Mesalabs Definer 220 Series User manual

Dener™ 220 Series

User Manual

Table of Contents

Introduction ................................ 1.0

Operation ....................................... 2.0

Battery ........................................ 2.1

Activation .................................... 2.2

Connections ................................. 2.3

Display Screen ............................. 2.4

Menu Navigation .......................... 2.5

Set Up ......................................... 2.6

Measurements ............................. 2.7

Single .......................................... 2.8

Burst ........................................... 2.9

Continuous .................................. 2.10

Data Port ........................................ 3.0

Dener 5V Feature ....................... 3.1

DryCal Pro Software ..................... 3.2

Dener Firmware Upgrades ........... 3.3

Annual Maintenance and Calibration . 4.0

Shipping ......................................... 5.0

Storage .......................................... 6.0

Dener 220 Specications ................ 7.0

Factory Default Settings ................... 8.0

Limited Warranty ............................ 9.0

Troubleshooting .............................. 10.0

Introduction

Operation

Data Port

Annual Maintenance and Calibration

Shipping

Storage

Dener 220 Specications

Factory Default Settings

Limited Warranty

Troubleshooting Guide

2.0

6.0

3.0

7.0

4.0

8.0

5.0

9.0

10.0

1.0

2

The Dener 220 measures volumetric and standardized gas ow with a volumetric ow

accuracy of 0.75% and standardized ow accuracy of 1% of reading. It uses our Proven

DryCal® Technology to measure volumetric gas ow and is manufactured in our accredited

laboratory in Butler, N.J.

This manual will provide the information needed to operate your Dener. If at any time

you have questions regarding its operation, please contact Mesa Labs through our web

site (drycal.mesalabs.com) or call us at 973.492.8400 to speak with a member of our

professional customer service staff.

Your Dener

Your Dener comes with the following:

• AC Power Adapter/Charger

• PC Serial Cable

• Leak Test Cap (1); Save for use during the Leak Test

• Calibration Certicate

• Manual

Carrying cases and accessories are available for purchase from Mesa or your distributor.

1.0 Introduction

2

3

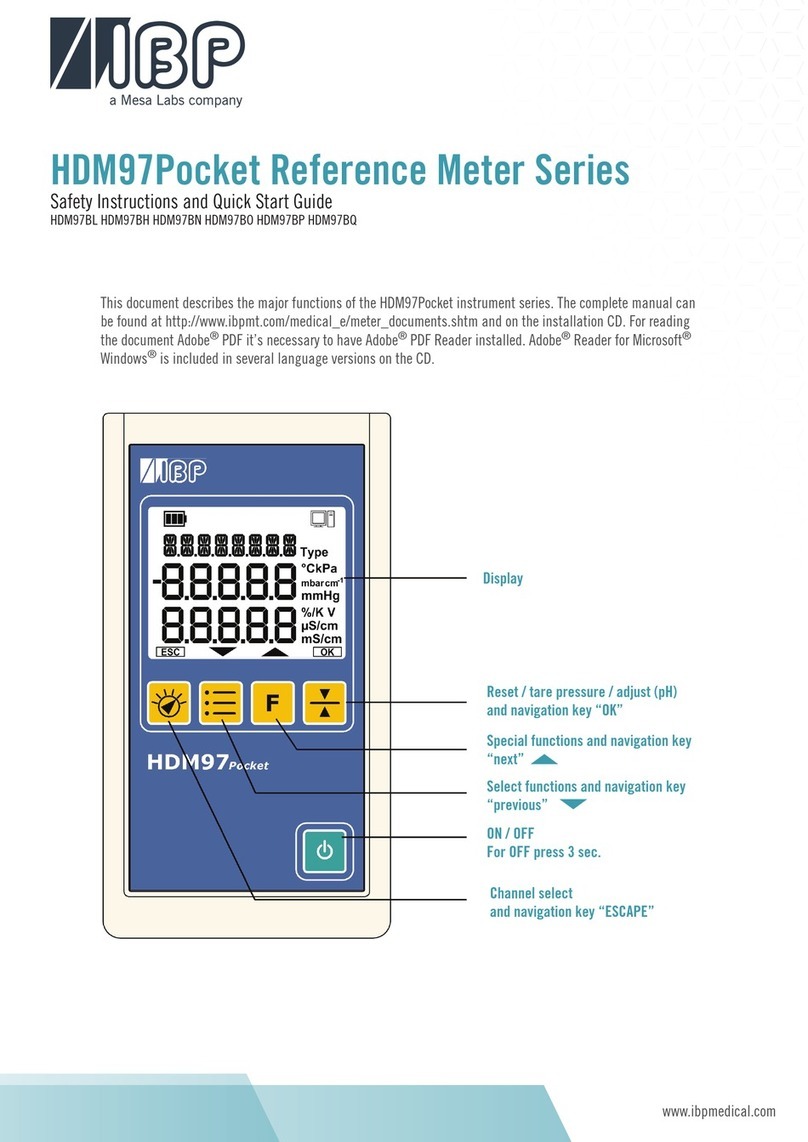

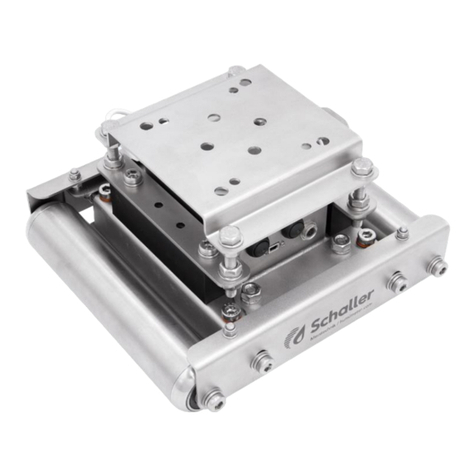

Data Port

Suction Fitting

Measuring Cell

Pressure Fitting

Charging Jack

Calibration Label

Reset Button

Display

Anti-tamper Label

1.0

3

4

2.1 Battery

Charging, installing and monitoring your Dener battery

Your Dener battery is charged at the factory, but we recommend that you make sure it is

fully charged before initial use.

• Connect the AC power adapter to the Dener’s Charging Jack (DC In).

• Plug the AC power adapter into an AC outlet.

Initial charging should take about eight (8) hours.

After the initial charge:

• You may continue to charge your Dener indenitely simply by leaving it connected to

the AC power adapter.

• Be sure to charge the battery at least every three (3) months, to maintain battery life.

The battery symbol on the LCD display indicates your Dener’s battery charge condition. A

shaded battery icon indicates a full charge. As the battery voltage drops, the indicator will

empty in 20% increments.

2.0 Operation

4

5

2.0

Disposal:

In compliance with the European Union CE directive 2006/66/EC the battery in your De-

ner should be removed for recycling prior to disposal of the Dener. The battery in the

Dener is a valve regulated sealed lead acid battery. Please note that opening the Dener

may damage connections so this procedure should only be used for battery disposal.

Procedure:

Remove ve Phillips head screws on the back of the Dener; one will be located under the

calibration void label. Lift off the rear cover and disconnect the two pin connector from the

battery to the printed circuit board. Lift the battery from the case.

5

6

2.2 Activation

Turning your Dener on and off

Simply press the power button.

• Press the On/Off button for 1 second to turn on your Dener.

• When rst turned on, your Dener displays an opening screen showing the product

name, model number and ow range.

• Press the On/Off button for 3 seconds to turn your Dener off.

2.3 Connections

Attaching your Dener to a device

Connect device to be calibrated to the appropriate Dener port. Dener 220 low and me-

dium units have 1/4” ID tube swage lock ttings whereas Dener 220 high ow has 3/8”

ID tube swage lock ttings at their ports. Contact Mesa Labs for 3/8”-to-1/4” swage lock

adapter to use 1/4” tubing in a high ow unit.

• Connect tubing to outlet at top (suction tting) when a device draws air (such as sam-

pler).

• Connect tubing to bottom inlet (pressure tting) for devices that push air in (pressure

devices).

6

7

2.4 Display Screen

Understanding the screen components

The Dener 220 provides a menu of operational settings and commands. The four direc-

tional arrow buttons on the control panel allow you to navigate through the menu and

select the desired settings for your Dener. Your location within the menu is highlighted

for easy identication.

2.5 Menu Navigation

Moving through operational menus

• Use the directional arrows , , and on the control panel to nd your way

through the menu.

• When your desired command is highlighted, simply press the ENTER button on the

control panel.

If you see a menu selection within angle brackets (<….>), that means you have multi-

ple options for an item. Press the left or right (or ) arrow button to see the options.

2.0

7

8

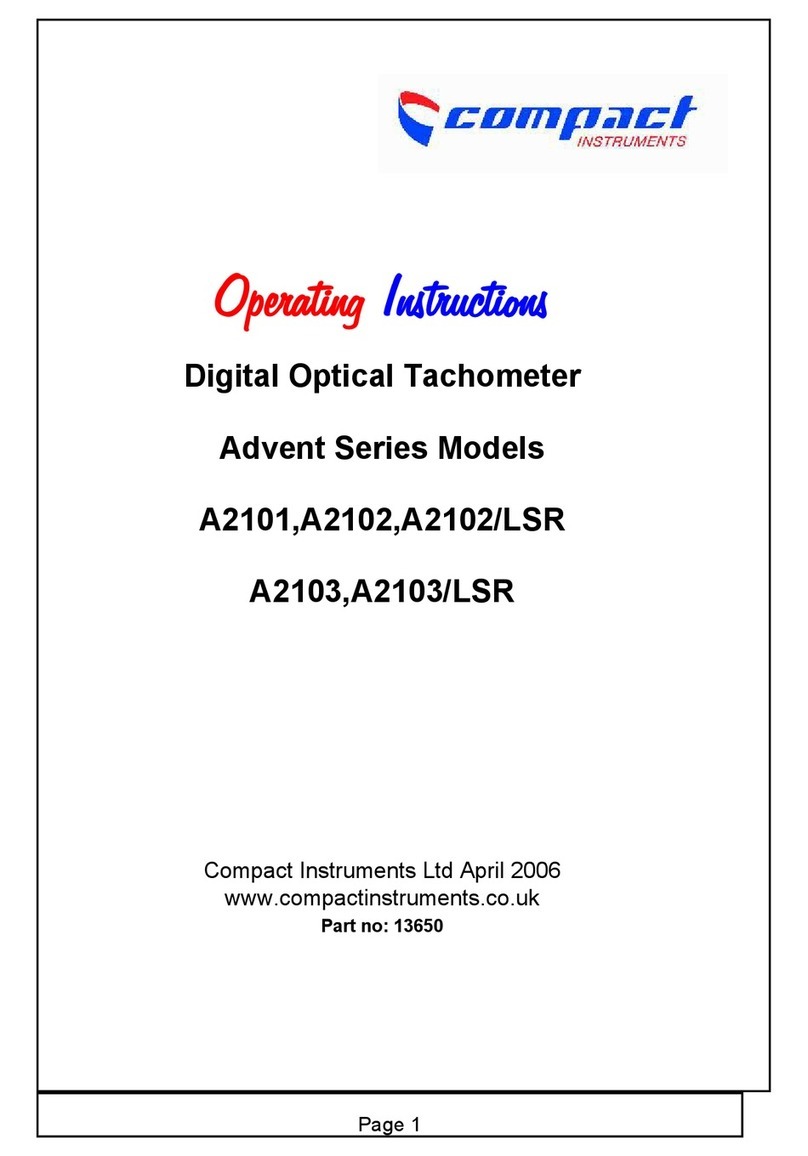

Dener 220 M

Range: 50–5,000 scc/min

with DryCal Technology®

MEASURE | SETUP

LCD Screen

Control Panel

On/Off Button

8

2.6 Set-up

Customizing the Dener to your needs

You can customize your Dener in the Setup menu. Highlight SETUP in the introduction

screen to enter the Setup Menu. Or, highlight SETUP after resetting and then exiting

a measurement mode screen. The Setup menu has eight submenus. (Readings, Units,

Time, Date, Preferences, Power, Diagnostics and About).

To select a submenu, use the directional arrow buttons to highlight the submenu and

press the Enter button.

In submenus, brackets (i.e., <...>) indicate different selection options. You can switch

back and forth by pressing the forward or backward (or ) arrow.

Highlight CONFIRM after making changes and press the Enter button to save the

changes made.

‘Conrmed, New Settings Will be Retained’ message will appear in the screen for a

brief period before it returns to Setup menu.

Highlighting EXIT and then pressing the Enter button will return you to the SETUP

menu without saving any submenu changes.

Dener 220

9

2.0

9

Readings

Choose the ow reading type to either volumetric ‘Vol’ or standardized ‘Std’. Volumetric

ow is the actual ow at the ambient temperature and pressure whereas the standard-

ized ow indicates a ow rate at a specic temperature and pressure. Standardizing pres-

sure is set to a default value of 760 mmHg whearas standardizing temperature is a user

settable value set in ‘Std To’ in the ‘Units’ sub-menu.

Choose the number of measurements in the average from one to 100.

If you wish to incorporate a time delay between consecutive measurements, set Time

Between from one to 60 minutes.

Set the Sensor Factor to any value from 0.200 to 3.000. Sensor factor scales the reading

for calibrating MFCs and MFMs with surrogate gases. Sensor factor effects the ow rate

measurement only when the reading ‘Type’ is set to standardized ‘Std’.

10

Units

Measure gas Flow in cubic centimeters, milliliters, liters or cubic feet (all units are per

minute).

Measure Pressure in mmHg, kPa or PSI and Temperature in Celsius or Fahrenheit.

Set the standardizing temperature by setting ‘Std To’ to a value from 0 to 50 deg C or 32

to 122 deg F. ‘Std To’ effects the ow rate measurement only when the reading ‘Type’ in

the ‘Reading’ sub-menu is set to standardized ‘Std’.

Time

Set the current time and the format.

The format can be selected as PM, AM, or 24H.

Date

Set the date and the format.

The format can be selected as DD (day)-MM (month)-YYYY (year) or MM (month)-

DD (day)-YYYY (year).

Preferences

Read Default

Allows you to select a preferred mode of measurement when the Dener is initially turned

on.

Default Settings

Select <No> to allow the ‘Read Default’ change. Selecting <Yes> will reset your Dener

to the factory default settings. (Factory default settings are provided elsewhere in this

manual.)

10

11

2.0

11

Magnication

It controls the amount of data on the display. Select <Zoom> to view only ow measure-

ments in larger font, or select <Detail> to simultaneously view ow measurements, tem-

perature, and pressure in a smaller font.

Power

Power Save

By selecting <On>, your Dener will save power by turning off after ve minutes of inac-

tivity. However, it will not turn off when connected to the AC power adapter/charger.

Select <Off>, and your Dener will remain on until you manually turn it off.

Backlight

Select <On> to illuminate the LCD display or <Off > to conserve battery power.

12

Diagnostics

The Dener Leak Test is designed only to verify the

internal integrity of the instrument and alert you to an

internal leak. We recommend performing the Leak Test

only as an intermediate quality control check or when-

ever the integrity of the instrument is questioned due

to misuse or accidental damage.

Please note that a leak test is not a substitute for a

comprehensive examination of the unit’s overall perfor-

mance and it does not ensure that your Dener is oper-

ating accurately.

• Invert your Dener and allow the piston to travel to

the top.

• Cap the port under test using the Mesa supplied leak

test cap. Leave the other port uncapped.

• Press Enter on the control panel while the unit is still

inverted.

• Return the unit upright. The leak test will progress.

About

Tells you more about your Dener; a useful screen to

refer to when speaking to a technical support represen-

tative or your distributor.

12

13

2.0

13

2.7 Measurements

Taking gas ow readings

To maintain the best possible accuracy and minimize thermal effects, Mesa Labs recom-

mends fully charging your battery before taking measurements. If this is not possible, we

recommend disconnecting your Dener from its AC power adapter/charger while taking

ow measurements — or to run gas through your Dener for 10 minutes before starting

the ow measurement.

Out of Range

If the ow you are measuring is outside the Dener’s ow range, the “Out of Range!”

warning appears. Immediately lower or disconnect the ow. When the ow is within the

proper range, select RESET to clear your Dener’s last measurement.

14

2.8 Single Measurement

Each time the ‘Enter’ button is pressed, one measurement will be made. When each

subsequent measurement is made, the current ow and average of all prior readings will

be displayed.

First steps

Press the power button.

• Press the On/Off button for 1 second to turn on your Dener.

• When rst turned on, your Dener displays an opening screen showing the product

name, model number and ow range.

• Press the On/Off button for 3 seconds to turn your Dener off.

Connect device to be calibrated to the appropriate Dener port. Use ¼ inch diameter

tubing.

• Connect tubing to outlet at top (suction tting) when a device draws air (such as

sampler).

• Connect tubing to inlet at bottom (pressure tting) when a device pushes air.

• Do not cap the unused port on the Dener.

• Select the reading type to Vol or Std. Set ‘Std To’ to the desired standardizing tem-

perature.

• Choose the measurement type, Single, Burst, or Continuous, then press Enter.

14

15

2.0

15

2.9 Burst Measurement

This setting functions in the same manner as ‘SINGLE’, but measurements continue

automatically until the preset number of measurements has been made. Operation then

ceases, and the last reading and average are displayed.

Note: (010 in series) indicates the number of measurements. 10 is the factory-preset

number. You can dene the number of measurement you preferred from 1 to 100 by ac-

cessing the SETUP menu.

In Continuous or Burst mode, select:

• PAUSE to terminate the current ow measurement but to leave the average ow mea-

surement and previous ow measurement on the screen. This allows you to resume

the ow measurement sequence if you wish to do so.

• RESET to terminate the ow measurement and clear the screen.

Press ENTER again to begin another preset sequence.

2.10 Continuous Measurement

This setting functions in the same manner as ‘BURST’, but new sequences will automati-

cally repeat until stopped by the user.

16

3.0 Data Port

3.0

2.0

16

3.1 Dener 5V Feature (optional)

Your Dener 220 can be purchased with a 5-volt output that provides a volt-

age signal proprtional to the ow rate measured. Zero volts represents no

ow and 5 volts corresponds to the Upper Range Flow (URV); a user settable

value that can be set from the maximum ow rate of a particular Dener

model to 10 percent of the maxiumum ow rate for that Dener.

The Upper Range Flow correspondent to 5 V can be set by accessing

SETUP>PREFERENCES>URV.

Cable/adapter part # 100-125 connects to the serial port of the Dener for

easy access to a voltage measurement point and for simultaneous serial

cable connection. Contact Mesa for details.

3.2 DryCal Pro Software

Visit Mesa Labs’ website to download your copy of DryCal Pro software

(drycal.mesalabs.com/drycal-pro-software). DryCal Pro captures ow data

from your Dener directly to a pre-congured table. The data can be export-

ed to selectable Microsoft ofce environment.

To run DryCal Pro, you must have Windows® XP or 7, Microsoft Excel®2003

and up, and an RS232 port, or if your PC does not have an RS232 port you

will need a USB to RS232 adapter.

3.3 Dener Firmware Upgrades

The Dener rmware is upgradable through the Data Port. Firmware up-

grades and procedures for your Dener are available through DryCal Pro Soft-

ware (drycal.mesalabs.com/drycal-pro-software).

17

17

4.0

4.0 Annual Maintenance and Calibration

Assuring top performance and accuracy

Your Dener is a precision measuring standard with moving parts machined

to extremely close tolerances. Various environmental factors, product wear,

drift of sensors, or inadvertent damage may adversely affect your Dener’s

measurement accuracy or general performance. For these reasons, Mesa

Labs highly recommends having your Dener annually veried by an ISO

17025–accredited laboratory, such as Mesa Labs’ Butler, NJ facility, to en-

sure its measurement integrity.

For the ultimate in Dener maintenance and to take advantage of any avail-

able rmware and mechanical upgrades, Mesa Labs offers an annual non-

mandatory Recertication program. This is a service package that provides

complete product refurbishment, testing and available upgrades; calibration

and NIST-traceable calibration certicates.

Recertication includes a 90-day service warranty should any related labor

or parts replacements prove faulty.

Turnaround time is generally two weeks from time of receipt. Expedited

48-hour turnaround is available.

3.0

18

18

5.0 Shipping

Tips and guidelines for sending your Dener to Mesa Labs

If you are sending your Dener for repair or evaluation (rather than elective Recertica-

tion), contact Mesa Labs for technical support or troubleshooting assistance prior to ship-

ping the unit. Pro-vide us a detailed description of your issues. If we are unable to resolve

the situation by phone or email, we will issue you an RMA (return merchandise authoriza-

tion) number. Follow online instruction for proper return procedure.

You can obtain an RMA number through our automated web-based system at

drycal.mesalabs.com/request-an-rma. RMAs also can be obtained through email

to [email protected], or by telephone at 973.492.8400. Our web site address is

drycal.mesalabs.com.

Note: Mesa Labs will not evaluate or service your instrument without an RMA number.

If we nd the issues you have identied are application related and not product related,

an evaluation fee will be charged.

Shipping

When shipping your Dener, be sure to follow some simple guidelines to avoid costly

damage to your property.

• Use adequate packing material. Whenever possible, use the original packing that came

with your Dener. Or use a Mesa Pelican carrying case, which provides a hard case shell

for protection of your valuable equipment.

• Use a major freight carrier (e.g., FedEx, UPS) that supplies tracking numbers.

• Insure your Dener. Mesa is not responsible for damage occurred during transit.

• Understand our mutual shipping obligations.

Table of contents

Other Mesalabs Measuring Instrument manuals