DINSE DIX GO 1156.M Puls User manual

DIX PI GO 1156.M

BA-0124

Welding Power Source

SCHWEISSEN WELDING WELDINGSCHWEISSEN SCHWEISSEN

Keepinsecureareaforfuturereference!

Operations manual

2

Introduction 2

Description 2

Technical data 3

Usage limits (IEC 60974-1) 3

How to lift up the welding power source 4

Open the packaging 4

Installation and connections 4

Connecting the welding welding power source to

the utility line 4

Command and control units (Fig.A) 4

Loading wire 5

Assembly of drive roller 5

MIG-MAG welding with GAS 6

MIG-MAG welding without GAS 7

Spot welding 7

Interval welding (Stitch) 8

Aluminium welding 8

TIG welding with “Lift” 8

Electrode welding (MMA) 9

Maintenance 9

The pointing out of any difficulties and their

elimination 10

Replacing the digital interface PCB 10

Troubleshooting table 11

Electro topographical diagram 12

Electro topographical diagram key 13

Meaning of graphic symbols on welding power

source 13

Colour key 13

Description

MULTI-FUNCTION INVERTER WELDING POWER SOURCE

SUITABLE FOR SINGLE-PHASE POWER SUPPLIES FOR

MIG-MAG, MMA, and TIG WELDING (with “Lift” type igni-

tion)

Multifunction synergic welding power source, based on the

leading-edge IGBT inverter technology and fully digitally con-

trolled, offer premium welding quality MIG/MAG on all materi-

als, especially stainless steel, aluminium and galvanized steel;

the spatter-free welding feature minimises reprocessing work.

It also ensures excellent performance in TIG and MMA weld-

ing prcesses.

Innovative, versatile, light-weight, easily portable, simple to use,

DIX PI GO 1156.M is a very high level product that is abso-

lutely irreplaceable technologically for all internal and external

maintenance works, vehicle bodyworks, agricultural and small

light metalwork jobs.

The principal characteristics of welding units are:

•

Multifunction power source with premium welding quality in

MIG/MAG, MMAand TIG with “Lift” type ignition welding pro-

cesses.

•

Standard polarity inversion for welding with the most com-

mon core wires and without gas.

• Central Euro connection on torch.

• Innovative practical design.

•

Supporting structure in metal with front panel in special

shockproof material.

• Protective visor on the control panel.

• Robust handle integrated into the chassis.

•

Professional 2-roller wire feeder that guarantees precise

feeding of the wire.

•

The double slot rollers can be replaced without using any

tools.

•

Agraduated knob for precise adjustment of the wire pressure

that stays unvaried when the arms open and close.

• Housing for coils of wire with max Ø 200 mm – 5 kg.

• Synergic digital control of all welding parameters, shown on

the display, also featuring the following functions:

-

Allows less expert operators to regulate all welding param-

eters, choosing the type of program on the basis of the ma-

terial, wire diameter, and gas used.

-

Innovative software “DIX ARC” for controlling all welding

parameters.

-

Digital Voltmeter /Ammeter with HOLD function (saving of

latest data on both displays).

-

“Energy Saving” function to operate the power source cool-

ing fan only when necessary.

- Auto-diagnostic feature for trouble shooting.

- Ability to store personalized welding programmes (JOB).

- MIG-MAG welding:

- BURN BACK control. At the end of each weld, in any

condition and with any material, the digital control en-

sures a perfect wire cut, prevents the typical “wire glob-

ule” from forming and ensures correct arc restriking.

-

WSC Wire start control. This arc striking control device

prevents wire from sticking to the workpiece or torch

nozzle and ensures precise and smooth arc striking,

particularly when welding aluminium.

-

Welding parameters that are controlled digitally by a

microprocessor, are monitored and modified in just a

few seconds, maintaining a consistently precise and

stable arc as the welding conditions continue to vary

due to the movement of the torch and the irregularities

of the parts to be welded.

Introduction

Thank you for buying our product.

In order to get the best performance out of the equipment and

ensure the maximum lifespan of its parts, the use and mainte-

nance instructions contained in this manual must be read and

strictly complied with, as well as the safety instructions con-

tained in the relevant folder. If repairs to the equipment are

required, we recommend that our clients contact our service

centre workshops, as they have the necessary equipment and

personnel that are specifically trained and constantly updated.

All our welding power sources and equipment are constantly

developed and so changes may be made in terms of their con-

struction and features.

DINSE G.m.b.H.

Tarpen 36 • D-22419 Hamburg

Tel. +49 (0)40 658 75-0

Fax +49 (0)40 658 75-200

Copyright © 2018 DINSE G.m.b.H., Hamburg.

Theseinstructionsorexcerptsthereofshallnotbeduplicated,translatedorreprodu-

ced, nor shall they be stored, processed, transmitted or distributed by any electronic

means without the prior written permission of DINSE G.m.b.H.

3

- MMAwelding:

-

“Arc Force” adjustable to select the best dynamic char-

acteristics for the welding arc.

- “Hot Start” adjustable to improve ignition with particu-

larly difficult electrodes.

- Anti-sticking function to avoid the electrodes sticking.

-

Vrd (Voltage Reduction Device), which makes it pos-

sible to use the welding power source in environments

where the risk of electric shock or electrocution caused

by arc welding is enormously increased by the pres-

ence of water, humidity, or heat, and particularly where

the ambient temperature exceeds 32°C.

- TIG welding:

-

“Lift” type ignition, with TCS “Thermal Control Start” de-

vice to further reduce tungsten inclusions.

-

Exclusive SWS “Smart Welding Stop” system at the

end of TIG welding. Lifting up the torch without switch-

ing off the arc will introduce a SLOPE DOWN and it will

switch off automatically.

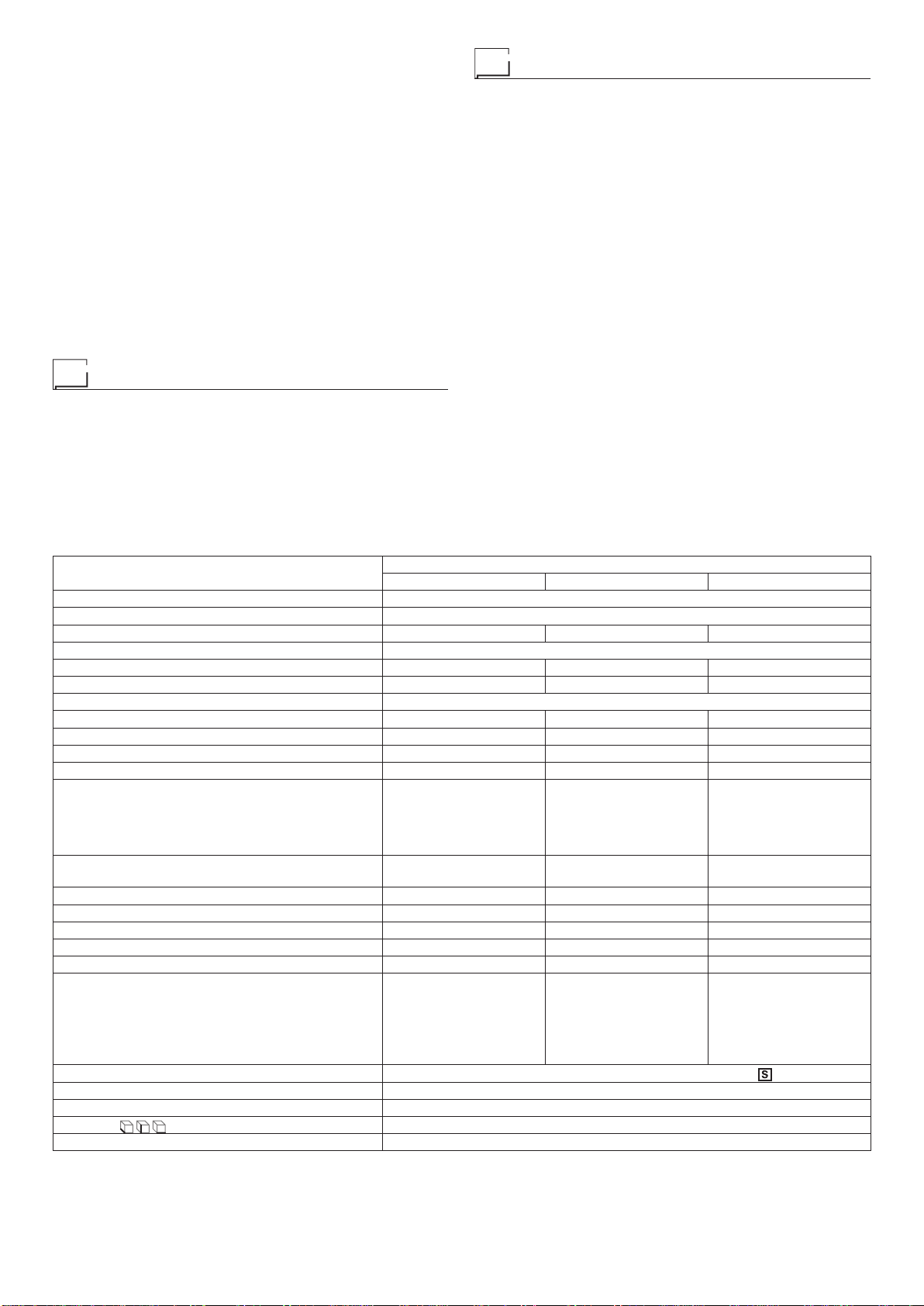

Technical data

The general technical data of the system are summarized in

table 1.

Usage limits (IEC 60974-1)

The use of a welder is typically discontinuous, in that it is made

up of effective work periods (welding) and rest periods (for the

positioning of parts, the replacement of wire and underflushing

operations etc. This welder is dimensioned to supply a I2max

nominal current in complete safety for a period of work of X%

of the total usage time. The regulations in force establish the

total usage time to be 10 minutes. The work cycle is considered

to be X% of this period of time. When the work cycle permit-

ted is exceeded a trip switch trips, which protects the welding

power source’s internal components against dangerous over-

heating and prevents incorrect functioning of the welding power

source.After several minutes the overheat cut-off rearms auto-

matically and the welder is ready for use again (Automatic re-

set error). This equipment is built to have a protection level of

IP 23 S, which means:

•

That it is protected against the penetration of solid foreign

bodies with diameters in excess of Ø 12 mm.

•

That it is protected against water spray hitting the surface

with an angle of incidence up to 60°.

• That the equipment has been tested for withstanding harm-

ful effects due to water getting in when the moving parts on

the equipment are moving.

Table 1

Model DIX PI GO 1156.M

MIG-MAG TIG MMA

Single-phase input 50/60 Hz V230 ± 15%

Mains supply: Zmax (*) Ω0,21

Power input (I2Max) kVA 8,1 6,4 7,8

Delayed fuse (Ieff) A16

Power factor / cosφ 0,63 / 0,99 0,63 / 0,99 0,63 / 0,99

Efficiency degree η0,83 0,8 0,83

Voltage without load V60

Current range A10 ÷ 175 5 ÷ 175 10 ÷ 150

Duty cycle @ 100% (40°C) A100 100 90

Duty cycle @ 60% (40°C) A115 115 110

Duty cycle @ X% (40°C) A175 (20%) 175 (20%) 150 (25%)

Wires diameter mm

•0,6/0,8/1,0 - Fe

•1,0 / 1,2 - Al

•0,8 / 1,0 - CrNi

•0,8 / 1,0 - Cu Si 3

•0,9 - Flux Cored

- -

Spool

Diameter / Weight mm / kg 200 / 5 - -

N° rollers 2 - -

Power output of feeder motor W40 - -

Rated wire feeding speed m/min 1 - 20 - -

MMAelectrodes mm - - 1,6 - 3,2

TIG electrodes mm -1,0 - 3,2 -

Protection gas

•Carbon dioxide

•Pure Argon

•Argon - Carbon dioxide

- Oxygen

•Argon and Carbon

dioxide blends

- -

Standards IEC 60974-1 - IEC 60974-5 - IEC 60974-10 -

Protection class IP 23 S

Insulation class H

Dimensions mm 500 - 425 - 220

Weight kg 16

(*) Mains supply Zmax: maximum impedance value allowed for the grid according to the EN/IEC 61000-3-11 standard.

WARNING: This equipment does not comply with EN/IEC 61000-3-12. If it is connected to a public low voltage system, it is the responsibility

of the installer or user of the equipment to ensure, by consultation with the distribution network operator if necessary, that the equipment may

be connected.

4

How to lift up the welding power source

The welding power source has a strong handle all in one with

the frame, used for transporting the welding power source man-

ually only.

NOTE: These hoisting and transportation devices conform to

European standards. Do not use other hoisting and transpor-

tation systems.

Open the packaging

Upon receiving the system:

•

Remove the welding power source and all relevant accesso-

ries-components from their packaging.

• Check that the welding power source is in good condition, if

not report any problems immediately to the seller-distributor.

• Make sure all ventilation grilles are open and that no foreign

bodies are blocking the air circulation.

Installation and connections

The installation site for the system must be carefully chosen

in order to ensure its satisfactory and safe use. The user is re-

sponsible for the installation and use of the system in accord-

ance with the producer’s instructions contained in this manual.

Before installing the system the user must take into consider-

ation the potential electromagnetic problems in the work area.

In particular, we suggest that you should avoid installing the

system close to:

• Signalling, control and telephone cables.

• Radio and television transmitters and receivers.

• Computers and control and measurement instruments.

• Security and protection instruments.

Persons fitted with pace-makers, hearing aids and similar

equipment must consult their doctor before going near a weld-

ing power source in operation. The equipment’s installation

environment must comply to the protection level of the frame

i.e. IP 23 S (IEC 60529 publication). The system is capable of

working in environments where working conditions are partic-

ularly hard.

This system is cooled by means of the forced circulation of air,

and must therefore be placed in such a way that the air may

be easily sucked in and expelled through the apertures made

in the frame.

The equipment must be assembled as follows:

• Mount on the trolley (optional extra).

• Fix the welding unit to the trolley.

• Connect the welding welding power source to the utility line.

• Connect up the welding cables.

Connecting the welding welding

power source to the utility line

Connection of the welding power source to the user line

(electrical current) must be performed by qualified per-

sonnel.

Before connecting the welding welding power source to

the mains power supply, make sure that rated voltage and

frequency correspond to those provided by the mains pow-

er supply and that the welding welding power source’s

power switch is turned to “O”.

Connection to the power supply must be carried out using the

tripolar cable supplied with the system, of which:

•

2 conducting wires are needed for connecting the welding

power source to the supply.

•

The third, which is YELLOW GREEN in colour is used for

making the “GROUND” connection.

Connect a suitable load of normalised plug (2p + e) to the

power cable and provide for an electrical socket complete

with fuses or an automatic switch. The ground terminal

must be connected to the ground conducting wire (YEL-

LOW-GREEN) of the supply.

Table 2 shows the capacity values that are recommended for

fuses in the line with delays.

NOTE: Any extensions to the power cable must be of a suita-

ble diameter, and absolutely not of a smaller diameter than the

special cable supplied with the welding power source.

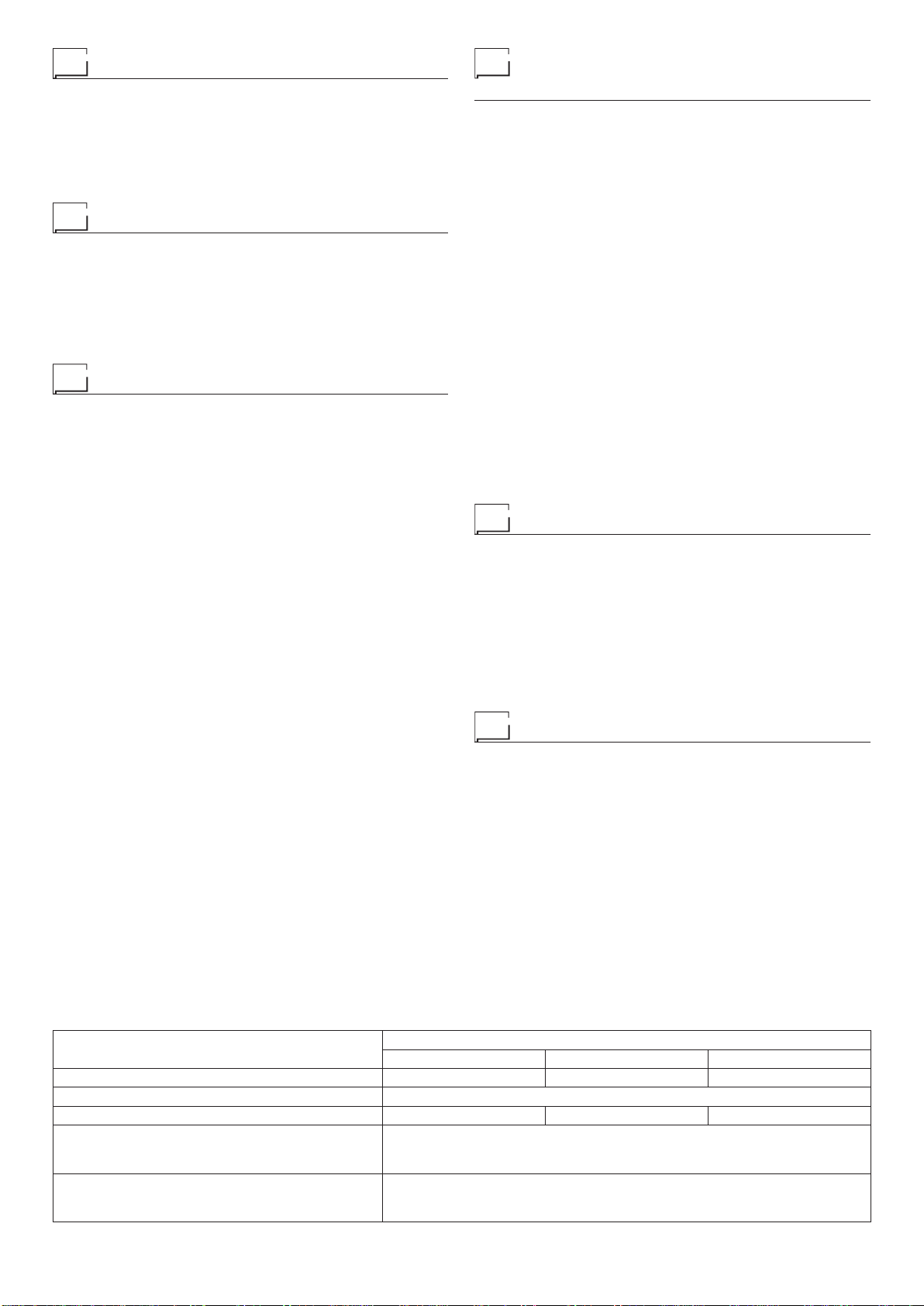

Command and control units (Fig. A)

Pos. 1 control panel.

Pos. 2 Fast coupling straight polarity.

Pos. 3 Fast coupling reverse polarity.

Pos. 4 Centralised MIG-MAG torch connection.

Pos. 5 Power supply switch. In the “O” position the welder

is off.

Pos. 6 Mains cable.

Pos. 7 Weld gas inlet coupling.

Pos. 8 Cable clamp for the welding cable to pass (with the

“Retrofit kit adaptor” fitted).

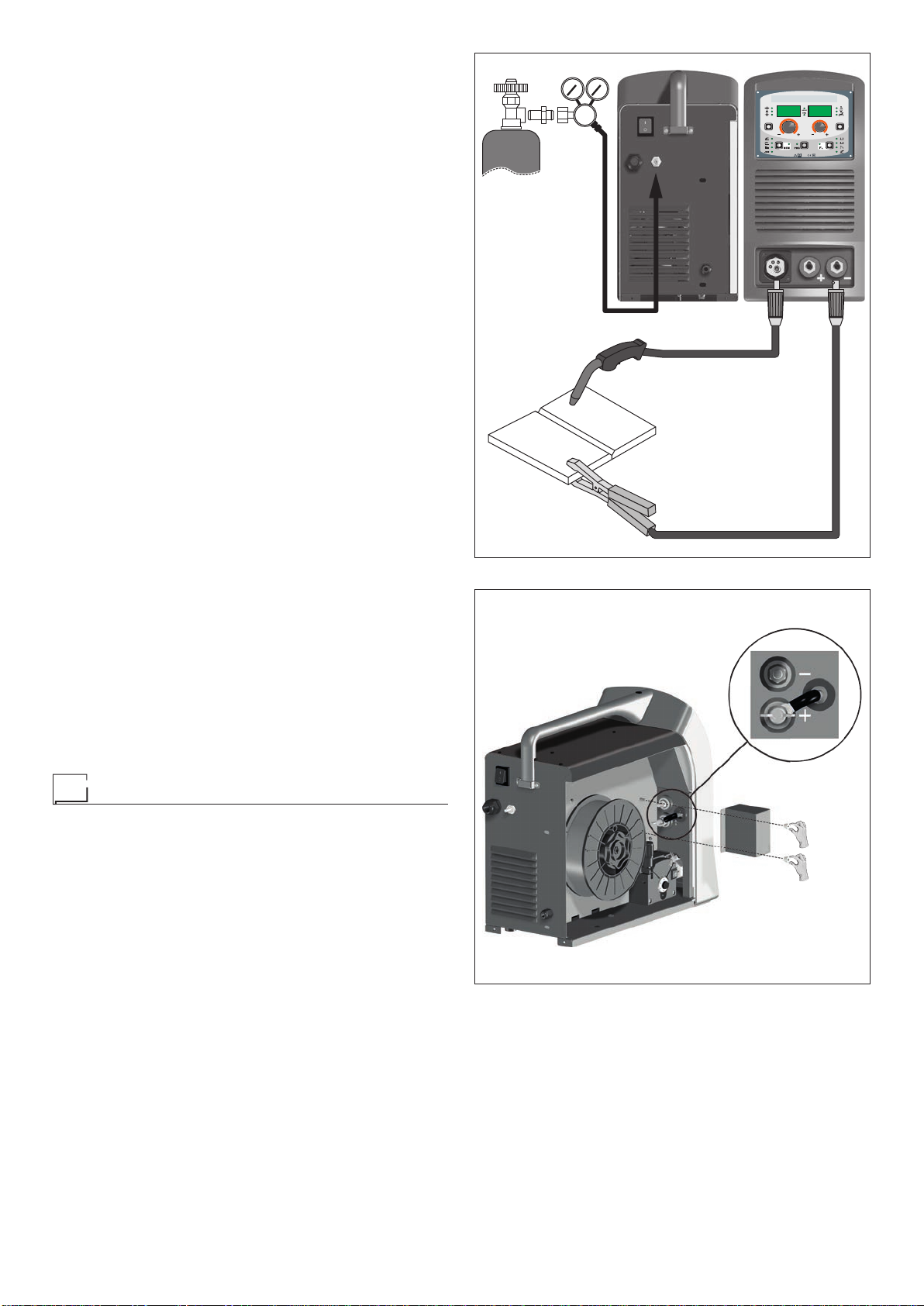

Loading wire

• Open the side panel on the left using the relevant Allen key

and insert the coil (use coils with a MAX diameter of 200 mm

and MAX weight of 5 kg) that suits the material to be welded

on the relevant support so that the wire unwinds anticlock-

wise and aligning the protruding marker on the support with

the relevant hole in the coil.

Table 2

Model DIX PI GO 1156.M

MIG-MAG TIG MMA

Power input (I2Max) kVA 8,1 6,4 7,8

Delayed fuse (Ieff) A16

Duty cycle @ X% (40°C) A175 (20%) 175 (20%) 150 (25%)

Mains cable

Length

Section m

mm23

2,5

Ground cable

Length

Section m

mm23

16

5

FIG. A

12

3

4

5

6

7

FIG. B

• Thread the end of the wire into the back guide (Pos. 7, Fig.

B) on the drawing mechanism.

• Lift up the idle roller Ø 26 mm (Pos. 1, Fig. B) releasing the

roller pressure mechanism (Pos. 6, Fig. B). Check that the

drive roller (Pos. 4, Fig. B) has the diameter corresponding

to the wire being used printed on the outer side.

• Thread the wire into the central wire guide and into the wire

guide of the centralized attachment (Pos. 3, Fig. B) for a few

centimetres. Lower the idle roll-holder arm making sure the

wire goes into the slot of the drive roll. If necessary, adjust the

pressure between the rollers with the screw provided (Pos.

5, Fig. B). The correct pressure is the minimum that does not

allow the rollers to skid on the wire. Excessive pressure will

case deformation of the wire and tangling on the entrance of

the sheath; insufficient pressure can cause irregular welding.

Assembly of drive roller

Follow instructions given below for mounting the drawing roll-

er onto the mechanism:

• Unscrew the screw (Pos. 5, Fig. B).

• Lift up the idle roll-holder arm Ø 26 mm (Pos. 2, Fig. B).

•

Each roller shows the type of wire and diameter on the two

external sides.

•

Mount the appropriate roller (Pos. 4, Fig. B) making sure the

groove is in the right position for the diameter of the wire be-

ing used.

• Screw the screw (Pos. 5, Fig. B).

MIG-MAG welding with GAS

To begin MIG-MAG welding, carry out the following tasks (with

the welding power source switched off):

1 - Connecting the cables (Fig. C1-C2)

1) Connect the gas hose to the pressure reducer fitted on

the cylinder beforehand. Gas cylinders are supplied with

6

a pressure reducer to adjust pressure of the gas used for

welding.

2) Screw the torch to the centralised connection on the front

panel of the welding welding power source (Pos. 4, Fig.A).

3) Connect up the earthing system cable to the rapid cou-

pling marked by a - (negative) symbol and then the rel-

evant ground clamps to the piece being welded or to its

support in an area free from rust, paint and grease. Using

particularly long earthing cables reduces the voltage and

causes some problems from increased resistance and in-

ductance of the cables that could cause faulty welding. Fol-

low instructions to avoid these problems:

•

Use earthing and extension cables with appropriate sec-

tion.

• Lay out the cables as a flat as possible to prevent them

from coiling up.

4) Open the moving cover, remove the protection box for

changing polarity (see Fig. C2) and make sure that the

change polarity cable is connected to the positive pole (+).

2 - Welding

1) Open the moving cover and fit the coil of wire.

2) Load the wire (see the “Loading the wire” paragraph).

3) Switch the welding welding power source on by moving the

power supply switch to I(Pos. 5, Fig. A).

4) Carry out the following operations on the MIG-MAG torch:

•

Remove the gas-guide and wire-guide nozzles, allowing

the wire to flow freely during loading. Remember that the

contact tip must correspond to the wire diameter.

•

Push the torch push button or the motor check push but-

ton until the wire end comes out from the torch.

• Tighten the contact tip on the torch.

• Attach the correct gas-guide nozzle.

• Protect the gas-guide nozzle and the wire-guide nozzle

of the torch from sprays of solder.

5) Make the adjustments and select the parameters on the

control panel.

6) Open the tap on the cylinder slowly and adjust the reduc-

er knob to obtain a pressure of about 1,0 to 1,5 bar, and

regulate the flow to about 15 lit/min (to suit the current to

used for welding).

7) The welding welding power source is ready for welding. To

begin welding, approach the point to be welded and press

the button on the torch.

8) When you have finished welding, remove the waste, turn

off the welding power source and close the gas cylinder.

MIG-MAG welding without GAS

To begin MIG-MAG welding without gas, carry out the following

tasks (with the welding power source switched off):

1 - Connecting the cables (Fig. D1-D2)

1) Screw the torch to the centralised connection on the front

panel of the welding welding power source (Pos. 4, Fig.A).

2) Connect up the earthing system cable to the rapid cou-

pling marked by a + (positive) symbol and then the relevant

ground clamps to the piece being welded or to its support in

FIG. C2

FIG. C1

2000HB98

7

an area free from rust, paint and grease. Using particularly

long earthing cables reduces the voltage and causes some

problems from increased resistance and inductance of the

cables that could cause faulty welding. Follow instructions

to avoid these problems:

•

Use earthing and extension cables with appropriate sec-

tion.

• Lay out the cables as a flat as possible to prevent them

from coiling up.

3) Open the moving cover, remove the protection box for

changing polarity (see Fig. D2) and move the change po-

larity cable, connecting it to the negative pole (-).

2 - Welding

1) Open the moving cover and fit a coil of wire with a core for

welding without using gas.

2) Load the wire (see the “Loading the wire” paragraph).

3) Switch the welding welding power source on by moving the

power supply switch to I(Pos. 5, Fig. A).

4) Carry out the following operations on the MIG-MAG torch:

•

Remove the gas-guide and wire-guide nozzles, allowing

the wire to flow freely during loading. Remember that the

contact tip must correspond to the wire diameter.

•

Push the torch push button or the motor check push but-

ton until the wire end comes out from the torch.

• Tighten the contact tip on the torch.

• Attach the correct gas-guide nozzle.

• Protect the gas-guide nozzle and the wire-guide nozzle

of the torch from sprays of solder.

5) Make the adjustments and select the parameters on the

control panel. Make sure that you have selected a program

that is suitable for wire with a core.

6) The welding welding power source is ready for welding. To

begin welding, approach the point to be welded and press

the button on the torch.

7) Once welding has been completed remove the slag and

switch off the welding power source.

Spot welding

FIG. E

Welding can be done with or without gas. The substantial dif-

ference with MIG-MAG welding is essentially related to the

torch and the adjustments that must be made on the TS con-

trol panel.

• Depending on the torch chosen and the work to be done, a

gas guide nozzle can be fitted on the torch that is specifical-

ly for spot welding (see Fig. E).

• Use the control panel to select the spot-welding mode and,

if necessary, make the changes to the related “Special func-

tions - Fx”, which allows the welding power source to do this

specific type of welding.

To begin spot welding:

•

Place the gas guiding nozzle perpendicular on the workpiece

to be spot welded.

•

Press the torch button to start the welding current and wire

feed.

•

When the spot welding time expires (SPOT WELD TIME),

the wire feed stops automatically.

•

When the torch button is pushed again a new welding cy-

cle starts.

• Release the torch button.

FIG. D1

FIG. D2

2000HB99

8

FIG. F

Interval welding (Stitch)

The substantial differences with the spot welding mainly con-

cern the adjustments that must be carried on the welding weld-

ing power source.

Use the control panel to select the interval welding mode and

then make the changes to the related “Special functions - Fx”,

which allows the welding power source to do this specific type

of welding.

To begin interval welding:

•

Press the torch button to start the welding current and wire

feed.

•

At this point the welding welding power source automatically

carries out a succession of welded portions (STITCH WELD

TIME) followed by a pause (STITCH WELD PAUSE), ac-

cording to the times entered previously. This procedure stops

automatically only when the TORCH BUTTON is released.

•

When the torch button is pushed again the torch begins a

new interval welding cycle.

Aluminium welding

To weld with aluminum wire proceed as follows:

•

Replace the drive roller with the appropriate for aluminum

wire.

•

We recommend to use a torch set with maximum lenght of

3 m and a capillary liner, e.g. DIX DSK 2-xx.

•

Set the pressure between the drive rollers at the minimum,

by turning the screw provided.

• Use argon gas at a pressure of 1,3 - 1,7 bar.

TIG welding with “Lift”

In the TIG process welding is achieved by melting the two metal

pieces to be joined, with the possible addition of material from

the outside, using an arc ignited by a tungsten electrode. The

“Lift” (TCS) type ignition used in the equipment makes it pos-

sible to reduce tungsten inclusions on ignition to a minimum.

The molten bath and the electrode are protected by and inert

gas (for example,Argon). This type of welding is used to weld

thin sheet metal or when elevated quality is required.

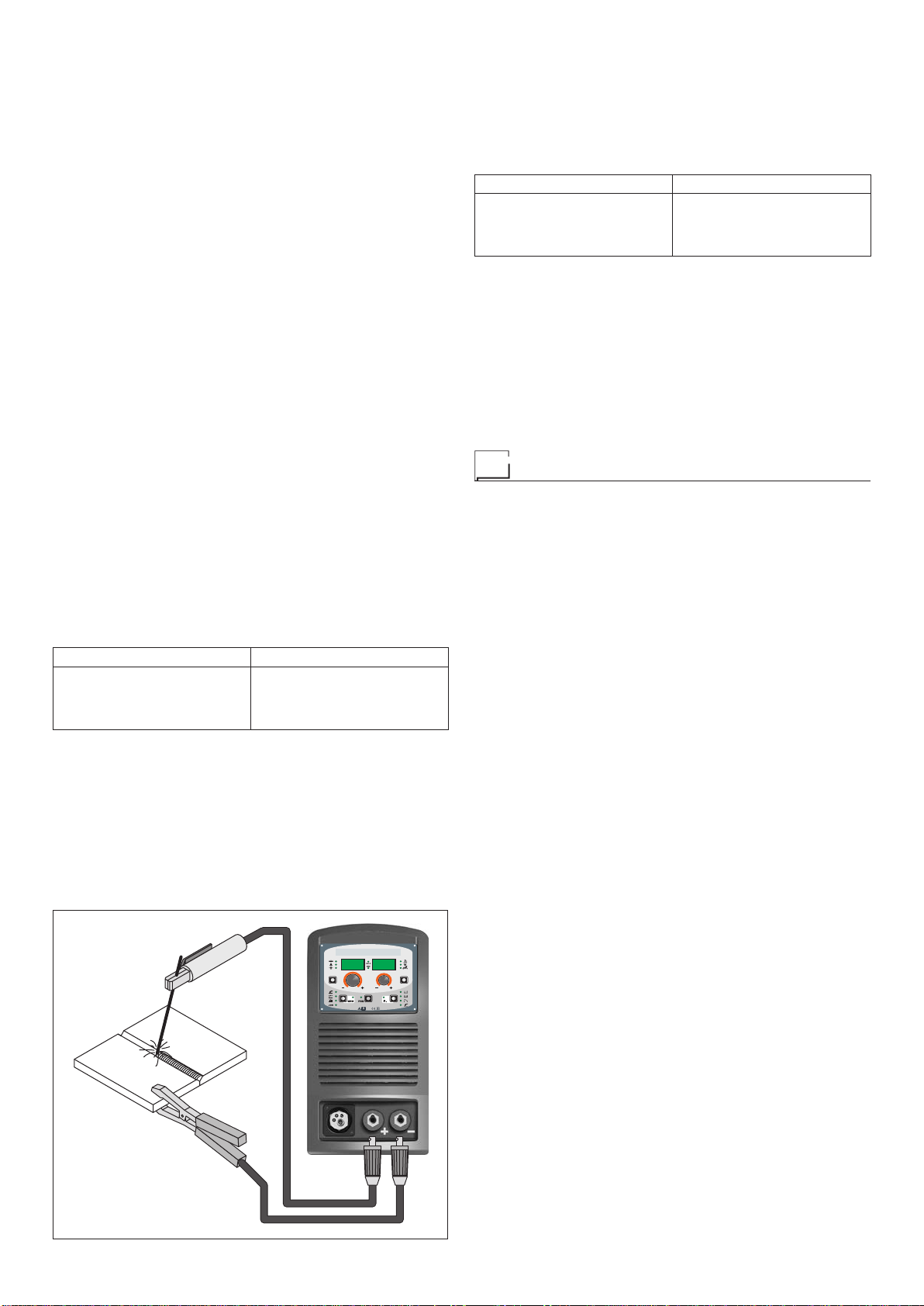

1) Connecting the welding cables (Fig. F):

•

Connect one end of the gas hose to the gas connecter on

the TIG torch and the other end to the pressure reducer

on the inert gas cylinder (Argon or similar).

• With the welding power source switched off:

-

Connect the ground cable to the snap-on connector

marked + (positive).

-

Connect the relative ground clamp to the workpiece or

to the workpiece support in an area free of rust, paint,

grease, etc..

-

Connect the TIG torch power cable to the snap-on con-

nector marked - (negative).

2) Switch the welding welding power source on by moving the

power supply switch to I(Pos. 5, Fig. A).

3) Make the adjustments and do the parameter settings on

the control panel.

4) Open the gas cylinder and regulate the flow by adjusting

the valve on the TIG torch by hand.

5) Ignite the electric arc by contact, using a decisive, quick

movement without dragging the tungsten electrode on the

piece to be welded (“Lift” type ignition - Fig. G).

6) The welder has a SWS “Smart Welding Stop” system for

the end of TIG welding. Lifting up the torch without switch-

ing off the arc will introduce a slope down and it will switch

off automatically.

7) When you have finished welding remember to shut the

valve on the gas cylinder.

Table 3 shows the currents to use with the respective elec-

trodes for TIG DC welding. This input is not absolute but is for

your guidance only; read the electrode manufacturers’instruc-

tions for a specific choice. The diameter of the electrode to use

is directly proportional to the current being used for welding.

Table 3

Ø ELECTRODE

(mm)

ELECTRODE TYPE

Current adjustment field (A)

TIG DC

Tungsten

Ce 1%

Grey

Tungsten

Rare ground 2%

Turchoise

110-50 10-50

1,6 50-80 50-80

2,4 80-150 80-150

3,2 150-250 150-250

Electrode welding (MMA)

Electrode welding is used to weld most metals (different types

of steel, etc.) using coated rutilic and basic electrodes with di-

ameters ranging from Ø 1.6 mm to Ø 3,2 mm.

1) Connecting the welding cables (Fig. H):

Disconnect the welding power source from the mains pow-

er supply and connect the welding cables to the output

terminals (Positive and Negative) of the welding welding

power source, attaching them to the clamp and ground

with the polarity specified for the type of electrode being

FIG. G

2000HA86

9

used (Fig. H). Always follow the electrode manufacturer’s

instructions. The welding cables must be as short as pos-

sible, they must be near to one another, positioned at or

near floor level. Do not touch the electrode clamp and the

ground clamp simultaneously.

2) Switch the welding welding power source on by moving the

power supply switch to I(Pos. 5, Fig. A).

3) Make the adjustments and select the parameters on the

control panel.

4) Carry out welding by moving the torch to the workpiece.

Strike the arc (press the electrode quickly against the met-

al and then lift it) to melt the electrode, the coating of which

forms a protective residue. Then continue welding by mov-

ing the electrode from left to right, inclining it by about 60°

compared with the metal in relation to the direction of weld-

ing.

PART TO BE WELDED

The part to be welded must always be connected to ground

in order to reduce electromagnetic emission. Much attention

must be afforded so that the ground connection of the part to

be welded does not increase the risk of accident to the user or

the risk of damage to other electric equipment. When it is nec-

essary to connect the part to be welded to ground, you should

make a direct connection between the part and the ground

shaft. In those countries in which such a connection is not al-

lowed, connect the part to be welded to ground using suitable

capacitors, in compliance with the national regulations.

WELDING PARAMETERS

Table 4 shows some general indications for the choice of elec-

trode, based on the thickness of the parts to be welded. The

values of current to use are shown in the table with the respec-

tive electrodes for the welding of common steels and low-grade

alloys. These data have no absolute value and are indicative

data only. For a precise choice follow the instructions provided

by the electrode manufacturer.

Table 4

WELDING THICKNESS (mm) Ø ELECTRODE (mm)

1,2 ÷ 2

1,5 ÷ 3

3 ÷ 5

5 ÷ 12

1,6

2

2,5

3,2

The current to be used depends on the welding positions and

the type of joint, and it increases according to the thickness and

dimensions of the part.

The current intensity to be used for the different types of weld-

ing, within the field of regulation shown in table 5 is:

• High for plane, frontal plane and vertical upwards welding.

• Medium for overhead welding.

•

Low for vertical downwards welding and for joining small pre-

heated pieces.

Table 5

Ø ELECTRODE (mm) CURRENT (A)

1,6

2

2,5

3,2

30 ÷ 60

40 ÷ 75

60 ÷ 110

95 ÷ 140

Afairly approximate indication of the average current to use in

the welding of electrodes for ordinary steel is given by the fol-

lowing formula: I = 50 × (Øe - 1)

Where:

I = intensity of the welding current

Øe = electrode diameter

Example:

For electrode diameter 4 mm

I = 50 × (4 - 1) = 50 × 3 = 150A

Maintenance

ATTENTION: Cut off the power supply to the equipment be-

fore effecting any internal inspection.

DIX PI GO 1156.M

IMPORTANT: Since the welding welding power sources are ful-

ly electronic, removing the dust that is sucked into the welding

power source by the fans, is of utmost importance.

In order to achieve correct functioning of the welding power

source, proceed as described:

•

Periodic removal of accumulations of dirt and dust inside the

equipment using compressed air. Do not point the jet of air

directly at the electrical parts as this could damage them.

•

Periodical inspection for worn cables or loose connections

that could cause overheating.

•

Make sure the air circuit is completely free of any impuri-

ties and that the connections are tight and free of any leaks.

In this connection, inspect the solenoid valve very carefully.

•

Check the wire feeder rolls periodically and replace them

when wear impairs the regular flow of the wire (slipping etc).

TORCH

The torch is subjected to high temperatures and is also stressed

by traction and torsion. We recommend not to twistthe wire and

not to use the torch to pull the welder. As a result of the above

the torch will require frequent maintenance such as:

• Cleaning welding splashes from the gas diffuser so that the

gas flows freely.

• Substitution of the contact point when the hole is deformed.

•

Cleaning of the wire guide liner using trichloroethylene or

specific solvents.

• Check of the insulation and connections of the power cable;

the connections must be in good electrical and mechanical

condition.

SPARE PARTS

Original spares have been specifically designed for our equip-

ment. The use of spares that are not original may cause vari-

ations in the performance and reduce the safety level of the

equipment. We are not liable for damage due to use of spare

parts that are not original.

FIG. H

10

The pointing out of any difficulties

and their elimination

The supply line is attributed with the cause of the most com-

mon difficulties. In the case of breakdown, proceed as follows:

1) Check the value of the supply voltage.

2) Check that the power cable is perfectly connected to the

plug and the supply switch.

3) Check that the power fuses are not burned out or loose.

4) Check whether the following are defective:

• The switch that supplies the welding power source.

• The plug socket in the wall.

• The mains switch.

NOTE: Given the required technical skills necessary for the

repair of the welding power source, in case of breakdown we

advise you to contact skilled personnel or our technical ser-

vice department.

Replacing the digital interface PCB

Proceed as follows:

• Unscrew the 4 screws that fix the front rack panel.

• Remove both the adjustment knobs.

• Disconnect the electrical connectors for the board.

• Unscrew the support columns.

• Remove the electronic board by lifting it off its supports.

• To fit a new board, follow this procedure in reverse.

11

Troubleshooting table

WARNING: Any internal inspections or repairs are only to be done by qualified personnel!

IMPORTANT: Remember to disconnect the mains power supply and wait for the internal capacitors to discharge (about 2 min-

utes) before starting to check and repair the welding power source if necessary.

Defect Solution

The welding welding power

source does not switch on,

control panel switched off.

• Check that the welding welding power source is installed correctly and that the

mains supply has sufficient power to supply the welding welding power source.

• Check the switch, cable and plug on the power supply line and replace them if necessary.

• Check, and if necessary replace, the digital interface PCB or the control PCB.

Line fuses fused

“instantaneously”. • Check that the welding welding power source is installed correctly.

• Check and if necessary replace the motor, transformer, or rectifier.

Line fuses fused after

a work period. • Check that you have fitted line fuses of adequate absorption capacity.

Welding welding power

source on, control panel

on, fan stopped.

• Check the wiring that powers the fans.

• Check that there are no mechanical impediments blocking the fans.

• Check and if necessary replace the digital interface PCB.

Welding welding power

source on, display does

not show correct values.

• See the error codes and signals shown in this manual.

• Check the wiring that powers the various boards.

• Check, and if necessary replace, the digital interface PCB or the control PCB.

No gas coming out of the torch. • Check and if necessary replace the solenoid valve or gas hose.

• Check the wiring that powers the gas solenoid valve.

• Check, and if necessary replace, the digital interface PCB or the control PCB.

The wire feed motor does not

work during MIG-MAG welding. • Check the wiring that powers the wire feed motor.

• Check that there are no mechanical impediments blocking the motor.

• Check that the motor is working correctly and if necessary replace it.

• Check and if necessary replace the digital interface PCB.

Welding current insufficient

or not constant. • Check the power supply line.

• Check and if necessary replace the wires (section or length inadequate).

• Check the line voltage using a voltmeter.

Arc ignition difficult, the arc

switches off immediately

after ignition during MIG-

MAG welding.

• Make sure you have set the various welding parameters correctly.

• Check compatibility of the torch and the wire used.

• Check that the torch and all its components are working correctly

and replace them if necessary (e.g. worn components).

• Check and if necessary replace the digital interface PCB.

The wire sticks to the

workpiece to be welded. • Check that there are no mechanical impediments blocking correct unwinding of the wire.

• Check that the motor is working correctly and if necessary replace it.

• Check and if necessary replace the digital interface PCB.

12

2101AC55/A

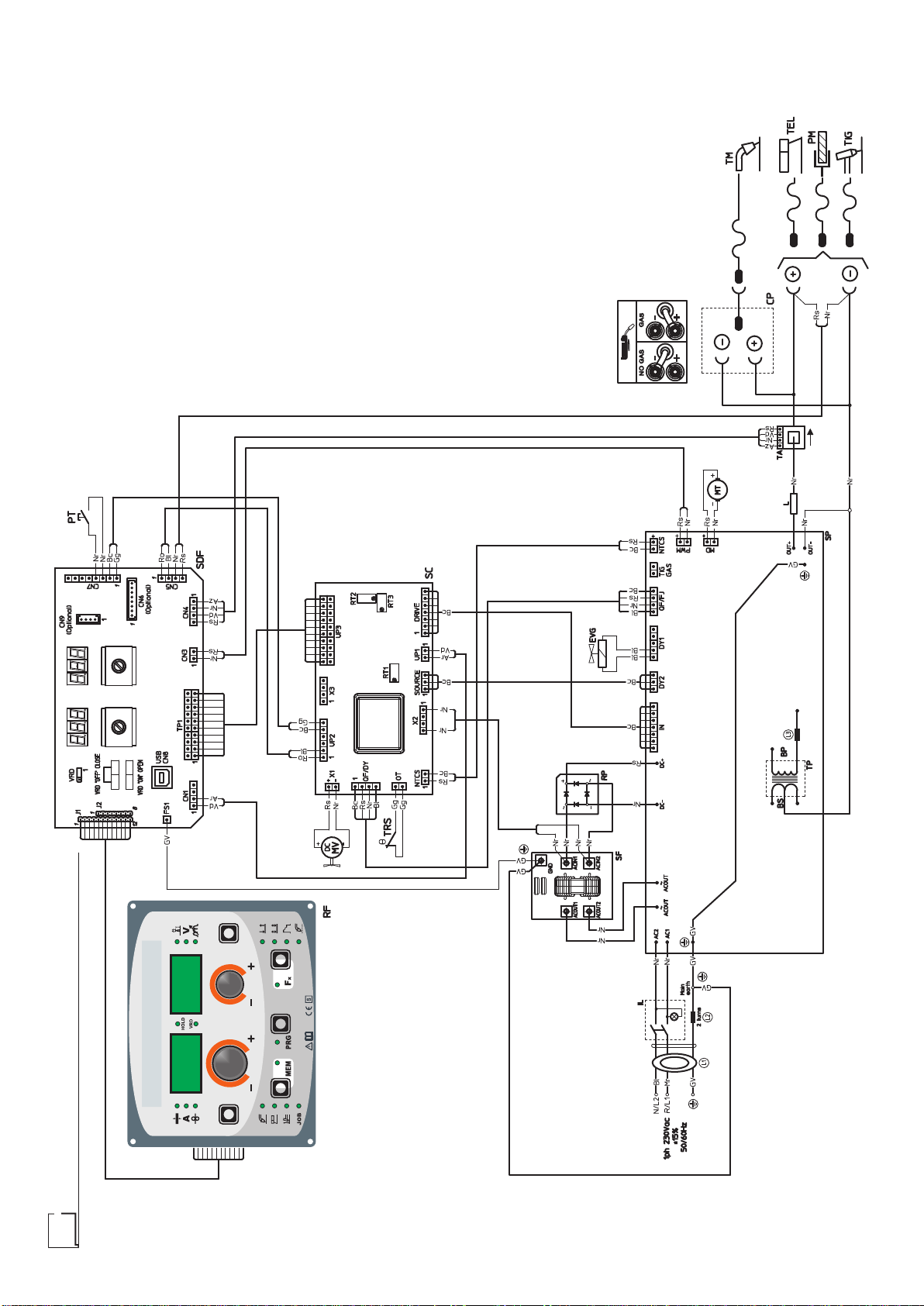

Electro topographical diagram

13

•1•2•3•4•5•6•7•8•9•10 •11

BP BS CP EVG IL LL1-2-3 MT MV PM PT

•12 •13 •14 •15 •16 •17 •18 •19 •20 •21 •22

RF RP SC SDF SF TA TEL TIG TM TP TRS

Electro topographical diagram key

•1 Primary transformer coil •2 Secondary transformer coil •3 Polarity change

terminal board •4 Gas solenoid valve •5 Mains switch •6 Secondary induct-

ance •7 Toroidal ferrite •8 Drive motor •9 Fan motor •10 Earth terminal •11

Torch button •12 Rack panel •13 Primary rectifier •14 Control PCB •15 Dig-

ital interface PCB •16 EMC filter PCB •17 Hall effect transformer •18 MMA

torch •19 TIG torch •20 MIG-MAG torch •21 Main transformer •22 Second-

ary diodes thermostat

Colour key

Ar Orange

Az Sky Blue

Bc White

Bl Blue

Gg Grey

Gl Yellow

GV Yellow-Green

Mr Brown

Nr Black

Ro Pink

Rs Red

Vd Green

Vl Violet

Meaning of graphic symbols on welding power source

System for use in environments with in-

creased risk of electroshock

Product suitable for free circulation in the Eu-

ropean Community

Dangerous voltage

Grounding protection

Positive pole snap-in connector

Negative pole snap-in connector

Warning!

Before using the equipment you should care-

fully read the instructions included in this man-

ual

Danger! Parts moving

It is forbidden to use gloves

14

Control panel

Welding Power Source

Introduction 13

KEYAND KNOB COMMANDS 14

Control panel 14

DISPLAYAND LED INDICATIONS 15

Switching on the welding power source and initial

screen 15

Viewing the software version installed 15

Loading of the wire 16

Special functions “Fx” 16

SETUP Menu 18

FACTORY DEFAULT (FAC) 18

TIMERARC ON 18

TIMER Welding power source ON 18

ERROR LOG 19

TEST 19

Menu SPECIAL FUNCTIONS 20

SAFETY CALIBRATION CODE (SCC) 20

MOTOR CALIBRATION (Mot CAL) 20

ARC LENGTHADJUST 21

SWITCH 21

WATER COOLING MODE 21

PASSWORD 22

BLOCKS 22

SERIAL NUMBER 22

MIG-MAG synergic / MIG pulse / double pulsed MIG 23

1 - WELDING PROCESS SELECTION 23

2 - SELECTION OF WELDING PROGRAMME 23

3 - WELDING MODE SELECTION 24

4 - SPECIAL FUNCTIONS “Fx” SELECTION 24

5 - PRE-SETTING 25

6 - WELDING 25

7 - HOLD 25

MIG-MAG manual 26

1 - WELDING PROCESS SELECTION 26

2 - WELDING MODE SELECTION 26

3 - SPECIAL FUNCTIONS “Fx” SELECTION 26

4 - PRE-SETTING 27

5 - WELDING 27

6 - HOLD 27

Special processes 28

Electrode (MMA) 28

1 - WELDING PROCESS SELECTION 28

2 - SELECTION OF WELDING PROGRAM 28

3 - SPECIAL FUNCTIONS “Fx” SELECTION 29

4 - PRE-SETTING 29

5 - WELDING 29

6 - HOLD 30

7 -ACTIVATING THE VRD DEVICE 30

TIG with “Lift” striking 30

1 - WELDING PROCESS SELECTION 30

2 - SPECIAL FUNCTIONS “Fx” SELECTION 30

3 - PRE-SETTING 31

4 - WELDING 31

5 - HOLD 31

JOB 32

1 - CREATINGAND SAVING A JOB 32

2 - JOB SELECTION 32

3 - PRE-SETTING / VIEWING MEMORISED JOB

DATA 32

4 - WELDING 33

5 - HOLD 33

6 - MODIFICATIONAND OVERWRITING OF A

MEMORISED JOB 33

7 - DELETINGA JOB SAVED 33

Error condition 34

Introduction

This manual contains all the information necessary to make the

best use of this control panel. This control panel is specifically for

multi-process welding power sources: MIG-MAG, PULSED MIG,

DOUBLE PULSED MIG, MMAand TIG.

15

Control panel

KEY AND KNOB COMMANDS

▪ ENCODER knob - V

▪ WELDING MODE

SELECTION key

▪ SPECIAL FUNCTIONS

key “Fx”

▪ PROGRAMME SELECTION key

▪ SET-UP MENU Key

▪ ENCODER knob - A

▪ WELDING PROCESS

SELECTION key

▪ SAVE “MEM” key

▪ PARAMETER

SELECTION key - A ▪ PARAMETER

SELECTION key - V

■PARAMETER SELECTION key - A

This is used to select the following welding parameters:

• THICKNESS OF WELDED ITEM ( ).

• WELDING CURRENT ( ).

• WIRE SPEED ( ).

■ENCODER knob - A

This is used to set and edit the PARAMETERS - A based on the

corresponding LED switched on and the value highlighted on the

DISPLAY PARAMETERS -Adisplay, required for correct function-

ing of the machine.

■PARAMETER SELECTION key - V

This is used to select the following welding parameters:

• ARC LENGTH ADJUSTMENT ( ).

• WELDING VOLTAGE ( ).

• ELECTRONIC INDUCTANCE ( ).

■ENCODER knob - V

This is used to set and edit the PARAMETERS - V based on the

corresponding LED switched on and the value highlighted on the

DISPLAY PARAMETERS - V display, required for correct function-

ing of the machine.

■PROGRAMME SELECTION key

It can be used to select the individual welding PROGRAM for MIG-

MAG and MMAwelding processes.

■SET-UP MENU Key (T > 3 s)

This provides access to the SET-UP menu, which in turn provides

access to a series of functions, suitable for an expert operator.

■WELDING PROCESS SELECTION key

It can also be used to select the following welding processes:

• MIG-MAG / PULSED MIG / Double PULSED MIG.

• MMA.

• TIG.

• JOB.

■SAVE“MEM”key(T≥2s)

It allows the saving of the parameters in the JOB.

It also allows one to view / change the parameters previously saved

in the JOB.

WARNING: No LED switches on when this key is activated!

■WELDING MODE SELECTION key

This is used to select the following welding modes (only for MIG

welding processes) and each time the key is pushed the welding

power source moves on to select the next welding mode in the

following order:

TWO STROKE (2T)

2T LED ( ) switched on

Pressing the TORCH TRIGGER starts the welding cycle, which

will stop when it is released.

FOUR STROKE (4T)

4T LED ( ) switched on

1) Pressing and releasing the TORCH TRIGGER will start the

welding cycle.

2) Pressing and releasing the TORCH TRIGGER will start the

welding cycle.

CRATER 2T

2T LED ( ) switched on - CRATER LED ( ) switched on

1) When theTORCHTRIGGER is pushed the arc ignites and the

parameters assume the values for the “initial crater” for a time

set by means of the CRATER START TIME (F10) function.

After that the parameter values become those for “welding” for

a time defined by the CRATER STARTSLOPE (F11) function.

2) When the TORCH TRIGGER is released the parameters take

on the “final crater” values for a time set by means of the CRA-

TER END TIME (F15) function, for a period of time set using

the CRATER END SLOPE (F12) function.

CRATER 4T

4T LED ( ) switched on - CRATER LED ( ) switched on

1) When the TORCHTRIGGER is pushed the arc ignites and the

parameters assume the values for the “initial crater”.

2) When the TORCH TRIGGER is released the parameters

take on the “welding” values for a time set using the CRATER

START SLOPE (F11) function.

3) When the TORCH TRIGGER is pushed again the parameters

take on the “final crater” values for a time defined using the

CRATER END SLOPE (F12) function.

4) Releasing the TORCH TRIGGER will end the welding cycle.

SPOT WELDING 2T

2T LED ( ) switched on - SPOT LED ( ) switched on

This is used so that on pressing the TORCH TRIGGER spot weld-

ing is done for a time period set beforehand (in seconds), after

which the arc switches off automatically (SPOT WELD TIME F07

function).

STITCH WELDING 2T

2T LED ( ) switched on - SPOT LED ( ) flashing

To begin stitch welding:

1) Press the TORCH TRIGGER to start the welding current and

wire feed.

At this point the welder will perform automatically a succession

of a welded tracts followed by a pause, respecting the times

set in the functions STITCH WELD TIME (F05) and STITCH

WELD PAUSE (F06).

This procedure stops automatically only when the TORCH

TRIGGER is released.

2) When the TORCH TRIGGER is pushed again the torch be-

gins a new interval welding cycle.

SWITCH mode

4T LED ( ) switched on - CRATER LED ( ) flashing

1) When the TORCH BUTTON is pushed, the arc is ignited and

the welding parameters take on the values for the initial cra-

ter.

2) When the TORCH BUTTON is released, the current goes to

that for welding at a time defined by the CRATER START

SLOPE function (F11).

3) When the SWITCH BUTTON is pressed and released within

1 second, the current goes to that defined by the (F19) and

(F20) “SWITCH” functions. By repeating this operation, you

can switch an infinite number of times between the I2 level

and welding level.

4) When the TORCH BUTTON is pushed again and held down

for more than 1 second, after a time defined by the CRATER

END SLOPE (F12) function, the welding parameters taken on

the values for the final crater. When the TORCH BUTTON is

released the welding cycle ends.

16

■SPECIALFUNCTIONSkey“Fx”(T≥2s)

This key is used to display and edit some parameters (ADJUST-

ABLE FUNCTIONS “Fx”) that are necessary and fundamental for

welding and that have already been set by the manufacturer in

the factory.

The parameters vary depending on the welding process and mode

used, and are saved in the memory for each automatic welding

point (JOB).

DISPLAY AND LED INDICATIONS

▪ VRD LED▪ HOLD FUNCTION LED

▪ PARAMETER

SELECTION LED - V

▪ PARAMETER

SELECTION LED - A

▪ PROGRAMME

SELECTION LED

▪ WELDING MODE

SELECTION LED

▪ Fx LED - SPECIAL

FUNCTIONS

▪ WELDING PROCESS

SELECTION LED

▪ JOB SAVING MEM LED

▪ PARAMETER DISPLAY screen - V▪ PARAMETER DISPLAY screen - A

■PARAMETER SELECTION LED - A

When one of these LEDs is on it means that the corresponding

welding parameter has been selected.

■PROGRAMME SELECTION LED

This LED will be lit only when the operator selects a welding pro-

cess (in which there welding programmes present) and the rela-

tive associated programme.

■PARAMETER DISPLAY screen - A

This Display shows the values / numbers (set or measured) of the

following parameters (if active):

• THICKNESS OF WELDED ITEM ( ).

• WELDING CURRENT ( ).

• WIRE SPEED ( ).

• WELDING PROGRAM ( ).

■HOLD FUNCTION LED

Flashing, it indicates that the values of the parameters views on

the PARAMETER DISPLAY -Aand V are respectively the values

that are set or measured at the conclusion of the last welding. The

LED flashes for 15 seconds consecutively before turning itself off or

until the moment that the operator varies any parameter by means

of the use of the handles.

■WELDING PROCESS SELECTION LED

When one of these LEDs is on it means that the corresponding

welding process has been selected.

■PARAMETER SELECTION LED - V

When one of these LEDs is on it means that the corresponding

welding parameter has been selected.

■PARAMETER DISPLAY screen - V

This Display shows the values / numbers (set or measured) of the

following parameters (if active):

• ARC LENGTH ADJUSTMENT ( ).

• WELDING VOLTAGE ( ).

• ELECTRONIC INDUCTANCE ( ).

■JOB SAVING MEM LED

Flashes while saving a JOB.

■Fx LED - SPECIAL FUNCTIONS

Switched on when special Fx parameters are displayed.

■VRD LED

The Voltage Reduction Device (VRD) is a safety device that re-

duces voltage. It prevents voltages forming on the output termi-

nals that may pose a danger to people.

Two-tone LED (off - red - green) indicates enabling of the VRD. In

the welding process:

• MIG MAG (Synergic and Manual) / JOB: the VRD device is not

managed and therefore the LED always will be off.

•

MMA: the operator can decide whether or not to activate the

VRD device (to activate the VRD device see the corresponding

paragraph) based on its necessities and therefore the LED will

be lit and will indicate the activation of the device.

•

TIG Lift: the VRD device is always inserted, independently from

the state of the JUMPER and therefore the LED always will be lit.

■WELDING MODE SELECTION LED

When one or a combination of these LED is lit, it means that the

corresponding manner of welding has been selected.

Switching on the welding power

source and initial screen

At the switching on of the welder (press the switch, located on the

back panel, at the position I), the control performs a short operation

of MACHINE CHECK (all of the LED light themselves simultane-

ously so as to verify their actual operation), and the panel display

the INITIAL SCREEN (see the demonstrative figure), after which

the operator can begin to work.

Viewing the software version installed

1) When the welding power source is working hold down the

WELDING PROCESS SELECTION key (T2) and WELDING

MODE SELECTION key (T3) together for about 2 consecu-

tive seconds.

T2 T3

17

2) On both displays appears a running string that indicates the

VERSION OF THE SOFTWARE installed on the welder.

The rotation of one of the two ENCODER Knobs - A (E1) or

V (E2) by the operator during the display of the string version

software provokes the block (for 1second), on both the dis-

plays, of the movement of the string itself.

E2E1

3) Ending viewing of the software version on the control panel

can come about in 2 different ways:

• Automatically: by waiting for the display time to elapse.

• Manually: by pushing any key.

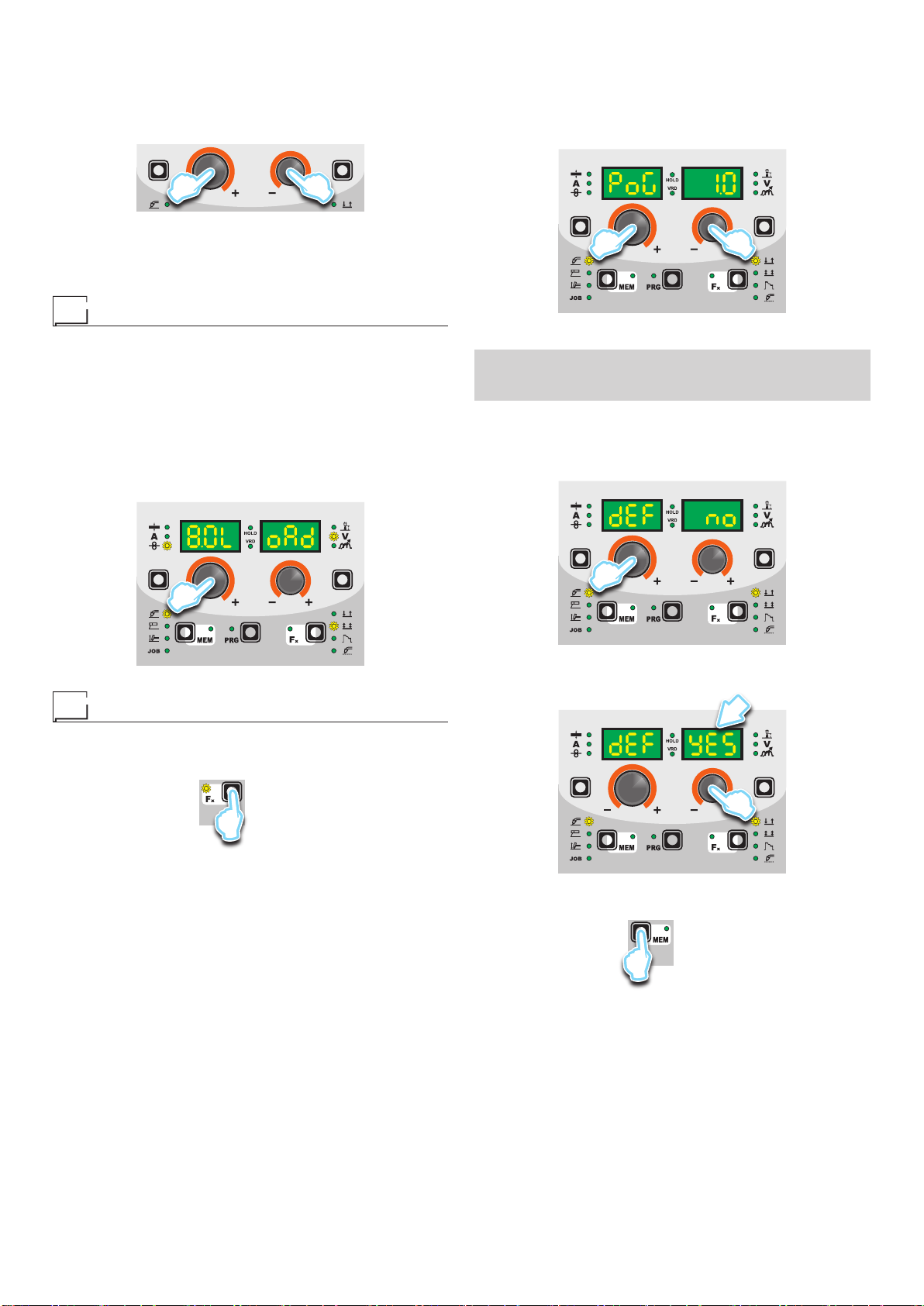

Loading of the wire

In the MIG-MAG-PULSE-DOUBLE PULSE welding processes,

with the welder in operation, it is possible to load the wire inside

the torch, following this simple procedure:

• Keep the torch button held down.

• After a time of about 2 seconds, the wire begins to load itself at

a constant speed.

•

This operation is also indicated by a message made up of a nu-

merical value for the wire speed, followed by “LoAd” (see figure).

•

Rotate the ENCODER - A (E1) knob to change the wire load-

ing speed.

• To finish the loading of the wire release the torch button.

E1

Special functions “Fx”

To access the SPECIAL FUNCTIONS “Fx” menu, hold the SPE-

CIAL FUNCTIONS “Fx” key (T3) down for at least 3 consecutive

seconds. The Fx LED switches on.

T3

T > 3 s

The special functions allow the operator to regulate further param-

eters, operations and do partial resetting, and are operative, in a

different way, within each welding process.

Table 1 shows the special functions available. Details of the mean-

ing of the columns are as follows:

• FUNCTION column: name of the special function.

•

DISPLAY column: symbol for the special function (message

shown in the PARAMETERS DISPLAY -A screen).

•

FACTORY column: Factory setting for the special function (mes-

sage shown in the PARAMETERS DISPLAY - V screen).

• RANGE column: regulation field for the special function.

•

The last two groups of columns, WELDING PROCESS and

MIG-MAG WELDING MODE indicate the welding process and

mode in which the special function can be selected. Example:

the SPOT WELDTIME function can be selected only when one

is welding in synergistic MIG-MAG-PULSE or manual SPOT

2T mode.

1) Rotate the ENCODER - A knob (E1) to select the SPECIAL

FUNCTION required. Rotate the ENCODER - V knob (E2) to

edit the VALUE for the special function selected.

WARNING: Changes to values are immediately activated (no fur-

ther confirmation is required and they will be displayed immedi-

ately) or, at least they will become active the next time welding is

done. The operator can edit the functions (not the wire speed and

other parameters) when welding is underway and continue weld-

ing without having to exit the SPECIAL FUNCTIONS “Fx” menu.

E2E1

2) PROGRAM DEFAULT (dEF)

WARNING: If carried out, this operation resets the program

in use to the factory default settings.

To carry out the reset of the settings / parameters, proceed in

the following manner:

• Rotate the ENCODER -A (E1) knob until both the displays

read dEF no (see figure).

E1

•

Rotate the ENCODER - V knob (E2) until the PARAME-

TERS DISPLAY - V screen (D2) reads YES.

D2

E2

• Hold the SAVE “MEM” key (T2) down for at least 2consec-

utive seconds.

T2

T ≥ 2 s

• The program in use has now been completed successfully.

To confirmation the above, the control panel of the welder

performs a short operation of MACHINE CHECK (all of the

LED stay lit simultaneously so as to verify their actual op-

eration), the generator itself starts, having memorised the

new settings and is again ready to weld.

18

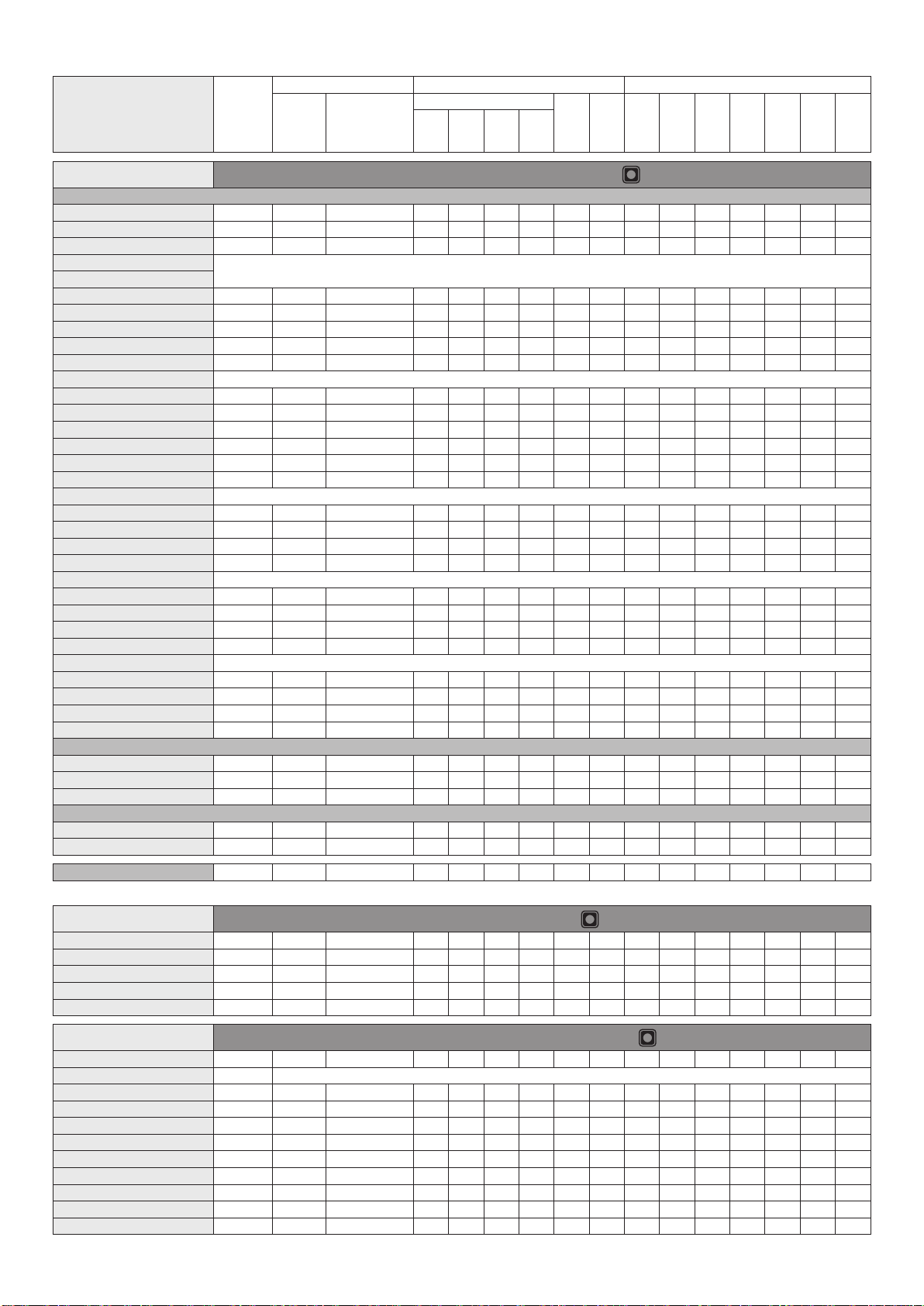

Table 1

FUNCTION DISPLAY

SETTINGS RANGE WELDING PROCESS MIG-MAG WELDING MODE

FACTORY RANGE

MIG MAG / PULSE

TIG MMA 2T 4T Cra

2T Cra

4T Spot

2T Stitch

2T Cycle

MiG

PLS

CLd dPL MAn SPd

ADJUSTABLE FUNCTIONS “Fx” Fx > 3s

MIG-MAG process

PRE GAS PrG 0.1s (0.0 ÷ 2.0)s ●●●● ●●●●●●●

STARTING SPEED Sts 0-30 ÷ +30 ●●●● ●●●●●●●

HOTSTART Hot 0-30 ÷ +30 ●●●● ●●●●●●●

CRATER

INITIALCRATER

CRATER START CURRENT F08 20% (-50 ÷ +100)% ● ● ● ● ● ●

CRATER START SPEED F08 5.0m/min (1.5 ÷ 22.0)m/min ● ● ● ●

CRATER START VOLTAGE F09 25.0V (10.0 ÷ 38.0/42.0)V ● ● ● ●

CRATER STARTTIME F10 1.0s (0.0 ÷ 20.0)s ●●●● ●

CRATER START SLOPE F11 1.0s (0.0 ÷ 20.0)s ●●●● ●● ●

FINALCRATER

CRATER END SLOPE F12 1.0s (0.0 ÷ 20.0)s ●●●● ●● ●

CRATER END CURRENT F13 -30 (-99 ÷ +50)% ● ● ● ● ● ●

CRATER END SPEED F13 5.0m/min (1.5 ÷ 22.0)m/min ● ● ● ●

CRATER END VOLTAGE F14 25.0V (10.0 ÷ 38.0/42.0)V ● ● ● ●

CRATER END TIME F15 0.0s (0.0 ÷ 20.0)s ●●●● ●

SPOTWELD TIME F07 3.0s (0.1 ÷ 20.0)s ●●●● ●

STITCH WELD

STITCH WELD TIME F05 1.0s (0.1 ÷ 20.0)s ●●●● ●

STITCH WELD PAUSE F06 1.0s (0.1 ÷ 20.0)s ●●●● ●

BURN BACK bUb 0-30 ÷ +30 ●●●● ●●●●●●●

POSTGAS PoG 1.0s (0.0 ÷ 10.0)s ●●●● ●●●●●●●

CYCLE

CYCLE CURRENT F19 20% (-99 ÷ 100)% ● ● ● ●

CYCLE WIRE SPEED F19 5.0 m/min (1.5 ÷ 22.0)m/min ● ●

CYCLEARC LENGTH F20 0-30 ÷ 30 ● ● ● ●

CYCLE VOLTAGE F20 25.0V (10.0 ÷ 38.0/42.0)V ● ●

DUAL PULSE FUNCTIONS

DUALPULSE DELTA CURRENT F23 50% (-99 ÷ +200)% ● ●●●●●●●

DUALPULSE BALANCE F25 0% (-40 ÷ +40)% ● ●●●●●●●

DUALPULSE FREQUENCY F26 2.7Hz (0.1 ÷ 5)Hz ● ●●●●●●●

DYNAMICS dYn 0-30 ÷ 30 ● ●●●●●●●

TIG process

UPSLOPE F29 0.0s (0.0 ÷ 20.0)s ●

DOWN SLOPE F30 2.0s (0.0 ÷ 20.0)s ●

SWS VOLTAGE LIMIT F31 0-30 ÷ 30 ●

MMAprocess

HOTSTART Hot 50 0 ÷ 100 ●

ARC FORCE ArC 50 0 ÷ 100 ●

PROGRAM DEFAULT dEF no no - YES ●●●●●●●●●●●●●

SETUP (SEtUP) menu PRG > 3s

FACTORYDEFAULT FAC no no - YES ●●●●●●●●●●●●●

TIMERARC ON ArC ont ●●●●●●●●●●●●●

TIMER Welding power source ON tiM Eon ●●●●●●●●●●●●●

ERROR LOG Err Log ●●●●●●●●●●●●●

TEST tES t ●●●●●●●●●●●●●

SPECIAL FUNCTIONS (SPC FnC) menu PRG > 3s

SAFETY CALIBRATION CODE SCC 70 ÷ 100 ●●●● ●●●●●●●

MOTOR CALIBRATION Mot CAL

SPEED MOTOR 1 SM1 75.0 50.0 ÷ 99.9 ●●●● ●●●●●●●

SPEED MOTOR 2 SM2 75.0 50.0 ÷ 99.9 ●●●● ●●●●●●●

SPEED MOTOR 3 SM3 75.0 50.0 ÷ 99.9 ●●●● ●●●●●●●

ARC LENGTHADJUST ArC UU - rPM ●●●● ●●●●●●●

CYCLE CYC oFF oFF - on ●●●● ●●●●●●●

WATER COOLING MODE H2o Dem Dem - Aon ●●●●●●●●●●●●●

PASSWORD PAS 00 ÷ 999 ●●●●●●●●●●●●●

BLOCKS bLC no no - L1 - L2 - L3 ●●●●●●●●●●●●●

SERIAL NUMBER SEr nUM ●●●●●●●●●●●●●

19

3) To exit the SPECIAL FUNCTIONS “Fx” menu, push and re-

lease the SPECIAL FUNCTIONS “Fx” (T3) key once.

T3

SETUP Menu

Hold the PRG key down for at least 3 seconds to open the SET-

UP menu, which provides access to various functions, which are

suitable for expert operators, such as advanced configurations,

system tests, and calibrations. For further information, see table 1.

FACTORY DEFAULT (FAC)

WARNING: If carried out, this operation results in complete

resetting of all editable parameters to the factory settings (in-

cluding cancellation of the JOBS).

To carry out the reset of the settings / parameters, proceed in the

following manner:

1) Rotate the ENCODER - A (E1) knob until both the displays

read FAC no (see figure).

E1

2) Rotate the ENCODER - V knob (E2) until the PARAMETERS

DISPLAY - V screen (D2) readsYES.

D2

E2

3) Hold the SAVE “MEM” key (T2) down for at least 2consecu-

tive seconds.

T2

T ≥ 2 s

4) At this stage the total reset or factory default procedure has

been completed successfully (the parameters have been tak-

en back to the factory values and any JOBS saved have been

deleted). To confirmation the above, the control panel of the

welder performs a short operation of MACHINE CHECK (all

of the LED stay lit simultaneously so as to verify their actual

operation), the generator itself starts, having memorised the

new settings and is again ready to weld.

TIMER ARC ON

This indicates the actual time the machine was used for welding.

WARNING: This time can only be zeroed using the FACTORY DE-

FAULT (FAC in the SEtUP menu) for the welding plant.

1) Rotate the ENCODER - A (E1) knob, until both the displays

(D1-D2) read ArCont.

D1 D2

E1

2) Push the PRG key to view the welding use time, expressed in

DAYS (d), HOURS (H), MINUTES (M). Example: 2d-3H-25M.

3) To go back to the SEtUP menu, push the SAVE “MEM” (T2)

key.

T2

TIMER Welding power source ON

This indicates the time the welding power source was switched on.

WARNING: This time can only be zeroed using the FACTORY DE-

FAULT (FAC in the SEtUP menu) for the welding plant.

1) Rotate the ENCODER - A (E1) knob, until both the displays

(D1-D2) read tiMEon.

D1 D2

E1

2) Push the PRG key to view the time the welding power source

was switched on, expressed in DAYS (d), HOURS (H), MIN-

UTES (M). Exam-ple: 120d-13H-22M.

3) To go back to the SEtUP menu, push the SAVE “MEM” (T2)

key.

T2

20

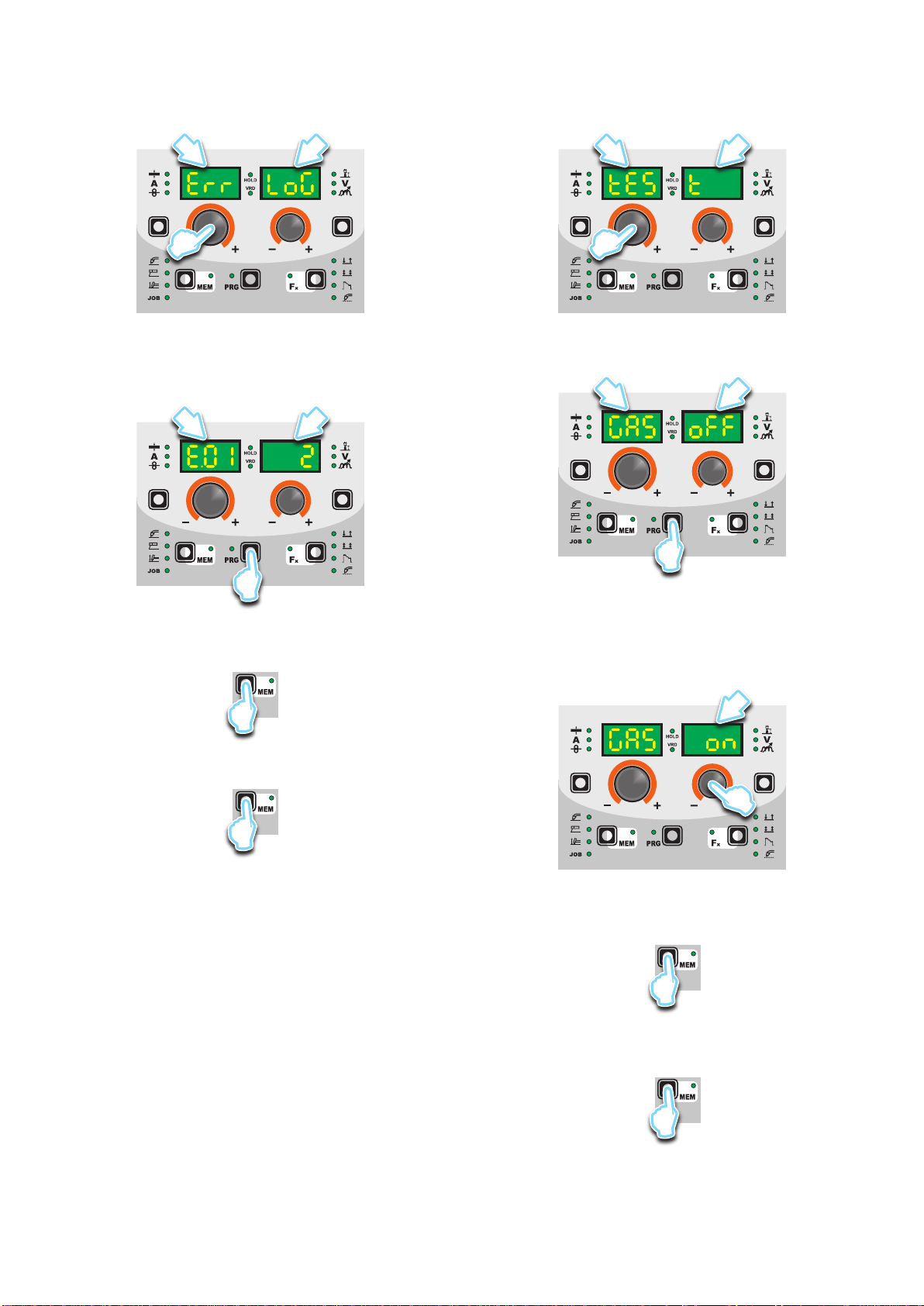

ERROR LOG

This allows the operator to know about the error states that have

arisen on the welding plant.

1) Rotate the ENCODER - A (E1) knob, until both the displays

(D1-D2) read Err Log.

D1 D2

E1

2) Push the PRG key (T5), and the display will show the error

code under DISPLAY PARAMETERS -A (D1), and the num-

ber of times under DISPLAY PARAMETERS - V (D2). For the

code error, see the list contained in the “Error Conditions” par-

agraph.

D1 D2

T5

3) Rotate the ENCODER - V (E2) knob to scroll the list.

4) To go back to the SEtUP menu, push the SAVE “MEM” (T2)

key.

T2

5) To exit the SEtUP menu, push the SAVE “MEM” (T2) key

again.

T2

TEST

This configuration allows the operator to check that some func-

tions of some devices.

1) Rotate the ENCODER - A (E1) knob, until both the displays

(D1-D2) read tESt.

D1 D2

E1

2) Push the PRG key (T5), and the display will show the param-

eter to be checked under DISPLAY PARAMETERS - A (D1),

and the set-ting under DISPLAY PARAMETERS - V (D2).

D1 D2

T5

3) Rotate the ENCODER -A(E1) knob to select the device to be

tested, from GAS (solenoid valve), Mot (wire feeder motor),

FAn (fans) and H2o (cooling unit, only if fitted).

4) Rotate the ENCODER - V (E2) knob clockwise to go from the

oFF state to the on state, which activates the device and al-

lows the user to check it is working.

D2

E2

5) To go back to the oFF state, rotate the ENCODER - V (E2)

knob anticlockwise.

6) Push the SAVE “MEM” (T2) key to go back to the SEtUP

menu.

T2

7) To check another device, repeat steps 2, 3 and 4.

8) To exit the SEtUP menu, push the SAVE “MEM” (T2) key

again.

T2

Other manuals for DIX GO 1156.M Puls

1

Table of contents

Other DINSE Welding System manuals