Metal Man MIG/Stick 200 Service manual

using product. Protect yourself and others by observing all safety information, warnings, and

cautions. Failure to comply with instructions could result in personal injury and/or damage to

product or property. Please retain instructions for future reference

1

Operating Instructions and Parts Manual

MIG/Stick 200

1. General Safety Information

1.1 Your Welding Environment

-Keep the environment you will be welding in free from flammable materials.

-Always keep a fire extinguisher accessible to your welding environment.

-Always have a qualified person install and operate this equipment.

-Make sure the area is clean, dry and ventilated. Do not operate the welder in

humid, wet or poorly ventilated areas.

-Always have your welder maintained by a qualified technician in accordance

with local, state and national codes.

-Always be aware of your work environment. Be sure to keep other people,

especially children, away from you while welding.

-Keep harmful arc rays shielded from the view of others.

-Mount the welder on a secure bench or cart that will keep the welder secure

prevent it from tipping over or falling.

-Check all cables, power cord and welding cable to be sure the insulation is not

damaged. Always replace or repair damaged components before using the

welder.

-Check all components to ensure they are clean and in good operating condition

before use.

1.3 Use of Your Welder

Do not operate the welder if the welding cables, electrode, MIG gun, wire or wire

feed system is wet. Do not immerse them in water. These components and the

welder must be completely dry before attempting to use them.

-Follow the instructions in this manual.

-Keep welder in the off position when not in use.

-Connect ground lead as close to the area being welded as possible to ensure a

good ground.

-Do not allow any body part to come in contact with the welding wire if you are in

contact with the material being welded, ground or electrode from another welder.

-Do not weld if you are in an awkward position. Always have a secure stance

while welding to prevent accidents. Wear a safety harness if working above

ground.

-Do not drape cables over or around your body.

-Wear a full coverage helmet with appropriate shade (see ANSI Z87.1 safety

standard) and safety glasses while welding.

METAL MAN

WORK GEAR

2

MIG/Stick 200 Operating Instructions and Parts Manual

-Wear proper gloves and protective clothing to prevent your skin from being

exposed to hot metals, UV and IR rays.

-Do not overuse or overheat your welder. Allow proper cooling time between duty

cycles.

-Keep hands and fingers away from moving parts and stay away from the drive

rolls.

-Do not point MIG gun at any body part of yourself or anyone else.

-Always use this welder in the rated duty cycle to prevent excessive heat and

failure.

1.4 Specific Areas of Danger, Caution or Warning

Electrical Shock

Electric arc welders can produce a shock that can cause injury or

death. Touching electrically live parts can cause fatal shocks and

severe burns. While welding, all metal components connected to

the wire are electrically hot. Poor ground connections are a hazard, so secure the

ground lead before welding.

-Wear dry protective apparel: coat, shirt, gloves and insulated footwear.

-Insulate yourself from the work piece. Avoid contacting the work piece or ground.

- Do not attempt to repair or maintain the welder while the power is on.

-Inspect all cables and cords for any exposed wire and replace immediately.

-Use only recommended replacement cables and cords.

-Always attach ground clamp to the work piece or work table as close to the weld

area as possible.

-Do not touch the welding wire and the ground or grounded work piece at the

same time.

-Do not use a welder to thaw frozen pipes.

Fumes and Gases

-Fumes emitted from the welding process displace clean air and can

result in injury or death.

-Do not breathe in fumes emitted by the welding process. Make sure

the air you breath is clean and safe.

-Work only in a well-ventilated area or use a ventilation device to remove welding

fumes from the environment where you will be working.

-Do not weld on coated materials (galvanized, cadmium plated or containing zinc,

mercury or barium). They will emit harmful fumes that are dangerous to breathe.

If necessary use a ventilator, respirator with air supply or remove the coating

from the material in the weld area.

-The fumes emitted from some metals when heated are extremely toxic. Refer to

WKHPDWHULDOVDIHW\GDWDVKHHWIRUWKHPDQXIDFWXUHU¶VLQVWUXFWLRQV

-Do not weld near materials that will emit toxic fumes when heated. Vapors from

cleaners, sprays and degreasers can be highly toxic when heated.

3

MIG/Stick 200 Operating Instructions and Parts Manual

UV and IR Arc Rays

The welding arc produces ultraviolet (UV) and infrared (IR) rays that

can cause injury to your eyes and skin. Do not look at the welding

arc without proper eye protection.

-Always use a helmet that covers your full face from the neck to top of head and

to the back of each ear.

-Use a lens that meets ANSI standards and safety glasses. For welders under

200 Amps output, use a shade 10 lens; for above 200 Amps, use a shade 12.

Refer to the ANSI standard Z87.1 for more information.

-Cover all bare skin areas exposed to the arc with protective clothing and shoes.

Flame-retardant cloth or leather shirts, coats, pants or coveralls are available for

protection.

-Use screens or other barriers to protect other people from the arc rays emitted

from your welding.

-Warn people in your welding area when you are going to strike an arc so they

can protect themselves.

Fire Hazards

Do not weld on containers or pipes that contain or have had

flammable, gaseous or liquid combustibles in them. Welding creates

sparks and heat that can ignite flammable and explosive materials.

-Do not operate any electric arc welder in areas where flammable or explosive

materials are present.

-Remove all flammable materials within 35 feet of the welding arc. If removal is

not possible, tightly cover them with fireproof covers.

-Take precautions to ensure that flying sparks do not cause fires or explosions in

hidden areas, cracks or areas you cannot see.

-Keep a fire extinguisher close in the case of fire.

-Wear garments that are oil-free with no pockets or cuffs that will collect sparks.

-Do not have on your person any items that are combustible, such as lighters or

matches.

-Keep work lead connected as close to the weld area as possible to prevent any

unknown, unintended paths of electrical current from causing electrical shock

and fire hazards.

-To prevent any unintended arcs, cut wire back to ¼" stick out after welding.

Hot Materials

Welded materials are hot and can cause severe burns if handled

improperly.

-Do not touch welded materials with bare hands.

-Do not touch MIG gun nozzle or electrode holder at the tip where electrodes are

held after welding until it has had time to cool down.

4

MIG/Stick 200 Operating Instructions and Parts Manual

Sparks/Flying Debris

Welding creates hot sparks that can cause injury. Chipping slag off

welds creates flying debris.

-Wear protective apparel at all times: ANSI-approved safety glasses

RUVKLHOGZHOGHU¶VKDWDQGHDUSOXJVWRNHHSVSDUNVRXWRIHDUVDQGKDLU

Electromagnetic Field

-Electromagnetic fields can interfere with various electrical and

electronic devices such as pacemakers.

-Consult your doctor before using any electric arc welder or cutting

device

-Keep people with pacemakers away from your welding area when welding.

-Do not wrap cable around your body while welding.

-Wrap MIG gun and ground cable together whenever possible.

-Keep MIG gun and ground cables on the same side of your body.

Shielding Gas Cylinders Can Explode

High pressure cylinders can explode if damaged, so treat them

carefully

-Never expose cylinders to high heat, sparks, open flames,

mechanical shocks or arcs

-Do not touch cylinder with MIG gun

-Do not weld on the cylinder.

-Always secure cylinder upright to a cart or stationary object.

-Keep cylinders away from welding or electrical circuits.

-Use the proper regulators, gas hose and fittings for the specific application.

-Do not look into the valve when opening it.

-Use protective cylinder cap whenever possible.

1.5 Proper Care, Maintenance and Repair

-Always have power disconnected when working on internal components.

- Do not touch or handle PC board without being properly grounded with a wrist

strap. Put PC board in static proof bag to move or ship.

-Do not put hands or fingers near moving parts such as drive rolls or fan

5

MIG/Stick 200 Operating Instructions and Parts Manual

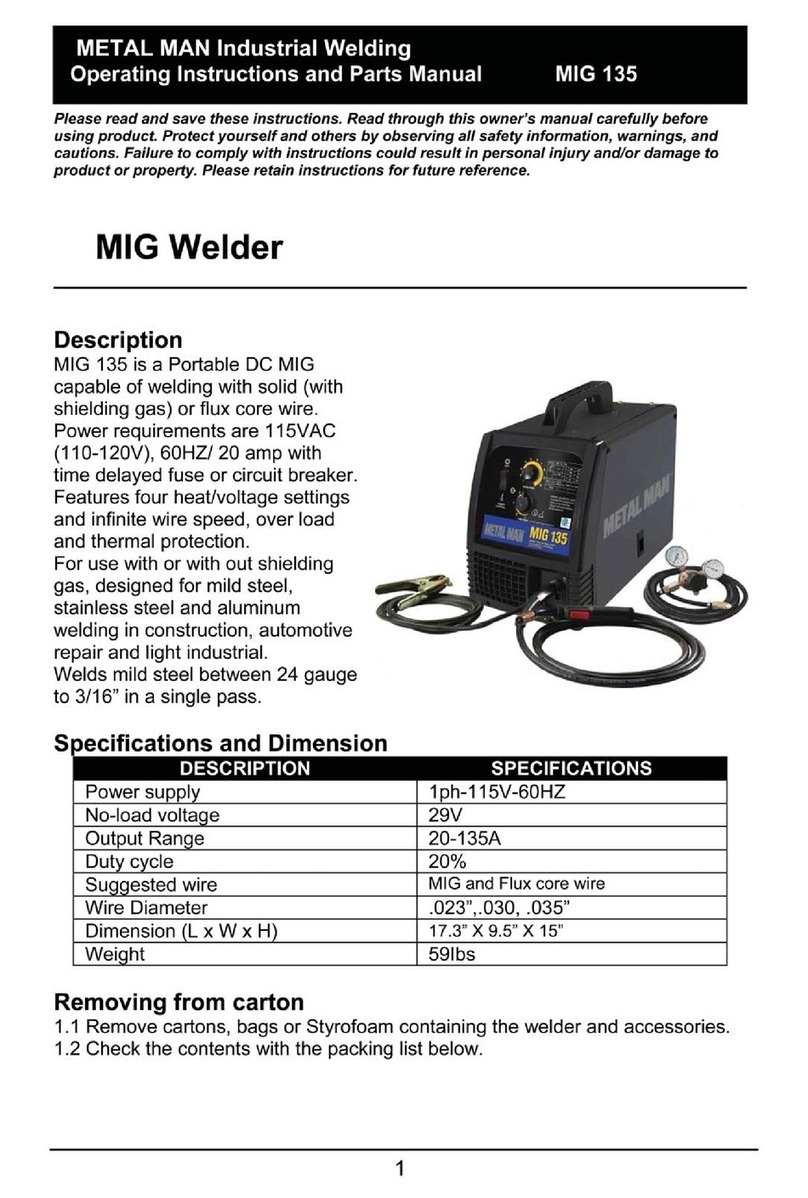

MIG/Stick 200 Welder

2. Description

The MIG/Stick 200 is a 230V input power

portable dual process inverter machine capable

of MIG welding up to 1/4" steel in a single pass.

It operates on 230VAC, 60HZ and requires a 30

amp time delayed fuse or circuit breaker. This

machine is capable of MIG Welding, Flux Core

Welding, and DC Stick Welding. It features an

infinite voltage control in the MIG mode and can

MIG weld 24 gauge to 1/4" mild steel. This unit

is also capable of MIG welding stainless steel

and aluminum with the optional spool gun. In the stick mode, this unit is capable

of welding up to 140 amps DC using electrodes from 1/16" to 1/8" for a single

pass capacity of 3/16" on mild steel. The MIG/Stick 200 is well equipped for the

home shop or for those on-the-go welders that need a portable multi-process

machine.

3. Specifications and Dimension

DESCRIPTION SPECIFICATIONS

Power supply 1ph-230V-60HZ

No-load voltage 78V

Output Range 30-200A DC

Duty cycle 30%

Suggested wire ´-´ MIG(solid) wire

RU´-´)lux core wire

Wire Diameter .023´,.030, .035´

Electrode diameter 1/16´, 5/64´´´

Dimension˄L x W x H˅17.7´;9.4´;13.8´

Weight 44 Lbs

6

MIG/Stick 200 Operating Instructions and Parts Manual

4. Package Contents

Please check the contents of your package.

1 MIG/Stick

200 Power

Source

1 Operator's

Manual

1 Regulator

with Gas

Hose

1 MIG Gun

1 Ground

Cable with

Clamp

1 Electrode

Holder with

Cable

1 8-Inch

Spool

Adapter

1 MIG

Consumable

Kit

7

MIG/Stick 200 Operating Instructions and Parts Manual

5. Know your Welder - Upper Front Panel

1. Power On Indicator - Lights up when primary power is connected and the

power switch is in the "On" position.

2. Thermal Overload Indicator - Lights up when the thermal overload circuit is

activated and protecting the unit. Weld output stops while in the thermal overload

mode however the units cooling fan will continue to operate.

3. Work Output Indicator - Lights up when the unit is producing weld power.

4. Mode Selector Switch - Selects the mode of welding

5. Wire Feed Speed Control - Adjusts the speed of the wire feeding while in the

MIG Mode

6. Voltage Control (MIG Mode) / Amperage Control (Stick Mode) - Adjusts the

welding voltage while in the MIG mode and adjusts the welding amperage while

in the stick mode.

8

MIG/Stick 200 Operating Instructions and Parts Manual

6. Know your Welder - Lower Front Panel

1. Ground Cable Connection - Connects the ground cable and clamp to the

welding machine.

2. MIG Gun Trigger Connection - 4-Pin Twist Connect trigger connection for the

MIG Gun.

3. Electrode Cable Connection - Connects the electrode cable and electrode

holder to the welding machine.

4. MIG Gun Connection - Connects the electrode cable and electrode holder to

the welding machine.

9

MIG/Stick 200 Operating Instructions and Parts Manual

7. Know your Welder - Back Panel

1. Specifications Label - This label communicates the specifications and the

serial number of this unit.

2. Primary Power Switch - This switch applies power to the unit in the "On"

position.

3. Primary Power Cable - Connects to 230VAC 50A Connection

4. Current Overload Circuit Breaker - Protects the unit from current overload

5. Inert Gas Fitting - Connect the Inert Gas Hose to supply this unit with

shielding gas in the MIG Mode.

8. Know your Welder - Spool Gun Selector

The spool gun selector is located inside the wire compartment. This switch is for

use with the optional spool gun. It should be in the MIG mode when not using the

spool gun.

10

MIG/Stick 200 Operating Instructions and Parts Manual

9. Assembly & Set-Up For Stick Welding

1. Choose a location for your welding unit. This location

should in an area free of debris and away from

flammable materials. A welding cart or cabinet may be

desired for easy moving of your welder to the area it will

be operating.

2. Install Ground Cable to the Ground Cable Connection

3. Install Electrode Cable & Holder to the Electrode Cable

Connection

4.

Plug the Primary Power Cord into a 230V, 50A

receptacle. The plug and receptacle design is a NEMA

6-50 design.

5.

Install desired electrode to the electrode holder

6.

Install the Ground Clamp to work surface or material you

are welding.

11

MIG/Stick 200 Operating Instructions and Parts Manual

9. Assembly & Set-Up For Stick Welding (Continued)

7.

Flip the Mode Selector Switch on the front panel to the

Stick Mode.

8.

Turn on the Primary Power Switch on the back panel.

See Section 16 for detailed information on operating a

stick welder.

10. Assembly & Set-Up For MIG Welding

1. Choose a location for your welding unit. This location

should in an area free of debris and away from

flammable materials. A welding cart or cabinet may be

desired to easily move your welder to the area it will be

operating.

2. Secure your bottle of shielding gas

3.

Install the supplied regulator to the bottle of shielding gas

12

MIG/Stick 200 Operating Instructions and Parts Manual

10. Assembly & Set-Up For MIG Welding (Continued)

4.

Connect the supplied gas hose to the regulator

5.

Install the other end of the gas hose to the inert gas

fitting on the back of the unit.

6.

Open the valve on the bottle of shielding gas and adjust

the gas flow rate (left gauge) on the regulator to 20 cubic

feet per hour. Follow the red scale.

See Section 15 for detailed information regarding gas

installation.

7.

Install Ground Cable to the Ground Cable Connection

8.

Open wire compartment door and loosen the gun

securement screw

9.

Install the MIG gun and trigger lead

10.

Hand tighten the gun securement screw until it is snug.

13

MIG/Stick 200 Operating Instructions and Parts Manual

10. Assembly & Set-Up For MIG Welding (Continued)

11.

Flip the mode selector switch on the front panel to MIG

12.

Open the wire compartment door and remove the

hardware from the wire spool support

13.

Slide on a 4" spool of wire. Be certain the wire is set to

feed off the bottom of the spool. Reinstall the hardware

with the washer first, then the black bushing and then the

wing nut. Tighten only so that there is slight tension on

the spool. You should be able to move the spool easily

with your hand.

14.

If you are using 8" spools of wire, install the 8 in spool

adapter first. Reinstall the hardware with the washer first,

then the black bushing and then the wing nut. Tighten

only so that there is slight tension on the spool adapter.

You should be able to move the spool adapter easily

with your hand.

15.

Then slide on your 8" spool of wire. Be certain the wire is

set to feed off the bottom of the spool.

See Section 13 for detailed information on installing the

welding wire.

16.

Release the drive roll tension adjuster and open up the

drive roll pressure arm. Snip the end of the wire off the

spool and thread the wire through the inlet guide, over

the drive roll and into the back of the gun. Make certain

to feed the wire a few inches into the gun. To avoid

unspooling of the wire, keep a good grip on the wire.

17.

Reinstall the drive roll pressure arm and the drive roll

tension adjuster.

See Section 14 for detailed information on setting drive

roll tension.

14

MIG/Stick 200 Operating Instructions and Parts Manual

10. Assembly & Set-Up For MIG Welding (Continued)

18.

Plug the Primary Power Cord into a 230V, 50A

receptacle. The plug and receptacle design is a NEMA

6-50 design.

See Section 11 for detailed information on power

requirements.

19.

Turn on the Primary Power Switch on the back panel

20.

Remove the Flux Core Nozzle and the contact tip from

the MIG Gun

21.

Pull trigger until the wire has feed all the way through the

gun.

Reinstall the contact tip and install the copper nozzle for

MIG welding. If welding with a flux core wire, reinstall the

black nozzle.

Check the weld polarity label in the wire compartment to

make certain the polarity is properly set whether you are

MIG welding or Flux Core Welding.

Install the Ground Clamp to work surface or material you

are welding

See Section 16 for detailed information on the operation

of a MIG welder.

15

MIG/Stick 200 Operating Instructions and Parts Manual

11. Power Requirements

This unit uses a single phase 230VAC(220-240V), 60HZ circuit with 50 amp time

delayed fuse or circuit breaker is required. DO NOT OPERATE THIS UNIT if the

ACTUAL power source voltage is less than 215volts ac or greater than 240 volts

AC.

High voltage danger from power source! Consult a qualified electrician for

proper installation of receptacle. This welder must be grounded while in

use to protect the operator from electrical shock.

Do not remove the ground prong or alter the plug in any way. Do not use

any DGDSWHUVEHWZHHQWKHZHOGHU¶VSRZHUFRUG and the power source

receptacle. Make sure the POWER switch is OFF when connecting your

ZHOGHU¶VSRZHUFRUGWRDSURSHUO\JURXQGHG 230VAC, 60Hz, single phase,

30amp power source.

Extension Cords

It is strongly recommended not to use an extension cord because of the voltage

drop it produces. This drop in voltage can affect the performance of the welder.

12. Drive Roll Installation

Before installing any welding wire into the unit, the proper sized groove must be

placed into position on the wire drive mechanism. Adjust the drive roller

according to the following steps, see following picture about the wire feeder

structure:

1. Drive Tension Arm

2. Drive Tension Adjustment

3. Inlet Guide Tube

4. Drive Roll

12.1 Open the door to the welder drive compartment.

16

MIG/Stick 200 Operating Instructions and Parts Manual

Remove the drive tension by loosening the tension adjusting knob and lifting the

Drive Tension Adjustor away from the Drive Tension Arm. Pull the drive tension

arm away from the driver roller.

If there is wire already installed in the welder, roll it back onto the wire spool by

hand-turning the spool counterclockwise. Be careful not to allow the wire to come

out of the rear end of the inlet guide tube without holding onto it or it will unspool

itself. Put the end of the wire into the hole on the outside edge of the wire spool

and bend it over to hold the wire in place. Remove the spool of wire from the

drive compartment of the welder.

12.2 Remove the drive roller.

Use the ³L´shaped hex wrench in the accessory package. And insert the tool into

the set screw in the drive roller and turn counter-clockwise to loosen the set

screw and remove the drive roller from the drive roller shaft, see the following

images

12.3 Match the drive roller wire groove to the wire diameter, see the chart below.

Wire Diameter Roller Groove

.024 inch 0.6

.030 inch 0.9

.035 inch 0.9

The drive roller has two wire size grooves in it. When installing the drive roller,

the number stamped on the drive roller indicates the wire groove it is aligned

with. Push the drive roll onto the drive roller shaft and use the ³L´shaped hex

wrench to tighten the drive roller to the shaft. To tighten turn set screw clockwise.

12.4 Close the door to the welder drive compartment.

17

MIG/Stick 200 Operating Instructions and Parts Manual

13. Installing Wire

13.1 Select the wire. The following wires can be used in this machine:

.023 - .035 MIG Wire

.030 - .035 Flux Core Wire

MIG wire can be either mild steel, stainless steel or aluminum solid wire. For use

ZLWK´RU´VSRROVRIZLUH

NOTE:

0HWDOWKLQQHUWKDQ24 gauge cannot be welded with this machine. Attempting to

do so will cause burn through in the metal you are intending to weld.

Remove any wire that is rusty, if the whole spool is rusty discard it.

4.2 Install the wire

Electric shock can kill! Always turn the POWER OFF and unplug the power

cord from the ac power source before installing wire.

NOTE:

%HIRUHLQVWDOOLQJPDNHVXUHWKDW\RXKDYHUHPRYHd any wire from the MIG gun

assembly. This will help to prevent the possibility of the wire jamming inside the

MIG gun liner.

%HFDUHIXl when removing the welding nozzle. The contact tip on this welder is

electrically live when the torch trigger is pulled. Make certain POWER is turned

OFF.

13.2 Remove the nozzle and contact tip from the end of the MIG gun assembly.

Please see following images for reference

13.3 Make sure the groove on the drive roller matches the wire size being

installed. If not, change the drive roller as described above.

13.4 Remove any wrapping from the outside of the spool of wire. DO NOT

UNHOOK THE WIRE AT THIS TIME.

13.5 Place the spool on the spool hub so that the wire comes off the bottom of

the spool. The welding wire should always come off the bottom of the spool into

the drive mechanism. See following figure.

18

MIG/Stick 200 Operating Instructions and Parts Manual

13.6 The welder can use both 4in and 8in spools, see the following figure for

installation: The wing nut is designed to adjust the pressure tension of the wire

spool.

13.7 Setting the wire spool tension:

a) Turn the spool of wire with one hand.

b) Increase the spool tension by tightening (turn clockwise) the wing nut while

turning the spool. Turn the spool while tightening the wing nut until the spool

slows down and operator feels a slight drag.

Stop tightening the wing nut, operator may need to repeat these steps until

proper spool tension is achieved.

NOTE:

If TOO MUCH tension is applied to the wire spool, the wire will slip on the drive

roller or will not be able to feed at all. If TOO LITTLE tension is applied, the spool

of wire will want to unspool itself when the gun trigger is released. Readjust the

spool hub tension as necessary to correct for either problem.

13.8. After checking to make sure that your welder is disconnected from the ac

power source, remove the leading end of the wire from the spool, DO NOT LET

GO OF THE WIRE until told to do so, or the wire will unspool itself.

13.9. Using a wire cutter, cut the bent end off the leading end of the wire so that

only a straight leading end remains.

13.10. Loosen the tension adjusting knob holding the drive tension arm in place

and lift the tension arm up off the drive roller.

19

MIG/Stick 200 Operating Instructions and Parts Manual

13.11. Insert the leading end of the wire into the inlet guide tube. Then push it

across the drive roller and into the torch assembly about six inches.

Make certain that the welding wire is actually going into the torch liner. If

not, the wire can jam or keep the wire from feeding correctly.

13.12 Check to see if the wire is in the drive roller groove, then position the drive

tension arm into place on the drive roller.

13.13 Flip the quick release drive tension back up into position on the drive

tension arm.

13.14 Tighten (turn clockwise) the drive tension adjusting knob until the tension

roller is applying enough force on the wire to prevent it from slipping out of the

drive assembly.

DO NOT OVERTIGHTEN

13.15. NOW YOU CAN RELEASE THE WIRE.

13.16. Plug in the welder, turn power switch to the ON position. Set the

VOLTAGE switch to the voltage (heat) setting recommended for the gauge metal

that is to be welded. Refer to the set up chart located inside the wire

compartment.

13.17. Set the WIRE SPEED control to the middle of the wire speed range.

13.18. Straighten the MIG gun cable and pull the trigger on the welding torch to

feed the wire through the torch assembly. When at least one inch of the wire

sticks out past the end of the torch, release the trigger.

12.19. Turn the Power Switch to the OFF position.

13.20 Select a contact tip stamped with the same diameter as the wire being

used.

NOTE:

Due to inherent variances in flux-cored welding wire, it may be necessary to use

a contact tip one size larger than your flux core wire if wire jams occur.

13.21. Slide the contact tip over the wire (protruding from the end of the torch).

Thread the contact tip into the end of the torch and hand-tighten securely with a

pliers

13.22. Install the nozzle on the gun assembly. To keep spatter from sticking to

inside of the nozzle use anti-spatter spray or gel.

Table of contents

Other Metal Man Welding System manuals

Metal Man

Metal Man MIG140 Series User manual

Metal Man

Metal Man FC125X User manual

Metal Man

Metal Man M190 User manual

Metal Man

Metal Man FC135T User manual

Metal Man

Metal Man FC130i User manual

Metal Man

Metal Man 200iDV User manual

Metal Man

Metal Man MP140T User manual

Metal Man

Metal Man Inverter 80 User manual

Metal Man

Metal Man ARC 200 9002203 User manual

Metal Man

Metal Man Mig 135 Service manual