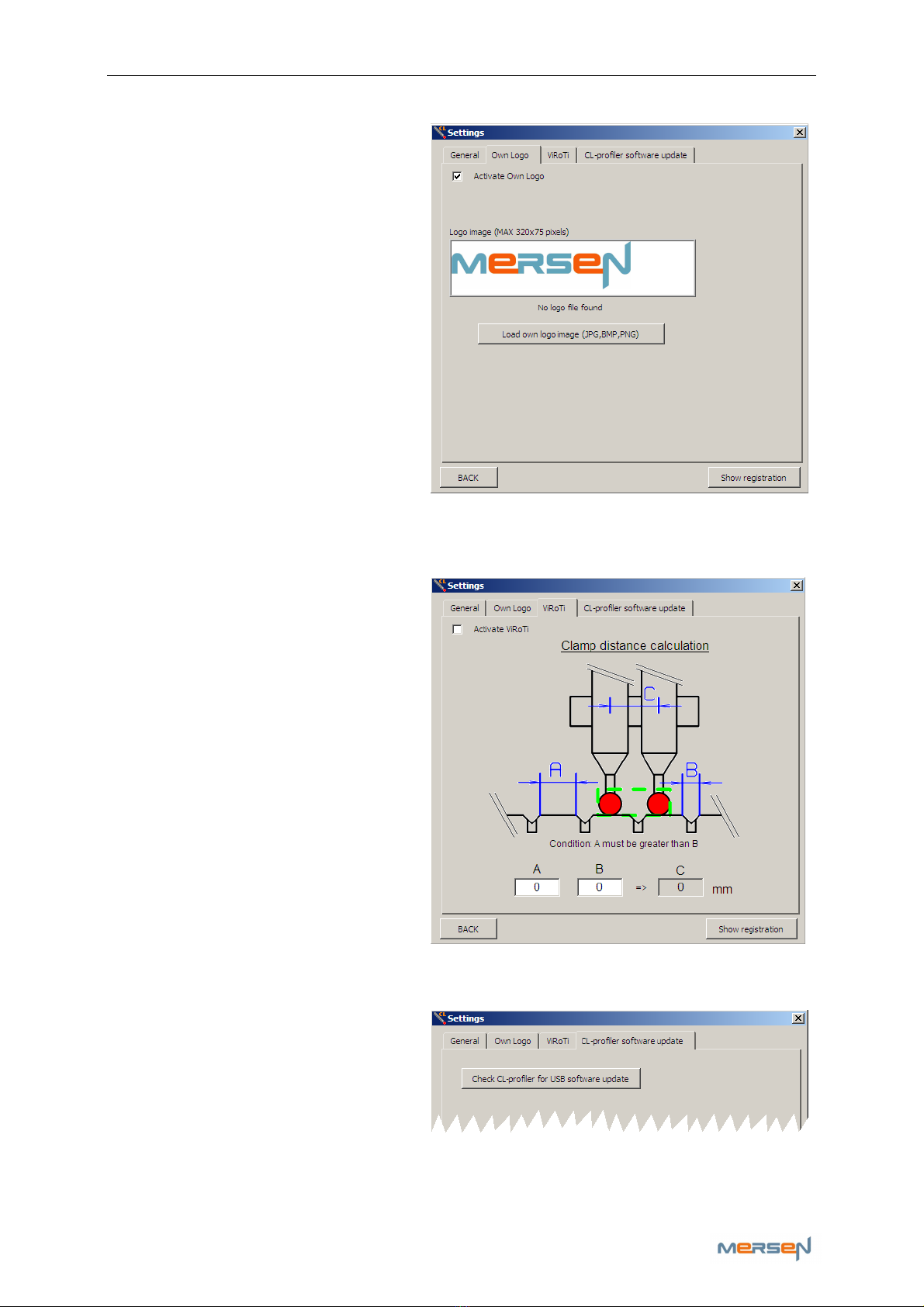

c – Vi oTi

ViRoTi stands for Virtual oller

Tip and is used to profile

grooved slip rings and commu-

tators. (Please check Chapter 7

on p.12 for more info)

To use the ViRoTi tool, wink ‘Ac-

tivate ViRoTi’.

In field A (the measure part) &

B (the wide of the groove in-

cluding the chamfer) you can fill

in the distances to let the soft-

ware calculate the necessary

distance for your clamp (C).

d – CL-profiler software update

To update the software of your

probe(s) , click the ‘Check CL-

profiler for USB software up-

date’. If necessary the probe

will then automatically update.

ATTENTION do not disconnect the probe during updating, this could

cause irreversible damage to the software remaining in a limbo state.

CL-Profiler operating instructions page 7 of 15

www.cl-profiler.com

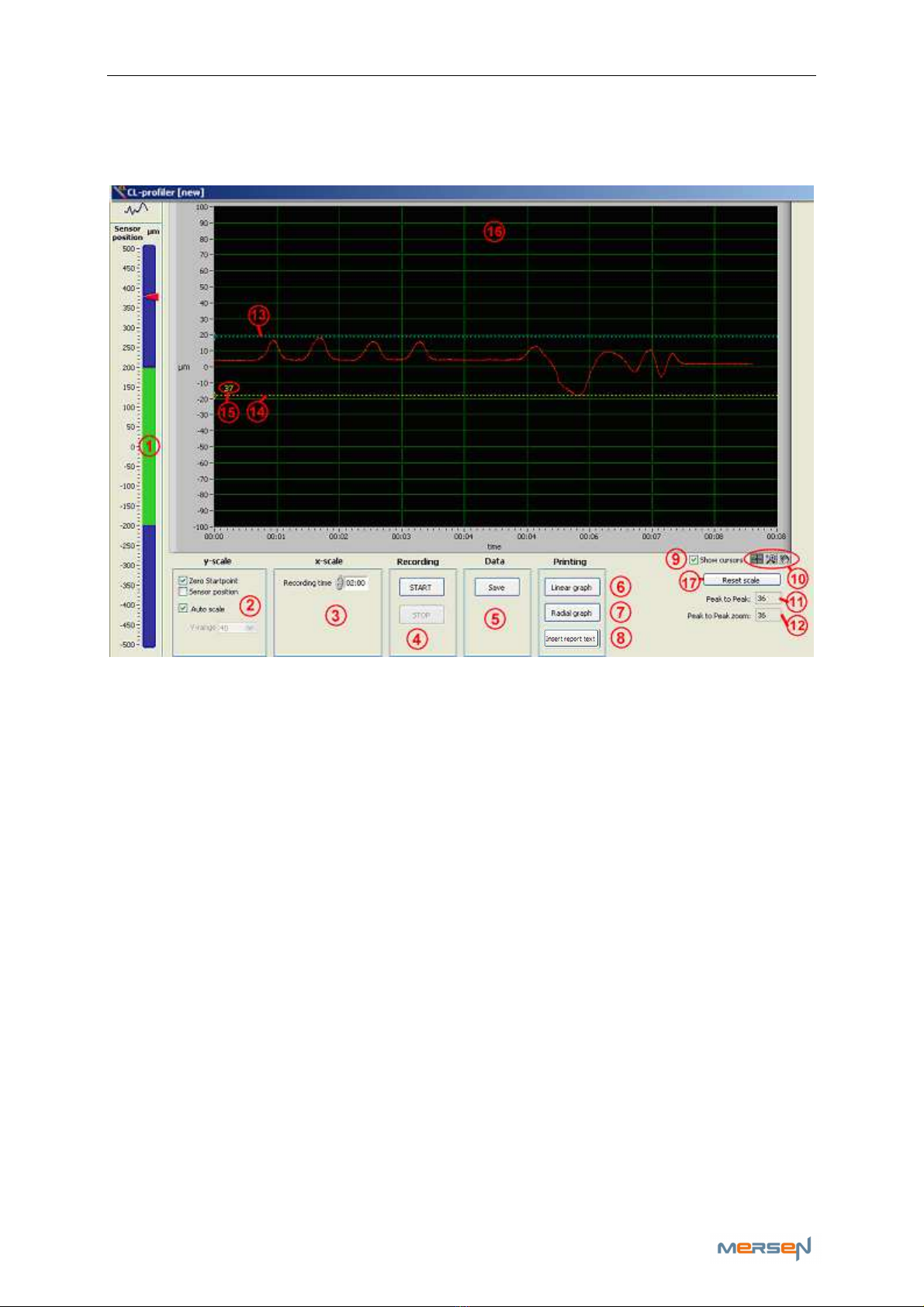

3) Linear measurement

Click on button (3) to open the linear measurement screen

a - Slider

On the left side, the slider (1) indicates the current location of the sensor,

in the centre or at the end of the range. The scale will become narrower

when the middle point (zero) is approached. It is better to move the sen-

sor close to the zero point since the sensor has lower noise around it.

b - Y-scale

There are several settings for setting the Y-scale (2). Select “Zero Start-

point” or “Sensor position” (is absolute value). “Zero Startpoint” will use

the start point as zero value when recording starts. When recording stops,

the y-scale will be adjusted so that the zero point is middle between

maximum and minimum.

Auto scale will make the scale of the graph (16) fit to the running meas-

urement. If auto scale is disabled, one can select the range of the Y-scale

by means of the menu “Y-range”.

c - ecording

The recording time (3) determines how long the signal will be recorded. A

running measurement can always be interrupted with the “STOP” button

(4).

CL-Profiler operating instructions page 8 of 15

www.cl-profiler.com

To start or stop recording, click on the “START” or “STOP” buttons (4).

When recording is busy, a red blinking indicator is shown on the bottom

right hand side of the screen.

d - Save data

When a measurement is finished, it can be saved with the “Save” button

(5). A new window will pop-up which allows you to enter some additional

information about the measurement (machine name…). Also note that the

scale information is saved together with the data. If one zooms in to a

part of the graph (see further), that scale position is also saved.

e - Printing

For the linear measurement there are two reports available, the “Linear

graph” (6) and the “Radial graph” (7). These reports can be printed or

saved as JPEG files so that they can be included in your own reports. Make

sure a printer is installed before attempting to print.

Measurements can also be transferred to a different computer with a USB

stick.

Before printing, one can add additional information that belong to this

measurement by clicking on “Insert report text” (8). This is the same text

as in the pop-up window when saving the data.

f - Graph

The graph (16) shows the current measurement. It is possible to zoom in,

on a part of the graph. This way one can, for example, take only that

piece of the X-scale that contains useful data. For example, if two rota-

tions of a device under test are recorded, you can zoom into a part so that

you get the data of only 1 rotation. When printing, only the part in which

you were interested will be printed.

The ZOOM tools are located above (10). Click on the magnifying glass to

see new options appear

CL-Profiler operating instructions page 9 of 15

www.cl-profiler.com

Click on button (17) “Reset scale” to reset the scale like it was before

modification.

The peak to peak indicator (11) shows the difference between maximum

and minimum of the whole curve. The “peak to peak zoom” indicator (12)

shows the difference between maximum and minimum of the zoomed area

(in the example it’s the same).

g - Cursors

When activating the selection “Show cursors” (9), two cursor lines will ap-

pear on the screen a blue (13) and a yellow (14) horizontal line. They are

useful for determining the difference between 2 points. The number (15)

at the yellow cursor shows the difference. For moving the cursor lines,

first select the cursor tool in the zoom palette, then move the mouse over

the blue or yellow cursor and click on to grab it.

Then you can drag it up or down.

The cursors will also be shown on the reports.

4) Bar to bar measurement

On the main screen click on button (4). A new window appears looking

very similar to the previous paragraph 3) Linear measurement. We will

only explain the difference.

Instead of a recording time there is now a setting “number of bars” (1).

While recording, the software tries to detect the bars by the peaks that

appear when the sensor jumps down between two successive bars. It is

important that the speed of the rotor is not too high, to be able to meas-

ure these peaks and bar values correctly. Limit the rotating speed to a

maximum of 30 bars per second. An indicator on the top of the graph will

show the speed. It is green when the speed

is OK, orange when it gets high, and red

CL-Profiler operating instructions page 10 of 15

www.cl-profiler.com

when it’s too high. If the speed is too high, it will be impossible to save

the data because it is not reliable.

During recording, the graph shows the real time sensor value, which also

includes the peaks between the bars.

Once recording is finished, the software will try to find the bars and show

one value for each bar. The curve is then converted from a flowing line to

a step-wise presentation, where each step represents a bar.

In the bar to bar measurement there are also 2 reports available, the Lin-

ear and Radial report. The bars can be represented in a circular plot (ra-

dial) or in linear fashion.

5) Open saved files

On the main screen, click on “Open measurement file’” (5) to open data

that was previously saved. When the data is shown, it is represented in

the graph exactly as it was when it was saved. The whole graph is in-

cluded in the data, also if one zoomed in, into a smaller part of the graph

when it was saved.

The tools and reports are the same as in previous paragraphs.

6) Measuring Analysing

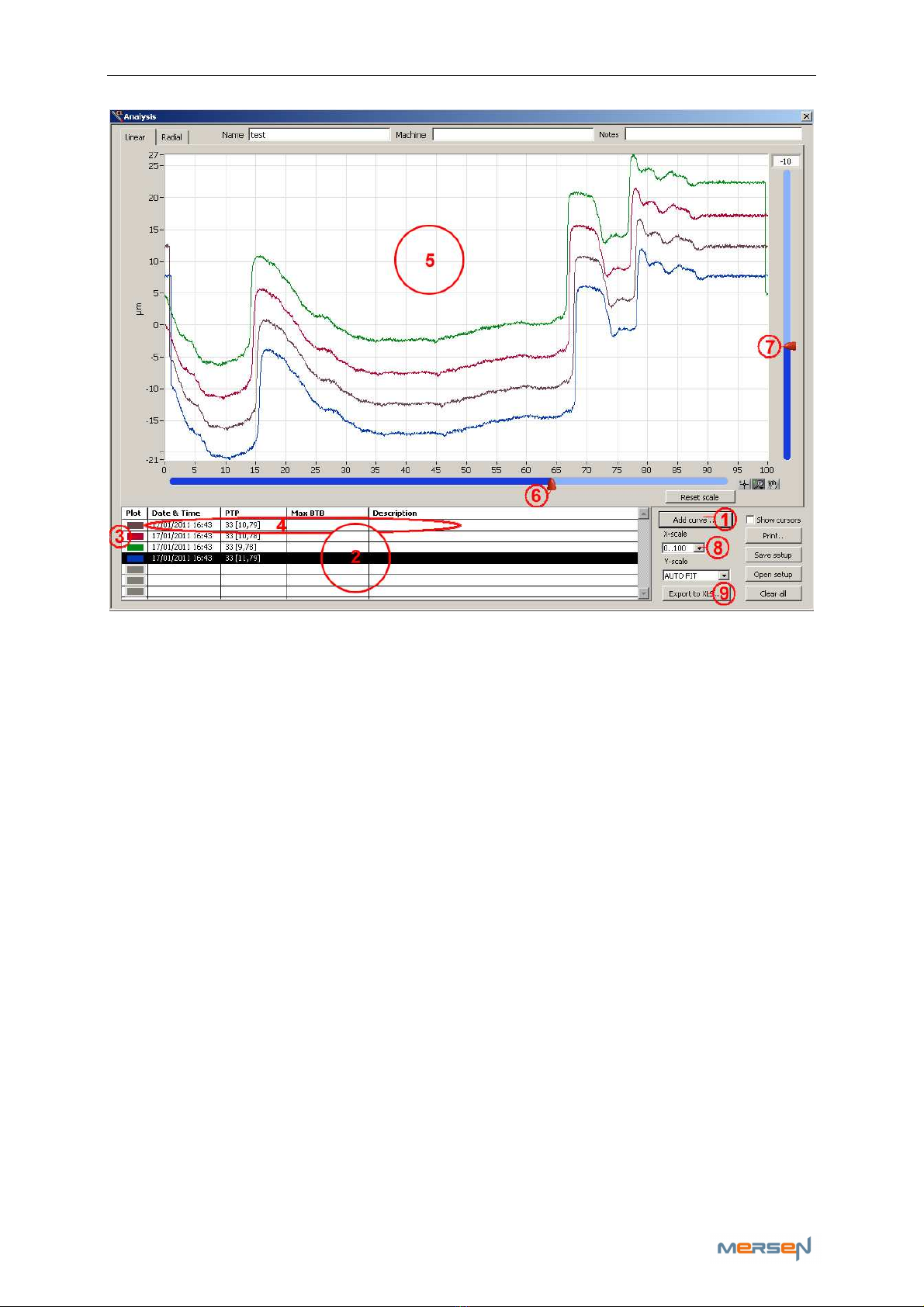

Click on button (6) in the main screen to open the additional measuring

analysing screen, a new window pops up

Fill in your ‘analysis registration

code’ and click “Register” to ac-

cess this additional tool.

This tool contains extra add-on functions for analysing and comparing re-

corded curves.

CL-Profiler operating instructions page 11 of 15

www.cl-profiler.com

a - Add Curves

Press ‘Add curve’ (1) to add new curves. They will appear in the small

window on the left (2). You have the possibility to add up to a maximum

of 10 curves.

You can change the color of your curve [click (3)] and change the descrip-

tion or remove the curve by double clicking on the curve’s information

zone (4).

b - Curve’s position

You can change the curve’s position in window (5) by selecting the specific

curve in window (2) [click to select], and then adjust the sliders (6) and

(7). This way we can, for example, compare a previous measurement with

a more recent one at the same starting point.

d - X-Scale

The X-scale (8) can be adjusted to view in percent, bars, length and de-

grees

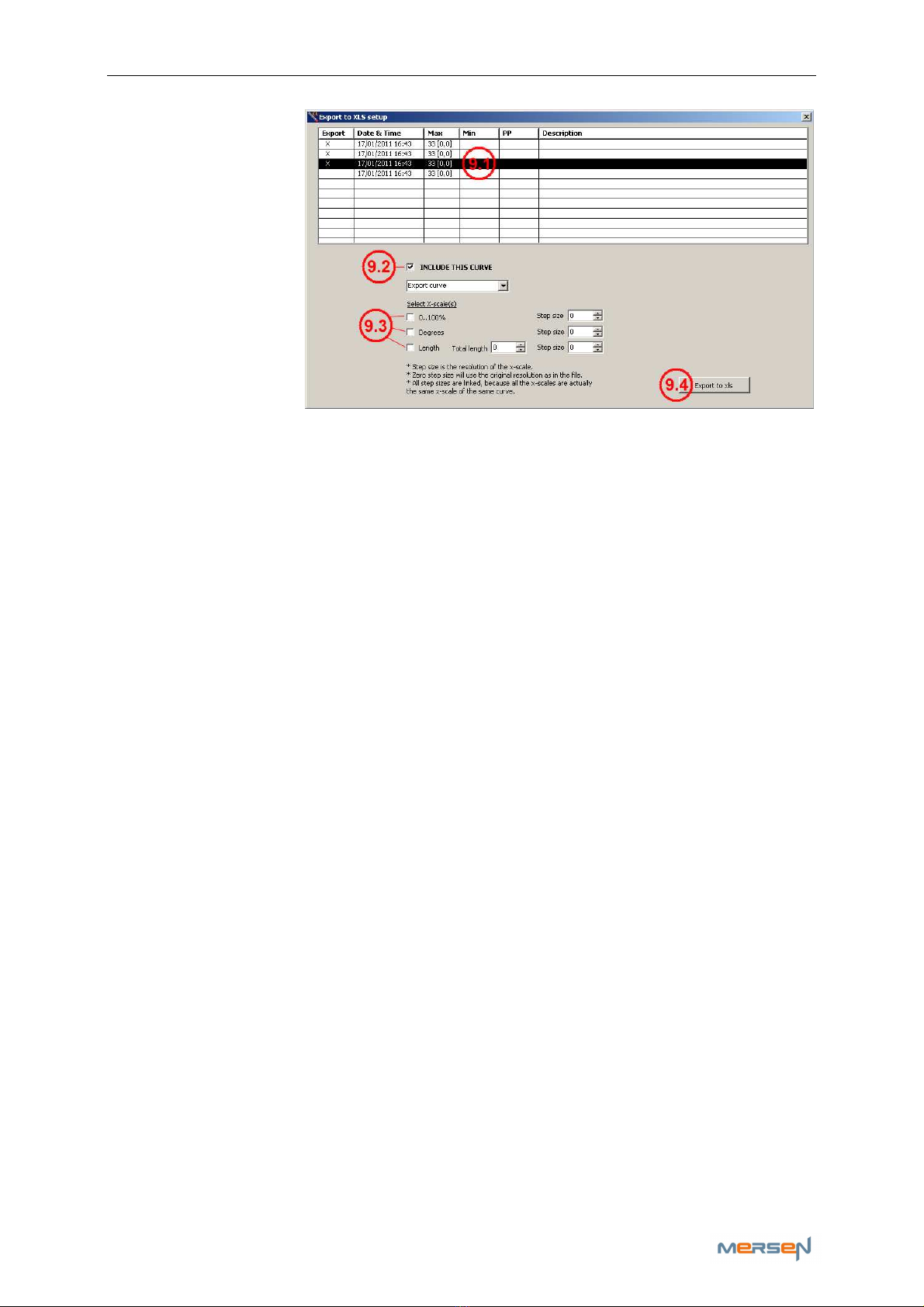

e - Export to Excel

Another additional feature in the ‘measuring analyzing’ function is export-

ing your measurements to an excel-file. This can be obtained by clicking

the ‘Export to XLS..’-button (9).

CL-Profiler operating instructions page 12 of 15

www.cl-profiler.com

A window pops up

“Export to XLS

setup” in which

you can select the

curves you’d like

to export to Excel.

Select a curve

(9.1) and wink the

“Include this

Curve”-box (9.2)

to export the rele-

vant curve.

“Select X-scale” (9.3), gives you the option to export you’re curve(s) in

percent and/or degrees and/or length.

Once exported to xls (9.4), you can create an automatic Excel format to

calculate the different measurements in your curve(s). This way you can

systematically judge your curve(s) state.

f - Other buttons

The remaining buttons have similar function as explained in chapter (IV)

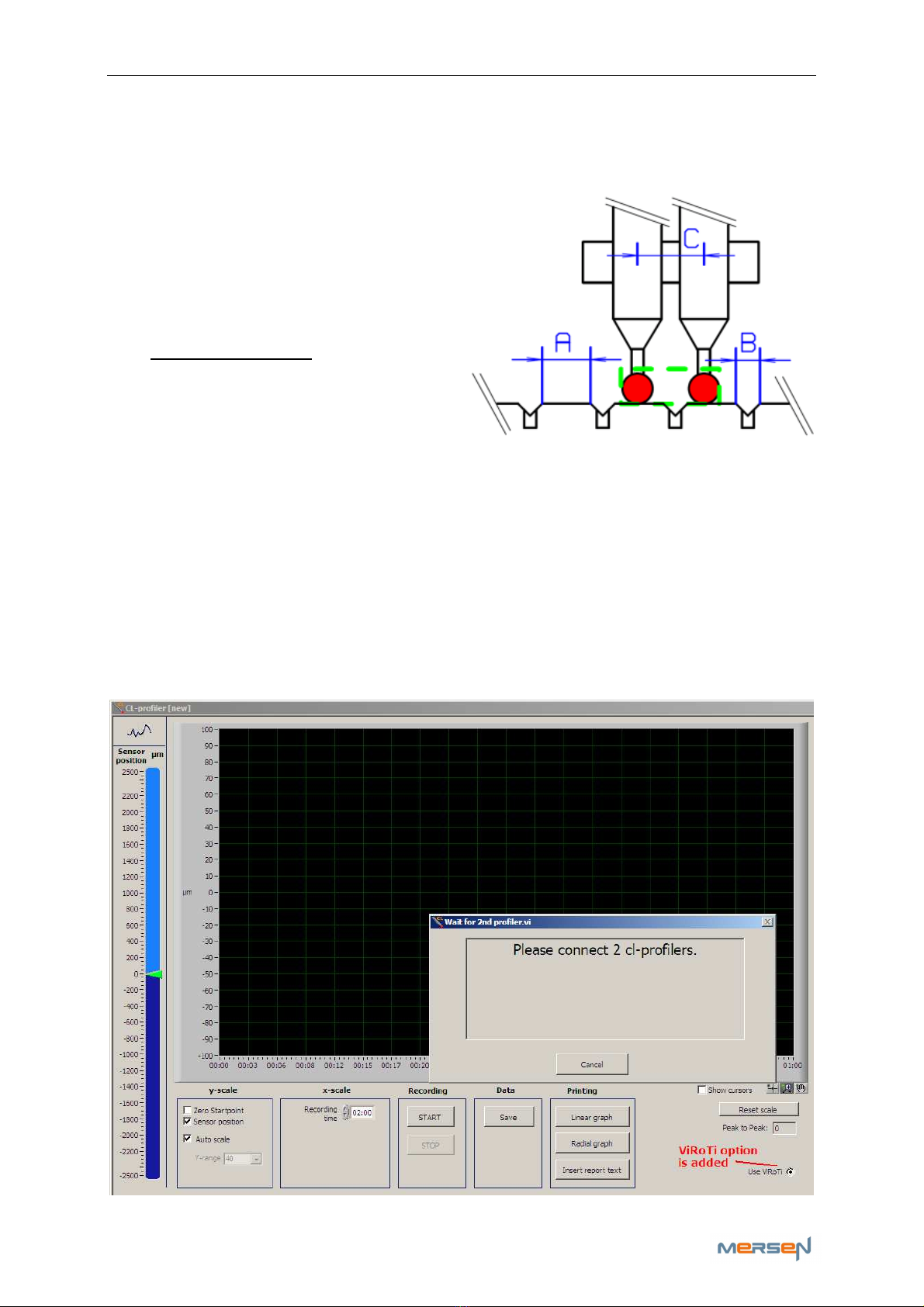

7) Vi oTi tool

ViRoTi stands for Virtual oller Tip and is used to profile grooved slip

rings and grooved commutators.

To use this tool you need

-two free USB ports on your computer

-two CL-profiler probes or one CL-profiler and one ViRoTi probe.

This function can only work on condition that the measure part “A” is

wider than the wide of the groove “B”, including the chamfers

Note Before using this tool you need to update the probe software. See

chapter (IV,2) d - CL-profiler software update

CL-Profiler operating instructions page 13 of 15

www.cl-profiler.com

a – How to use

Place the probes radial, with an ax-

ial distance “C”, on your slip ring or

your collector.

To start the profiling both probes

must be located on your measure

part of the slip ring or collector,

and not in the groove.

Distance “C” depends on the wide

of the measure part (A) and the

groove (B). The probe distance “C”

can be calculated using the ViRoTi calculator in the “Settings menu”.

See chapter (IV,2) c - Vi oTi

Connect only the registered probe on your PC and start the CL-

profiler software.

Activate the ViRoTi tool by winking the box ‘Activate ViRoTi’ in the “Set-

tings”. A ViRoTi activation option will now be added in your measurement

window. If you activate the ViRoTi tool in your measure window, the soft-

ware will ask you to connect the second probe on your PC.

CL-Profiler operating instructions page 14 of 15

www.cl-profiler.com

After connecting the second probe on your PC you will see two needles

(red and green) in your measure window.

You can adjust the radial position of each probe separately, but it is not

necessary that both probes are exact identical. You can simply activate

“zero startpoint” before you start the profiling. The software will then

place both probes on the same level independent of the physical position

of the Ruby tip positions.

Please note for wide grooves or/and mica slots that you use the 8mm ruby

tips on both probes.

V) Maintenance

Make sure the cable to the sensor and USB port is not damaged. Clean

sensor when necessary.

It is recommended that the sensor is calibrated every two years.

VI) Warranty

The warranty covers construction and material faults of the CL-profiler

equipment.

The warranty period is valuable for 1 year starting on the invoice date.

Damage due to incorrect or inexpert handling is excluded from the war-

ranty.

The CL-profiler probe must be placed as radial as possible especially on

commutators. Angled probe position, can cause to damage.

The ballpoint tip diameter must be

-for mica slots approximately 4 times larger then the full width of

the mica slot including the chamfers.

-for spiral grooves approximately 3 times larger then the full width

of the groove including the chamfers.

CL-Profiler operating instructions page 15 of 15

www.cl-profiler.com

VII) Technical data

- Interface USB

- Dimensions 8 mm diameter

- Weight 0,1 Kg

- Max operating temperature 40°C

- Max Storage temperature 50°C

- Measurement range +/-2,5mm

- Max. variation speed to be measured 120/40Hz

- Sample rate 250Hz

- Typical noise level 0,5 µm

- Accuracy repetitive +/- 0,25 µm

- Accuracy relative +/- 1 µm

- Accuracy absolute by 20°C +/- 2 µm

VIII) Contact information

Mersen France Amiens S.A.S.

10, avenue Roger Dumoulin

F-80084 Amiens

France

Tel. +33 (0)3 22 54 45 00 - Fax +33 (0)3 22 54 45 62

www.mersen.com

www.cl-profiler.com

Table of contents