Metal-Fach ecoMAX860P TOUCH User manual

Boiler controller

ecoMAX860P TOUCH

FOR AUTOMATIC SOLID FUEL FIRED BOILERS WITH INGITION

(GUTTER AND RETORT FEEDERS), execution: ecoMAX920P1-T

INSTRUCTION INSTALLATION AND OPERATING MANUAL

ISSUE: 1.0

APPLIES TO SOFTWARE:

MODULE A

PANEL

v01.XX.XX

v.01.XX.XX

ecoSTER TOUCH**

ecoNET300**

functions available in the

additional module B

** room panel ecoSTER TOUCH and internet module ecoNET300 - not the standard equipment of the

controller.

02-2017

ecoNET.apk

www.econet24.com

TABLE OF CONTENTS

1 SAFETY REQUIREMENTS ..................................... 4

2 GENERAL INFORMATION .................................... 5

3 INFORMATION ABOUT DOCUMENTATION......... 5

4 STORAGE OF DOCUMENTATION......................... 5

5 APPLIED SYMBOLS .............................................. 5

6 DIRECTIVE WEEE 2012/19/UE............................. 5

INSTRUCTION MANUAL ............................................... 7

7 STRUCTURE –MAIN MENU................................. 8

8 OPERATING THE REGULATOR ............................. 9

8.1 DESCRIPTION OF DISPLAY MAIN WINDOW ................. 9

8.2 SWITCHING ON/OFF THE BOILER............................ 10

8.3 SETTINGS PRESET TEMPERATURE..................... 10

8.4 FIRING UP...................................................... 10

8.5 OPERATION ....................................................... 10

8.6 REGULATION MODE.......................................... 10

8.7 SUPERVISION ................................................ 11

8.8 BURNING OFF................................................ 11

8.9 STANDSTILL ................................................... 11

8.10 DOMESTIC HOT WATER SETTINGS HUW................. 11

8.11 SETTING HUW PRESET TEMPERATURE................... 12

8.12 HUW CONTAINER HYSTERESIS.............................. 12

8.13 HUW CIRCULATION ........................................... 12

8.14 ENABLING THE SUMMER FUNCTION .................... 12

8.15 DISINFECTION HUW CONTAINER .......................... 12

8.16 MIXER CIRCUITS SETTINGS ................................... 12

8.17 WEATHER CONTROLLED ...................................... 13

8.18 DESCRIPTION OF NIGHT TIME DECREASE SETTINGS .... 14

8.19 FUEL LEVEL SETUP .............................................. 15

8.20 INFORMATION................................................... 15

8.21 MANUAL CONTROL ............................................ 15

8.22 GRATE ............................................................. 15

8.23 FAVOURITE MENU.............................................. 16

8.24 ROOM PANEL ECOSTER TOUCH.......................... 16

8.25 INTERNET MODULE............................................. 16

INSTALLATION AND SERVICE SETTINGS ..................... 17

9 HYDRAULIC DIAGRAMS..................................... 18

10 TECHNICAL DATA .............................................. 21

11 STORAGE AND TRANSPORT CONDITIONS......... 21

12 REGULATOR INSTALLATION .............................. 21

12.1 ENVIRONMENTAL CONDITIONS ............................. 21

12.2 MOUNTING REQUIREMENTS................................. 21

12.3 MODULE INSTALLATION ...................................... 21

12.4 IP PROTECTION RATE .......................................... 22

12.5 ELECTRIC CONNECTION........................................ 22

12.6 CONNECTION OF TEMPERATURE SENSORS ............... 26

12.7 CONNECTING WEATHER SENSOR ........................... 26

12.8 CONNECTING EXHAUST SENSOR ............................ 26

12.9 CHECKING TEMPERATURE SENSORS........................ 27

12.10 CONNECTION OF MIXERS ROOM THERMOSTAT ......... 27

12.11 CONNECTION OF BOILER'S ROOM THERMOSTAT ....... 28

12.12 CONNECTION OF RESERVE BOILER.......................... 28

12.13 CONNECTION OF ALARM SIGNALING....................... 29

12.14 CONNECTION OF MIXER....................................... 30

12.15 CONNECTING TEMPERATURE LIMITER STB .............. 30

12.16 DS INPUT ......................................................... 30

12.17 CONNECTING ROOM PANEL.................................. 30

12.18 SOFTWARE UPDATE ............................................ 31

13 SERVICE MENU.................................................. 32

14 SERVICE SETTINGS............................................. 34

14.1 BURNER .........................................................34

14.2 BOILER ...........................................................35

14.3 CH AND HUW ..................................................36

14.4 BUFFER ..........................................................37

14.5 MIXER ............................................................37

14.6 OTHER PARAMETRES .....................................38

15 ALARM DESCRIPTION ........................................40

15.1 MAX.BOILER TEMP.EXCESS..................................40

15.2 EXCEEDING MAX.FEEDER TEMPERATURE .................40

15.3 FAULTY FUEL FEEDING SYSTEM ..............................40

15.4 BOILER TEMP.SENSOR DAMAGED ..........................40

15.5 FEEDER TEMP.SENSOR DAMAGED..........................40

15.6 EXHAUST SENSOR TEMP.DAMAGED .......................40

15.7 UNSUCCESSFUL FIRING UP ATTEMPT .......................41

15.8 EXHAUST TEMPERATURE NOT MET.CHECK FUEL QUALITY

.......................................................................41

15.9 BOILER OVERHEATING STB, OPEN CONTACT.............41

15.10 MAX EXHAUST TEMPERATURE EXCEEDED.SENSOR

DAMAGE DANGER!..............................................41

15.11 NO COMMUNICATION .........................................41

15.12 UNSUCCESSFUL ATTEMPT OF BUFFER LOADING .........41

15.13 NO POWER SUPPLY .............................................41

15.14 FAN OR FAN SPEED SENSOR DAMAGED ....................41

16 ADDITIONAL FUNCTIONS...................................42

16.1 POWER SUPPLY DECAY.........................................42

16.2 ANTI-FREEZING PROTECTION.................................42

16.3 FUNCTION OF PROTECTING PUMPS AGAINST

STAGNATION .....................................................42

16.4 FEEDER BUNKER .................................................42

17 REPLACEMENT OF PARTS AND COMPONENTS .42

17.1 REPLACEMENT OF MAINS FUSE ..............................42

17.2 REPLACEMENT OF CONTROL PANEL ........................42

17.3 LAMBDA SENSOR ................................................42

4

1Safety requirements

Requirements concerning safety are

described in detail in individual chapters of

this manual. Apart from them, the following

requirements should in particular be

observed.

Before starting assembly, repairs or

maintenance, as well as during any

connection works, please make sure

that the mains power supply is

disconnected and that terminals and

electric wires are devoid of voltage.

After the regulator is turned off using

the keyboard, dangerous voltage still

can occur on its terminals. The

regulator cannot be misused.

The regulator is designed to be

enclosed.

Additional automatics which protect

the boiler, central heating (CH)

system, and domestic hot water

system against results of malfunction

of the regulator, or of errors in its

software, should be applied.

Choose the value of the programmed

parameters accordingly to the given

type of boiler and fuel, taking into

consideration all the operational

conditions of the system. Incorrect

selection of the parameters can cause

malfunction of the boiler (e.g.

overheating of the boiler, the flame

going back to the fuel feeder, etc.),

The regulator is intended for boiler

manufacturers. Before applying the

regulator, a boiler manufacturer

should check if the regulator’s mating

with the given boiler type is proper,

and whether it can cause danger.

The regulator is not an intrinsically

safe device, which means that in the

case of malfunction it can be the

source of a spark or high

temperature, which in the presence of

flammable dusts or liquids can cause

fire or explosion. Thus, the regulator

should be separated from flammable

dusts and gases, e.g. by means of an

appropriate body.

The regulator must be installed by a

boiler manufacturer in accordance

with the applicable safety standards.

The programmed parameters should

only be altered by a person

familiarized with this manual.

The device should only be used in

heating systems in accordance with

the applicable regulations.

The electric system in which the

regulator operates must be protected

by means of a fuse, selected

appropriately to the applied loads.

The regulator cannot be used if its

casing is damaged.

In no circumstances can the design of

the regulator be modified.

In the regulator there is applied

electronic disconnection of connected

devices (2Y type of operation

according to PN-EN 60730-1) as well

as micro-disconnection (2B type of

operation according to PN-EN 60730-

1).

Keep the regulator out of reach of

children.

5

2General information

Boiler regulator ecoMAX860P TOUCH is a

modern electronic device intended to control

boiler operation with automatic feeding of

solid fuel and with the ignitors. Flame is

detected via the exhaust temperature

sensor.

The regulator is a multipurpose device:

it automatically maintains a preset boiler

temperature by controlling the fuel

combustion process,

it controls timing fuel feeder and fan

(modulating its power),

it automatically stabilizes a preset

temperature of the domestic hot water

container,

it automatically maintains preset

temperature of several independent

mixer heating cycles.

The preset temperature of heating cycles and

the boiler can be set on the basis of a

weather sensor readouts.

The device includes the control panel with

horizontal regulation of its position, the main

operating unit and optional modules to

control additional heating circuits.

The regulator can cooperate with an

additional room panel ecoSTER TOUCH

situated in living quarters and module for the

web WiFi ecoNET300.

It can be used in a household and similar

facilities, as well as in lightly industrialized

facilities.

3Information about documentation

The regulator manual is a supplement for the

boiler manual. In particular, except for this

manual, the boiler manual should also be

observed. The regulator manual is divided

into two parts: for user and fitter. Yet, both

parts contain important information,

significant for safety issues, hence the user

should read both parts of the manual.

We are not responsible for any damages

caused by failure to observe these

instructions.

4Storage of documentation

This assembly and operation manual, as well

as any other applicable documentation,

should be stored diligently, so that it was

available at any time. In the case of removal

or sale of the device, the attached

documentation should be handed over to the

new user / owner.

5Applied symbols

In this manual the following graphic symbols

are used:

- useful information and tips,

- important information, failure to

observe these can cause damage of

property, threat for human and

household animal health and life.

Caution: the symbols indicate important

information, in order to make the manual

more lucid. Yet, this does not exempt the

user from the obligation to comply with

requirements which are not marked with a

graphic symbol.

6Directive WEEE 2012/19/UE

Act on electrical and electronic

equipment.

Recycle the product and the packaging at

the end of the operational use period in

an appropriate manner.

Do not dispose of the product together

with normal waste.

Do not burn the product.

6

INSTRUCTION MANUAL

ecoMAX 860P TOUCH

8

7STRUCTURE –MAIN MENU

Boiler settings

Preset boiler temperature

Weather control the boiler*

Boiler heating curve*

Curve shift*

Room temperature factor*

Output modulation

Max. boiler output

100%% Blowing power

100%% Blow-in

100% Oxygen*

50% Hysteresis H2

Boiler medium power

50% Blowing power

50% Blow-in

50% Oxygene*

30% Hysteresis H1

Minimum boiler output

30% Blowing power

30% Blow-in

30% Oxygene*

Blow firing grate*

Boiler hysteresis

Feeding correction

Minimum boiler output FL

Maximum boiler output FL

Heat source

Burner

Grate

Reserve boiler*

Regulation mode:

Standard

FuzzyLogic

Max kW

Avg kW

Min kW

Fuel selection

Fuel level

Alarm level

Calibration of fuel level

Lambda sonde calibration*

Scheduled

On

Reduction value

Schedule

HUW settings

HUW preset temperature

HUW pump mode

Off

Priority

No priority

HUW container hysteresis

HUW disinfection

Schedule - HUW

On [No/Yes]

Reduction value

Schedule

Schedule - circulation pump*

Mixer 1-4 settings*

Preset mixer temperature

Mixer room thermostat

Mixer weather control*

Heating curve mixer*

Curve translation*

Room temperature factor*

Schedule

On [No/Yes]

Reduction value

Schedule

Summer/Winter

SUMMER mode

Winter

Summer

Auto*

SUMMER mode act. temperature

SUMMER mode deact. temperature

General settings

Clock

Date

Screen brightness

Sound

Language

Software update*

WiFi settings*

* unavailable if no adequate sensor or

additional module is connected or the

parameter is hidden.

Main menu

Information

Boiler settings

HUW settings*

Summer/Winter

Mixer 1-4 settings*

General settings

Manual control

Alarms

Services settings

9

8Operating the regulator

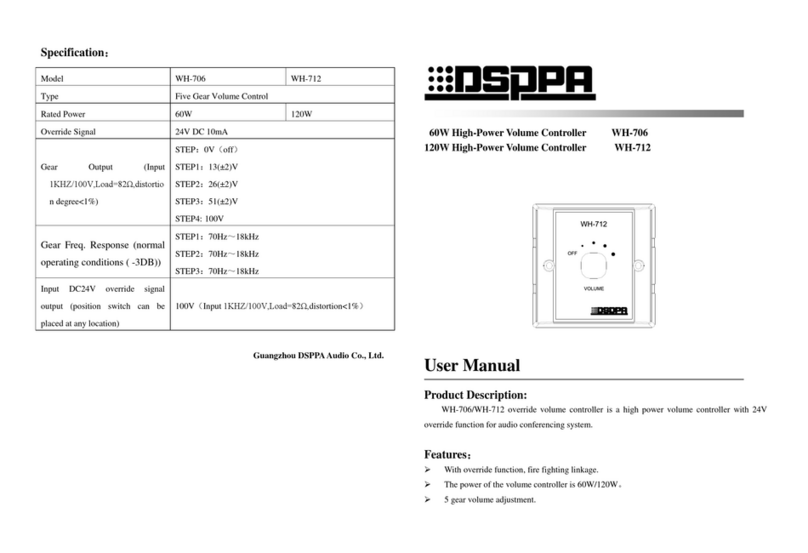

8.1 Description of display main window

1. mode of regulator operation: FIRING UP,

OPERATION, SUPERVISION BURNING

OFF, STANDSTILL

2. preset boiler temperature

3. measured boiler temperature

4. key to enter ’’Menu” list

5. Information field:

fan

feeder

pumps

igniter

6. measured temperature of HUW container

7. preset temperature of HUW container

8. clock time and weekday

9. outside temperature (weather)

10. field of functions, which modify preset

temperature -meaning of the symbols:

- opening of room thermostat contacts

–preset room temperature has been

reached,

- of preset boiler temperature for

active time intervals,

- increase of preset boiler temperature

for the time of HUW container filling,

- increase of preset boiler temperature

by mixer circuit,

- increase of preset temperature for

buffer loading,

- operation mode –grate,

- work on the reserve boiler (gas- or oil-

).

Both, left and right window may

display different information. By

touching the screen, user may

navigate between displayed

information: mixer circuits

information window, HUW window,

fuel level window.

Fuel level may be displayed on ecoSTER

TOUCH room control panel.

OPERATION

THU

10

8.2 Switching on/off the boiler

Make sure fuel is present in the tank and

tank hatch is closed. Now boiler may be

switched on. To start the boiler - press

BURNER OFF? at any place on the screen.

The message: „Active regulator?”appears.

Confirm the message. Boiler enters firing-up

stage.

There is also another method of boiler start-

up. Press MENU button and find and press

button in pie menu.

To stop the boiler - press MENU button, and

find and press button in pie menu.

8.3 Settings preset temperature

Preset boiler temperature or preset HUW

temperature, just like the preset mixer

circuit temperature, can be set in the menu:

Boiler settings →Preset boiler temp.

HUW settings →HUW preset temp.

Mixer 1-4 settings →Preset mixer temp.

The value set as Preset boiler temp. is

ignored by the regulator if the preset boiler

temperature is controlled by weather sensor.

Regardless of that, the preset boiler

temperature is automatically increased in

order to fill the hot utility water tank and

feed heating mixer cycles.

8.4 FIRING UP

The FIRING UP mode is used for automatic

firing up of furnace in the boiler.

All parameters which influence the firing-up

process can be found in menu:

Service settings →Burner settings →

Firing up

If firing up the furnace fails, further attempts

are carried. Consecutive attempts are

visualised by numbers next to the lighter

symbol .

After three unsuccessful attempts, an alarm

Failed firing up attempt is reported. In such

case, the boiler operation is halted. Boiler

operation cannot be continued automatically

- service crew must intervene. After

removing causes of impossibility to fire up,

the boiler must be restarted.

8.5 OPERATION

The fan operates continuously. Fuel feeder is

activated cyclically. A cycle consists of feeder

operation time and duration of feeding

interval

Parameters related with the Operation mode

are: Feeder operation time and Fan output

in:

Boiler settings →Output modulation

8.6 Regulation mode

There are two regulation modes for

stabilizing the set temperature of the boiler:

Standard and FuzzyLogic

Boiler settings →Regulation mode

Operating in Standard Mode

When the boiler temperature reaches its set

value, the regulator switches to

SUPERVISION mode.

The regulator has a boiler output modulation

mechanism allowing it to gradually reduce

the output as the boiler temperature nears

its set value

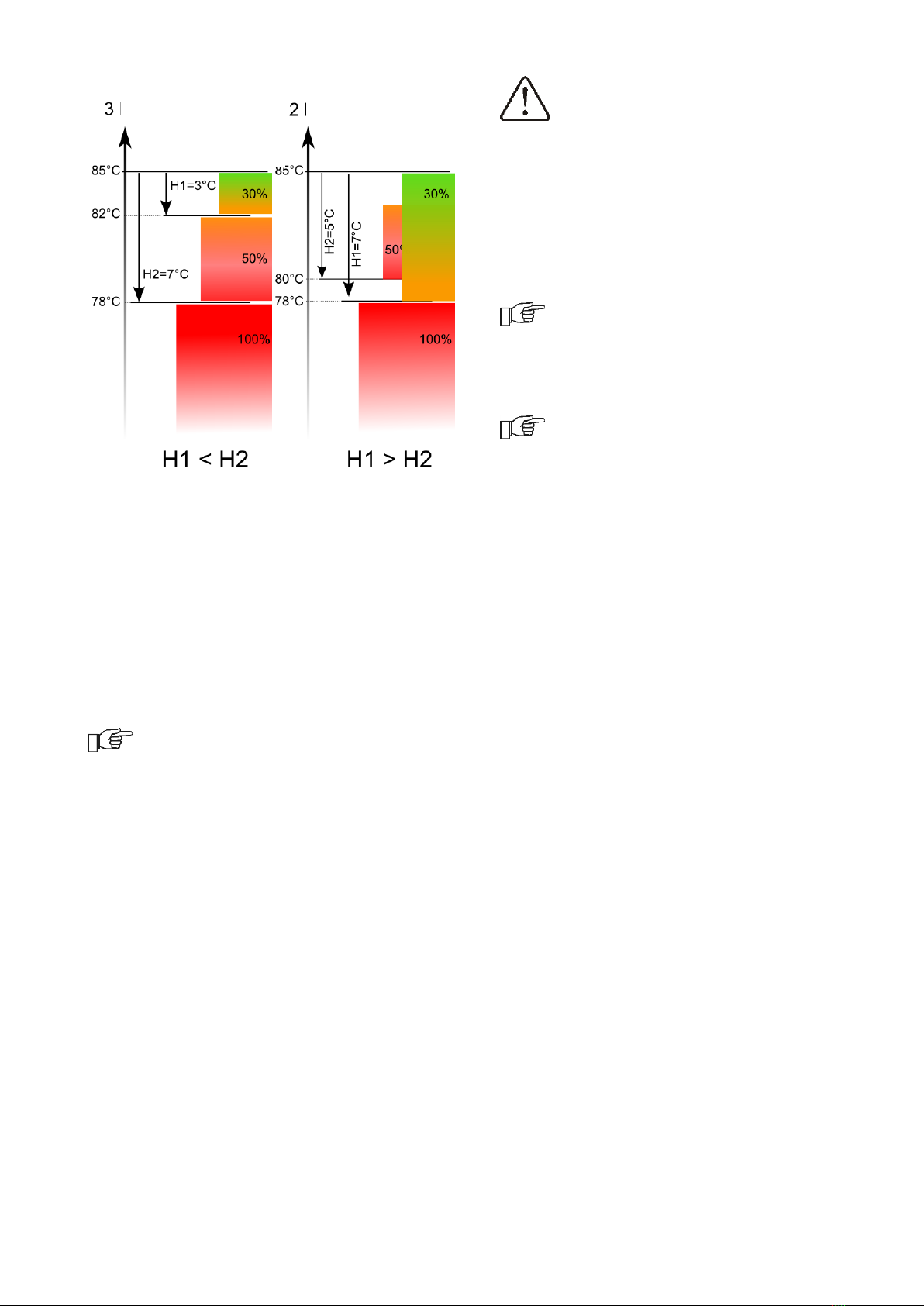

Three boiler output levels can be set:

maximum, medium, and minimum. Each

level can be additionally adjusted with

individual fuel feeding times and fan speeds,

affecting the actual output of the boiler. The

output level parameters are accessible

through the menu

Boiler Settings →Output modulation.

The regulator sets the current output of the

burner depending on the set temperature of

the boiler and H1 and H2 hysteresis settings

It is possible to set the H1 and H2 values to

modulate the output withouth the medium

power stage, ie. reducing output from 100%

11

to 30%, skipping the 50% output (right side

of the figure below).

Operating in FuzzyLogic mode

In FuzzyLogic mode, the regulator

automatically sets the output of the burner in

order to maintain the set boiler temperature.

The regulator uses the output settings

predefined in Standard mode. This mode

does not require setting the H1 and H2

hysteresis.

Note: If only the HUW is heated

(summer mode), it is recommended

to set the regulator to Standard

mode.

After the set temperature is exceeded by

5ºC, the boiler switches to SUPERVISION

mode.

8.7 SUPERVISION

In SUPERVISION mode, the fan and the

feeder are switched on cyclicall at larger

intervals than in OPERATION mode. This is to

prevent the fire from being extinguished.

Supervision parameters can be found in

menu:

Service Settings →Burner Settings →

Supervision

SUPERVISION parameters should be set in

accordance with the recommendations of the

boiler or burner manufacturer. The

parameters should be adjusted to prevent

the furnace from extinguishing during

intervals.

Parameters should be so selected

that the boiler temperature in this

mode gradually drops. Incorrect

settings may lead to boiler

overheating.

When the supervision time expires, the

regulator switches to BURNING OFF mode,

unless the boiler temperature decreases and

the boiler automatically switches to

OPERATION mode.

For the setting Supervision time =

0, the regulator skips the

SUPERVISION mode and enters the

BURNING-OFF mode.

When the Supervision time = 255,

the regulator will work continuously

in SUPERVISION mode, until the

boiler temperature decreases and it

automatically switches to

OPERATION mode.

8.8 BURNING OFF

The extinguishing process does not occur

when coal is the fuel of choice. When pellets

are the fuel, they are burned off for several

minutes (depending on the set time). After

BURNING OFF, the regulator switches to

STANDSTILL.

8.9 STANDSTILL

In the STANDSTILL mode, the boiler is put

out and awaits signal to resume heating.

A signal to start heating can be:

decrease in preset boiler temperature

below the preset temperature minus the

value of boiler hysteresis Boiler hysteresis,

if the boiler is set to work with a buffer -

decrease in upper buffer temperature

below the preset value Buffer loading start

temperature.

8.10 Domestic hot water settings

HUW

The device controls temperature of the

domestic how water - HUW –tank, provided

that a HUW temperature sensor is

connected. If the sensor is disconnected, an

information about lack thereof is displayed in

the main window. The parameter:

Menu →HUW settings →HUW pump

mode allows the user to:

disable filling of the tank, parameter Off,

Power levels

Power levels

Preset

temperature T=85°C

Preset

temperature T=85°C

12

set HUW priority, using the Priority

parameter - in this case, the CH pump is

deactivated to speed up filling of the

HUW tank.

set simultaneous operation of the CH and

HUW pump, using parameter No priority.

8.11 Setting HUW preset

temperature

Preset HUW temperature is defined by

parameter:

HUW settings →HUW preset temp.

8.12 HUW container hysteresis

Below HUW preset temp. –HUW container

hysteresis starts HUW pump to load the HUW

container.

After setting a low hysteresis value,

HUW pump will run faster when

HUW temperature falls.

8.13 HUW circulation

The settings can be found in:

HUW Settings → Schedule - circulation

pumps

and

Service settings → CH and HUW settings

Setting of circulating pump control is

analogical to night decrease setting.

Circulating pump switches on in selected

time intervals. In disregarded time intervals

circulating pump will start and remain in

operation for the period of time set in

Circulating pump operation time , then will

stop and remain out of operation for the

period of time set in Circulating pump

standstill time.

8.14 Enabling the SUMMER function

In order to activate the SUMMER function,

which enables to load the HUW tank in the

summer, without the need for activating the

CH system and mixer cycles, set the

parameter SUMMER mode to Summer.

Summer/Winter →SUMMER mode

In Summer mode, all heat

receivers may be shut off, so

before enabling it please make

sure that the boiler does not

overheat.

If the weather sensor is connected SUMMER

function can be activated automatically with

the Auto parameter including settings for

SUMMER mode act. temperature, SUMMER

mode deact. temperature.

8.15 Disinfection HUW container

The regulator has a function of automatic,

periodic heating of HUW container to 70°C to

eliminate bacterial flora from the HUW

container.

Keep the tenants informed of

activating the disinfection function

as there is risk of being burnt with

hot usable water.

The regulator increases the HUW container

temperature once a week, at 2:00 a.m.

Monday. After 10 minutes of maintaining the

temperature at 70°C, the HUW pump is

switched off and the boiler returns to normal

operation. Do not activate the disinfection

function when the HUW support is off.

8.16 Mixer circuits settings

Settings for the first mixer circuit can be

found in the menu: Mixer 1 settings

Settings for other mixers can be accessed in

next menu items and they are identical for

each circuit.

Settings for mixer without weather

sensor

It is necessary to manually set the required

water temperature in the heating mixer

circuit using parameter Preset mixer temp.,

e.g. at a value of 50°C. The value should

allow to obtain the required room

temperature.

After connecting room thermostat, it is

necessary to set a value of decrease in

preset mixer temperature by thermostat

(parameters Mixer room therm.) e.g. at 5°C.

This value should be selected by trial and

error. The room thermostat can be a

traditional thermostat (NO-NC), or room

panel ecoSTER TOUCH. Upon activation of

the thermostat, the preset mixer circuit

temperature will be decreased, which, if

proper decrease value is selected, will stop

growth of temperature in the heated room.

13

Settings for mixer with weather sensor

without room thermostat ecoSTER

TOUCH

Set parameter Mixer weather control to On.

Select weather curve. Using parameter

Curve translation, set preset room

temperature following the formula:

Preset room temperature = 20°C + heating

curve translation.

In this setup, it is possible to connect a room

thermostat which will equalize the inaccuracy

of selecting heating curve, if the selected

heating curve value is too high. In such case,

it is necessary to set the value of preset

mixer temperature decrease by thermostat,

e.g. at 2°C. After opening of the thermostat

contacts, the preset mixer circuit

temperature will be decreased, which, if

proper decrease value is selected, will stop

growth of temperature in the heated room.

Settings for mixer with weather sensor

and with room thermostat

Set parameter Mixer weather control to On.

Select weather curve. The room panel

automatically translates the heating curve,

depending on the preset room temperature.

The regulator relates the setting to 20°C,

e.g. for preset room temperature = 22°C,

the regulator will translate the heating curve

by 2°C, for preset room temperature = 18°C,

the regulator will translate the heating curve

by -2°C. In some cases it may be necessary

to fine-tune the heating curve translation.

In this setup, the ecoSTER TOUCH room

thermostat can:

- decrease the heating cycle temperature by

a constant value when the preset room

temperature is reached. Analogously, as

specified in the previous point (not

recommended), or

- automatically, continuously correct the

heating cycle temperature.

It is not recommended to use both options at

the same time.

Automatic correction of room temperature is

carried out in accordance with the following

formula:

Correction = (Preset room temperature -

measured room temperature) x room

temperature coefficient /10

Example:

Preset temperature in the heated room (set

at ecoSTER TOUCH) = 22°C. Temperature

measured in the room (by ecoSTER TOUCH)

= 20°C. Room temp. factor. = 15.

Preset mixer temperature will be increased

by (22°C - 20°C) x 15/10 = 3°C.

It is necessary to find appropriate value of

the Room temp. factor. The higher the

coefficient, the greater the correction of

preset boiler temperature. If the setting is

“0”, the preset mixer temperature is not

corrected. Note: setting a value of the room

temperature coefficient too high may cause

cyclical fluctuations of the room temperature!

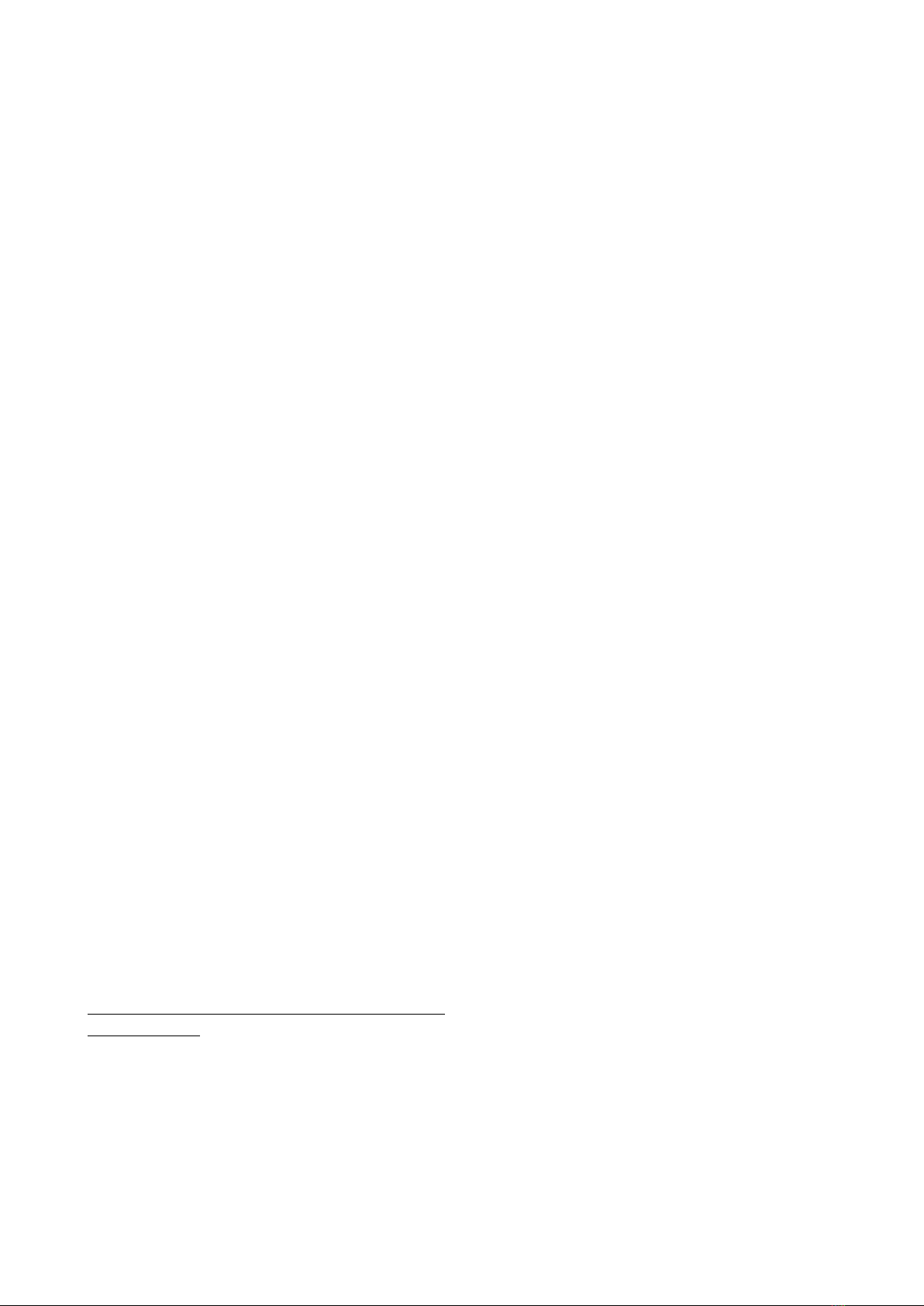

8.17 Weather controlled

Depending on the temperature measured

outside the building, both preset boiler

temperature and temperatures of mixer

circuits can be controlled automatically. If

proper heating curve is selected, the

temperature of the circuits is calculated

automatically, depending on the outdoor

temperature. Thus, if the selected heating

curve is appropriate for the given building,

the room temperature stays more or less the

same, regardless of the temperature outside.

Note: during trial and error selection of

appropriate heating curve, it is necessary to

exclude influence of the room thermostat on

regulator operation (regardless of whether

the room thermostat is connected or not), by

setting the parameter:

Mixer 1 settings →Mixer room therm. =

0.

If a room panel ecoSTER TOUCH is

connected, it is also necessary to set the

parameter Room temperature factor = 0.

Guidelines for proper setting of the heating

curve:

floor heating 0,2 -0,6

radiator heating 1,0 - 1,6

boiler 1,8 - 4

14

Guidelines for selection of appropriate

heating curve:

- if the outdoor temperature drops, and the

room temperature increases, the selected

heating curve value is too high,

- if the outdoor temperature drops, and the

room temperature drops as well, the selected

heating curve value is too low,

- if during frosty weather the room

temperature is proper, but when it gets

warmer - it is too low, it is recommended to

increase the Curve translation and to select a

lower heating curve,

- if during frosty weather the room

temperature is too low, and when it gets

warmer - it is too high, it is recommended to

decrease the Curve translation and to select

a higher heating curve.

Buildings with poor thermal insulation require

higher heating curves, whereas for buildings

which have good thermal insulation, the

heating curve can have lower value.

The regulator can increase or decrease the

preset temperature, calculated in accordance

with the heating curve, if it exceeds the

temperature range for the given circuit.

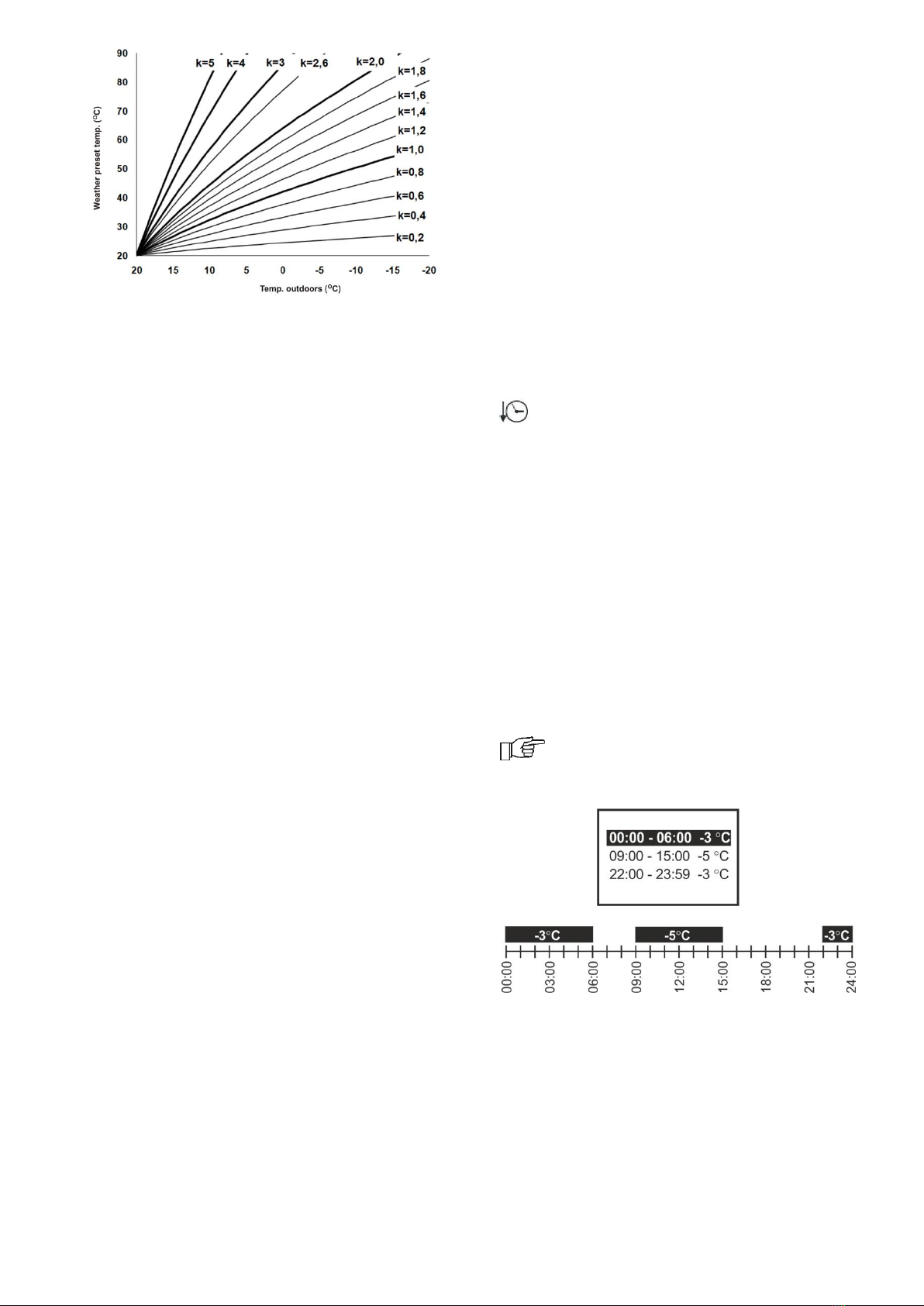

8.18 Description of night time decrease

settings

Night time decreases for boiler, heating

circuits, HUW container and circulation

pump operation.

The intervals can be used to define time

periods at which lower preset temperature

may be set e.g. for a night time or when the

user is not at home. This feature enables

automatic reduction of preset temperature

without compromising the heat comfort and

reduces fuel consumption.

Decrease of preset temperature in selected

time intervals is indicated by the symbol:

on the main screen.

To activate time intervals, set the parameter

Schedule for boiler or for the given heating

circuit to ON.

The parameter Reduction value set the

temperature reduction, one for all time

intervals.

Night time decreases can be defined

separately for every day of the week set

Schedule.

The example of night time decrease of preset

temperature from 22:00 to 06:00 next day

and from 09:00 to 15:00 is given below.

Note! Setting of time intervals for

24 hours (one day) should start

from 00:00!

In the given example, the regulator will set

the decrease of preset temperature by 3°C

from 00:00 to 06:00, and will keep the

preset value (without the decrease) from

06:00 to 09:00. Then, it will set the decrease

by 5°C from 09:00 to 15:00, and will keep

the preset value (without the decrease)

again from 15:00 to 22:00; and again will

15

set the decrease by 3°C from 22:00 to

23:59.

Time interval is disregarded when

its decrease is set to "0" even

though "from... to ..." values have

been entered.

8.19 Fuel level setup

Activating the fuel level gauge

In order to enable display of the fuel level,

set value of parameter

Boiler settings →Fuel level →Alarm level

to a value greater than zero, e.g. 10%. By

pressing the right or left box in the main

window you can select the fuel level

indicator. Fuel level can also be displayed on

the ecoSTER TOUCH room panel.

Operation of fuel level indicator

Any time upon filling fuel tank, press and

hold pressed current fuel level value.

Following prompt appears:

"Set fuel level at 100% Once selected and

confirmed YES, fuel level is set at 100%.

Once selected and confirmed YES, fuel level

is set to 100%.

Note: Fuel may be replenished at any time

without a need to wait for complete empty

fuel tank. Replenish fuel always to the level

corresponding to 100% level of the fuel tank

and set 100% level as described above.

Description of operation

The regulator calculates the fuel level basing

on the current fuel consumption. Default

settings do not always correspond to the

actual consumption of fuel by the given

boiler, therefore, for proper operation this

method requires the regulator user to

perform level calibration. No additional fuel

level sensors are required.

Calibration

To perform calibration - fill the fuel tank to

the level corresponding to its full load and

set the parameter:

Boiler settings →Fuel Level → Fuel level

calibration →Fuel Level 100%

The indicator in the main window will be set

to 100%. On-going calibration process is

signalled by flashing fuel level gauge. The

gauge will flash until the time of marking the

point corresponding to minimal fuel level.

One must systematically control the

decreasing level of fuel in the bin. When the

level reaches the requested minimum, set

the value of the parameter:

Boiler settings →Fuel Level → Fuel level

calibration →Fuel Level 0%

Calibration can be skipped if the Feeder

Efficiency and Tank capacity, parameters are

set correctly in: Menu →Service settings

→Burner settings → Operation

8.20 Information

Information" menu allows to preview

temperatures being measured and to

recognize which equipment is currently ON.

Upon connection of mixers'

extension module, information

windows of additional mixers are

displayed.

8.21 Manual control

Regulator offers possibility to manual start of

working equipment such as pump, feeder

motor or fan. This feature enables checking

whether the given equipment is fault-free

and properly connected

Note: Access to manual control

menu is possible only in the STAND-

BY mode, i.e. when the boiler is

OFF.

Note: Long-term operation of the

fan, the feeder or other working

equipment may lead to occurrence

of hazardous conditions.

8.22 Grate

16

The regulator is able to work with a Grate,

where the fuel is loaded manually. The

feeder is switched off, but the fan is

operational. You can switch between Burner

and Grate modes in:

Boiler settings → Heat source

Fan speeds are regulated in:

Boiler settings →Output modulation

Fan speed settings are different for the grate

than for the burner. Other parameters are

set in the service settings.

Changing modes between grate and

burner can be done via the ecoNET

internet module, but only after all

the manually loaded fuel is burned

off. In order to change modes, turn

the regulator off and on by clicking

“Work mode” in the “Current

information” tab.

8.23 Favourite menu

In Touch version in the menu bar at the

bottom of the screen there is a button:

. Upon activation of this key, a

quick selection menu appears. To add new

item to this menu - hold respective icon

pressed in pie menu for a while.

To remove selected item from favourite

menu - hold corresponding icon pressed and

confirm REMOVE.

8.24 Room panel ecoSTER TOUCH

The controller can work together with

ecoSTER TOUCH remote control device,

which have a built-in room thermostat. This

room panel shows useful information such

as: fuel level, alarm indication etc.

8.25 Internet module

The controller can work together with

ecoNET300 internet module. It enables

online control and supervision over the

controller for the help of the website

www.econet24.com. You can use the

convenient mobile application ecoNET.apk.

Mobile application can be downloaded free of

charge from the website:

INSTALLATION AND SERVICE SETTINGS

ecoMAX 860P TOUCH

18

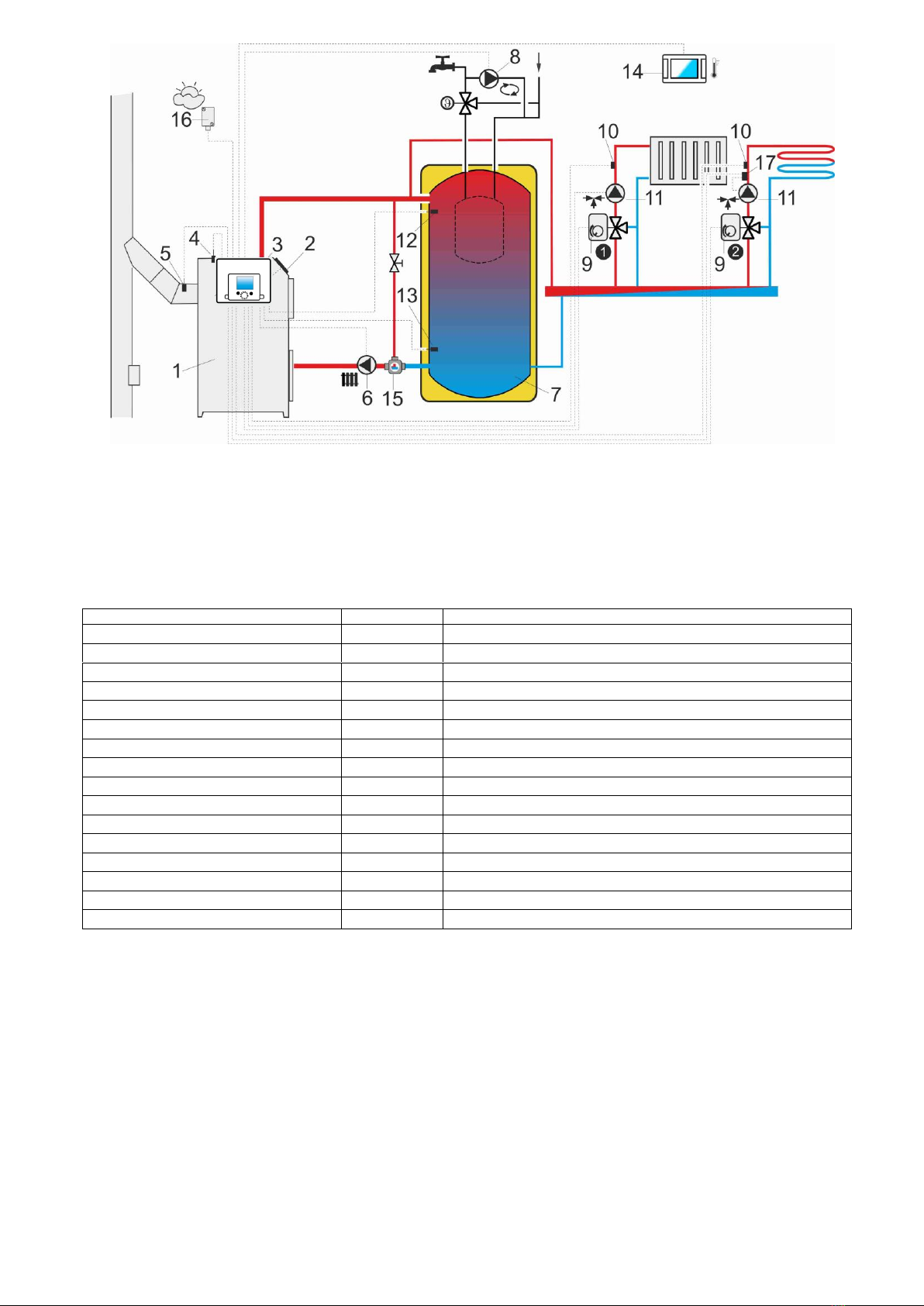

9Hydraulic diagrams

The presented hydraulic diagram does not replace central heating engineering

design and may be used for information purposes only.

Diagram with 4-way control valve for central heating circuit: 1 –boiler, 2 –controller, 3 - water

temperature sensor returning to the boiler, 4 –boiler temperature sensor, 5 –exhaust temperature sensor

(temperature monitoring only), 6 –4-way valve servo, 7 –mixer circuit pump, 8 –mixer circuit temperature

sensor, 9 –HUW container, 10 –HUW pump, 11 –HUW sensor, 12 –weather temp. sensor, 13 –ecoSTER

TOUCH room control panel or standard room thermostat, 14 –thermal isolation.

In order for the valve (6) to be able to effectively increase the return water temperature,

set a high set temperature of the boiler. In order to improve the water circulation in

natural systems (highlighted circuit in the figure): use large nominal diameter pipes and

four-way valve, avoid unnecessary angles and reductions, maintain a min. 2° horizontal

pipe slope, etc. If the sensor (3) is attached to the pipe, isolate it with foam surrounding

the pipe and sensor.

RECOMMENDED SETTINGS:

Parameter

Setting

MENU

Preset boiler temperature

75-80C

menuBoiler settings

Min. preset boiler temperature

65C

menuService settingsBoiler settings

Increasing of preset boiler temp.

5-20C

menuService settingsCH and HUW settings

Mixer 1 support

CH ON

menuService settingsMixer 1 settings

Maxer 1 preset temperature

70C

menuService settingsMixer 1 settings

Mixer 1 heating curve

0.8 –1.4

menuMixer 1 settings

Mixer 1 weather control

ON

menuMixer 1 settings

Mixer 1 thermostat selection

ecoSTER T1

menuService settingsMixer 1 settings

19

Diagram with two adjustable heating circuits and the HUW container:1 –boiler, 2 –heat exchanger,

3 –controller, 4 –boiler temperature sensor, 5 –exhaust temperature sensor (temperature monitoring

only), 6 –boiler pump, 8 –HUW pump, 9 –HUW container, 10 –HUW temperature sensor, 11 –mixer

pump, 12 –ecoSTER TOUCH room control panel with room thermostat feature , 13 –HUW container

temperature sensor CT4, 14 - weather temp. sensor, 15 - safety thermostat off the underfloor heating

pump, 16 - expansion tank.

RECOMMENDED SETTINGS:

Parameter

Setting

MENU

CH pump activation temperature

55C

menuService settingsCH and HUW settings

CH pump = boiler pump

YES

menuService settingsCH and HUW settings

Mixer 1 support

CH activated

menuService settingsMixer 1 control

Max. preset temp. of mixer 1

70C

menuService settingsMixer 1 settings

Mixer 1 heating curve

0.8 –1.4

menuMixer 1 settings

Mixer 1 weather control

activated

menuMixer 1 settings

Mixer 1 thermostat selection*

ecoSTER T1

menuService settingsMixer 1 settings

Mixer 2 support

Activate floor

menuService settingsMixer 2 settings

Max. preset temp. of mixer 2

45C

menuService settingsMixer 2 settings

Mixer 2 heating curve

0.3 –0.8

menuMixer 2 settings

Mixer 2 weather control

activated

menuMixer 2 settings

Mixer 2 thermostat selection*

ecoSTER T1

menuService settingsMixer 2 settings

20

Diagram with heat buffer, where: 1 –boiler, 2 –burner, 3 –controller, 4 –boiler temperature sensor, 5

–exhaust temperature sensor, 6 –boiler pump, 7 –heat buffer, 8 –HUW pump , 9 - mixing valve actuator,

10 - mixer temperature sensor, 11 - mixer pump, 12 - upper sensor of buffer temperature, 13 - lower

sensor of buffer temperature, 14 - ecoSTER TOUCH room control panel, 15 - thermostatic three-way valve

to the return protection, 16 –weather temp. sensor, 17 - thermostat to turn off the pump.

RECOMMENDED SETTINGS:

Parameter

Setting

MENU

Boiler preset temperature

80C

menuBoiler settings

Min. boiler preset temperature

75C

menuService settingsBoiler settings

CH pump activation temperature

55C

menuService settingsCH and HUW settings

Buffer support

activated

menuService settingsBuffer settings

Loading start temperature

50C

menuService settingsBuffer settings

Loading stop temperature

75C

menuService settingsBuffer settings

Mixer 1 support

CH activated

menuService settingsMixer 1 settings

Max. preset temp. of mixer 1

70C

menuService settingsMixer 1 settings

Mixer 1 heating curve

0.8 –1.4

menuMixer 1 settings

Mixer 1 weather control

activated

menuMixer 1 settings

Mixer 1 thermostat selection*

ecoSTER T1

menuService settingsMixer 1 settings

Mixer 2 support

Activate floor

menuService settingsMixer 2 settings

Max. preset temp. of mixer 2

45C

menuService settingsMixer 2 settings

Mixer 2 heating curve

0.3 –0.8

menuMixer 2 settings

Mixer 2 weather control

activated

menuMixer 2 settings

Mixer 2 thermostat selection*

ecoSTER T1

menuService settingsMixer 2 settings

* When using a standard room thermostate with ON/OFF terminals instead of the ecoSTER TOUCH (14),

select the Universal option, or when the setting is hidden, do not choose anything.

Table of contents

Other Metal-Fach Controllers manuals

Popular Controllers manuals by other brands

Nice

Nice One-Max Installation and use instructions and warnings

Meaco

Meaco LAE quick start guide

Viconics

Viconics VT7600W Series installation guide

G-Scale Graphics

G-Scale Graphics LSCM2 Operation and installation manual

Siemens

Siemens Sirius 3RW44 V.6.2 Getting started

BleBox

BleBox shutterbox user manual

Advanced Control Technologies

Advanced Control Technologies th104 installation instructions

Unitronics

Unitronics Vision V350-35-TU24 installation guide

WEG

WEG SSW900 Series user guide

Samson

Samson TROVIS 5433 quick guide

T-solution

T-solution SV-iG5 user manual

Armacost Lighting

Armacost Lighting ProLine 713429 instructions