NOVENCO ZERAX AZL-AZN-AZW Instruction Manual

Pure competence in air.

ENGLISH 922950-0

NOVENCO® ZERAX® FAN TYPES

AZL-AZN-AZW

INSTALLATION AND

MAINTENANCE

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 2 of 30

Important

This document is provided ’as is’. Novenco Building & Industry A/S reserves the right to

changes without further notice due to continuous product development.

The fans are designed for continuous operation. The following kinds of operation may cause

fatigue break in the rotors and endanger people.

•Operation in stall area

• Operation with pulsating counter pressure – called pump mode

•Operation with exceedingly starts and stops

If in doubt, Novenco should be contacted to assess the suitability of the fans.

Copyright © 2009 - 2022, Novenco Building & Industry A/S. All rights are reserved.

Document revision no.: MU16068 0822

Document item no.: 922950-0

Patents and trademarks

Novenco®, , and are registered trademarks of Novenco Marine & Offshore

A/S.

ZerAx®is a registered trademark of Novenco Building & Industry A/S.

AirBox™, NoVa™ and NovAx™ are trademarks of Novenco Building & Industry A/S.

The Novenco ZerAx processes of manufacture, technologies and designs are patented by

Novenco A/S or Novenco Building & Industry A/S.

Pending patents include India no. 821/CHENP/2014 and 825/CHENP/2014; PCT no. EP2012/

064908 and EP2012/064928.

Granted patents include Brazil no. BR-11-2012-008543-3; BR-11-2012-008545-0, BR-11-2012-

008607-3, BR-11-2014-002282-8 and BR-11-2014-002426-0; Canada no. 2.777.140, 2.777.141,

2.777.144, 2.832.131 and 2.843.132; China no. ZL2010800458842, ZL2010800460965,

ZL2010800464275 and ZL2012800387210; EU no. 2488759, 2488760, 2488761, 2739860 and

2739861; India no. 312464, 360298 and 367515; South Korea no. 10-1907239, 10-1933724, 10-

1980600, 10-2011515 and 10-2127529; US no. 8.967.983, 9.200.641, 9.273.696 B2, 9.683.577 and

9.926.943 B2.

Granted designs include Brazil no. BR-30-2012-003932-0; Canada no. 146333; China no. 1514732,

1517779, 1515003, 1555664 and 2312963; EU no. 001622945-0001 to 001622945-0009 and

001985391 - 0001; India no. 246293; South Korea no. 30-0735804; UK no. 001622945-0001 to

001622945-0009 and 001985391 - 0001; US no. D665895S, D683840S, D692119S, D704323S,

D712023S, D743018S, D755363S, D756500S, D821560S and D823452S.

Other trademarks in this document are the property of their respective owners.

This document is provided ’as is’. Novenco Building & Industry A/S reserves the right to

changes without further notice due to continuous product development.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 3 of 30

1. Application . . . . . . . . . . . . . . . . 4

1.1 Reading guide . . . . . . . . . . 4

2. Handling. . . . . . . . . . . . . . . . 4

2.1 Marking . . . . . . . . . . . . . . . 4

2.2 Weights. . . . . . . . . . . . . . . . 4

2.3 Design conditions . . . . . . . 5

2.4 Transport and lifting . . . . 5

3. Storage. . . . . . . . . . . . . . . . . 6

4. Installation. . . . . . . . . . . . . . 6

4.1 Before installation . . . . . . . 6

4.2 Set up fans . . . . . . . . . . . . . 7

4.3 Support frames . . . . . . . . . 8

4.4 Vibration dampers . . . . . . 9

4.5 Flexible connections . . . . . 9

4.6 Wire guards . . . . . . . . . . . . 9

4.7 Duct connection . . . . . . . . 9

4.8 Electrical connection. . . . 11

5. Start of operation . . . . . . . 12

5.1 Before start-up. . . . . . . . . 12

5.2 Motors with Y/-start . . 13

5.3 Start-up procedure . . . . . 13

5.4 Air volumes for free inlet

fans . . . . . . . . . . . . . . . . . . 13

6. Maintenance . . . . . . . . . . . 14

6.1 Before maintenance . . . . 15

6.2 Cleaning . . . . . . . . . . . . . . 15

6.3 Vibration levels . . . . . . . . 15

6.4 Fan casings. . . . . . . . . . . . 15

6.5 Rotors . . . . . . . . . . . . . . . . 15

6.6 Motors. . . . . . . . . . . . . . . . 16

6.7 Motor removal. . . . . . . . . 17

6.8 Mounting of motor . . . . . 18

6.9 Blade angles . . . . . . . . . . . 19

7. Troubleshooting . . . . . . . . 19

8. Inspection and test . . . . . . 19

9. Sound . . . . . . . . . . . . . . . . . 20

10. Safety . . . . . . . . . . . . . . . . . 20

11. Reference documentation 20

12. Disposal . . . . . . . . . . . . . . . 20

13. Quality management . . . . 21

14. Warranty . . . . . . . . . . . . . . 21

14.1Rotor weldings . . . . . . . . 21

15. Spare parts. . . . . . . . . . . . . 21

16. Classifications and certifica-

tions . . . . . . . . . . . . . . . . . . . . . 22

17. Product lifetime. . . . . . . . . 22

18. Declaration of conformity. 23

Appendices . . . . . . . . . . . . . . . . . . 25

Appendix - A.

Max. fan casing weights . . . . 25

Appendix - B.

Fan assembly . . . . . . . . . . . . . 26

Appendix - C.

How to mount puller. . . . . . . 27

Appendix - D.

Wiring – six-leads motor – no

frequency converter. . . . . . . . 28

Appendix - E.

Wiring – terminal box to fre-

quency converter . . . . . . . . . . 28

Appendix - F.

Wiring – three-leads motor –

with frequency converter . . . 28

Appendix - G.

Checklists . . . . . . . . . . . . . . . . 29

Contents

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 4 of 30

1. Application

The high performance Novenco®ZerAx®axial flow fans types AZL-AZN-AZW are for

applications within land-based industries and marine sectors.All types arefor duct connection.

The AZL type has a free inlet and connects to duct on the outlet side.

1.1 Reading guide

Please read this complete guide, before beginning

installation or maintenance.

2. Handling

Avoid exposure of fans and motor parts to shocks, as these can result in imbalance and

deformations. Motor bearings and fan components are vulnerable parts.

2.1 Marking

The AZL-AZN-AZW fans have nameplates on the fans and motors.

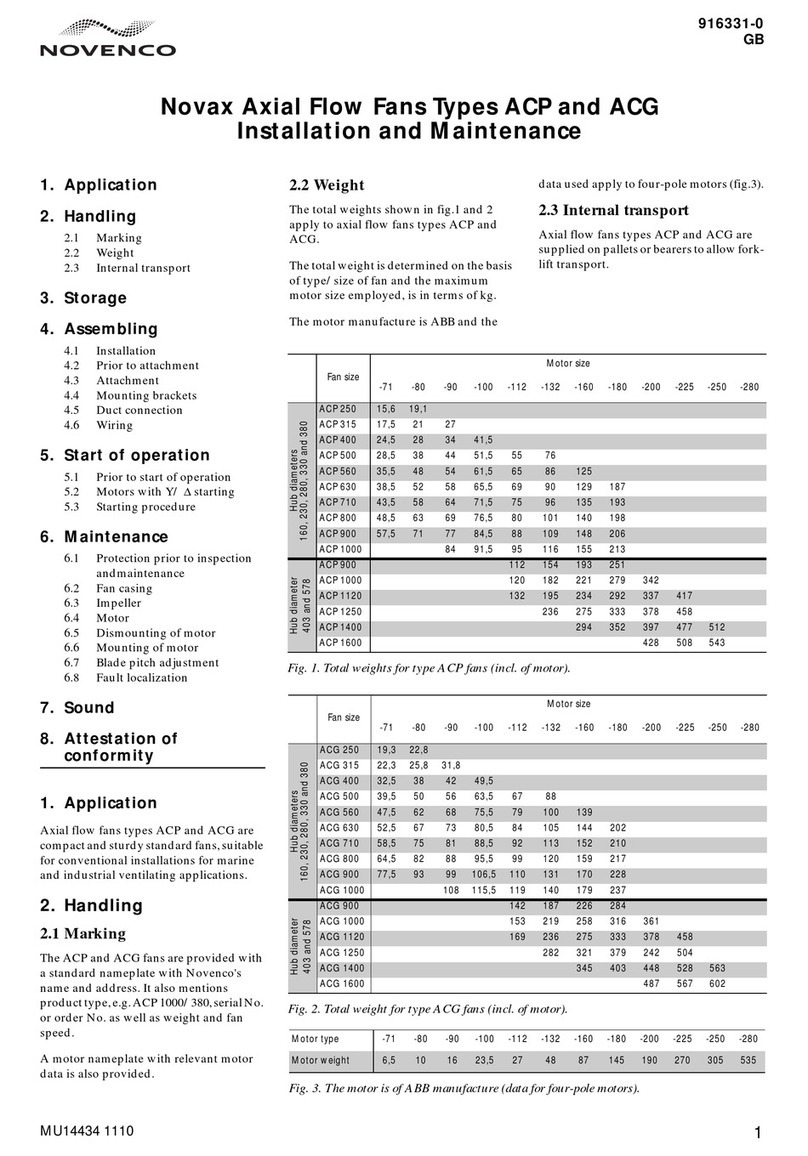

2.2 Weights

The total weight depends on the fan size, casing thickness, motor size and accessories.

Refer to the technical fan specifications from Novenco AirBox program for further information

and weights of specific fan solutions.

Icons Descriptions

Risk of damage to equipment

Risk of injury or death

Installation tip

Table 1. Icons in guide

Fan nameplate information

•Manufacturer information

•Product type, e.g. AZN 1000/350

•Serial no.

•Fan speed

•Year of manufacture

•Weight

Motor nameplate information

•Manufacturer information

•Power consumption and efficiency

•Voltages

•RPMs

•Weight

•Terminal connections

•Lubrication and service info.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 5 of 30

2.3 Design conditions

The AZL-AZN-AZW fans are designed for operation at standard temperatures from -20 to

+50 °C. With reduced fan speed and increased blade clearance the temperature range can be

extended from -40 to +120 °C. Contact Novenco for further information.

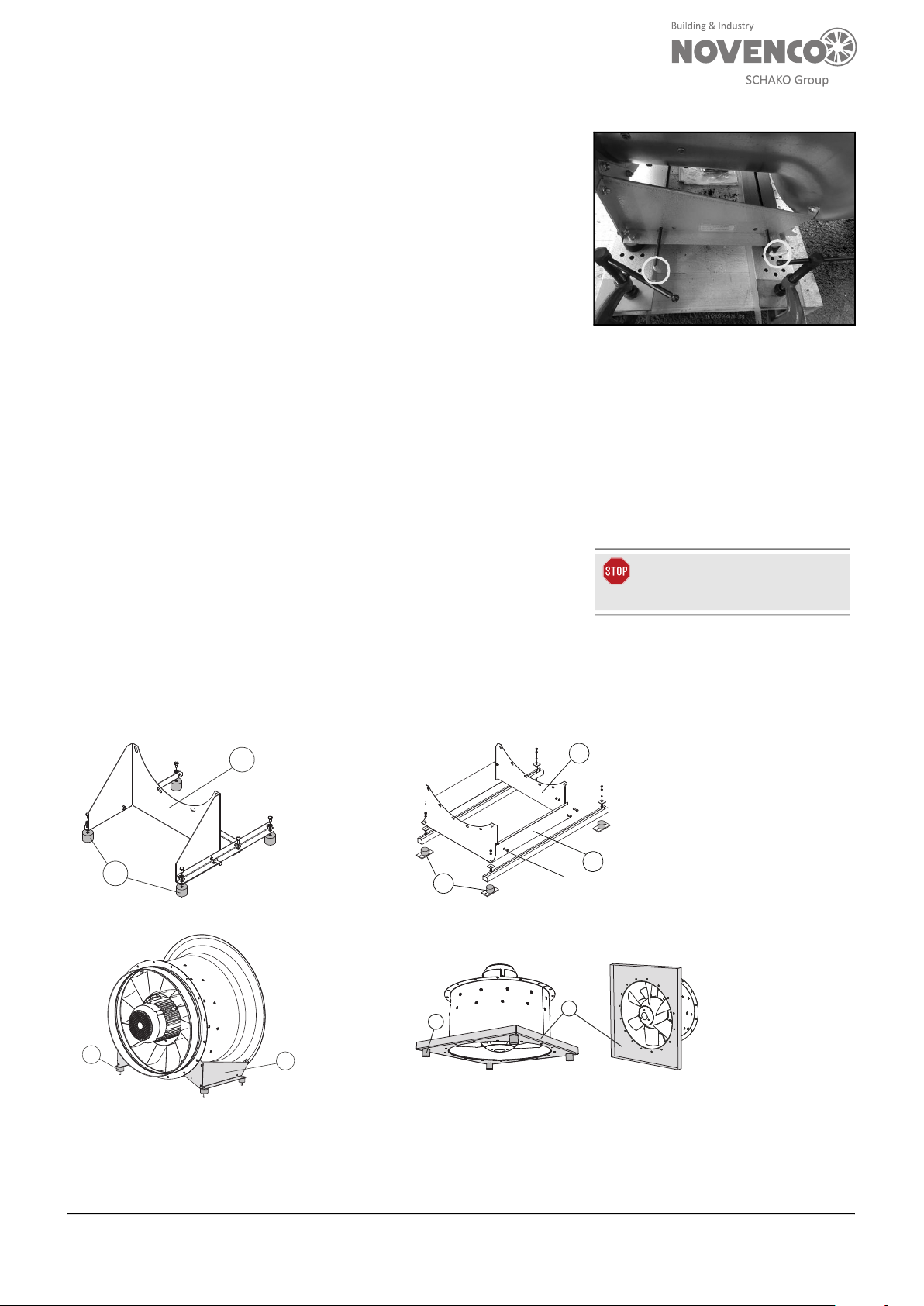

2.4 Transport and lifting

The fans are delivered on pallets or bearers to

allow for forklift transport.

Transport and lifting must be done with care,

as the fans are vulnerable to vibrations and

shocks. These can result in imbalance and

deformations.

Refer to the weights in the shipping papers,

on the motor and fan casing nameplates and

in appendix “Appendix - A. Max. fan casing

weights”on page 25.

Any transport or lifting of the fans must

be in accordance to current directives,

regulations and guidelines for safety.

Pay attention to limitations and direction for

use of lifting gear.

Verify that the fans and accessories are

undamaged upon receipt. Also, spin the

rotors by hand to see they rotate freely in the

fan casings. Inform the carrier and Novenco

immediately of damages.

Further transport depends on the fan size and the fitted accessories.

Figure 1. Lift of fan with

one strap

Figure 2. Lift of fan with

two straps

Transport

•Fans mounted on support frames

Transport and store these on pallets.

Leave in the transport rods for fans with

vibration dampers.

•Fans without support frames

Transport fans resting on the inlet flanges

or cones. The rotors must point

downwards.

•Large fans or fans with large motors

Transport and store these on pallets.

Store very large fans on suitable bearers.

Eyebolts on motors are unsuited for

lifting the fans.

Lifting

•With straps – horizontal fans

Lift with a single strap around the fan

casing at the centre of gravity.

Avoid lifting fans in the flange holes.

Novenco recommends lift of fans with

straps.

•With straps – vertical fans

Lift with two straps around the fan

casing. Support the fan to control the

rotation especially for horizontal fan

installations.

•In flange holes – horizontal fans only

Lift in a minimum of three holes – two in

the outlet flange and one in the inlet. On

fans with inlet cones, remove the bolt in

the topmost position and use the hole as

the third point for lifting. Reinsert and

tighten the bolt once the fan is in place.

Deformation of the flanges must be

avoided.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 6 of 30

3. Storage

Correct storage conditions are important for the

function and durability of the fans.

4. Installation

4.1 Before installation

Complete the below checklist to ensure a safe work environment and fan functionality. See also

the checklists in the appendices.

Before installation

•Unpack the fan with care.

•Check that the rotor rotates freely in the fan casing with equal blade tip distances to the

casing around the circumference.

•Outdoor installations: Make sure the installation location is sheltered. Fans, motors and

frequency converters must be protected from rain and water that drips.

•Ground the fan before installation to avoid static electricity. For example, by assembly on

non-conductive vibration dampers and foundations.

•Clear the fan installation location to ensure free and unimpeded airflows for the inlet and

outlet. The free area in front of the fan inlet must be at least 1x the fan diameter, D, or ½D

for optimal or reduced performance, respectively. Optimal airflow from all sides removes

risk of stall, gives best performance and keeps sound levels down.

•Secure the installation to at least IP20, i.e. protect people and surroundings against solid

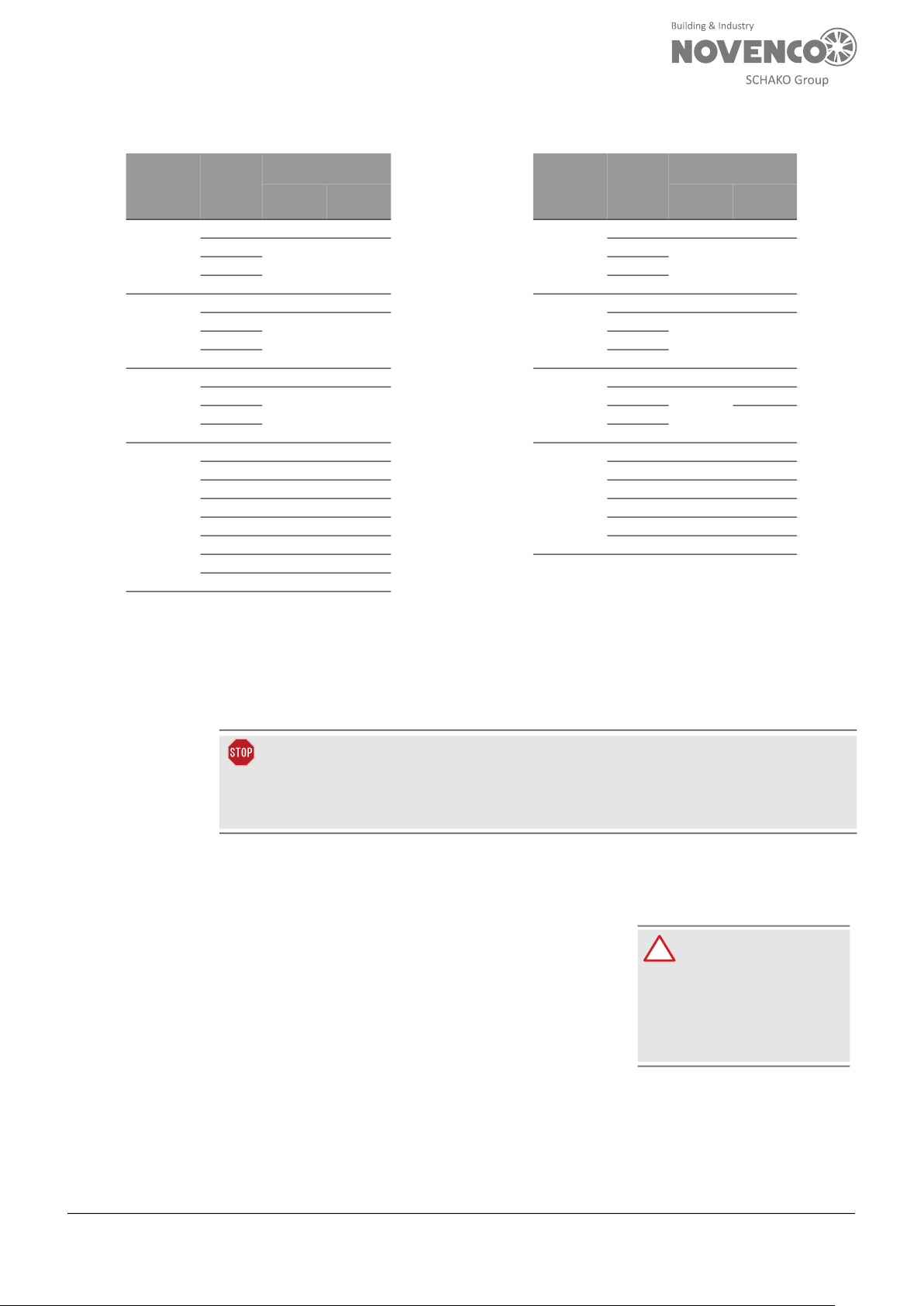

Conditions Specifications Comments

Outdoor One month • Packaging must be intact

Indoor or sheltered Max. six months

• For unprotected fans with no or broken packaging

• Ventilated location

• No condensation

Prolonged Max. two years

• Indoor

• Remove packaging

• Ventilated location

• No condensation

• Turn rotor 20 times every six months

• Add additional anti-corrosive coating on motor shaft

• Change motor ball bearings after two years of storage

Vibrations No • Location must be vibration free

Temperatures -20 to 50 °C

• Constant temperature, preferably 20 °C

• Ventilated

• No condensation

Humidity Below 70%

• Avoid condensation

• Exceedance requires airtight packaging of complete fan and use of

a moisture absorbent agent such as silica gel

Table 2. Storage recommendations

Damages due to incorrect storage

void the warranty.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 7 of 30

objects up to 12 mm.

Also, install wire guards on fans where there is direct access to the rotor. Wire guards from

Novenco can be installed as close as 120 mm before and after the rotor.

See section “4.7 Duct connection”for minimum distances for undisturbed airflow.

The vibration level of the installation depends on how the fans are installed, the

operational conditions and the natural frequency of the foundation and supports.

Follow the below guidelines to avoid resonance.

•Soft suspension: Fan is fixated through springs or dampers. The natural frequency

[Hz] of the system should be at least 20% below fan speed.

Soft suspensions are available from Novenco.

•Stiff suspension: Fan is fastened to a duct or a hard surface. The natural frequency

of this system should be at least 20% above fan speed.

•Elastic structure: Fan is fastened to an elastic structure. The natural system

frequency should be at least 20% higher or lower than fan speed.

The owner is responsible for compliance with the above requirements. Non-compliance

affects the product warranty.

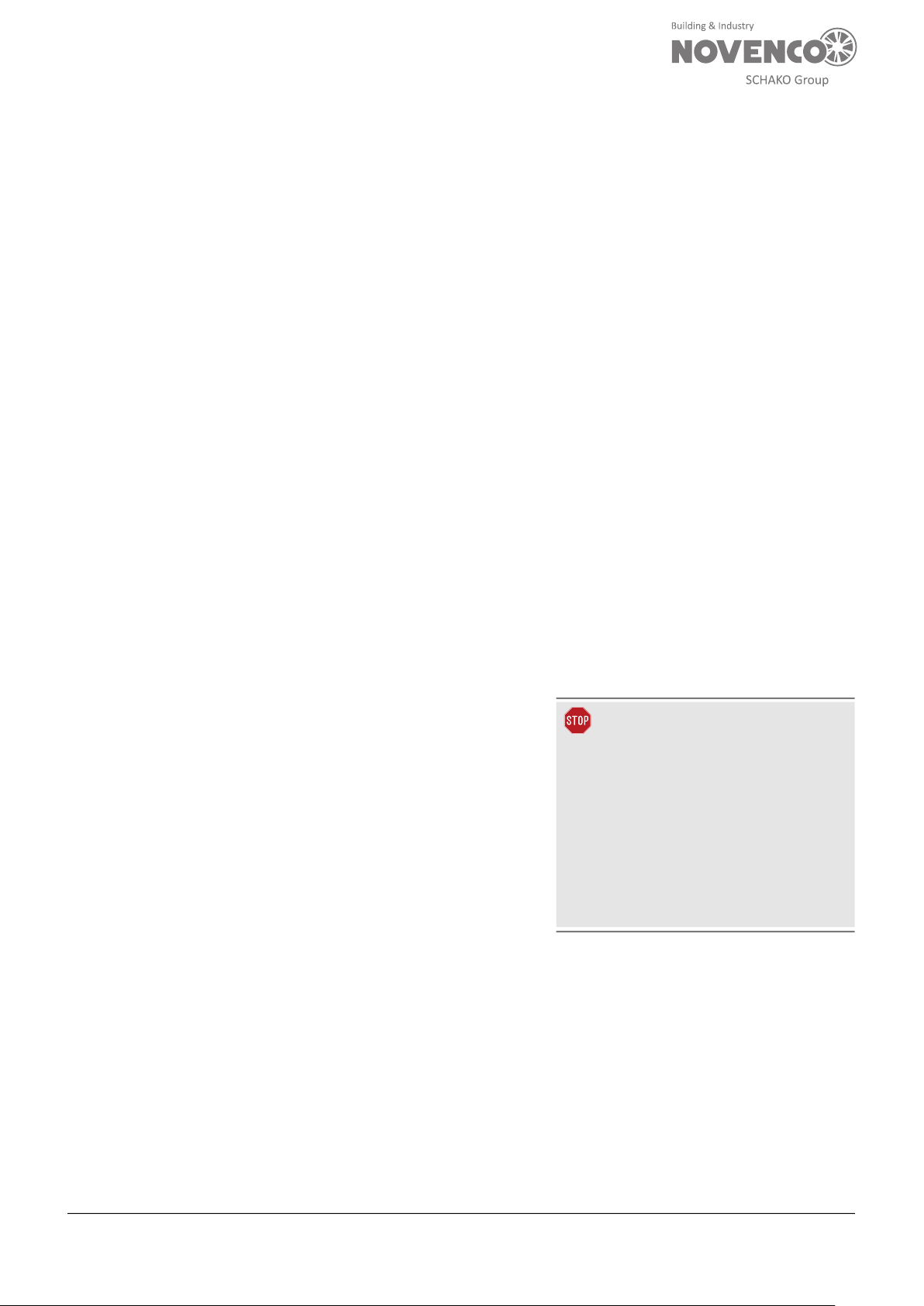

4.2 Set up fans

Prepare fans for installation

1. Fit the support options needed for mounting the fan. This may include the following.

•Special carriers

•Support frame (recommended)

•Mounting plate

•Vibration dampers (recommended)

Proper support ensures safety and installation stability. See sections “4.3 Support frames”

and “4.4 Vibration dampers”.

The fan support must be strong enough to support the fan weight and any fittedaccessories.

See “Appendix - A. Max. fan casing weights”on page 25 and the Total weight of installation

in the technical fan specifications from AirBox.

2. Optional: Install flexible connections on the fan flanges.

See section “4.5 Flexible connections”on page 9.

3. Optional: Install wire guards on one or both sides of the fan casing.

See section “4.6 Wire guards”on page 9.

Connect fans

1. Check that the fan motor drain holes point

downward and are in the lowest possible location.

Adjust the fan position, if necessary.

2. Unplug the fan motor drain holes.

3. Place and orient the fan in accordance with the

airflow. Refer to the arrows on the fan casing.

•Duct fans: These can be installed horizontally

or vertically as part of duct works or connected

to duct openings as supply or exhaust fans.

The installation space must at least meet the

reduced requirements and preferably those for

optimum installation space. See section “4.7 Duct connection”on page 9.

The motor drain holes must

point downwards at the lowest

point as the installation

environment and operation

conditions may cause condensation

in the fan motors. Fan motors

mounted at angles typically have the

drain holes in the back covers.

Contact Novenco if the drain holes

are missing.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 8 of 30

•Fans on support frames and AHU

incorporation: Fans mounted on support

frames can be connected to wall openings, duct

works or incorporated in AHUs.

Remove the transport rods in the support

frames for fans delivered on support frames

and with vibration dampers. The handles are

marked with a strong colour.

See section “4.7 Duct connection”on page 9 for

installation space requirements.

4. Check that the fan rotors rotate freely once the fans

are in position.

5. Connect fan to duct or similar mounting point in

the fan flange.

6. Connect fan electrically.

See section “4.8 Electrical connection”on page 11.

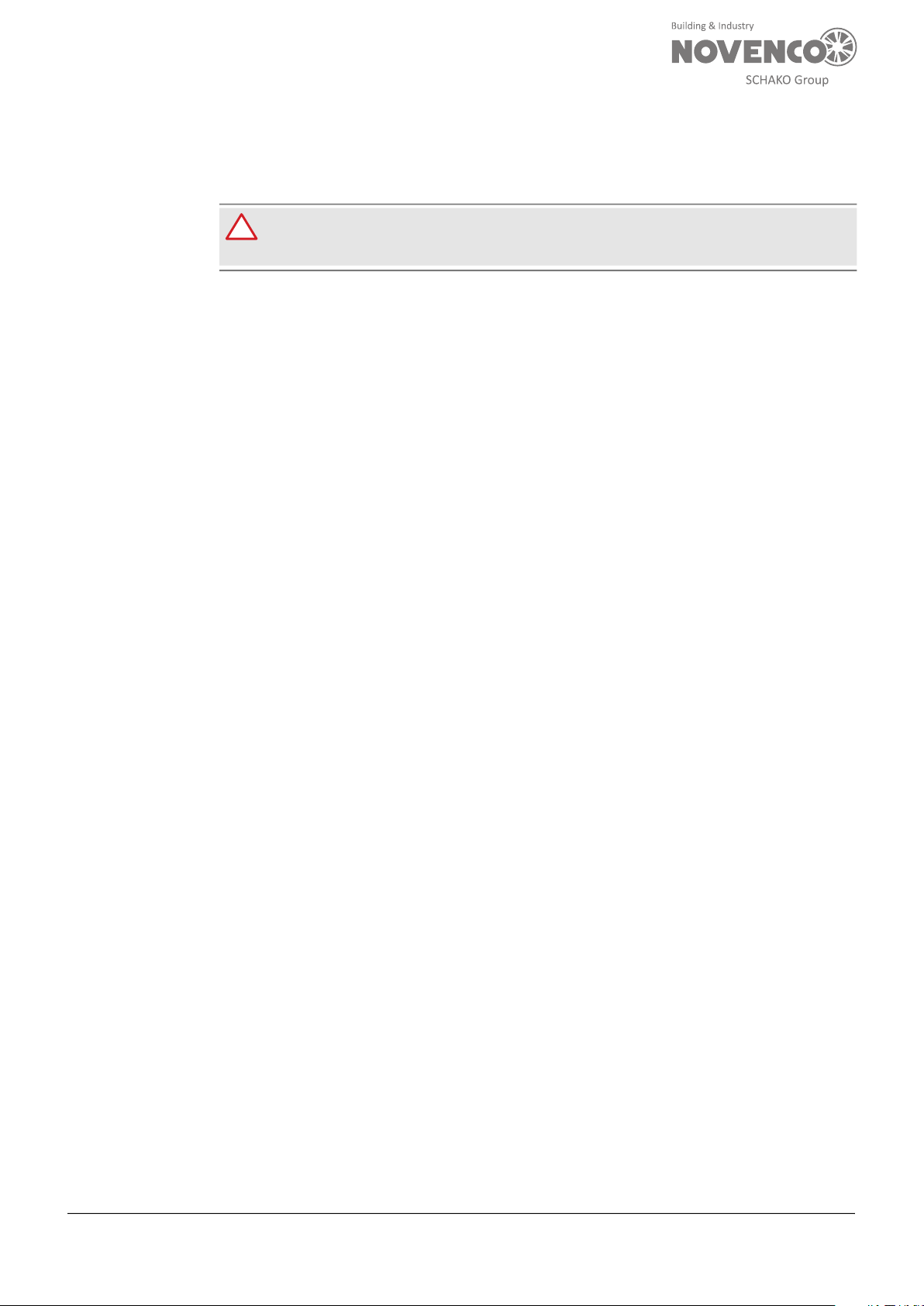

4.3 Support frames

Support frames are optional extras and recommended

for most fan installations.

All ZerAx fan types can be fitted with support frames

for horizontal installation. In figure 4, support frame

types 1 and 2 are for horizontal installation of the AZL. The type 2 can furthermore be mounted

on rails transversally to the airflow for easy incorporation in AHUs.

Support frames type 3 are for horizontal installation of the AZN and AZW.

For vertical fan installations, the type 4 is available for the AZL and AZN. The AZW cannot be

installed vertically.

Figure 3. Transport rods in AZL support

frame

Support frames must be

groundedto preventelectrical

shocks.

Figure 4. Novenco ZerAx support frames

01

02

Type 1 - Horizontal frame for AZL

Type 2 - Compact horizontal frame for AZL

and suited for incorporation in AHUs

03

M10x20

02

01

Type 3 - Horizontal frame for AZN and AZW

01

02

Type 4 - Vertical frame for AZL and AZN with

(left) and without vibration dampers

01

02

1. Frame plates

2. Vibration dampers (optional)

3. Stiffeners

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 9 of 30

4.4 Vibration dampers

Secure vibration dampers to the support frames by

means of bolts. Mount base plates between the rubber

elements and the foundation.

The vibration dampers help ensure the natural

frequency of the system is below 10 Hz and that the

damping is at least 80%.

Ensure an even load of the vibration dampers by

placement of the fan the distance X from the centre of the

front damper element to fan front flange. See figure 5.

The distance is in the technical fan specifications from the

AirBox program.

The load of the dampers depends on air pressure.

4.5 Flexible connections

To prevent spread of vibrations to the surroundings,

it is recommended, in addition to vibration dampers,

also to install flexible connections in the ducts before

and after the fans. These accessories are available as

optional extras from Novenco.

4.6 Wire guards

Fans must always be installed so that parts

that rotate cannot be touched or fly off in case

of material failure. It is therefore

recommended to fit wire guards on the inlet

and outlet sides. If ducts are connected, these

can alternatively be provided with wire

guards.

Novenco offers wire guards for in-pipe

installation on outlets. Drill holes in the pipe

and fixate with the bolts and nuts included in

the kit.

4.7 Duct connection

Install the fans with optimal conditions in mind to

ensure smooth and undisturbed airflows. The space

before and after the fans should preferably meet the

optimal requirements in the below figure.

Allow for free areas to facilitate assembly and

disassembly as well as maintenance.

X

Figure 5. AZN-AZW on support frame

Uneven damper loading

strains and reduces damper

functionality.

The natural frequency of the

support must lie at least 20%

from the fan speed.

20 mmEyebolt

Nut

Figure 6. In-pipe installation of wire guard

The fans cannot be used as

structural elements, e.g. for

duct or building support.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 10 of 30

Flexible connections can be placed as close as ½D before the fan inlet.

Figure 7. Installation spaces in ducts – optimal (left) and reduced

D>D>

½Dr>

½D>D>

Built into duct

Free inlet D = Fan diameter

3 x D>3 x D>

½Dr>

D>D>

D = Fan diameter

Built into duct

Free inlet

Figure 8. Installation in duct

Figure 9. Installation in duct

Fan size,

ØD, [mm]

RPM 1 2

1. Fan speeds depend on the installation space.

2. Fans with Ø160 hubs can run at maximum RPMs

irrespective of the installation conditions.

Maximum Optimal Reduced

Hub diameters

160

250 4919 — —

280 4747 — —

315 4570 — —

355 4408 — —

400 4269 — —

450 4145 — —

500 4086 — —

Hub diameters

350

500 3660 3660 3483

560 3460 3460 3286

630 3238 3238 3059

710 3000 3000 2804

800 2751 2751 2523

900 2498 2498 2217

1000 2270 2270 1918

1120 2029 1900 1568

1250 1809 1500 1201

Hub diameters

560

1000 2034 2034 1904

1120 1893 1893 1727

1250 1751 1751 1552

1400 1599 1599 1371

1600 1419 1419 1166

1800 1262 1262 1002

2000 1130 1130 878

Table 3. Max. allowable speed at 20 °C

AZN-AZW fans are for circular duct

connections with flanges on both inlet and

outlet sides. The AZL has a flange on the outlet

side only.

Flanges on AZL-AZN fans are as standard

according to Eurovent 1/2. Fan type AZW has

flanges of type DIN 24154 row 4 as standard.

Systems with high vibration levels or more

exacting performance requirements must be

provided with expansion joints between fan

and duct.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 11 of 30

4.8 Electrical connection

The installation and connection to the supply network must be done by authorised

personnel and according to current legislation, e.g. the EU standard for electromagnetic

compatibility (EMC).

Connection of the fans to the supply network depends on the drive type, i.e. if frequency

converters are to control the fan motors.

Connection of drive types

•Fixed speed (Direct On Line)

- Connect the supply voltage directly in the

terminal box.

•Frequency converter (AC and PM motors)

- Connect the supply voltage to the frequency

converter and the converter to the terminal box.

The terminal box is on the outside of the fan casing.

Connection diagrams are inside the box lid.

The cable run must be in accordance with current

regulations, e.g. the EU standard for electromagnetic compatibility (EMC).

Frequency converters must be installed in accordance to the manufacturer’s installation

documentation. Refer also to the Novenco document “Configuration of frequency converters

for Novenco fans”.

Shield and connect the fans electrically to ground to eliminate interference and protect the

motor bearings and windings.

Refer to the motor documentation for methods to avoid impairment of the supply voltage

quality, among them distances between supply and signal cables. Methods may involve

installation of rectifiers, filters etc.

ZerAx fans with

permanent magnet (PM)

motors require connection

through frequency converters.

Direct connection of the supply

voltage in the terminal boxes on

PM motors ruins the motors and

voids the warranty.

Connection references

•Connection diagram in terminal box lid

on fan

•Motor nameplate

•Order specification

•Appendices D, E and F on wiring on

page 28

Verify that the rotational direction of

the rotor complies with the arrow on

the outside of the fan casing. Flick the

fan power briefly On, then Off. If the

direction is wrong, disconnect the

main power supply and check the

connections.

Only fans with steel inner hubs may be run in

reverse and this for short periods at speeds up

to the max. allowable of normal direction. The

airflow is reduced to approx. 50% of normal for the

same system resistance. The pressure is reduced to

25%.

Reversible operation increases the risk of stall and

shortens fan life.

The rotor must be completely stationary, before

restart of the fan for directional change of rotation. It

is recommended to install a time delay for this

purpose.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 12 of 30

5. Start of operation

Fans fitted with frequency converters must have the control unit set up, before start of

operation. Refer to the Novenco document “Configuration of frequency converters for

Novenco fans”.

Perform the below steps every time the fans have been stopped.

5.1 Before start-up

Check the fans and installation location in accordance to the below checklist and correct and

improve as necessary. See also the checklists in the appendices.

Checklist

•Safe operation

The blade clearance must be minimum

0.1x motor shaft diameter (min. 2 mm,

max. 13 mm) all around the rotor

circumference.

The axial distance between the rotor hub

and stator must be min. 3.5 mm.

Wire guards should be mounted on the

inlet and outlet sides.

•Transport rods

Fans on support frames and with

vibration dampers have transport rods in

the support frames, which must be

removed before start of operation. The

handles are marked with a strong colour.

•Clean ducts

The fans and duct connections must be

clean and free from tools and objects that

can affect the airflow.

•Electrical connections

The electrical connections must be

correct and in accordance to the

prescribed requirements. Switch the fan

power briefly On, then Off, to check the

rotational direction of the rotor.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 13 of 30

5.2 Motors with Y/start

Set the relay for start of the fans to the

Start-up time from the technical

specifications from the AirBox

program. Alternatively, calculate the

value with the formula.

The motor torque can vary within the

below limits and affect the start-up

time.

5.3 Start-up procedure

Refer to the motor manual and the technical specifications from theAirBox program for specific

information and procedures.

Start-up procedure

1. Start the fan.

2. Check that no abnormal noises are present.

3. Check that the vibration levels are

acceptable.

See section “6.3 Vibration levels”.

4. Check that the fan operates normally after

30 minutes of operation.

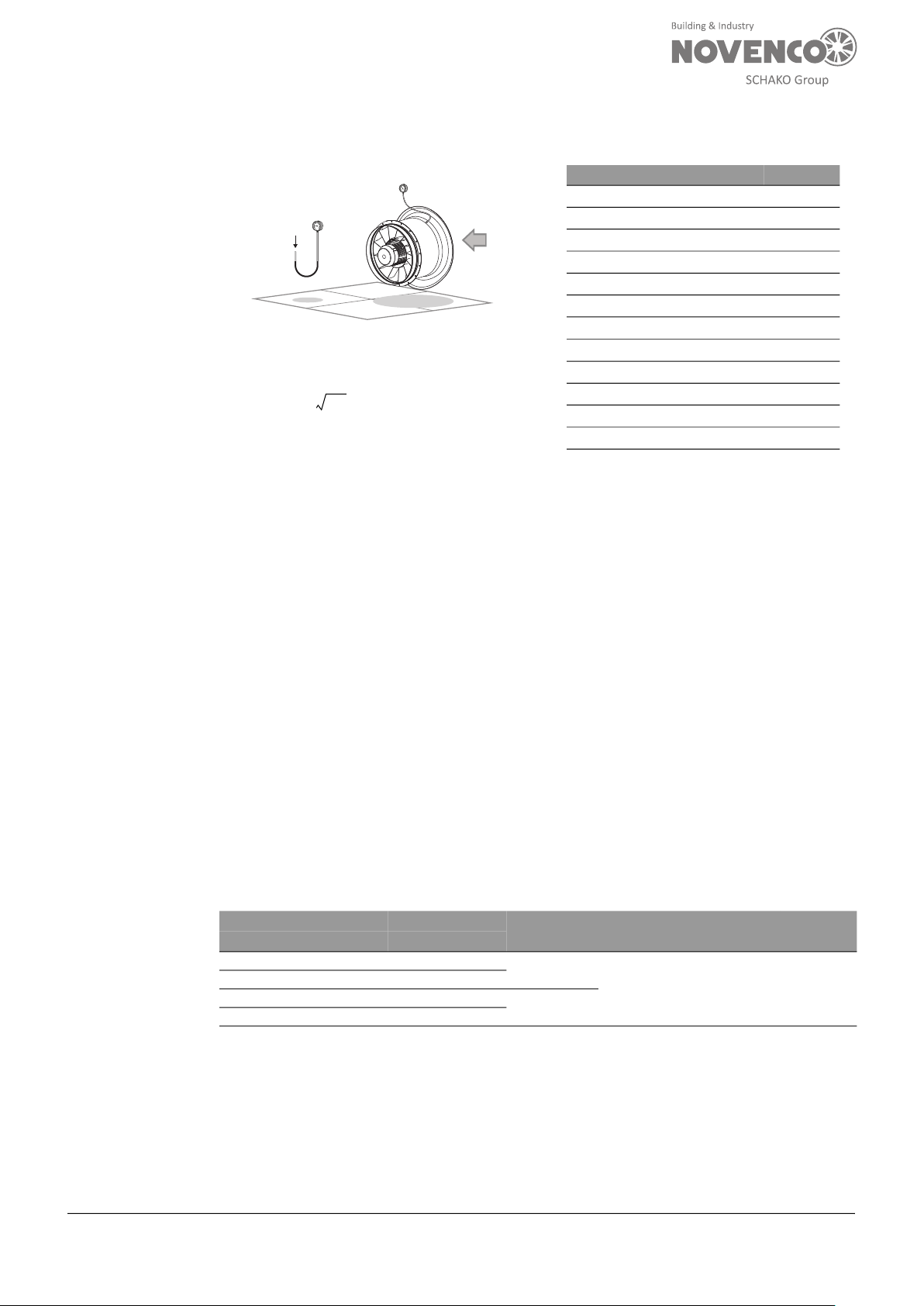

5.4 Air volumes for free inlet fans

For fans with measuring pipes and free inlets, the air volume can be calculated as shown below.

The measuring pipes are optional accessories and fitted close to the fan inlet.

The below formula gives the air volume in m3/s. Multiply by 3,600 to convert to m3/h, or by

Ms: -15% to +25% of

catalogue value

Mk: -10% to 0% of

catalogue value

Calculation of start-up time

ts=

ts: Start-up time [s]

P: Rated output of motor [kW]

Pv: Required power of fan [kW]

n: Fan speed [RPM]

:Ratio between the start and the nominal

motor torque

:Ratio between maximum and nominal

motor torque

Iv: Polar moment of inertia for fan [kgm2]

Im: Polar moment of inertia for motor [kgm2]

0.24 n2ImIv

+

104PMs

M

-------

Mk

M

--------

Pv

P

------–+

-----------------------------------------------------------------

Ms

M

-------

Mk

M

--------

The fans aredesigned for continuous

operation. The below kinds of

operation may cause fatigue breaks

in the rotors and endanger people.

•Operation in stall area, i.e. with

counter pressure that pulsates -

called pump mode

•Operation with uninterrupted

and repeated starts and stops

•Uneven flow velocity through

the fans

Ask Novenco if in doubt.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 14 of 30

2188.88 to convert from m3/s to CFM.

For the fan types AZN and AZW with wire guards, the constant in table 3 must be reduced by

up to 10%. For these fan types without wire guards, the constant is used directly.

For the AZL with wire guards, the constant must be reduced by up to 20%. For this fan type

without wire guards, the constant must be reduced by 10%.

Free inlet cones are integrated on the AZL and is an accessory for the AZN and AZW.

The suction must be directly from the suction chamber.

Fans with low blade angles can make noise at high pressures, which affects the measurement.

Operation close to the stalling area produces poor results also.

6. Maintenance

In the following, please also see “Appendix - G. Checklists”on page 29.

Figure 10.Measurement of pressure

difference

q=

q:Air volume [m3/s]

k:A constant, see table 3.

dps :Difference between paway and pfan

[Pa]

pfan :Static pressure at fan inlet [Pa]

paway :Static pressure away from fan [Pa]

paway

pfan

k dps

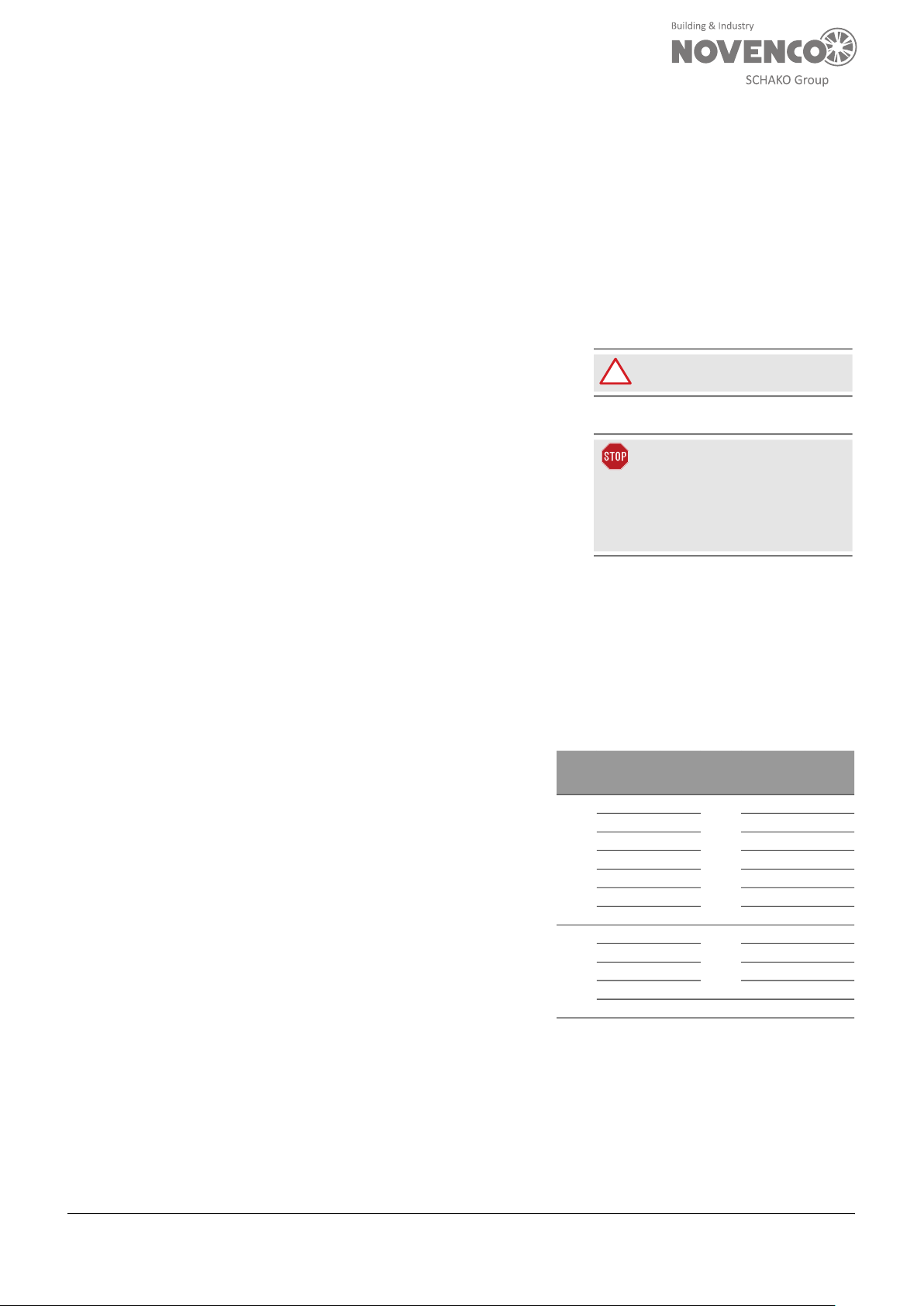

Fan sizes Constant, k Fan sizes Constant, k

250/160 0.0510 900/350 0.7204

280/160 0.0694 1000/350 0.9001

315/160 0.0917 1120/350 1.2019

355/160 0.1183 1250/350 1.5636

400/160 0.1502 1000/560 0.871

450/160 0.1894 1120/560 1.129

500/160 0.2343 1250/560 1.441

500/350 0.1921 1400/560 1.844

560/350 0.2537 1600/560 2.453

630/350 0.3324 1800/560 3.142

710/350 0.4329 2000/560 3.913

800/350 0.5603

Table 3. Constants for calculation of air

volumes for ZerAx fans

Test and

inspection 1

1.The site operator may have set other test intervals. Smoke control fans and other fans, which run infrequently

or in case of emergencies, must be run tested every week, for example during normal operation.

Service and

lubrication 2

2.The motor manufacturer’s recommendations may call for shorter lubrication intervals. See section “6.6 Motors”

on page 16. Please note that fans with permanent magnet motors are lubricated for life.

Cleaning 3

3.Intervals for cleaning depend on the operating conditions and environment. See section “6.2 Cleaning” on page

15.

Bearings

Fan types Bearing types

Standard temperature Sealed for life 6 months

6 months 3 months 3 months

Lubricated

Smoke — Weekly +

6 months

ATEX and EX —

Table 4. Maintenance intervals

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 15 of 30

Repair and maintenance of Novenco fans must be carried out by authorised personnel

and in accordance with Novenco instructions. Keep records signed by the competent

personnel for all services, tests and changes performed.

6.1 Before maintenance

Switch off the power and disconnect the motor cable in the terminal box, before

beginning work on the rotor and motor.

For fans with PM motors, make sure the motor axles cannot rotate during service, e.g.

by blocking the fan rotors. PM motors can generate high voltages when the motor axles rotate,

even though the power is disconnected.

6.2 Cleaning

Clean the fans at least quarterly. The intervals may have to be adjusted, dependent on the

operation and operational conditions. Corrosive and dust filled atmospheres typically shorten

the intervals. Please note that deposits of dust can be ignited by high surface temperatures and

constitute a safety risk.

6.3 Vibration levels

After installation and also in connection with regular

inspection and cleaning, the vibration levels must be

measured and be less than or equal to max. 6.3 mm/s.

Measure the levels at operational fan speed, radially at two

points with a 90° offset and at the free shaft end of the motor.

Fans that exceed the limits usually require cleaning or

balancing of the rotors. Alternatively, the causes must be

investigated and removed. Refer to ISO 14694.

For variable speed fans the vibration level limits are likely

to be exceeded at certain speeds. Continuous operation at

these speeds must be avoided.

6.4 Fan casings

The fan casings require no other maintenance than ordinary cleaning.

Check painted casings regularly and keep them in good condition.

6.5 Rotors

The rotors are carefully balanced and the rotor blades are set at precise angles in the production.

The rotors are thereby optimised for vibration free operation at the desired operation point with

regard to pressure, airflow and fan speed.

Fan vibration levels

depend on installation

type and fan speed.

Vibrationshavesignificanteffect

on fan life and efficiency.

Shut down fans with

vibration levels that

exceed 12.5 mm/s RMS.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 16 of 30

Vibrations that occur in operation may be due to accumulation of dust and dirt on the hubs and

blades. If vibrations persist after cleaning, expert assistance should be called for immediately.

Continued operation with vibrations shorten the life of the fan and motor bearings.

6.6 Motors

Refer to the motor manufacturer’s documentation and the nameplates for how to service the

motors.

Motor maintenance

•Lubricate bearings

Refer to the motor manual for service information such as lubrication intervals, grease

amounts, when to replace bearings etc. Observe differences between motor Drive End (DE)

and Non-Drive End (NDE).

-Permanent magnet motors are lifetime lubricated. Bearings may, however, need

replacement.

-AC motors up to size 132 have lifetime-lubricated

bearings. Motor sizes 160 to 280 require lubrication

according to the manufacturer’s instructions.

Fans with motor sizes 225 to 280 have nipples on the

outer fan casings. For fans with motor sizes 160 to 200,

nipples on the outer fan casings are optional.

Refer to the motor nameplates for recommended

grease type, amount and interval.

•Inspect the motor for wear signs and

damaged parts.

•Clean the motor casing, motor cooling

fan and motor shell.

•Drain the motor of condensed water.

•Check supply cables and electrical

connections for impairments.

•Check terminal box seals and cable

glands.

Use a manual grease

gun for lubrication.

Excess grease causes

bearings to overheat and

results in failure.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 17 of 30

6.7 Motor removal

Switch off the power and disconnect the motor cable in the terminal box, before

beginning work on the rotor and motor.

For fans with PM motors, make sure the motor axles cannot rotate during service, e.g.

by blocking the fan rotors. PM motors can generate high voltages when the motor axles rotate,

even though the power is disconnected.

The below procedure is with reference to figures 12 and 13 beginning on page 26.

Motor removal

1. Dismount any ducts on the inlet and outlet sides.

2. Remove the screws (figure 12, comp. 1) that hold the hub

cap and remove the cap (figure 12, comp. 2).

3. Remove the rotor centre bolt and washers (figure 12,

comp. 3).

4. Fans with hub clips: Remove the hub clip, screws and

washers (figure 12, comp. 4).

5. Dismount the rotor with a puller fastened in the threaded holes of the hub boss (figure 12,

comp. 5). See also figure 13. “Mounting of puller in Ø350 hubs with hub clips” on page 27

6. Disconnect the motor cable from the motor.

7. Support the motor. See the technical fan specifications from the AirBox program.

Motor

size Poles

Lubrication

intervals [hours]

50 Hz 60 Hz

160

2 22000 20000

4

25000 250006

8

180

2 17000 14000

4

25000 250006

8

200

2 15000 12000

4

25000 250006

8

225

250

280

2 5000 4000

4 14000 12000

6 20000 17000

8 24000 20000

2 4000 4000

4 13000 10000

6 18000 16000

8 20000 20000

Table 5. Grease amounts and intervals for WEG

W22 TEFC motors – ball bearings

Motor

size Poles

Lubrication

intervals [hours]

50 Hz 60 Hz

160

2 16000 12000

4

25000 250006

8

180

2 11000 8000

4

25000 250006

8

200

2 9000 6000

4

25000

21000

625000

8

225

250

280

4 11000 9000

6 16000 13000

8 20000 19000

4 9000 7000

6 14000 12000

8 19000 17000

Table 6. Grease amounts and intervals for WEG

W22 TEFC motors – roller bearings

Avoid exposure of fans

and motor parts to

shocks, as these can

result in imbalance and

deformations. Motor bearings

and fan components are

vulnerable parts.

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 18 of 30

8. Detach the motor from the motor shell by removing the nuts and bolts (figure 12, comp. 7a

and 7b) for hub sizes Ø350 and Ø560, or bolts and washers (figure 12, comp. 7b and 7c) for

hub sizes Ø160.

Notice: Access nuts holding motors mounted in rear motor shells through the front motor

shells.

9. Remove the motor (figure 12, comp. 8).

6.8 Mounting of motor

The component numbers in the below procedure refer

to figure 12 on page 26.

Mounting of motor

1. Remount the motor (comp. 8) and make sure the

motor shaft is centred in the fan casing.

A centring tool is available as an accessory from

Novenco.

2. Fans with Ø350 hubs and motor sizes 160 or 180:

These motors are mounted with pins. The pins

must be replaced with new ones when re-

mounting the motors.

3. Insert and tighten the nuts and bolts (comp. 7a and 7b) to the prescribed torques for hub

sizes Ø350 and Ø560, or bolts and washers (comp. 7b and 7c) for hub sizes Ø160. See table 9

on page 26.

Notice: Access nuts holding motors mounted in rear motor shells through the front motor

shells.

4. Mount the rotor (comp. 6) on the motor shaft with a tool fastened in the threaded hole of

the motor shaft. The rotor hub must rest against the motor shaft collar.

5. Use a feeler gauge to check that the blade tip

clearance between the rotor blade tips and

fan casing is the same throughout the

circumference.

6. Adjust the motor position. See step 5.

7. Mount the centre washers and bolt (comp.

3).

8. Fans with hub clips: Mount the hub clip,

screws and washers (comp. 4).

9. Mount the hub cap (comp. 2) and screws

(comp. 1).

10. Connect the motor cable to the motor and the

power cables in the terminal box.

11. Reconnect any ducts.

Follow the procedure in section “5. Start of operation”to start the fan.

Replace lock washers and nuts

during assembly.

Consult Novenco if the

replacement motor weight

exceeds the original

specifications. Refer to the technical

specifications from the AirBox

program.

Hub,

[mm]

Rotor,

ØD [mm]

Min.

[mm]

Hub,

[mm]

Rotor,

ØD [mm]

Min.

[mm]

Ø160

250 0.5

Ø560

1000 0.8

280 0.5 1120 0.9

315 0.5 1250 1.0

355 0.5 1400 1.1

400 0.5 1600 1.3

450 0.5 1800 1.4

500 0.5 2000 1.6

Ø350

500 0.5

Ø350

900 0.9

560 0.6 1000 1.0

630 0.6 1120 1.1

710 0.7 1250 1.3

800 0.8

Table 7. Blade tip clearances at standard

temperatures

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 19 of 30

6.9 Blade angles

The fan rotor blade angles are the result of careful calculations to achieve a specific and

sometimes delicate point of operation. The mount on the hub and balancing are therefore

closely related to the angles and cannot be changed. Please contact Novenco for further

information.

7. Troubleshooting

Check for the below faults in case of breakdowns or lack in

performance. Call for service, if problems persist.

8. Inspection and test

It is recommended to test and inspect the fans at regular intervals with regard to operability

and operation conditions.

Inspect the fans twice a year to ensure satisfactory function and long product life. Fans with

inspection hatches allow for inspection through these.

Extent of inspection

Novenco recommends keeping a log of all values and observations regarding the fans.

Lack in performance

•Blocked

- Inlets

- Outlets

- Dampers

•Supply air reduced

•Motors defective

•Motors disconnected

•Wrong fan rotation direction

Noises and vibrations

•Motor bearings defective

•Rotors out of balance

•Rotors damaged or worn

•Bolts or components loose

•Wrong rotor blade pitch angles

Fans that operate in the

stall area are more likely

break down.

•Measure power consumption

•Verify torques of fixation bolts

•Cleaning

- inside with pressurised air

- outside with a lint-free cloth witha mild

soapy water solution

•Visual inspection

- Rotors

- Fan casings

- Electrical connections

Novenco ZerAx axial fan types AZL-AZN-AZW – Installation and maintenance 20 of 30

9. Sound

The sound emissions depend on the installation and operation conditions, hence no general

data can be given.

Refer to the technical specifications from the AirBox calculation program for specific emissions

and to the product catalogue for more general data.

10. Safety

The installation must be in accordance to Novenco’s, the current and the local safety

regulations. At a minimum these include EN 13850.

It is recommended to review and revise safety procedures regularly.

11. Reference documentation

Please refer to the below documents for further information about the fans.

12. Disposal

Dispose of fans suitable for scrapping in environmentally safe ways and in accordance to

current regulations.

The fans and especially the electric motors contain recyclable materials. Make sure worn-out

motors and fan parts are disassembled and recycled for the benefit of the environment.

•Test if safety procedures and the

installation work correctly.

•Check for changes in safety regulations

and revise the installation accordingly.

•Consider additional measures to

improve the safety of the installation.

Safety check

•Catalogue

ZerAx axial flow fans standard, ATEX

and EX

•Novenco configuration user guide

Frequency converter Danfoss FC101

•Technical specifications

Table of contents

Other NOVENCO Fan manuals

NOVENCO

NOVENCO AUO 290 Instruction Manual

NOVENCO

NOVENCO RS35x-CX0-E series User manual

NOVENCO

NOVENCO CNA Series Instruction Manual

NOVENCO

NOVENCO NOVAX ACN-ACW-ARN Instruction Manual

NOVENCO

NOVENCO Novax Instruction Manual

NOVENCO

NOVENCO Novax ACP Series Instruction Manual

NOVENCO

NOVENCO FALKINN ACN Instruction Manual

NOVENCO

NOVENCO ACP Series Instruction Manual

Popular Fan manuals by other brands

Sulion

Sulion BOMBAY L 1694604 instructions

Airflow

Airflow iCONstant T user manual

Ebmpapst

Ebmpapst S3G560-AP68-21 operating instructions

Ellington

Ellington WOD52ABZ5PC1 installation guide

Stelpro

Stelpro ULTRA QUIET Series installation guide

PAC

PAC PAC-350WM Installation, operation & maintenance instructions