m&h Inprocess 40.01-TX User manual

m&h Inprocess Messtechnik GmbH xAm Langholz 11 xD-88289 Waldburg

Infrared Probe 40.01

-

TX/RX

www.mh

-

in

p

rocess.com

OPERATING INSTRUCTIONS

(Translation of the original operating instructions)

Page

System Components, Technical Data, Dimensions 1

Probe ON / OFF Angle, Transmitting / Receiving 2

Stylus Change, Battery Replacement, Optical Status Display 3

Aligning Stylus to Spindle Centre 4

Infrared Signal Range / Power Off Delay / Battery Life,

Maintenance, Cleaning Jets 5

Shank Mounting, HSK Shanks 6

SK Shanks, Coromant Capto Shanks

Tool Holder VDI 7

Other Shanks, THERMO-LOCK®Shanks,

Aligning probe in shank with 90° Adapter 8

Styli 9

Spare Parts, Accessories 10

BA4001-TX/RX-3010-WEST Subject to change without notice

1

Infrared Probe 40.01

-

TX/RX

Infrared Receiver

91.40-RX/TX/°C

91.30-RX/TX

Infrared Probe

40.01-TX/RX

System Components

Technical Data Dimensions

Probing Directions:

±

X;

±

Y; -Z

Max. Overtravel: XY

±

12,5°; Z –5mm

Probing Force Z = 7N

with 50mm Stylus: X/Y = 1N

Recommended 254mm/min –

Probing Speed: 2000mm/min

Power Supply: 1x3V Battery

Type CR2 (IEC)

Standby: 12 months

Alternative 1x3,6V Battery

Power Supply: Type ½ AA (IEC)

Material: Stainless steel

Weight without Shank: ca. 390g

Temperature: Operating: 10° - 50°C

Storage: 5° - 70°C

Repeatability: max. 2Sigma

±

1µm

with 50mm stylus at

254mm/min

Sealing: IP68: EN60529

(15 m) tested

Maximum

Probing Frequency: 30 Hz = 30 points / sec

Shock tested: in

±

X;

±

Y; -Z

50G for 7ms (5000 times)

Resonant

Frequency Test: Passed

M4 Stylus

Infrared

receiver unit

High Power

Infrared diodes

Stylus aligned

to spindle center

Customer specified

shank

Battery compartment

Cleaning jets

Infrared Probe 40.01

-

TX/RX

2

O

N

OF

F

0

V

>10VD

C

<1s

<1

,

5s

M-Code

Probe ON / OFF Angle – during ON / OFF

Transmitting / Receiving

= Receiving

= Transmitting

= Receiving

= Transmitting

Infrared Probe

40.01-TX/RX

Adjustable Range

≤1.6m (5.2´)

≤3.3m (10.8’)

≤4.0m (13.1´)

Infrared Receiver

91.40-RX/TX/°C

ON/Off Range

≤4.0m (13.1’)

alternative

Infrared Receiver

91.30-RX/TX

ON/OFF Adjustable Range

≤1.5m (4.9’)

≤2.2m (7.4´)

≤3.0m (9.8´)

ON/OFF Pro

c

edure

Infrared Probe 40.01

-

TX/RX

3

M

≈

2Nm

(

1.47 lbf.ft

)

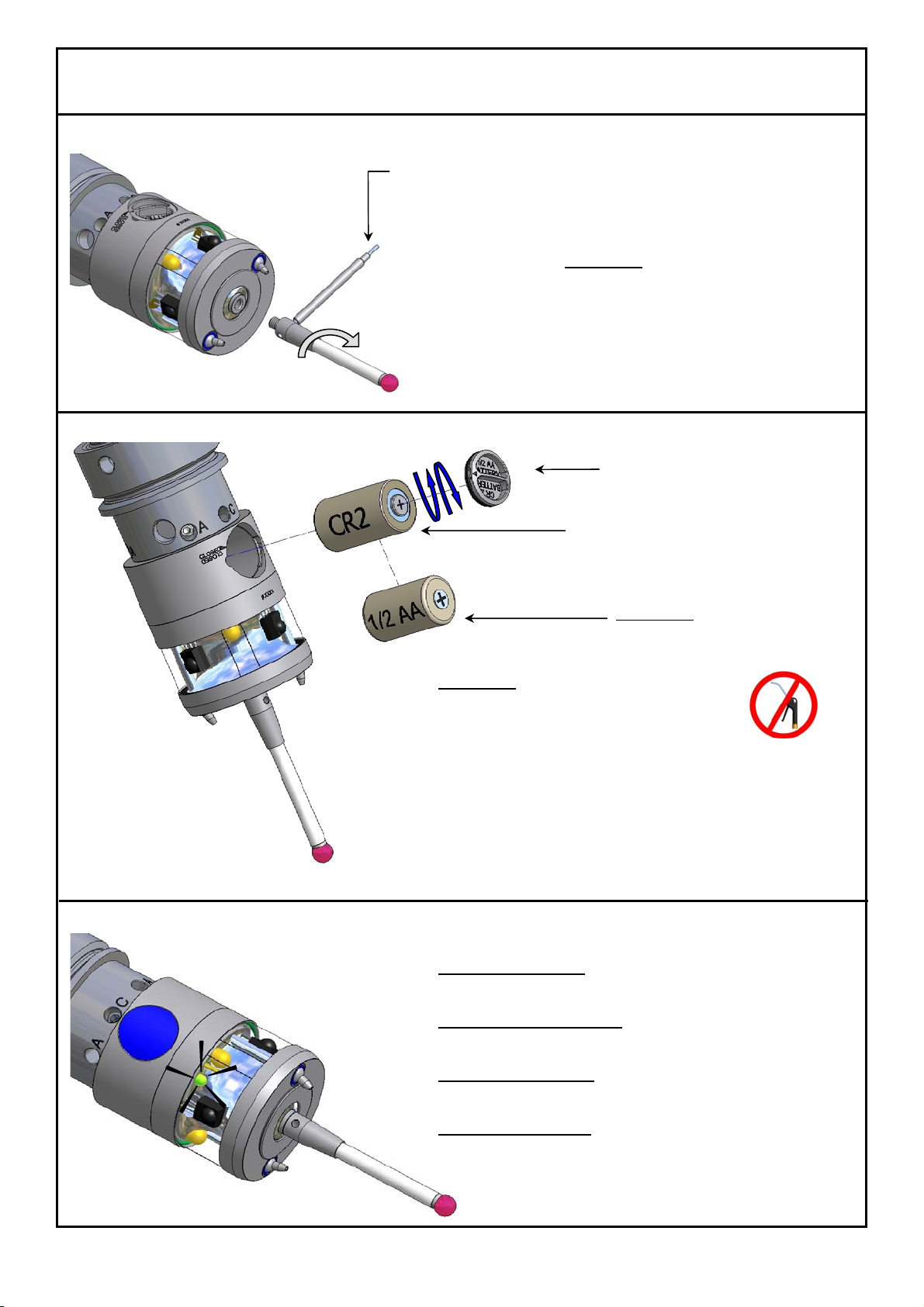

Stylus Change

Attention !

After changing the stylus:

eAlign stylus to spindle centre

eCalibrate probe

Battery Replacement

Attention !

eWipe probe clean and dry

before opening!

Do NOT use compressed

air to clean!

eTurn battery cover with bayonet lock to open and close !

eWhen closing the battery compartment check the

O-Ring for any damage !

eReplace empty battery immediately !

Optical Status Display

LED blinking green:

eProbe transmitting signal

LED blinking green / red:

eLow battery warning

LED blinking orange:

eStylus deflected

LED continuous red:

eWrong battery type

Alternative:

Battery 3,6V

Type ½ AA

Mounting pin

#0885

Battery Type CR2 (3V)

#3869

Battery cover #3920

with O-Ring 13x1 Viton #3549

Infrared Probe 40.01

-

TX/RX

4

Aligning Stylus to

Spindle Centre

1 Set „C“ Screws

- Loosen all "A" screws 2 turns

- Loosen the "C" screws

- Using the long end of the Hex key

tighten both "C" screws lightly

3Tighten „C“ Screws

- Tighten both “C” screws using the

short end of the Hex Key

5Retighten „C“ Screws

- Using the short end of the Hex Key

- Securely retighten both "C" screws

2Adjustment to <20µ

- Set dial gauge in front of the probe (see pict.)

- Turn the probe until the maximum deviation

is shown on the indicator

- Turn the "A" screws

half of the indicator reading

- Loosen the "A" screws that were

used 1 turn

- Repeat procedure

until runout is < 20µ

4Adjustment to <2µ

- Turn the probe until the maximum deviation

is shown on the indicator

- Turn the "A" screws

half of the indicator reading

- Loosen the "A" screws that were

used 1 turn

- Repeat procedure

until runout is < 2µ

6Set „A“ Screws against each other

- Set opposing „A“ screws (0° - 180°)

against each other

- Repeat with the other two opposing

„A“ screws (90 - 270°)

If the runout goes out

of adjustment:

- Turn the probe until the maximum deviation

is shown on the indicator

- Carefully loosen the „A“ screws

on the opposite side until the

runout is < 2µ

- Set the opposing „A” screws

against the newly adjusted

one

Hexagon key

AF2.5mm

#1346

Hexagon key AF2mm

#1097

Infrared Probe 40.01

-

TX/RX

5

±

30°

Infrared Signal Range / Power Off Delay / Battery Life

Infrared signal range:

There are 3 infrared range settings which can be selected: 1.6m – 3.3m – 4.0m.

A reduced range can be useful to ensure that nearby infrared systems are not interfered with.

A high range setting shortens the battery life.

Power off delay:

If the probe is not triggered within a given time, it is automatically shut off.

3 settings for the delay time are possible: 60s – 120s – 180s.

For removing the shank, see page 6

Attention !

eAfter removing the shank, wipe the probe

clean and dry !

Do NOT use compressed air to clean!

eEnsure the probe is turned off !

eAdjust the desired range !

eRemount the shank.

eAlign the stylus !

eCalibrate the probe !

Maintenance Cleaning Jets

Dirt can accumulate under the metal eyelid Cleaning the workpiece and the stylus tip

To clean : with through-spindle air.

eRemove service cover with eyelid and

conical spring by hand.

eClean probe and parts under flowing water.

eReplace parts and close probe by hand.

eCalibrate probe.

Attention !

eDo NOT use compressed air or high pressure

water to clean!

eDo NOT use any sharp tools!

(These could damage the inner seal)

Optional: Cleaning jets 40.01-Jets

Infrared Signal

Range

(Typical)

Power Off

Delay

Battery Life in Continuous Use

CR2 5%

usage

½ AA 5%

usage

0≤4.0m Infrared OFF 180h 130d 270h 190d

1≤4.0m 180s 180h 130d 270h 190d

2≤3.3m 180s 220h 145d 350h 210d

3≤1.6m 180s 290h 170d 440h 240d

4≤4.0m 120s 180h 130d 270h 190d

5≤3.3m 120s 220h 145d 350h 210d

6≤1.6m 120s 290h 170d 440h 240d

7≤4.0m 60s 180h 130d 270h 190d

8≤3.3m 60s 220h 145d 350h 210d

9≤1.6m 60s 290h 170d 440h 240d

Attention !

Only use through-

spindle air !

Pressure < 7bar

Do NOT use coolant !

Screwdriver

Service cover

#3240

Metall eyelid

#2906

Conical spring

#2931

Inner Seal

Factory Settings

t

Infrared Probe 40.01

-

TX/RX

6

Mounting the Shank

Removing the shank:

eRemove all „A“ and „C“ screws.

eRemove shank.

Assembling the shank:

eEnsure the O-Rings are properly seated!

eCarefully slide the shank onto the probe body. Align

the „C“ threads with the conical bores.

eInsert both clamping screws „C“ and tighten lightly.

eInsert adjustment screws „A“.

eAlign the stylus to spindle center.(see page 4)

eCalibrate the probe.

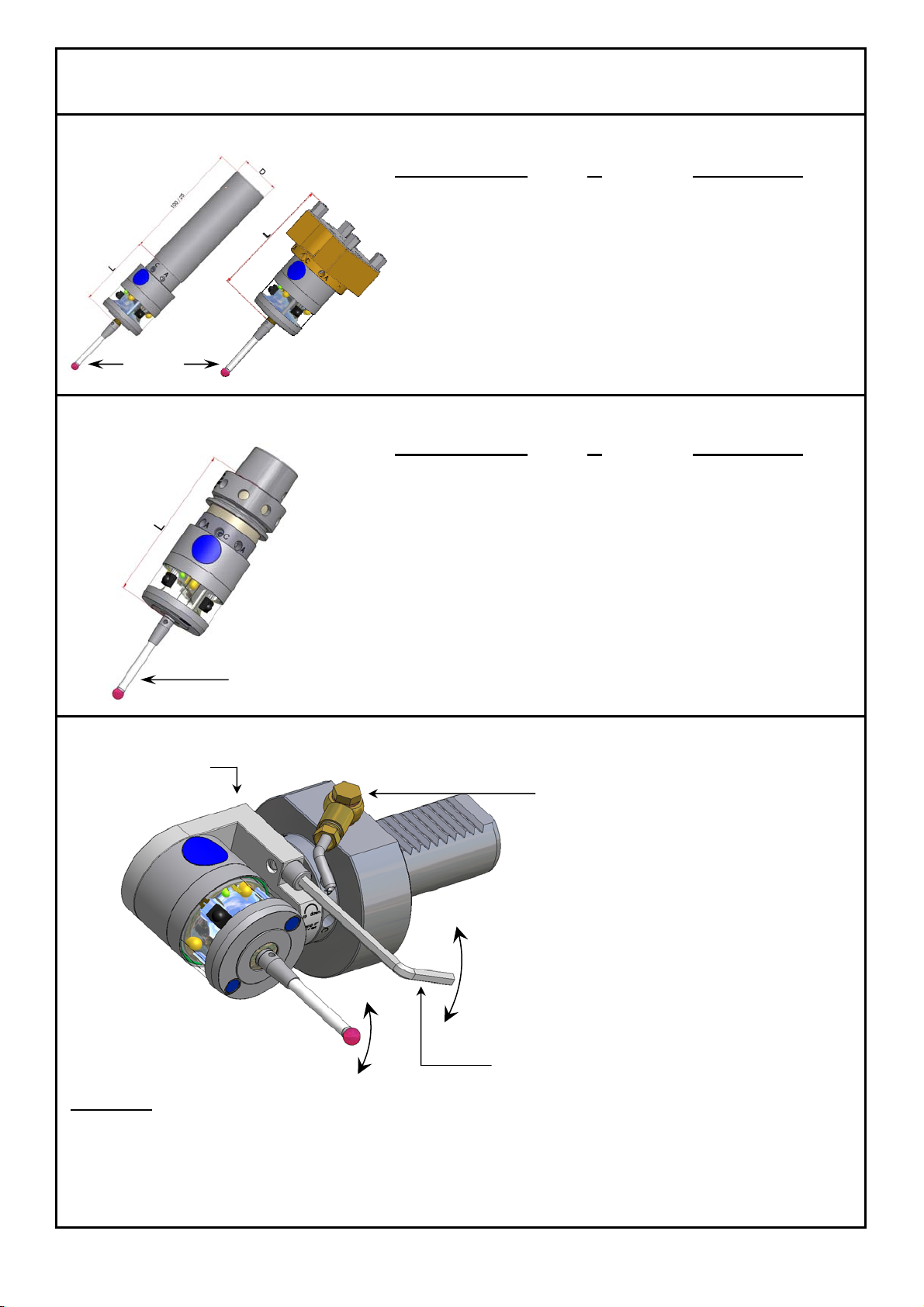

Probe with shank HSK Available Shanks: L: Order Number:

DIN69893-HSK-E25 69 (2.71”) 40.01-HSK25E

DIN69893-HSK-A32 86 (3.39”) 40.01-HSK32A

DIN69893-HSK-E32 86 (3.39”) 40.01-HSK32E

DIN69893-HSK-A40 86 (3.39”) 40.01-HSK40A

DIN69893-HSK-E40 86 (3.39”) 40.01-HSK40E

DIN69893-HSK-F40 86 (3.39”) 40.01-HSK40F

DIN69893-HSK-A50 86 (3.39”) 40.01-HSK50A

DIN69893-HSK-A50 116,5 (4.59”) 40.01-HSK50A-116,5

DIN69893-HSK-E50 92 (3.62”) 40.01-HSK50E

DIN69893-HSK-E50 116,5 (4.59”) 40.01-HSK50E-116,5

DIN69893-HSK-F50 92 (3.62”) 40.01-HSK50F

DIN69893-HSK-A63 86 (3.39”) 40.01-HSK63A

DIN69893-HSK-A63 116,5 (4.59”) 40.01-HSK63A-116,5

DIN69893-HSK-A63-70 120 (4.72”) 40.01-HSK63A-120

DIN69893-HSK-E63 116,5 (4.59”) 40.01-HSK63E

DIN69893-HSK-F63 121,5 (4.78”) 40.01-HSK63F

DIN69893-HSK-A80 121,5 (4.78”) 40.01-HSK80A

DIN69893-HSK-A100 92 (3.62”) 40.01-HSK100A

DIN69893-HSK-A100 121,5 (4.78”) 40.01-HSK100A-121,5

Kennametal KM63 121,5 (4.78”) 40.01-KM63

Kennametal KM80 121,5 (4.78”) 40.01-KM80

Other shanks upon request

C = Clamping screw AF2.5mm (2x)

#1351 M=2 Nm (1.47 lbf.ft)

A

= Adjustment screw DIN913 M4x8 (AF2mm) (4x)

#1352 M=1.5 Nm (1.1 lbf.ft)

Hexagon Key

A

F2mm #1097 / AF2.5mm #1346

Clamping screw „C“

in conical bore

Adjustment screw „A“ in thread

Shank

Probe

O-Ring 17x1 Viton

#3239

Not included

Infrared Probe 40.01

-

TX/RX

7

Probe with shank SK

Available Shanks: L: Order Number:

DIN69871-SK30 94,5 (3.72”) 40.01-SK30

DIN69871-SK30-Mube 94,5 (3.72”) 40.01-SK30-Mube

DIN69871-SK40 96,5 (3.8”) 40.01-SK40

DIN69871-SK40-70 120 (4.72”) 40.01-SK40-120

DIN69871-SK50 96,5 (3.8”) 40.01-SK50

DIN69871-SK60 116,5 (4.59”) 40.01-SK60

BT30 77 (3.03”) 40.01-BT30

BT30 94,5 (3.72”) 40.01-BT30-94,5

BT30 127 (5”) 40.01-BT30-127

BT30 152 (5.98”) 40.01-BT30-152

BT30 177 (6.97”) 40.01-BT30-177

BT40 96,5 (3.8”) 40.01-BT40

BT40-70 120 (4.72”) 40.01-BT40-120

BT50 111,5 (4.39”) 40.01-BT50

CAT40 96,5 (3.8”) 40.01-AN40

CAT40-70 120 (4.72”) 40.01-AN40-120

CAT50 96,5 (3.8”) 40.01-AN50

Other shanks upon request

Probe with shank Coromant Capto

Available Shanks: L: Order Number:

Coromant Capto C4 86 (3.39”) 40.01-C4

Coromant Capto C5 86 (3.39”) 40.01-C5

Coromant Capto C5 121,5 (4.78”) 40.01-C5-121,5

Coromant Capto C5-90° 102,5 (4”) 40.01-C5-90°

Coromant Capto C6 92 (3.62”)) 40.01-C6

Coromant Capto C6 121,5 (4.78”) 40.01-C6-121,5

Coromant Capto C6-90° 102,5 (4”) 40.01-C6-90°

Coromant Capto C8 92 (3.62”) 40.01-C8

Coromant Capto C8 121,5 (4.78”) 40.01-C8-121,5

Coromant Capto C8-90° 102,5 (4”) 40.01-C8-90°

Other shanks upon request

Probe with tool holder VDI Available Tool holders: L: Order Number:

VDI 16 75,0 (2.95”) 40.01-VDI16

VDI 16-90° 56,0 (2.2”) 40.01-VDI16-90°

VDI 20 75,0 (2.95”) 40.01-VDI20

VDI 20-90° 56,0 (2.2”) 40.01-VDI20-90°

VDI 25 75,0 (2.95”) 40.01-VDI25

VDI 25-90° 56,0 (2.2”) 40.01-VDI25-90°

VDI 30 79,0 (3.11”) 40.01-VDI30

VDI 30-90° 60,0 (2.36”) 40.01-VDI30-90°

VDI 40 98,5 (3.38”) 40.01-VDI40

VDI 40-90° 79,5 (3.13”) 40.01-VDI40-90°

VDI 50 98,5 (3.38”) 40.01-VDI50

VDI 50-90° 79,5 (3.13”) 40.01-VDI50-90°

VDI 60 98,5 (3.38”) 40.01-VDI60

VDI 60-90° 79,5 (3.13”) 40.01-VDI60-90°

VDI 80 98,5 (3.38”) 40.01-VDI80

VDI 80-90° 79,5 (3.13”) 40.01-VDI80-90°

Other tool holders upon request

Not

included

Not

included

Not included

91.00-SWV

not

included

Infrared Probe 40.01

-

TX/RX

8

up

down

±5° down

up

Probe with other shanks

Available Shanks: L: Order Number:

D20-D8-L25-B 65 (2.56”) 40.01-D8-L25

D20-D32-L100-B 62 (2.44”) 40.01-D32-L100

NIKKEN-NC5-46 115,5 (4.55”) 40.01-NC5-46

NIKKEN-NC5-63 115,5 (4.55”) 40.01-NC5-63

D20-Erowa-ITS 91 (3.58”) 40.01-ITS

Probe with shank THERMO-LOCK®(patented)

Available Shanks: L: Order Number:

DIN69893 HSK-E32 86 (3.39”) 40.01-HSK32E-TI

DIN69893 HSK-E40 86 (3.39”) 40.01-HSK40E-TI

DIN69893 HSK-E50 92 (3.62”) 40.01-HSK50E-TI

DIN69893 HSK-A63 92 (3.62”) 40.01-HSK63A-TI

Patented THERMO-LOCK®Technology prevents thermal

expansion of the HSK and heat transfer from the spindle to the

probe. This ensures that the probe delivers stable, precise results

even by large temperature differences between the spindle and

the HSK.

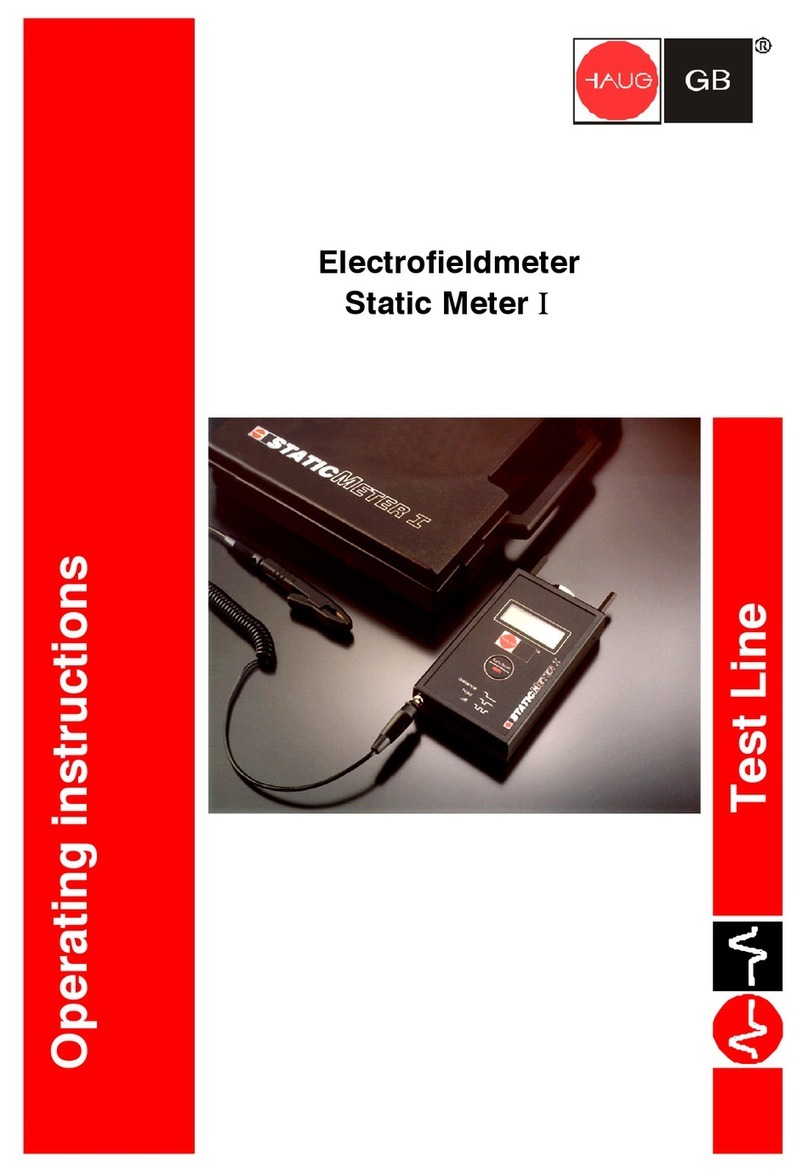

Aligning probe in shank with 90°Adapter

Procedure:

eLoosen adjustment screws „A“ (4x) then tighten lightly.

eLoosen clamping screws „C“ (2x) then tighten lightly.

eAdjust the angular position of the probe using cylinder screw AF4mm to (±5°).

eTighten the clamping screws „C“ (2x).

eAlternately tighten the adjustment screws „A“ (4x).

eCalibrate probe.

Hexagon key AF4mm

#3489

Not included

Not

included

Air Nozzle with rotary joint

for tool holder VDI

91.00-SWV

90° Adapter for

Tool Holder VDI

D2

0

-VDI

-

90

°

Infrared Probe 40.01

-

TX/RX

9

M4-Styli, Shaft-Ø7

All styli with ceramic shaft

Order Number:

91.00-T103/6-KE-M4

(Ruby ball)

91.00-T83/6-KE-M4

(Ruby ball)

91.00-T53/6-KE-M4

(Ruby ball)

91.00-T103/6-KE-M4-Si

(Silicon nitride ball)

91.00-T53/6-KE-M4-Si

(Silicon nitride ball)

91.00-TV30-KE-M4

(Stylus extension)

M4-Styli, Shaft-Ø5

All styli with ruby ball

Order Number:

91.00-TK-ST-M4

(5-way Stylus centre)

91.00-T20/2-HM-M4

(Tungsten carbide shaft)

91.00-T20/3-HM-M4

(Tungsten carbide shaft)

91.00-T20/4-HM-M4

(Tungsten carbide shaft)

91.00-T20/5-ST-M4

(Steel shaft)

91.00-T20/6-ST-M4

(Steel shaft)

91.00-T20/7-ST-M4

(Steel shaft)

91.00-T20/8-ST-M4

(Steel shaft)

M3-Styli, Shaft-Ø4

All styli with ruby ball and tungsten carbide

shaft

Order Number:

91.00-TA-M4/M3

(Stylus

Adapter)

21.00-T20/1-HM-M3

21.00-T20/2-HM-M3

21.00-T20/3-HM-M3

21.00-T20/4-HM-M3

21.00-T20/5-HM-M3

21.00-T20/6-HM-M3

21.00-T30/2-HM-M3

21.00-T30/3-HM-M3

21.00-T30/4-HM-M3

21.00-T30/5-HM-M3

21.00-T30/6-HM-M3

Other styli available upon request.

10

Infrared Probe 40.01

-

TX/RX

Spare Parts, Accessories

Probe Parts

Order Number Description

#3869 Battery Type CR2 (3V)

#3920 Battery cover

#3549 O-Ring 13x1 Viton

for battery cover

#1351 Clamping screw AF2.5mm

#1352 Adjustment screw DIN913 M4x8 (AF2mm)

#3240 Service cover

#3455 O-Ring 16x1 Viton

for service cover

#2906 Metal eyelid

#2931 Conical spring

#3239 O-Ring 17x1 Viton

for Shank

Tools

Order Number Description

#0885 Mounting pin

#1346 Hexagon key AF2.5mm

#1097 Hexagon key AF2mm

#3489 Hexagon key AF4mm

#3079 Dial gauge

Infrared Probe 40.01

-

TX/RX

11

Spare Parts, Accessories

Accessories

Order Number Description

40.01-TB

Toolbox:

1x Mounting Pin #0885

2x Hexagon key AF2mm #1097

1x Hexagon key AF2.5mm #1346

91.00-SWV Air Nozzle with rotary joint

for VDI shanks

D20-VDI-90° 90°Adapter for Tool Holder VDI

#3611 Storage box

This manual suits for next models

1

Table of contents

Popular Measuring Instrument manuals by other brands

SUTO

SUTO S520 Instruction and operation manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 646B00 Assembly, installation and operating manual

Haug

Haug Test Line Static Meter I operating instructions

Bartec

Bartec TECH600PRO user guide

3M

3M Stormscope Series 2 instruction manual

B&K

B&K 2250 Light user manual