Elvaco CMi4170 User manual

CMi4170

User manual

1.3 Edition

Copyright © 2023 Elvaco AB

All rights reserved. No part of the contents of this manual may be transmitted or reproduced in any form

by any means without the written permission of Elvaco AB. Printed in Sweden.

All trademarks and copyrights are acknowledged.

The contents of this manual, including product data, diagrams, charts, etc. represent information on

products at the time of publication and are subject to change without prior notice. It is therefore

recommended to contact Elvaco AB for the latest product information before purchasing the product.

The documentation and product are provided on an “as is” basis only and may contain deficiencies or

inadequacies. Elvaco AB takes no responsibility for damages, liabilities, or other losses resulting from

the usage of this product or manual.

Table of Contents

1. About this manual ............................................................................................................ 4

1.1. Symbols ................................................................................................................. 4

1.2. Terms and abbreviations .......................................................................................... 4

2. Safety ............................................................................................................................... 5

3. Product ............................................................................................................................ 6

3.1. Application description ............................................................................................. 6

3.2. Features ................................................................................................................. 6

3.3. Compatibility ........................................................................................................... 6

3.4. Parts overview ........................................................................................................ 7

4. Installation ....................................................................................................................... 8

4.1. Mounting the module ............................................................................................... 8

4.2. Activating the module .............................................................................................. 8

4.3. Joining the LoRaWAN network ................................................................................. 9

5. Operation ....................................................................................................................... 10

5.1. Server configuration .............................................................................................. 10

5.2. Configuration ........................................................................................................ 10

5.3. Transmit interval .................................................................................................... 11

5.3.1. Transmit interval in EcoMode ...................................................................... 11

5.4. Time handling ....................................................................................................... 12

5.5. Adaptive data rate (ADR) ....................................................................................... 12

5.6. Message encoding ................................................................................................ 12

5.7. Security and access control ................................................................................... 13

5.8. Meter communication error messages .................................................................... 13

5.9. Reset procedures .................................................................................................. 13

5.9.1. Rebooting the module ................................................................................. 13

5.9.2. Switching off the module ............................................................................. 13

6. Configuration options .................................................................................................... 14

6.1. Elvaco OTC app configuration options .................................................................... 14

6.2. Downlink configuration options ............................................................................... 15

6.3. Message formats ................................................................................................... 16

6.3.1. Unscheduled message formats ................................................................... 16

6.3.2. Scheduled message formats ....................................................................... 19

7. Technical specifications ................................................................................................. 28

8. Simplified Declaration of Conformity ............................................................................. 30

9. Document history ........................................................................................................... 31

CMi4170

3

1. About this manual

This manual covers information needed to mount, install, configure, and use the product. It is intended

for installers and system integrators.

To download the latest version of this User manual, visit the Elvaco website, https://www.elvaco.com.

There you will also find information about Elvaco’s other products and services.

1.1. Symbols

The following symbols are used throughout the manual to emphasize important information and useful

tips:

WARNING

Indicates a potentially dangerous situation that could result in severe injuries or serious equipment damage.

CAUTION

Indicates a potentially dangerous situation that could result in minor injuries or equipment damage.

NOTE

Indicates information that is important to take into consideration for safety reasons or to assure correct operation of

the product.

TIP

Indicates information intended to help you get the most out of your product. It can for example be used to highlight a

possible customization option related to the current section.

1.2. Terms and abbreviations

Abbreviation Description

DIB Data Information Block

DIF Data Information Field

VIF Value Information Field

MCM Meter Connectivity Module

Number representation

• Decimal numbers are represented as normal number, i.e. 10 (ten)

• Hexadecimal numbers are represented with prefix 0x, i.e. 0x0A (ten)

• Binary numbers are represented with the prefix 0b, i.e. 0b00001010 (ten)

European standards

M-Bus standard EN 13757-3:2013: Communication systems for and remote reading of meters – Part 3:

Dedicated application layer.

CMi4170

4

2. Safety

The following safety precautions must be observed during all phases of the operation, usage, service,

or repair of the product. Users of the product are advised to convey the following safety information to

users and operating personnel and to incorporate these guidelines into all manuals supplied with the

product. Failure to comply with these precautions violates safety standards of design, manufacture and

intended use of the product. Elvaco AB assumes no liability for customer’s failure to comply with these

precautions.

CAUTION

Electrostatic-sensitive product. Observe the necessary ESD protective measures when installing the product.

NOTE

The product receives and transmits radio frequency energy while switched on. Remember that interference can occur

if the product is used close to TV sets, radios, computers or inadequately shielded equipment. Follow any special

regulations and always switch off the product wherever forbidden, or when you suspect that it may cause interference

or danger.

NOTE

Waste electrical products should not be disposed of with household waste. Please recycle where facilities exist.

Contact your Local Authority for recycling advise.

CMi4170

5

3. Product

3.1. Application description

CMi4170 is a meter communication module mounted inside a Engelmann Sensostar S3/S3C to deliver

meter data to a receiving server via a LoRaWAN network. The module is energy-efficient and has

eleven years battery life. It can be retrofitted into deployed meters and is ideal for applications where

long range is required. CMi4170 is easily configured through Elvaco OTC mobile app. With CMi4170,

Elvaco offers a meter communication module designed for customers that require a user-friendly and

cost-effective solution.

3.2. Features

CMi4170 offers a combination of battery operation with long lifetime and a versatile application through

its many configuration options. Key features of the module include:

•Extensive battery lifetime

The module’s EcoMode feature enables the module to achieve a battery-lifetime of 6+1 or 10+1 years

with a new internal meter battery (“+1” refer to 1 year of storage).

•Easy start-up

As soon as the meter connectivity module is mounted in the meter and activated, it will join the

LoRaWAN network.

•Easy and secure commissioning

With Elvaco’s One-Touch Commissioning (OTC), deployment, configuration and key transferring can

be performed in a secure and flexible way.

•Unique and flexible message formats

CMi4170 has several different message formats, this makes it easy to customize the payload to the

unique demands of each application.

3.3. Compatibility

CMi4170 is compatible with Engelmann Sensostar meters with a compatible firmware version. Once the

module is mounted and starts up, a compatibility check is made to ensure that it is compatible with the

meter firmware. If the module is mounted in an incompatible meter, this is indicated in the OTC App.

The meter’s firmware version can be shown in the meter’s display, for further information, refer to the

meter’s manual.

The following table shows the minimum firmware versions required.

Table 1. CMi4170 - Meter firmware compatibility

Meter Minimum firmware version

Engelmann SensoStar S3 103/14

Engelmann SensoStar S3C 100/5

CMi4170

6

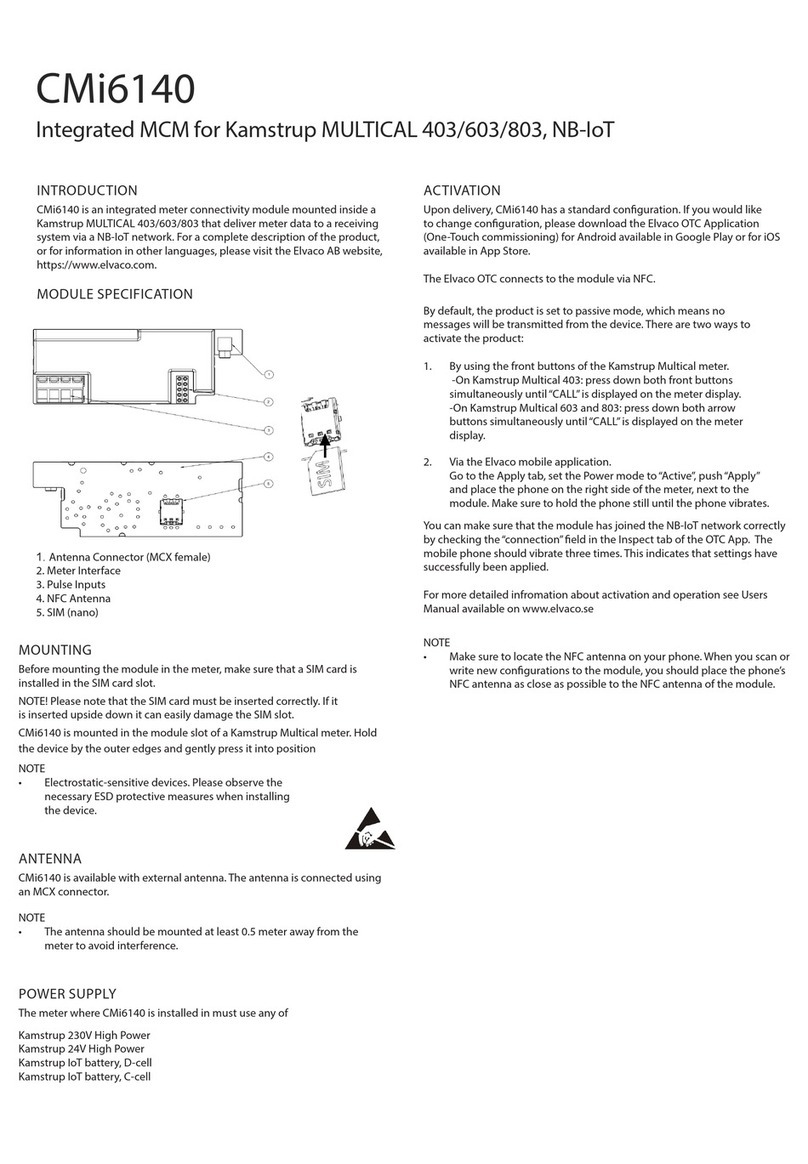

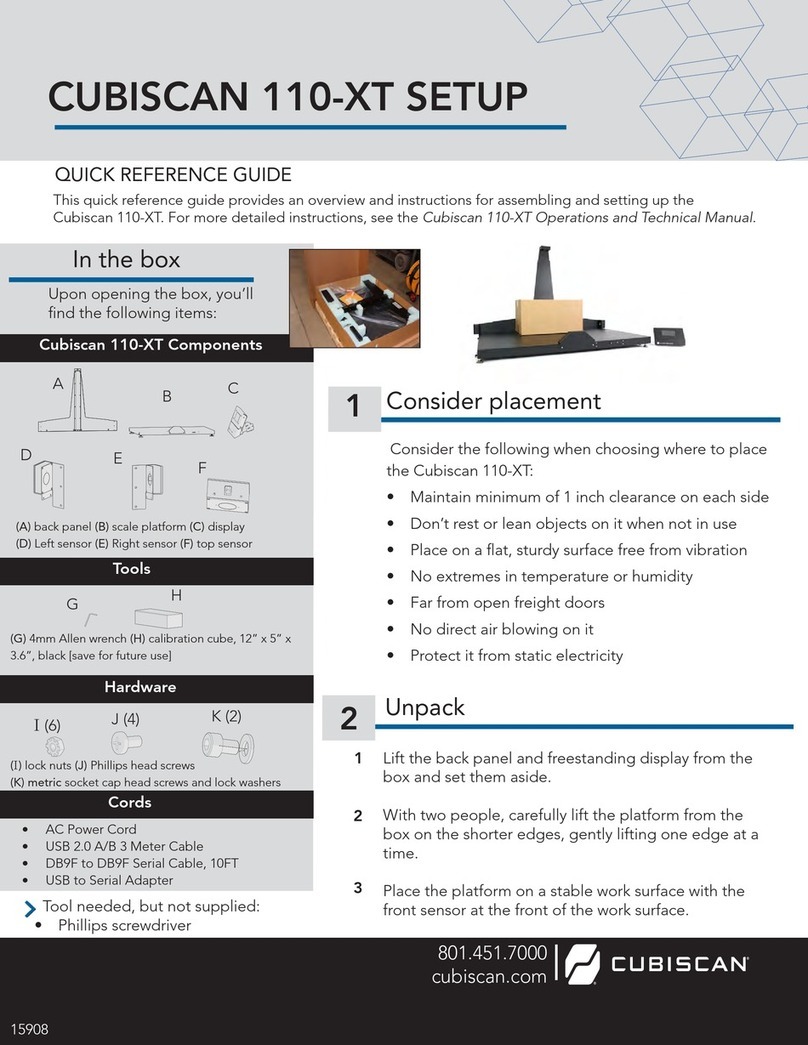

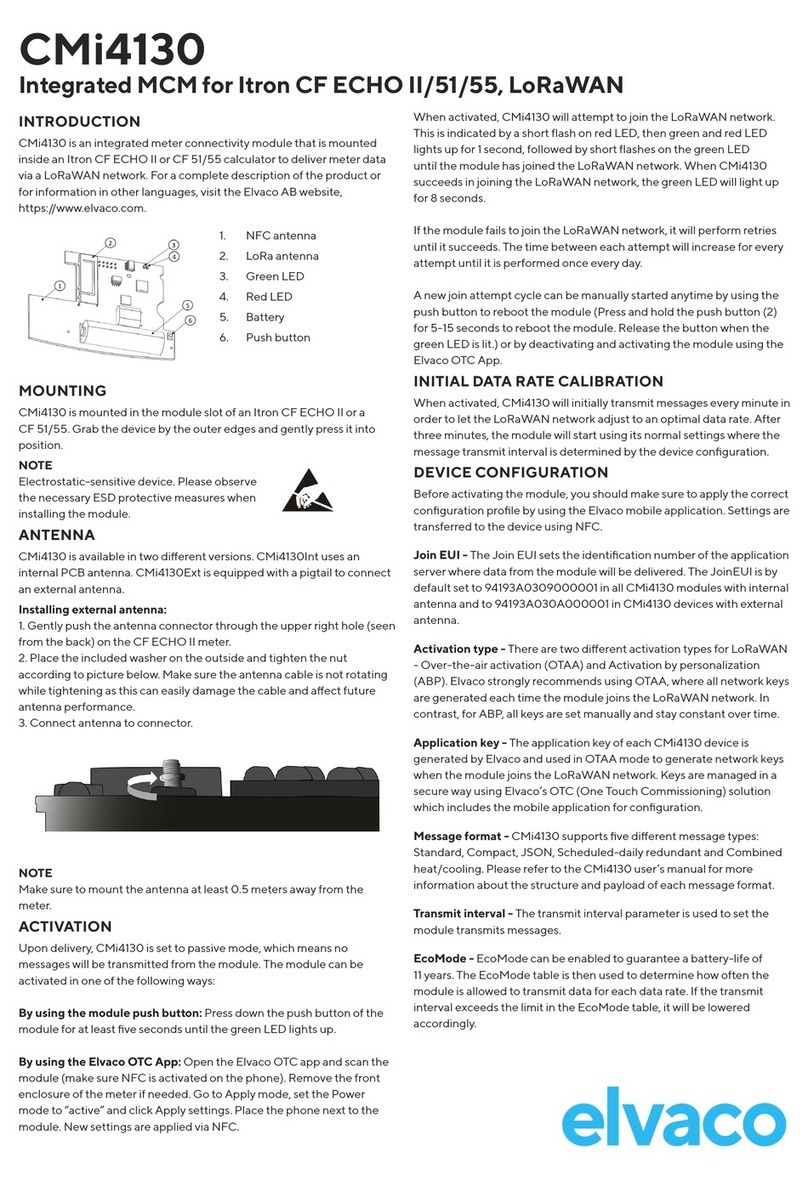

3.4. Parts overview

1. Green LED

2. Red LED

3. Interface connector

4. Push button

5. Pulse input

6. LoRaWAN antenna

NOTE

The NFC antenna is integrated in the edge of the PCB.

CMi4170

7

4. Installation

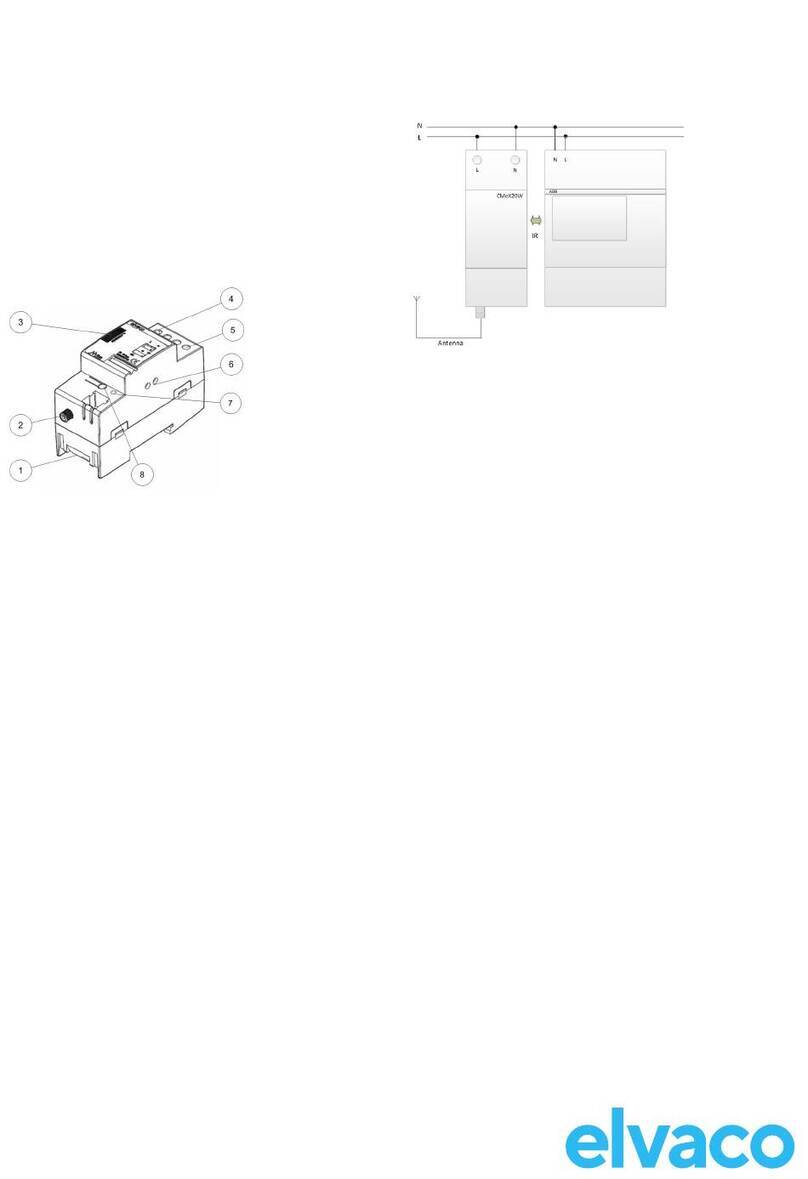

4.1. Mounting the module

CMi4170 is mounted in an Engelmann Sensostar S3/S3C meter.

1. Grab the device by the outer edges.

2. Gently press it into postition in the module slot.

• Make sure that the module's push button (2) is facing upwards.

• Make sure that interface connector of the meter (1) fits the interface connector of the module (3).

Engelmann Sensostar (left), CMi4170 (right)

4.2. Activating the module

Upon delivery, CMi4170 is set to passive mode, which means no messages will be transmitted from the

module. The module can be activated in one of the following ways:

Via the module push button

1. Press down the push button of the module for at least five seconds.

2. Release when the green LED lights up.

3. Wait for one to eleven seconds.

The module indicates start-up by flashing red and green LEDs for one second.

Via Elvaco OTC app

1. Open Elvaco OTC app (downloadable via Google Play).

2. Scan the module (make sure NFC is activated on the phone).

3. Go to Apply mode.

4. Set the power mode to “Active”.

5. Select Apply settings.

6. Scan the module to apply new settings.

To verify that the module has been activated, go to the Inspect, scan the module, and make sure

that power mode is set to “Active”.

CMi4170

8

TIP

The NFC field is easiest accessible if placing the phone in the middle part of the front.

Via device monitor

Device monitor refers to Engelmann's optical configuration tool. For more information see Engelmann

documentation.

Via meter menu

Refer to Engelmann documentation.

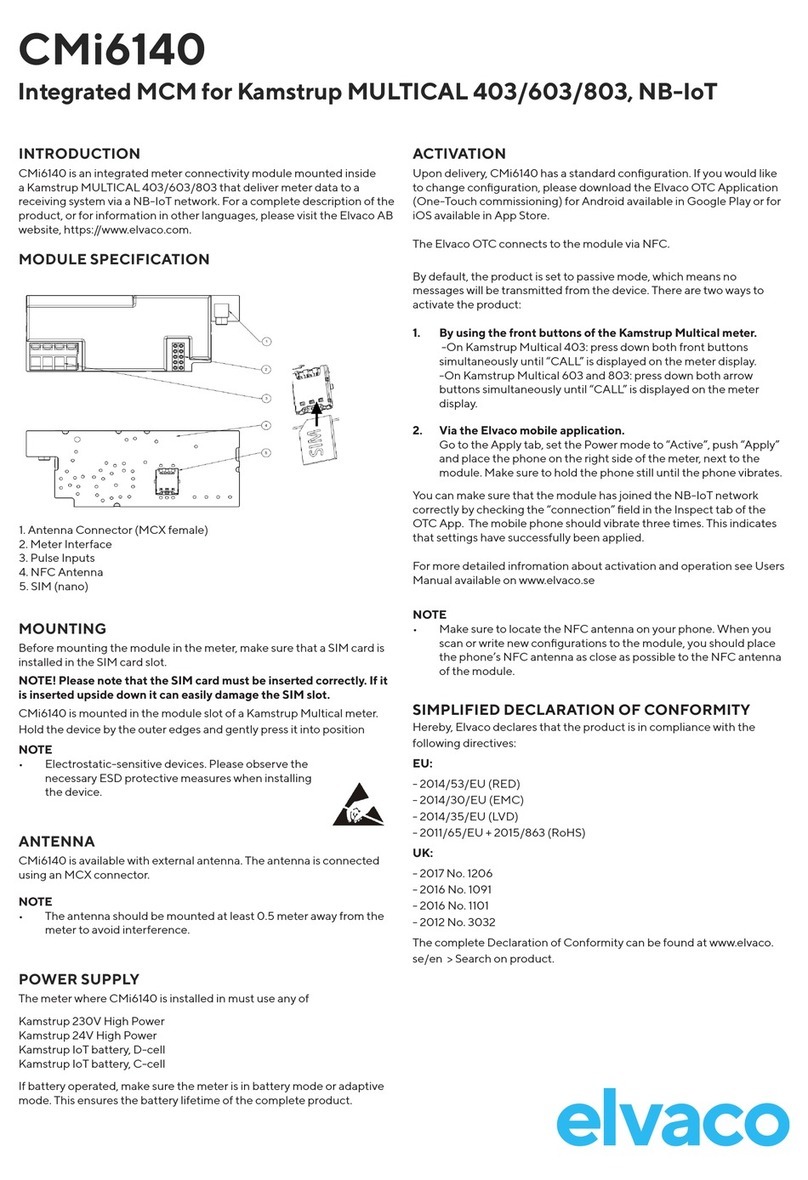

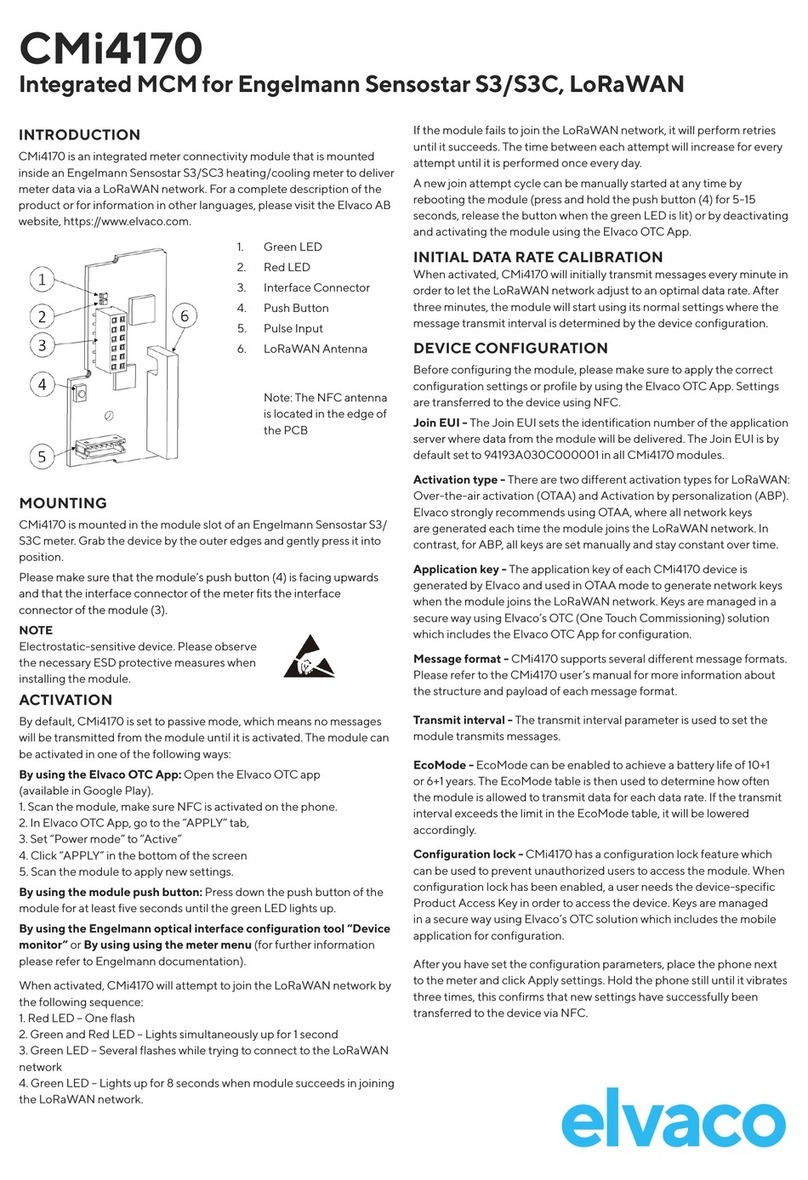

4.3. Joining the LoRaWAN network

When activated, the product will attempt to join the LoRaWAN network by the following sequence:

1. Red LED – One flash

2. Green and Red LED – Lights simultaneously up for 1 second

3. Green LED – Several flashes while trying to connect to the LoRaWAN network

4. Green LED – Lights up for 8 seconds when module succeeds in joining the LoRaWAN network

The network join sequence is illustrated in the figure below:

Network join LED indication

If the module fails to join the LoRaWAN network, it will perform retries until it succeeds. The time

between each attempt will increase for every attempt until it is performed once every day. A new join

attempt cycle can be manually started anytime by using the push button to reboot the module or by

deactivating and activating the module using the Elvaco OTC App.

When the module has joined the LoRaWAN network, it will perform three quick transmissions (regard-

less of transmit interval settings) before starting to use its configured transmit interval settings. By using

the Elvaco OTC App, you can easily verify that the module is successfully communicating with the

meter (“Meter communication”) and is connected to the LoRaWAN network (“Network joined”).

CMi4170

9

5. Operation

5.1. Server configuration

There are two different activation types for LoRaWAN - Over-the-air activation (OTAA) and Activation by

personalization (ABP). Elvaco strongly recommends using OTAA, where all network keys are generated

each time the module joins the LoRaWAN network. In contrast, for ABP, all keys are set manually and

stay constant over time.

In OTAA mode

Before the module is able to transmit messages via the LoRaWAN network, device information needs

to be added to the network server. More specifically, the following parameters needs to be registered in

order to enable the network server to receive messages from the module:

Device EUI

The device EUI is a 16 digit module unique identification number. It is not configurable.

Application key

The application key of each device is generated by Elvaco and used in OTAA mode to generate

network keys when the module joins the LoRaWAN network. Keys are managed in a secure way

using Elvaco’s OTC (One Touch Commissioning) solution which includes the mobile application for

configuration.

Join EUI

The Join EUI sets the identification number of the application server where data from the module shall

be delivered. The identification number is set to a default value in all devices. The default value is

presented in Elvaco OTC configuration options.

In ABP mode

If the activation mode is set to ABP, the application key does not need to be added to the network

server. Instead the following information will be needed:

• Network session key

• Application session key

• Device address

5.2. Configuration

Via Elvaco OTC app

The module is configured via the Elvaco OTC app. The app uses NFC to transfer settings to the

module. It is compatible with iPhone or Android phones with Android 5.0 or later. The OTC app can be

downloaded from Google Play for Android and App Store for iOS.

It is possible to create a configuration profile to apply preconfigured settings to multiple devices. For

further information, refer to the OTC app documentation, available on the Elvaco website.

1. Open the Elvaco OTC app on your smartphone.

2. Place your smartphone close to the device and press SCAN.

3. After a successful scan, the current settings will be displayed on the INSPECT tab.

4. To change settings, go to the APPLY tab. Use the toggle button to activate an option, and make

your changes.

5. When done with changes press APPLY at the bottom of the screen, then Apply settings. Repeat

step 2 to change the settings in the device.

CMi4170

10

A successful change is acknowledged by a vibration.

TIP

The NFC field is easiest accessible if placing the phone in the middle part of the front.

Via downlink

The product supports configuration via downlink, i.e. sending commands to an end-device via the

LoRaWAN network. Communication via downlink is sent on LoRa port 2 and can only be made in a

short window after an uplink transmission from module to server. Therefore, time-critical communication

should not be performed over downlink.

Downlink commands are structured according to the following format: “0x00” "TLV" "Number of bytes in

configuration" "Configuration".

NOTE

This feature should only be used sparingly due to bandwidth consideration.

5.3. Transmit interval

The transmit interval is used to set how frequently the module should transmit data on the LoRaWAN

network. The parameter can be set to a value between 5 and 1440 minutes (i.e. between 5-minute and

daily values).

5.3.1. Transmit interval in EcoMode

When EcoMode is active, the module has a battery lifetime of 6+1 or 10+1 years, depending on what

EcoMode alternative is set. EcoMode setting is ignored when PSU (external power supply Engelmann)

is connected. The module can achieve battery life of 6+1 or 10+1 years by using a table of allowed

transmit intervals settings for each data rate.

When radio conditions are poor (and data rate is low), the module will send data less frequently to

conserve battery-life. When signal conditions are good, the module will send data more frequently.

When EcoMode is enabled, the module will continuously check if the set transmit interval is “allowed”

by the EcoMode table. If a lower transmit interval is needed for the specific data rate to achieve 6+1 or

10+1 years of battery life, the module will adjust the parameter accordingly.

See the following tables for the transmit interval allowed in each data rate.

CAUTION

Anticipated battery lifetime cannot be assured if:

• EcoMode is disabled (Even if EcoMode is activated later)

• Changing from 6+1 to 10+1 years battery lifetime in EcoMode

NOTE

When using the “Engelmann” message format, the transmit interval is doubled to compensate for the additional

telegrams transmitted in this message format, with the exception of DR0 in 10 year EcoMode where the transmit

interval is capped at 1440 minutes (corresponding to once every 24 hours).

Table 2. EcoMode transmit interval settings, EcoMode (6 years)

Data rate Transmit interval (minutes) Transmit interval, Engelmann mes-

sage format (minutes)

DR0 180 360

DR1 120 240

DR2 60 120

DR3 30 60

CMi4170

11

Data rate Transmit interval (minutes) Transmit interval, Engelmann mes-

sage format (minutes)

DR4 15 30

DR5 15 30

Table 3. EcoMode transmit interval settings, EcoMode (10 years)

Data rate Transmit interval (minutes) Transmit interval, Engelmann mes-

sage format (minutes)

DR0 1440 1440

DR1 360 720

DR2 180 360

DR3 120 240

DR4 90 180

DR5 60 120

5.4. Time handling

The module relies on the meter’s clock for keeping time. Time in the meter is assumed to be in standard

local time (no DST). When synchronizing time in the meter using the OTC App, local standard time

is always used, even if DST is in effect. The timestamped meter data sent from the module can be

adjusted to be sent in UTC by specifying the “UTC offset” configuration parameter. The UTC offset will

be subtracted from the timestamp prior to transmission. If the meter is in Sweden, which uses CET

(Central European Time), it should have UTC offset set to +60 (+1h). In this case at time 12.00 a

telegram is sent with timestamp 11.00 as this is the corresponding UTC time. A meter in New York

(USA) should have a UTC offset of -300 (-5h) etc. A UTC offset of 0 means the meter time is used

as-is.

If the meter is set to used DST this is ignored by the module and the standard time is used. Thus, the

time on the meter’s display may not match the time in the telegram or in the OTC App.

5.5. Adaptive data rate (ADR)

ADR is part of the LoRaWAN standard where the network server determines the optimal rate of

communication for the module based on current signal conditions. In the best radio conditions, the

module will use its highest data rate (DR5) in order to be as energy-efficient as possible. When signal

conditions are poor, the network server will incrementally lower the data rate until it is able to receive

the message. When the data rate is low, the energy consumption per telegram will increase.

5.6. Message encoding

All message formats encoded to M-bus standard will have the following structure. Each telegram begins

with one byte specifying the message format. Then follows a sequence of data information blocks

(DIBs). The data and structure of the DIBs depends on the message type set. Each DIB contains a data

information field (DIF), a value information field (VIF) and a data field (DATA), where the actual payload

is stored.

CMi4170

12

M-Bus message structure

For message type JSON, the data is presented as plain text.

5.7. Security and access control

The product has a configuration lock feature, which prevents unauthorized access to the module. When

configuration lock has been enabled, a device-specific Product Access Key (PAK) will be needed to

access the device. Keys are managed in a secure way using Elvaco’s OTC solution which includes the

mobile application for configuration.

NOTE

For more information about security and access control for the product, refer to the One-touch commissioning (OTC)

documentation, available on the Elvaco website.

5.8. Meter communication error messages

The payloads using M-Bus encoded data uses the Function field of the DIF to indicate errors. In this

case it is set to “value during error state” (M-Bus standard EN 13757-3:2013) and the value sent should

not be used. A typical case for this is when the module is unable to communicate with the meter and

retrieve meter values, in which case all the fields in the payload have the DIF indicating “value during

error state”. In case of erroneous data or if the module is unable to communicate with meter, bit 4-5 of

the bit of the DIF code (first byte of each index field) will be set to 11b.

Example 1. Example

A DIF code of 0x02 will be set to 0x32 in case of error. (This applies to all message format except

JSON.) For message format JSON, the actual value will be replaced with “null” in case of error state. If

no meter communication is possible at all, all fields have this error indication set.

5.9. Reset procedures

5.9.1. Rebooting the module

1. Press and hold the push button for 5-15 seconds.

2. Release the button when the green LED is lit.

5.9.2. Switching off the module

1. Press and hold the push button for 15-20 seconds.

2. Release the button when the red LED is lit.

CMi4170

13

6. Configuration options

6.1. Elvaco OTC app configuration options

Table 4. All configuration options

Field name

(Abbr.)

Description Default value Locked de-

vice

&

correct Prod-

uct Access

Key

or

open device

Locked de-

vice

&

no Product

Access Key

Downlink

Meter ID Meter identification number

of the meter. Not configura-

ble.

N/A Readable Readable N/A

Power mode Used to activate/deactivate

the module.

Passive Readable /

Writeable

Readable N/A

EcoMode When activated, a minimum

battery-life of 6+1 or 10+1

years depending on the

configuration) can be ach-

ieved by the module.

10 years Readable /

Writeable

Readable Writeable

Message for-

mat

The message format deter-

mines the meter data inclu-

ded in the telegram from the

module.

0x24 (Stand-

ard)

Readable /

Writeable

Readable Writeable

Transmit inter-

val

Sets the number of minutes

between each transmission

from the module.

60 minutes Readable /

Writeable

Readable Writeable

Date & Time Date and time of the meter. N/A Readable /

Writeable

Readable N/A

Set Time Rel-

ative

Adjusts the time of the me-

ter relative to the current

time.

N/A N/A N/A Writeable

Set absolute

time

Sets the time of the meter Writeable N/A N/A N/A

Configuration

Lock

Locks the module to prevent

unauthorized access.

Open Readable /

Writeable

Readable Writeable

Pulse input

selection

Select which of the three

pulse inputs to include when

using the Engelmann mes-

sage format. One or more

can be selected.

0x00 (None) Readable /

Writeable

Readable Writeable

LoRaWAN settings

Device EUI Unique module identification

number. Not configurable.

Device-unique

64-bit number

Readable Readable N/A

Activation type Sets the way the device

joins the LoRaWAN net-

work.

OTAA Readable /

Writeable

Readable Writeable

Network join Used to display whether the

module has joined the LoR-

aWAN network

N/A Readable Readable N/A

Join EUI Application identifier that de-

termines where data ends

up.

94193A030C0

00001

Readable /

Writeable

Readable Writeable

Device ad-

dress

32-bit address used by the

device to identify itself on

the LoRaWAN network.

N/A Readable /

Writeable

Readable Writeable

CMi4170

14

Field name

(Abbr.)

Description Default value Locked de-

vice

&

correct Prod-

uct Access

Key

or

open device

Locked de-

vice

&

no Product

Access Key

Downlink

Current data

rate

The current data rate used

for the module.

N/A Readable Readable N/A

6.2. Downlink configuration options

Table 5. Downlink commands

Field name TLV Number

of bytes

in con-

figura-

tion

Configuration Example

Configura-

tion lock

0x05 0x01 0x00 = Locked

0x01 = Open

0x00050101

(Enables configuration lock)

Transmit in-

terval

0x06 0x02 0xNumber of minutes between transmission

(lsByte -> msByte)

0x0006021E00

(Sets the Tx interval to 30 minutes)

Message

format

0x07 0x01 0x24 = Standard

0x25 = Compact

0x26 = JSON

0x27 = Scheduled-daily redundant

0x28 = Scheduled - Extended

0x29 = Combined heat/cooling

0x2C = Engelmann

0x0007010XX

(Sets the message format to com-

pact)

EcoMode 0x0F 0x01 0x00 = Disable EcoMode

0x01 = Enable EcoMode, 10 years

0x02 = Enable EcoMode, 6 years

0x000F0100

(Disables EcoMode)

Set Time

Relative

0x13 0x02 0xNumber of minutes* (lsByte -> msByte)

*Negative numbers supported.

0x0013020F00 (Adds 15 minutes

to the current time)

0x0013020F80 (Subtracts 15 mi-

nutes from the current time)

UTC offset 0x17 0x02 0xNumber of minutes* (lsByte -> msByte)

*Negative numbers supported.

0x0017023C00 (Sets the UTC off-

set to +60 minutes)

0x0017023C80 (Sets the UTC off-

set to -60 minutes)

Reboot 0x22 0x02 0x9E75 is used to reboot device 0x0022029E75

(Reboots the device)

CMi4170

15

Field name TLV Number

of bytes

in con-

figura-

tion

Configuration Example

Pulse input

selection

0x1D 0x01 Bit flags for selecting which pulse inputs are

to be included in the Engelmann message

format.

0 = disabled, 1 = enabled

Bit 0: Input 1

Bit 1: Input 2

Bit 2: Input 3

Bits 3-7 are reserved and shall be set to 0.

0x001D0101

(Only input 1)

0x001D0107

(Input 1, 2 & 3)

6.3. Message formats

CMi4170 has several different message formats.

Table 6. CMi4170 Message formats

Field Size Description

Message format 1 byte 0x24 = Standard

0x25 = Compact

0x26 = JSON

0x27 = Scheduled – daily redundant

0x28 = Scheduled - Extended

0x29 = Combined heat/cooling

0x2C = Engelmann telegram 1

0x2D = Engelmann telegram 2*

*Engelmann telegram 2 cannot be selected as a telegram type. It is the ID of the second telegram when

using message format Engelmann.

6.3.1. Unscheduled message formats

6.3.1.1. Standard

Table 7. Payload, message format Standard [0x24]

DIB Field Size Data type Description

0 Message for-

mat

1 byte - 0x24 (= Standard)

CMi4170

16

DIB Field Size Data type Description

1 Energy 6-7 bytes INT32 Energy consumption (Wh, J, Cal)

0400xxxxxxxx = xxxxxxxx,xxx Wh

0401xxxxxxxx = xxxxxxxx,xx Wh

0402xxxxxxxx = xxxxxxxx,x Wh

0403xxxxxxxx = xxxxxxxx Wh

0404xxxxxxxx = xxxxxxxx * 10 Wh

0405xxxxxxxx = xxxxxxxx * 100 Wh

0406xxxxxxxx = xxxxxxxx kWh

0407xxxxxxxx = xxxxxxxx * 10 kWh

040Exxxxxxxx = xxxxxxxx MJ

040Fxxxxxxxx = xxxxxxxx * 10 MJ

04FB0Dxxxxxxxx = xxxxxxxx MCal

04FB0Exxxxxxxx = xxxxxxxx * 10 MCal

04FB0Fxxxxxxxx = xxxxxxxx * 100 MCal

2 Volume 6 bytes INT32 Volume ( m³ )

0411xxxxxxxx = xxxxxxxx * 0.00001 m³

0412xxxxxxxx = xxxxxxxx * 0.0001 m³

0413xxxxxxxx = xxxxxxxx * 0.001 m³

0414xxxxxxxx = xxxxxxxx * 0.01 m³

0415xxxxxxxx = xxxxxxxx * 0.1 m³

0416xxxxxxxx = xxxxxxxx m³

0417xxxxxxxx = xxxxxxxx * 10 m³

3 Power 4 bytes INT16 Power (W)

022Bxxxx = xxxx W

022Cxxxx = xxxx * 10 W

022Dxxxx = xxxx * 100 W

022Exxxx = xxxx kW

022Fxxxx = xxxx * 10 kW

4 Flow 4 bytes INT16 Flow ( m³/h)

023Bxxxx = xxxx * 0.001 m³/h

023Cxxxx = xxxx * 0.01 m³/h

023Dxxxx = xxxx * 0.1 m³/h

023Exxxx = xxxx m³/h

023Fxxxx = xxxx * 10 m³/h

5 Fw temp 4 bytes INT16 Forward temperature (°C)

0258xxxx = xxxx * 0.001 °C

0259xxxx = xxxx * 0.01 °C

025Axxxx = xxxx * 0.1 °C

025Bxxxx = xxxx °C

CMi4170

17

DIB Field Size Data type Description

6 Rt temp 4 bytes INT16 Return temperature (°C)

025Cxxxx = xxxx * 0.001 °C

025Dxxxx = xxxx * 0.01 °C

025Exxxx = xxxx * 0.1 °C

025Fxxxx = xxxx °C

7 Meter ID 6 bytes According to

M-Bus

EN13757-3

identification

field

Meter ID

0C78xxxxxxxx

8 Error flags 4 bytes INT8 Error and warning flags

01FD17xx

6.3.1.2. Compact

Table 8. Payload, message format Compact [0x25]

DIB Field Size Data type Description

0 Message for-

mat

1 byte - 0x25 (= Compact)

1 Energy 6-7 bytes INT32 Energy consumption (Wh, J, Cal)

0400xxxxxxxx = xxxxxxxx,xxx Wh

0401xxxxxxxx = xxxxxxxx,xx Wh

0402xxxxxxxx = xxxxxxxx,x Wh

0403xxxxxxxx = xxxxxxxx Wh

0404xxxxxxxx = xxxxxxxx * 10 Wh

0405xxxxxxxx = xxxxxxxx * 100 Wh

0406xxxxxxxx = xxxxxxxx kWh

0407xxxxxxxx = xxxxxxxx * 10 kWh

040Exxxxxxxx = xxxxxxxx MJ

040Fxxxxxxxx = xxxxxxxx * 10 MJ

04FB0Dxxxxxxxx = xxxxxxxx MCal

04FB0Exxxxxxxx = xxxxxxxx * 10 MCal

04FB0Fxxxxxxxx = xxxxxxxx * 100 MCal

2 Meter ID 6 bytes According to

M-Bus

EN13757-3

identification

field

Meter ID

0C78xxxxxxxx

3 Error flags 4 bytes INT8 Error and warning flags

01FD17xx

6.3.1.3. JSON

In message format JSON, data is presented on a plain text format.

The following table contains a description of all field included in the telegram.

CMi4170

18

Table 9. Payload, message format JSON [0x26]

Field Description

Energy Energy consumption (Wh, J, Cal)

Unit Unit of energy consumption

Meter ID Identification number of the meter in which the module is mounted.

Below shows an example of a telegram sent using the JSON message format.

{"E":12345.678,"U":"MWh","ID":87654321}

6.3.2. Scheduled message formats

For message formats of type “Scheduled” (Scheduled – Daily redundant and Scheduled – Extended),

two types of messages will be transmitted from the module - a clock message and a data message.

The difference between a clock message and a data message is described in the following table.

Table 10. Clock message and data message

Message Time interval Description

Clock message Once per day The clock message presents the current time of the meter. It

can be used to verify that the clock is correct and has not

drifted more than accepted.

Data message Determined by Transmit in-

terval parameter

The actual meter data collected from the meter.

The following table contains a detailed description of the payload of the clock message.

Table 11. Payload, clock message

DIB Field Size Data type Description

0 Message for-

mat identifier

1 byte - 0xFA (=Clock message)

1 Data/Time 6 bytes 32 bit binary

integer M-Bus

type F

046Dxxxxxx = Valid date/time message

346Dxxxxxx = Invalid date/time message

The clock message will be transmitted once every day and the data message at least (regulated by

transmit interval parameter or EcoMode) once every day. The transmit interval can only be set the

values listed in Table 12, “Transmit interval options ” [19].

Although the meter readout will occur on top-of-the-hour, the data message will not necessarily be

transmitted at that exact time. The LoRa transmission will occur after a random delay of 0-15 minutes

to decrease the risk of collisions. The readout for the clock message occurs at a random hour (00:00-

23:00) at a random minute in the 35-45 interval and will be transmitted immediately after the readout.

NOTE

When using message format Scheduled, the transmit interval cannot not be set to higher than 1440 (24 hours).

Table 12. Transmit interval options

Parameter Values Unit

Transmit interval 60, 120, 180, 240, 360, 480, 720, 1440 Minutes

6.3.2.1. Scheduled - Daily redundant

The data message of Scheduled mode-daily redundant contains an accumulated daily energy field,

which is updated at 24:00 each day. Depending on transmit interval settings and data rate, the field

will be included in between 1-24 data messages per day. This will increase the probability of the value

CMi4170

19

being received. For example, if the transmit interval is set to “120”, the accumulated energy read at

24:00 will be transmitted 12 times during the 24 next coming hours.

Table 13. Payload, message format Scheduled – Daily redundant [0x27]

DIB Field Size Data type Description

0 Message for-

mat

1 byte - 0x27 (= Scheduled – daily redundant)

1 Heat energy

E1 / Cooling

Energy E3

6-7 bytes INT32 Energy consumption (Wh, J, Cal)

0400xxxxxxxx = xxxxxxxx,xxx Wh

0401xxxxxxxx = xxxxxxxx,xx Wh

0402xxxxxxxx = xxxxxxxx,x Wh

0403xxxxxxxx = xxxxxxxx Wh

0404xxxxxxxx = xxxxxxxx * 10 Wh

0405xxxxxxxx = xxxxxxxx * 100 Wh

0406xxxxxxxx = xxxxxxxx kWh

0407xxxxxxxx = xxxxxxxx * 10 kWh

040Exxxxxxxx = xxxxxxxx MJ

040Fxxxxxxxx = xxxxxxxx * 10 MJ

04FB0Dxxxxxxxx = xxxxxxxx MCal

04FB0Exxxxxxxx = xxxxxxxx * 10 MCal

04FB0Fxxxxxxxx = xxxxxxxx * 100 MCal

2 Volume 6 bytes INT32 Volume ( m³ )

0411xxxxxxxx = xxxxxxxx * 0.00001 m³

0412xxxxxxxx = xxxxxxxx * 0.0001 m³

0413xxxxxxxx = xxxxxxxx * 0.001 m³

0414xxxxxxxx = xxxxxxxx * 0.01 m³

0415xxxxxxxx = xxxxxxxx * 0.1 m³

0416xxxxxxxx = xxxxxxxx m³

0417xxxxxxxx = xxxxxxxx * 10 m³

3 Meter ID 6 bytes According to

M-Bus

EN13757-3

identification

field

Meter ID

0C78xxxxxxxx

4 Error flags 4 bytes INT8 Error and warning flags

01FD17xx

CMi4170

20

Other manuals for CMi4170

2

Table of contents

Other Elvaco Measuring Instrument manuals

Elvaco

Elvaco CMi4110 User manual

Elvaco

Elvaco CMe3100 User manual

Elvaco

Elvaco CMi4110 User manual

Elvaco

Elvaco CMi6140 User manual

Elvaco

Elvaco CMeX10S Installation guide

Elvaco

Elvaco CMi4170 User manual

Elvaco

Elvaco CMi4130 User manual

Elvaco

Elvaco CMeX20w User manual

Elvaco

Elvaco CMi4170 User manual

Elvaco

Elvaco CMe2100 Installation guide

Popular Measuring Instrument manuals by other brands

PASCO

PASCO ES-9077 instruction sheet

ETS

ETS SM3 instructions

Precision Pro

Precision Pro NX9 product manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 604M25 Installation and operating manual

socomec

socomec DIRIS A40 operating instructions

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS OAKTON WD-35413-21 instruction manual