Mestek RBI TORUS 1250 Owner's manual

is manual is intended only for use by a qualied heating installer/technician. Read and follow this manual, all supplements and related

instructional information provided with the boiler. Install, start and service the boiler only in the sequence and methods given in these

instructions. Failure to do so can result in severe personal injury, death or substantial property damage.

Do not use the boiler during construction. Construction dust and particulate, particularly drywall dust, will cause contamination of

the burner, resulting in possible severe personal injury, death or substantial property damage. e boiler can only be operated with a dust-

free air supply. Follow the instruction manual procedures to duct air to the boiler air intake. If the boiler has been contaminated by operation

with contaminated air, follow the instruction manual guidelines to clean, repair or replace the boiler if necessary.

Ax these instructions near to the boiler/water heater. Instruct the building owner to retain the instructions for future use by a qualied

service technician, and to follow all guidelines in the User’s Information Manual.

4/20 Copyright 2020 Mestek, Inc.

Stainless Steel Condensing Boilers

Models 1250, 1500, 2000, 2500,

3000, 4000

Optional

PVC/CPVC

Vent System

Installation Instructions

Supplement

TR-PVS-IOM-1

82-0957-001

Also read and follow:

Torus Installation and

Operation Manual

H & HLW

Torus Optional PVC/CPVC Vent System Installation Instructions Supplement

2

ese instructions are specic to using schedule 40 PVC/CPVC pipe

asthe ventsystem fortheTorus. einstructions containedinthe Torus

InstallationandOperationManual, includingallapplicableCombustion

Air & Ventilation and Venting instructions must be followed.

Venting of the Torus with PVC/CPVC material requires

the factory supplied PVC/CPVC adapter kit. e vent

system must conform to local codes and/or the latest

edition of the National Fuel Gas Code ANSI Z223.1/

NFPA 54. Failure to properly vent this product can result

in CO poisoning causing severe personal injury or death!

When using the PVC/CPVC vent option, the Torus

inlet water temperature must not exceed 160°F and a

maximum 20°F - delta t. A temperature exceeding these

limitations will result in a high limit shutdown.

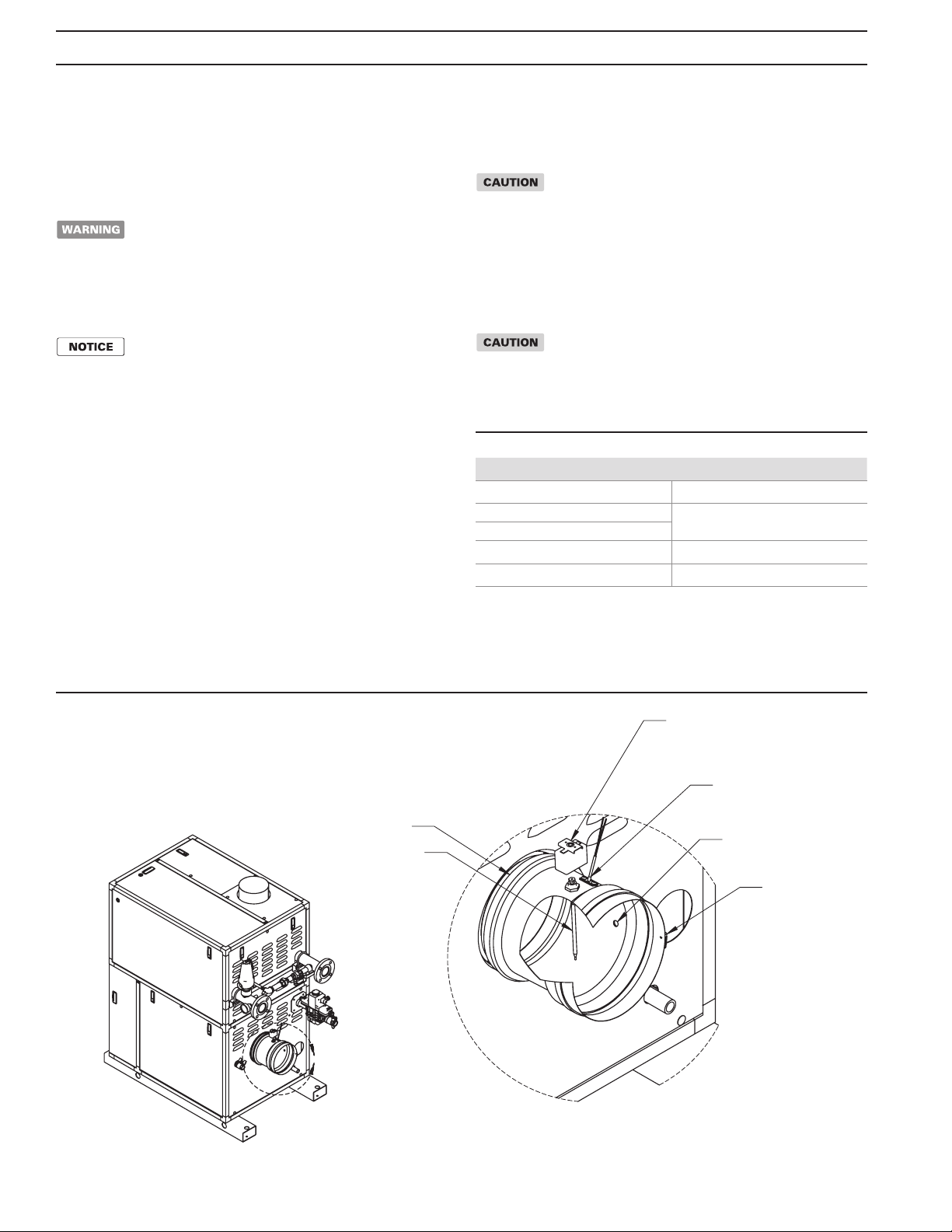

e PVC/CPVC vent adapter, (Figure 1), comes ed with a ue

temperature sensor and flue temperature high limit switch. This

system provides redundant over-temperature protection for the

PVC/CPVC vent system. e ue temperature sensor continuously

monitors the temperature of the ue gas exiting the Torus. If the

return water temperature exceeds 160°F the HeatNet Control, via

the ue temperature sensor, will recognize the resultant increase in

ue temperature and reduce the ring rate. Should the sensor fail, the

manual reset high limit switch will trip and shut down the Torus

before the ue temperature can exceed a safe limit.

e Torus vent collar connection point is accessible at the back of

the unit, (Figure 1). Carefully push the PVC/CPVC Vent Adapter

(1250-4000), into the ue outlet vent collar until it booms against

the stop bead on the adapter and tighten the ring clamp to secure the

vent adapter to the Torus vent collar.

PVC/CPVCVENT ADAPTOR INSTALLATION

ImproperinstallationofthePVC/CPVCventadaptorcan

cause pooling of corrosive condensate and result in

premature failure of the vent adaptor voiding the

manufacturer’s warranty!

WiththePVC/CPVCventadaptorpositionedattherearoftheunitcare-

fully insert the manual reset high limit through the ue pipe opening in

therearcabinetpanel.Mountthehigh limittothe economizerbracketas

shown in Figure 1.

Do not kink or damage the high limit capillary tube or the

limit may be ruined voiding the manufacturer’s warranty!

Position the vent adaptor so the high limit switch capillary is at the top of

the adaptor, Figure 1.

Table 1 PVC/CPVC Vent Adapter Kits

Figure 1 PVC/CPVC Vent Adapter

Model Size RBI Part Number*

1250 & 1500 (8"x6") 75-0553-001

1250 & 1500 (8"x8") 75-0553-002

2000 (8"x8")

2500 & 3000 (10"x10") 75-0553-003

4000 (12"x12") 75-0553-004

* Includes: adapter, Jumo high limit, HeatNet stack temperature

sensor, and misc. wiring.

A

DETAIL A

SCALE 1 : 6

BAND CLAMP

BAND CLAMP

ANALYZER FITTING

JUMO HIGH LIMIT

RIOM-0315_A

STACK SENSOR

HIGH LIMIT PROBE

Torus Optional PVC/CPVC Vent System Installation Instructions Supplement

3

PVC/CPVC VENT ADAPTOR WIRING

Failure to properly connect the uetemperature sensor

and ue temperature high limit switch will prevent the

Torus from operating.

Locate the wire harness inside the rear cabinet. Connect the two

wires with the 1/4 in/ft, 6.4 mm/m quick connects to the flue

temperature high limit switch. Connect the two wires with the 3/16

in, 4.8 mm quick connects to the ue temperature sensor.

PVC/CPVC VENT SYSTEM INSTALLATION

Neverinsulateor encapsulatethePVC/CPVCventsystem

oroverheatingandfailureofthe ventsystemmayoccur.e

PVC/CPVC vent system must be exposed to ambient air

andreadilyvisible forinspection.Failuretoproperlyventthis

productcanresultinCO poisoningcausingseverepersonal

injuryordeath!Exception:PerNFPA54Secion12.6.8:e

remaining space surrounding a chimney liner, gas vent,

special gas vent or plastic piping installed within a masonry

chimneyshall notbeused toventanother appliance.

e PVC/CPVC vent adapter has been engineered to directly accept

PVC/CPVC vent pipe. e internal gasket in the vent adaptor will form

a gas and water tight seal. No glues or sealants are required at this

connection.SlidetherequiredhorizontallengthofPVC/CPVCpipeinto

the vent adaptor and tighten the ring clamp to secure it in place. e vent

system must be sized per Table 2.

Table 2 Category IV Maximum Equivalent Vent Length

e maximum equivalent length for a positive pressure PVC/CPVC

vent system is as noted in Table 2. Each 90° elbow and the vent ter-

minal are equal to 10 linear , 3.0 linear m of pipe.

To maximize the performance of the vent system, locate 90° elbows

as far from the Torus and one another as possible.

When horizontal vent runs exceed 5 , 1.5 m they must be supported

at 3 , 0.91 m pitched intervals with overhead hangers. e ventsystem

mustbepitcheddown, towardtheventterminal,1/4 in/, 6.4 mm/m.

If the vent system contains vertical sections horizontal vent runs be-

tween the Torus and the vertical section must be pitched back, to-

ward the economizer, 1/4 in/, 6.4 mm/m, to prevent condensate

from pooling in the vent.

PVC/CPVC VENT PIPE PREPARATION

& ASSEMBLY

Only schedule 40 PVC/CPVC pipe sized per Table 1 is

to be used. e use of heavier wall pipe may prevent the

Torus from operating properly!

1. Cut pipe ends squarely and remove all burrs, ridges and foreign

maer using the appropriate tools and materials.

Failure to remove burrs or ridges will result in the cement

in the ing socket being scraped from the socket surface

producingadry jointwhich will havea high probabilityof

failure.

2. Before applying any cement dry t pipe and ings together to

ensure that the parts t properly.

3. Disassembledryedpartsandcleanthepipeandingsurfaces

to be joined with a PVC/CPVC cleaner. Surfaces to be joined

must be free of dirt, moisture, oil and other foreign maer.

All primers, cleaners and cements must meet all local

codes. Before using primers, cleaners and cements, stir or

shakewell, makingsurethecontentsareliquid. Donotuse

if found to be lumpy or in a jelly-like state. Do not add

solvents or thinners to reclaim thickened or lumpy

material.PrimersandcementshouldbeNSF and/orUPC

listed. Failure to use proper materials when venting this

product can result in CO poisoning causing severe

personal injury or death

Use of cellular core PVC (ASTM F891), cellular core

CPVC,orRadel (polyphenolsulfone)in ventingsystems

shall be prohibited.

Coveringnon-metallicventpipeandingswith thermal

insulation shall be prohibited.

Primers, cleaners and cements are extremely ammable

and harmful or fatal if swallowed. Always store primers,

cleaners and cements in a cool, dry, well ventilated place.

Do not store them near heat, sparks or flames. Keep

containers closed when not in use. Wear impervious

clothingwhile handling.Donot smoke,eatordrinkwhile

handlingprimers,cleanersandcements.Wash thoroughly

after handling and before eating. Wear eye protection

when handling. The harmful vapors can be absorbed

through the skin and may irritate eyes and skin. If inhaled,

getfreshairandseekmedicalaentionifillfeelingspersist.

Incaseof eyeand/or skin contact, immediately ushwith

plenty ofwaterfor 15minutesand seekmedicalaention

if irritation persists. If swallowed, drink water, do not

induce vomiting and call a physician or poison control

center immediately. Failure to read and observe all safety

information printed on primer, cleaner and cement

containers can result in severe personal injury or death!

Cleaners and primersareintendedfor dierentfunctions

and should not be considered inter-changeable. Verify

with ventmaterial manufacturerforspecic requirements.

4. Apply a coatofprimertothepipeandingsurfacesthatwill

be joined.

5. Applyathincoatofcementtotheingsurfacethatwillbejoined

makingsurenotoverapplythecementwhichcancausepuddling

inside the ing.

6. Applyaliberalcoatofcementtothepipesurfacethatwillbejoined

making sure to completely coat the area so it is free of voids.

7. QUICKLY assemble the parts while the cement is uid! If the

cement dries before the parts are assembled, re-coat the surfaces

with cement then assemble them.

Model Size Outlet Diameter Max Equiv. Length

In In

1250 6 40

8 90

1500 6 40

8 90

2000 8 90

2500 & 3000 10 90

4000 12 90

8. Push the end of the pipe completely into the ing socket so

it booms out and rotate the ing or pipe at least 1/4 turn

to achieve proper cement spread. Make sure the parts are in

the correct orientation before the cement cures. e cement

bonds by melting the PVC/CPVC so once the joint is made

it cannot be disassembled.

9. Hold the pipe and ing for 30 seconds to allow the joint to

suciently cure then carefully clean o any excess cement

with a cloth.

10. FollowthePVC/CPVCcementmanufacturer’sinstructions

toallowtheconnectionssucienttimetocurebeforepuing

any stress on the joint.

PVC/CPVC VENT TERMINALS

When vented horizontally the vent and air intake systems may be

terminated using standard PVC/CPVC ings with 1/4 in stainless

steel bird-screen inserts as shown below. e minimum distance from

the wall must be maintained as shown in the Figures below.

Figure 2 Horizontal PVC/CPVC TEE Terminal

Figure 3 Horizontal PVC/CPVC 45° Elbow Terminal

Figure 4 Horizontal PVC/CPVC 90° Elbow Terminal

Figure 5 Horizontal PVC/CPVC Coupling Terminal

Figure 6 Vertical PVC/CPVC Terminal

e input of the unit must be set per Table 3 or nuisance shutdowns

may occur under strong wind conditions.

Table 3 Turn Down vs Combustion Air Source

When vented vertically the vent and air intake systems should be

terminated using standard 45° and 90° PVC/CPVC Elbow ings

with a 1/4 in stainless steel bird-screen insert as shown below.

e rest of the applicable Combustion Air & Ventilation and Venting

instructions contained in the INSTALLATION & OPETION

MANUAL MUST BE FOLLOWED.

10'' Min

1/4'' SS Bird Screen

In Opening

8'' Min

1/4'' SS Bird Screen

In Openings

8'' Min

1/4'' SS Bird Screen

In Openings

10'' Min

1/4'' SS Bird Screen

In Opening

1/4'' SS Bird Screen

In Opening

Exhaust Combustion Air Turn Down Ratio

Vent Terminal Indoor 3:1

Outdoor 5:1

Copyright 2008 Mestek, Inc.

260 North Elm Street 7555 Tranmere Drive

Westeld, MA 01085 Mississauga, Ontario L5S 1L4 Canada

Phone: (833) 265-5371 Phone: (905) 670-5888

Fax: (413) 568-9613 Fax: (905) 670-5782

www.rbiwaterheaters.com

This manual suits for next models

5