Vitals Mi 200md User manual

Mi 200md Mi 200m Mi 200da Mi 225da•• •

MANUAL FOR TECHNICAL USE

КЕРІВНИЦТВО З ЕКСПЛУАТАЦІЇ

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ

I

N

V

E

R

T

E

R

W

E

L

D

I

N

G

M

A

C

H

I

N

E

СОДЕРЖАНИЕ

ЗМІСТ

1. Общее описание

2. Комплект поставки

3. Технические характеристики

4. Требования безопасности

4.1. Важная информация по безопасности

4.2. Безопасность эксплуатации

5. ксплуатация

5.1.

5.2.

5.3. Сварочные работы

6. Техническое обслуживание

7. Транспортировка и хранение

8. Возможные неисправности и пути их устранения

Гарантийные обязательства9.

4.2. Заземление

Применение

Подготовка к работе

7.1. Транспортировка

7.2. Хранение

1. Загальний опис

2. Комплект поставки

3. Технічні характеристики

4. Вимоги безпеки

4.1. Важлива інформація з безпеки

4.2. Безпека експлуатації

5. Експлуатація

5.1.

5.2. Підготовка до роботи

5.3. Зварювальні роботи

6. Технічне обслуговування

7. Транспортування та зберігання

8. Можливі несправності та шляхи їх усунення

. Гарантійні зобов'язання9

4.3. Заземлення

Застосування

7.1. Транспортування

7.2. Зберігання

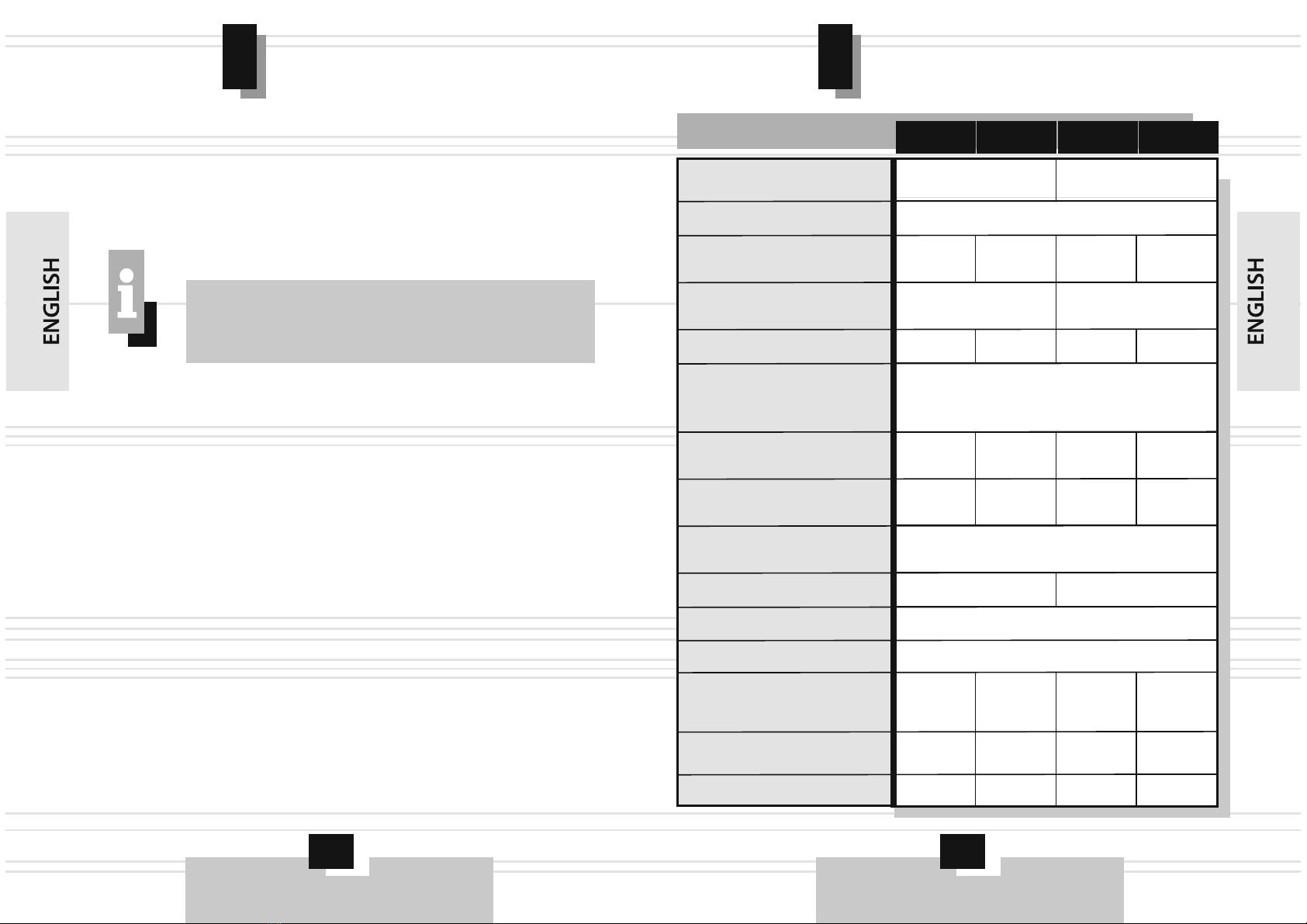

1. General description

2. Delivery kit

3.

4.

4.1. Important safety information

4.2. Safety of

5. Operation

5.3.

6. Maintenance

7.

8.

9. Warranty

5.1.

5.2.

Technical data

Safety requirements

4.3. Grounding

Application

Getting Started

Welding

Transport and storage

7.1. Transportation

7.2. Storage

Possible problems and their solution

operation

CONTENTS

УКРАЇНСЬКА ENGLISH

РУССКИЙ

6

12

13

15

15

17

20

22

22

2

25

29

31

31

32

33

38

2

42

48

49

51

51

53

56

58

58

58

61

65

67

67

68

69

47

7

8

8

8

8

8

9

9

9

9

9

10

10

10

10

10

11

8

4

5

7

7

9

2

5

5

5

8

2

4

4

5

6

1

5

DEAR BUYER!

Thank you for purchasing a welding machine inverter TM "Vitals".

The TM technique "Vitals" developed by the European quality standards

and using the latest technologies.

Improper use of inverter welding machine and unsafe practices that may

result in damage or serious injury!

This manual contains all the necessary information on safety measures

during the operation of inverter welding machine. Carefully read the manual

before using the product.

Please provide the other users of this manual, before they begin to work

with the welder inverter. This manual must be stored for later use.

We are constantly working to improve its products and, therefore, reserve

the right to make changes in the appearance, equipment and production

technology, without changing the basic principles of management, without

notice to the consumer. All possible changes will be directed at improving and

upgrading the product.

Indicates a potentially hazardous situation that may result

in minor injury or damage to the product.

NOTE!

The important additional information.

WARNING!

Indicates a potentially hazardous situation that should be

avoided, otherwise there is a danger to life and health.

KEY WORDS VALUE

4

CAUTION!

7

6

GENERAL DESCRIPTION

1

Professional Inverter welding machine

designed to perform manual metal arc

welding of metal products covered electrode. Welding is carried out at a

constant current of metal consumable electrodes for AC and DC with basic,

rutile, cellulosic, sour, mixed and other types of coatings.

the power transformer, step-down power supply voltage to the required

load voltage welding machine;

unit of electrical power circuits;

stabilizing the throttle, reducing ripple rectified current.

The most simple principle of inverter welding machine (hereinafter - the

welding machine) is based on the transformation of voltage 220 V AC, 50 Hz to

DC voltage, after which a DC voltage is applied to the welding arc.

These products are made in accordance with the current requirements of

the standard and level of technology, current safety regulations are robust in

operation, a modern design, economical, reliable in operation, easy to use

and maintain.

The modern design of these products based on advanced inverter

technology and incorporating a microprocessor-based control parameters of

an electric arc can not even fully qualified welder to quickly and easily get a

reliable weld.

The use of inverter technology has led to a decrease in weight and size of

welding machines, improved quality indicator of the arc, increase efficiency,

smooth adjustment of the welding current.

Smooth and precise adjustment of the welding current can achieve a

perfect weld quality;

high stability of the welding process parameters for all values of the

welding current;

resistance and arc stability regardless of fluctuations in the mains voltage:

Special development for Ukraine's electricity - operating voltage models Mi

200md and Mi 200m is 170V-245V, model Mi 200da and Mi 225da - 170V-

270V;

"Vitals "Professional" Mi 200md,

Mi 200m, Mi 200da and Mi 225da

Inverter welding machine consists of the following structural units:

Distinctive features of welding machines:

low degree of reaction on the mains supply, the lack of it was excessive

overload;

availability of digital information display. Three models (Mi 200md,

Mi 200da and Mi 225da) equipped with a digital information display, which

shows the exact value of the welding current. When you select the desired

welding current should be guided by the value shown on the display;

Professional electrode 300A;

reliable and rugged clamp "weight" of 300A;

high resistance of the product, providing maximum rate constant load;

The "anti-freeze" a complete loss of the welding current (models Mi 200da

and Mi 225da);

greater length of welding cable (2.5 meters).

1. Feature «Hot Start» - automatic transient increase in current for easy

ignition of the arc.

2. Feature «Anti Sticking».

3. Function «Arc Force» - «welding current modulation" (automatic current

up to 30% depending on the distance from the electrode to the metal).

Modern technology incorporated into the design of products:

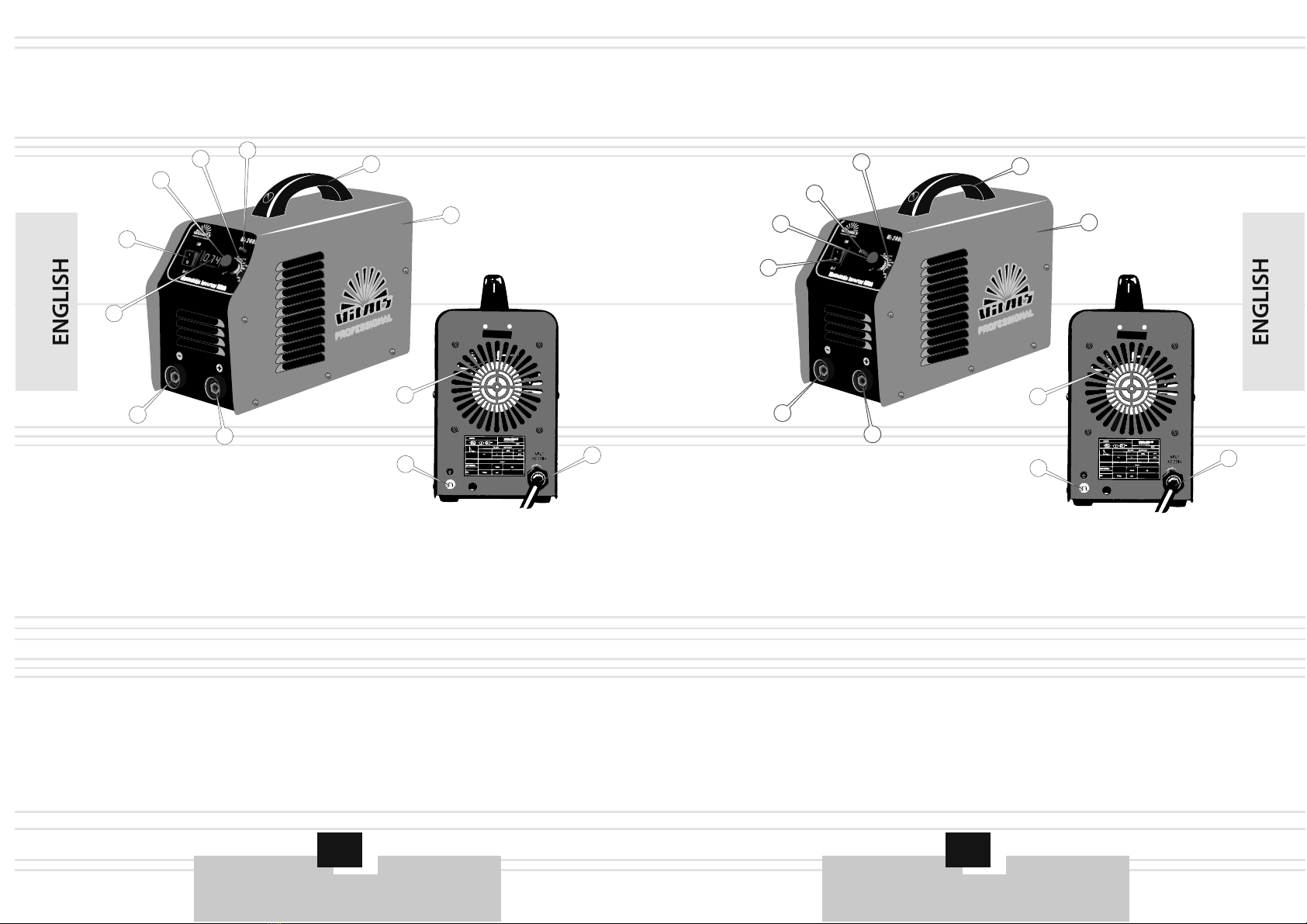

Description of main components of the welding machine is provided

below.

9

8

1. Power switch with light indicator (key «ON / OFF»).

2. Manual control of welding current.

3. The graduated scale (size of the welding current, the

diameter of the electrode used.)

4. The indicator light "Overheat".

5. Carrying handle welding machine.

6. The protective cover.

7. BNC connector "+".

8. BNC connector "-".

9. Power cable.

10. Ground terminal.

11. Ventilation grille.

12. Digital information display (display of the selected

welding current value).

figure 1

1. Power switch with light indicator (key «ON / OFF»).

2. Manual control of welding current.

3. The indicator light "Overheat".

4. The graduated scale (size of the welding current, the

diameter of the electrode used.)

5. Carrying handle welding machine.

6. The protective cover.

7. BNC connector "+".

8. BNC connector "-".

9. Power cable.

10. Ground terminal.

11. Ventilation grille.

figure 2

Model: Mi 200mModel: Mi 200md

1

12

2

4

8

7

35

6

9

10

11

1

2

4

8

7

3

5

6

11

9

10

11

10

1. Switch (key «ON / OFF»).

2. Manual control of welding current.

3. The indicator light "Overheat".

4. The graduated scale (size of the welding current, the

diameter of the electrode used.)

5. Carrying handle welding machine.

6. protective shroud

7. BNC connector "+".

8. BNC connector "-".

9. Power cable.

10. Ground terminal.

11. Ventilation grille.

12. Digital information display (display of the selected

welding current value).

figure 3

Model: Mi 200da

1. Automatic fuse (key «ON / OFF»).

2. Manual control of welding current.

3. The indicator light "Overheat".

4. The graduated scale (size of the welding current, the

diameter of the electrode used.)

5. Carrying handle welding machine.

6. protective shroud

7. BNC connector "+".

8. BNC connector "-".

9. Power cable.

10. Ground terminal.

11. Ventilation grille.

12. Digital information display (display of the selected

welding current value).

figure 4

Model: Mi 225da

2

345

6

7

8

12 1

9

10

11

19

10

11

2

345

6

7

8

12

13

12

DELIVERY KIT

2

1. Welding machine with a handle for carrying.

2. Welding cable with clamp "mass".

3. Welding cable with electrode holder.

4. Instruction manual.

NOTE

The manufacturer reserves the right to make the look,

design and delivery welding machine minor changes that do

not affect product performance.

TECHNICAL DATA

3

AC Voltage, В 170 - 245

Frequency Hz,

The maximum power

consumption, kW

The open circuit voltage, V

Duty cycle at maximum

welding current, %

The diameter of the

electrode used, мм

Power factor (cos )φ

Length of cable, m

Gross weight, gк

Weight welding machine, gк

Welding current, А

Dimensions of the welding

machine (L B B), mmхх

Mi 200md Mi 200m Mi 200da Mi 225da

8,7

465х270х

330

8,0

10,5

2,5

IP 21

0,93

155

60

50

8,7

465х270х

330

10,5

155

8,5

340х130х

280

6,0

8,10

140

9,4

387х157х

305

8,4

11,30

8,0

170 - 270

61 75

Welding current at

100% DC, А

Insulation class

Class of protection

20 - 200

20 - 200 20 - 200 20 - 225

180

16-40,, 16-40, , 16- 0, 5, 16- 0,5,

FH

MODEL

15

14

Overheating protection

The "anti-freeze"

This alarm system designed to prevent damage to the welding machine

when overheated. In the course of a long and intensive welding at high

ambient temperatures may operate products protect against overheating and

come off the welding circuit.The system cooling welding machine will continue

its work. On the control panel will light up LED "Overheat". Work welding

machinewill continue automatically when the product cools. The indicator light

"Overheat" disappears.

During welding, the metal droplets separated from the electrode, which

drastically reduces the length of the arc and electrode be welded to the

product. When sticking the electrode current automatically turned off, thus the

electrode easily away from the work surface.

NOTE

Models Mi 200da and Mi 225da have the function of "anti-

freeze" a complete loss of current.

NOTE

All models are equipped with a system to protect the

product from overheating.

SAFETY REQUIREMENTS

4

4.1. IMPORTANT SAFETY INFORMATION

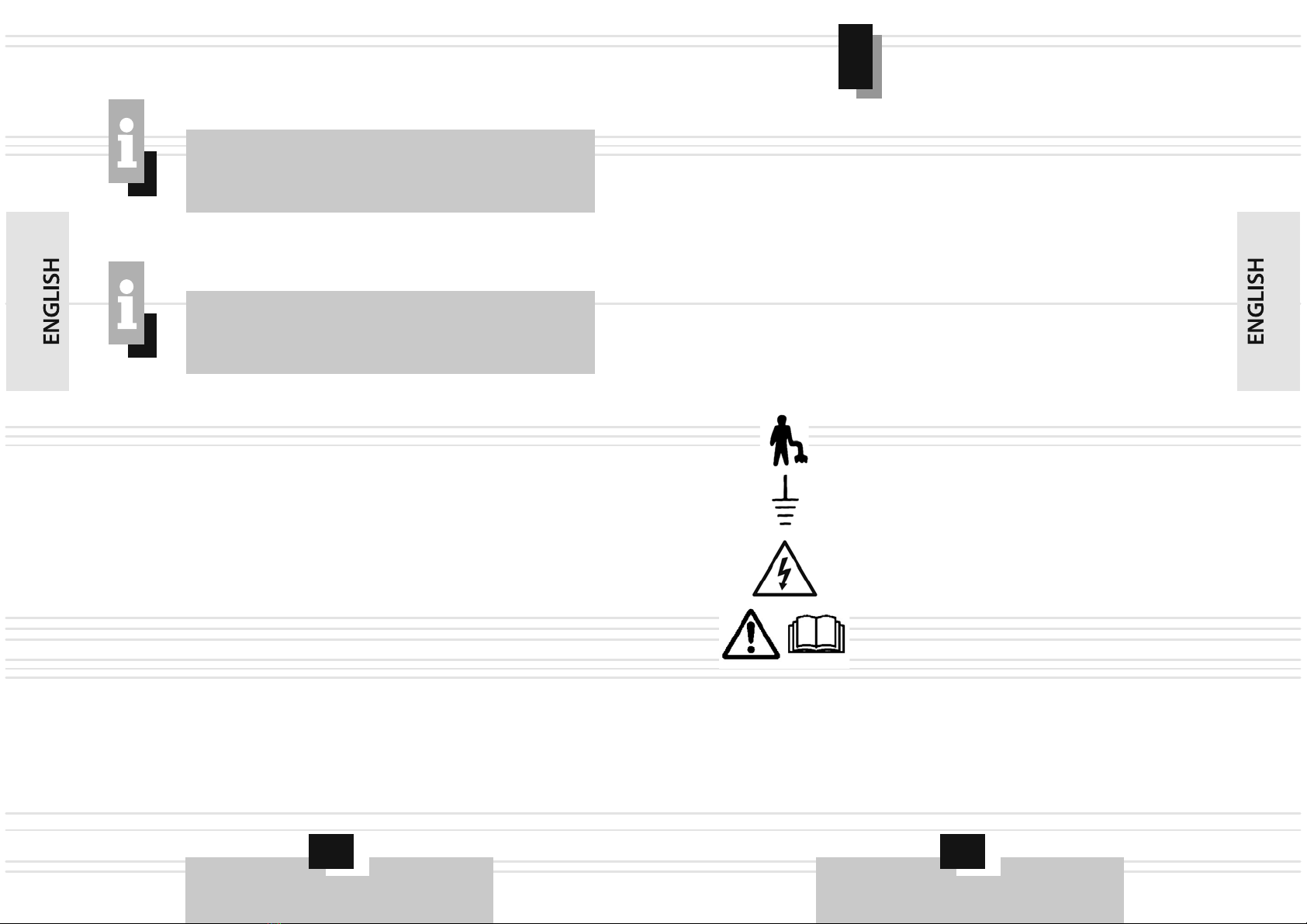

Description of symbols

PLEASE READ ALL INSTRUCTIONS

Before the beginning of the welding machine, please read the

requirements on safety instructions and warnings contained in this manual.

Most injuries during the operation of the product is the result of non-

compliance with the provisions of the basic safety rules. Injuries and accidents

can be avoided if strict safety precautions in advance and provide a potential

danger.

Do not, under any circumstances, use a product in a manner or for

purposes not specified in this manual.

Improper handling or operation of an untrained person can cause an

accident.

Remove dust inside the cabinet is two times per

month with compressed air, low pressure

(1.5 - 2 atm).

Wipe the product must be grounded

Watch out! High Voltage. To avoid accidents, do

not try to repair the product. Repairs should be

conducted by an experienced specialist

Before using the product, carefully review the

requirements of this manual.

For safe use of the product should review instructions and appropriate

training. Improper use or operation of the welding machine by untrained

person can be dangerous. Read and understand the basic components of the

welding machine. Learn how to stop the operation of the product, if necessary.

17

16

WARNING!

Before moving, checking and maintenance of welding

machine disconnect it from the mains.

4.2. SAFETY OF OPERATION

1. DO NOT ALLOW PRODUCT FOR CHILDREN AND PERSONS WITH

DISABILITIES.

2. BE FULLY CONCENTRATE ON WORK.

Do not get distracted during welding machine, as this may cause a loss of

control and cause injury of varying severity.

3. DO NOT OPERATE IN THE EVENT OF ILLNESS, IN STATE OF FATIGUE,

DRUGS OR ALCOHOL, OR UNDER THE INFLUENCE OF DRUGS

POTENT DRUGS, REDUCES THE RATE OF REACTION AND

ATTENTION.

4. FOLLOW INTEGRITYANDTHE PRODUCT TO.

Do not start and use the product if damaged, with insecure cables. Do not

operate with a damaged power cable.

5. WEAR APPROPRIATE CLOTHING AND SHOES WHEN USING THE

ARTICLE.

When welding, wear protective clothing, shoes with non-slip rubber soles,

thick leather gloves or mittens, a face shield or goggles with tinted windows,

as well as other means of protection to prevent burns and injuries. Use

insulating mats.

6. DO NOT WORK WITH WELDING MACHINE REMOVE COVER, WITH A

FAULTY ELECTRODE HOLDERAND CLAMP "WEIGHT".

7. DO NOT USE IN THE DAMAGED OR HOMEMADE WELDING CABLES

AND EXTENSION OF WELDING CABLE, POWER CABLE.

8. DO NOT TOUCH THE WELDING CABLE, BAYONET DURING WELDING

MACHINE.

While the product cables are high voltage - danger of electric shock or

death.

9. DO NOT TOUCH THE WELDED PARTS AND SURFACES UNTIL THEY

ARE COOL.

Welding is a high temperature process that heats the metal to the point of

melting - risk of scalding.

Failure to follow these instructions may result in electric shock and lead to

death of a person, serious damage to health or property.

When welding machine malfunction there is a danger of electric shock or

death from electrical shock. Use of the product under conditions of high

humidity, near the water in the wet grass in the rain or snow, can cause death

from electrical shock. Do not weld wet items or items that are under water.

Always keep the welding machine dry.

The product not intended for use and storage of unprotected outdoors.

Moisture or ice can cause a malfunction of the welding machine or a circuit

of electrical parts, which can also lead to death due to electric shock.

Each time before using the welding machine inspect all of its electrical

parts.

RISK OF ELECTRIC SHOCK

CAUTION!

Before the start, welding machine pre-ground the product.

Failure to do so will result in the death of a person or the

scrapping of the product..

19

18

10. DURING WELDING MACHINE KEEP TO THE PLACE OF WORK

CARRIED OUT WITHIN 5 METERS OF STRANGERSANDANIMALS.

The welding process is a source of electromagnetic waves, heat,

ultraviolet radiation, and glare. Before welding sure to check the area of

welding works outside people and animals, which can be caused by

trauma. Set-sparking screens.

11. TO REDUCE THE RISK OF VIEW DO NOT WATCH EVEN WITH CLOSE

DISTANCE OF 15 METERS ON WELDING WITHOUT SPECIAL

PROTECTIVE MASKS OR GLASSES WITH TINTED WINDOWS.

Ultraviolet radiation of the arc can cause irreparable damage to the eyes.

You can not carry out welding work and to approach closer than 15 meters

to the place of welding to people who wear contact lenses, eyeglasses,

pacemakers and devices stabilize heart rhythm.

12. KEEP AWAY FROM THE WELDING MACHINE FLAMMABLE

MATERIALS.

During welding operations should not be closer than 15 meters from the

site of welding fuel, engine oil, matches, oily clothes, straw, trash and

other flammable materials. Be careful with the presence of fire

extinguishers.

13. DO NOT COVER WELDING MACHINE IN OPERATION.

The product is equipped with a forced air cooling system, and if it is

covered, the welding machine may overheat.

14. AVOID DIRECT CONTACT WITH THE WELDING CIRCUIT, THE

DISCOVERY OF LIVE PARTS OF THE WELDING MACHINE AND

CABLES, INCLUDING ITS PRODUCTS IN IDLE.

15. DO NOT WELDING INTHE RAIN OR WET HANDS.

Work welding machine in rain or snow can cause electrical shock or

damage to the product. If the welding machine gets wet, before turning it

necessary to wipe dry. Do not pour water on the product, do not wash it.

16. DO NOT LEAVE THE WELDING MACHINE IS UNATTENDED,

DISCONNECT THE SUPPLY PRODUCT IMMEDIATELY AFTER

WELDING.

17. REMEMBER, THE GAS GENERATED DURING THE WELDING

PROCESS - HARMFULTO HUMAN HEALTH.

Carry out welding work outdoors or in a well-ventilated area. Materials

having in its composition lead, cadmium, mercury, zinc and beryllium,

under the influence of the welding arc may release toxic gas in dangerous

to life and health of people and animals concentrations. When welding

these materials be sure to use personal respiratory protection.

18. BEFORE STARTING WELDING MACHINE ON A FLAT, LEVEL

SURFACE.

To avoid turning the product or place it on an uneven, and the vibrating

surface.

19. IF, DURING WELDING OPERATIONS SPARKS GOT INTO THE VENT

WELDING MACHINE, IMMEDIATELY UNPLUG THE PRODUCT FROM

THE WALLAND CONTACTTHE SERVICE CENTER.

20. OPERATION, STORAGE AND TRANSPORTATION OF WELDING

MACHINES, PROTECTS IT FROM THE EFFECTS OF

PRECIPITATION, WATER VAPOR, CORROSIVE FLUIDS,

MECHANICALDAMAGE, SPARKS, MOLTEN METAL, DUSTAND DIRT.

21. DO NOT ATTEMPT TO REPAIR THE UNIT, CONTACT THE SERVICE

CENTER.

All the models of welding machines have passed the required tests for

electromagnetic compatibility and safety, in accordance with the

requirements. However, during welding, these products can influence on

nearby radio-electronic devices and computer control system.

CAUTION!

Always be aware of the fact that, when connected to an

electrical welding machine Electrode with the electrode does

not touch the clip "mass" and the apparatus. Do not use the

power and welding cables, if they have damaged or worn

insulation.

WARNING!

Be sure to monitor the serviceability of the product. In case

of failure, you can smell typical of burning insulation, flame,

sparks, immediately stop the operation of the product and

contact a service center.

21

20

4.3. GROUNDING

As an earth electrode can be used are metal pipes in the ground water,

sewage or metal frames of buildings that have a connection to the land.

Grounding prevents the possibility of electric shock. For proper grounding

products recommended to use a ground wire, which is connected to the

ground terminal and the earth electrode (wire and earthing switch with the

product is not included) (see Figure 5).

If the above grounding you are unable to use it, use one of the following

earthing:

metal pipe of not less than 1500 mm and a diameter of 50 mm;

metal rod length not less than 1500 mm and a diameter of not less than

15 mm;

sheet of galvanized steel, uncoated size 1500x1000 mm.

WARNING!

The ground wire should have a cross section of at least

1.5 mm , preferably of twisted copper wire.

Ground terminal and earthing should have good contact

with the ground wire

CAUTION!

To make a proper connection grounding get expert advice

from the relevant specialist or use its services.

WARNING!

This guidance does not take into account all the possible

cases that may occur in actual use of the product. In this case

should be guided by common sense, to comply with the

utmost attention and care when carrying out welding work.

NOTE!

User welder must take all feasible precautions to avoid

applying direct or indirect damage to third parties and

organizations (hospitals, laboratories, centers of information

processing, etc.).

CAUTION!

Do not use the welding machine without a ground

connection!

CAUTION!

Electrical outlet that connects the welding machine must

be grounded. The ground wire outlet cross section must be at

least 1.5 mm .

figure 5

23

22

OPERATION

5

5.1.

5.2.

APPLICATION

GETTING STARTED

The procedure for preparing the welding machine to work

Inverter welding machinecan be used in stationary conditions (at service

stations vehicles, construction sites, home and garden land, garages, etc.)

and in the field in mobile systems equipped with gasoline or diesel mini power

stations.

1. Carefully remove the welding machine out of the box, do not apply shock

or mechanical impact on the parts of the product.

2. Place the unit on a horizontal surface.

3. Visually inspect the product for mechanical damage on the body of the

welding machine, welding cable, power supply and cables.

4. Check the BNC connectors, clips, electrode holders and "mass".

5. Ensure that the surface on which the welding machine is installed and

that there is enough space (at least 0.5 m on each side and from the top) to

ensure proper operation of the ventilation system.

6. Make sure the power switch (button «ON / OFF») is in position «OFF».

1. Connect with the welding machinewelding cables, observing the

necessary polarity. To secure the welding cable to the bayonet connector, it is

necessary to combine the tab on the cable connector with the slot bayonet

connector, push the plug with a little effort and turn it clockwise until it stops.

Before you start welding machine run:

2. Securely connect with the welding machine wire (see section 4.3.

Guidance): Connect one end of the wire to earth, and the other end of the wire

to the ground terminal, connect the product and tighten the clamping nut.

3. Securely fasten the clamp welding cable "mass" in the immediate vicinity of

the weld to reduce the resistance welding circuit.

4. Connect the power cable to the power (electrical outlet, minipower ) single-

phase AC 220 V, 50 Hz. Source power supply must be sufficient to provide the

welding power supply unit. The source must be equipped with an automatic

safety device (fuse) with the appropriate current operation. Do not connect the

product to a power supply with parameters other than those specified in

Section 3 of this manual, as it will damage the welding machine malfunction.

WARNING!

Unreliable contact will result in overheating and rapid

output BNC connectors and plugs of the system, and may

also result in inefficient operation welding machine.

WARNING!

Rated current trip a circuit breaker must be 40A.

Rated current circuit breaker must not exceed the

permissible load currents for electrical wiring home network.

CAUTION!

The electrical outlet must be grounded. The ground wire

outlet cross section must be at least 1.5 mm . If the electrical

outlet is not grounded, be sure to ground the product as

specified in 4.3. this manual.

Connect this product only to the power sockets 2P + T with

transmittance of not less than 40A.

NOTE!

Grounding of the welding machine can be accomplished in

one of two ways: to connect the grounding terminal of the unit

"Ground" or the product is connected to a grounded outlet.

25

24

5.3. WELDING

1. Clean the surface of the metal in the weld zone and the connection point

of the clip "mass" of dust, dirt, water, rust and paint.

2. Make a one-sided or two-sided V-shaped edge processing (if the

workpiece thickness of 3 mm).

3. Place the electrode in the electrode.

4. Set the desired welding current value.

The required value of the welding current is adjusted by turning the manual

knob to match the index mark on the controller with the desired value on the

graduated scale. In this case, it should be noted that the exact value of the

welding current will be displayed on the electronic display (models Mi 200md,

Mi 200da and Mi 225da). Value of the welding current is set depending on the

thickness of the weld metal and the diameter of the electrode used (see the

specifications of the electrode at its packing box): 1,6 mm - 60-90 A;

2,5 mm - 90-100 A; 3,2 mm - 110-140 A; 4,0 mm - 140-200 A,

5, 0 mm - 200-225A.

5. Touch the part to be welded.

6. To excite the arc pull the electrode from the work piece at a distance

(depending on the diameter of the electrode spacing should correspond to the

diameter of the electrode used 1-1.5) and hold it for the entire length of the

welding process (see Figure 6).

5. Turn on the power switch, turning the key «ON / OFF» to position «ON».

6. After turning the system of forced cooling products (inaudible hum

characteristic), by turning the manual control of welding current to set the

desired current value. Information on the digital display shows the set value of

welding current (models Mi 200md, Mi 200da and Mi 225da).

7. Check the status indicator light "Overheat".

8. The welding machine is ready for operation.

WARNING!

If it is lit, welding machine stays in the mode of thermal

protection, which occurred due to overloading. Let cool

product. Automatic welding machine is ready for operation

when the internal temperature decreases, the indicator light

will go off.

CAUTION!

Making any connections to the welding circuit must be

disconnected from the power supply when the product.

WARNING!

Do not use welding cables longer than 10 meters

CAUTION!

Do not use metal objects that are not part of the structure to

be welded (metal rods, tubes, strips, etc.) for replacement or

extension of welding cable with clamp "weight", as it leads to

violations of safety rules, an increase in resistance welding

circuit and accordingly, reduce the quality of weld joint.

WARNING!

Before welding, always use a protective mask welding or

special goggles with tinted glasses to protect your eyes from

strong light and ultraviolet radiation, formed by an electric

arc.

WARNING!

Do not knock the welding electrode strong surface because

it can lead to damage of the electrode and arcing difficult.

27

26

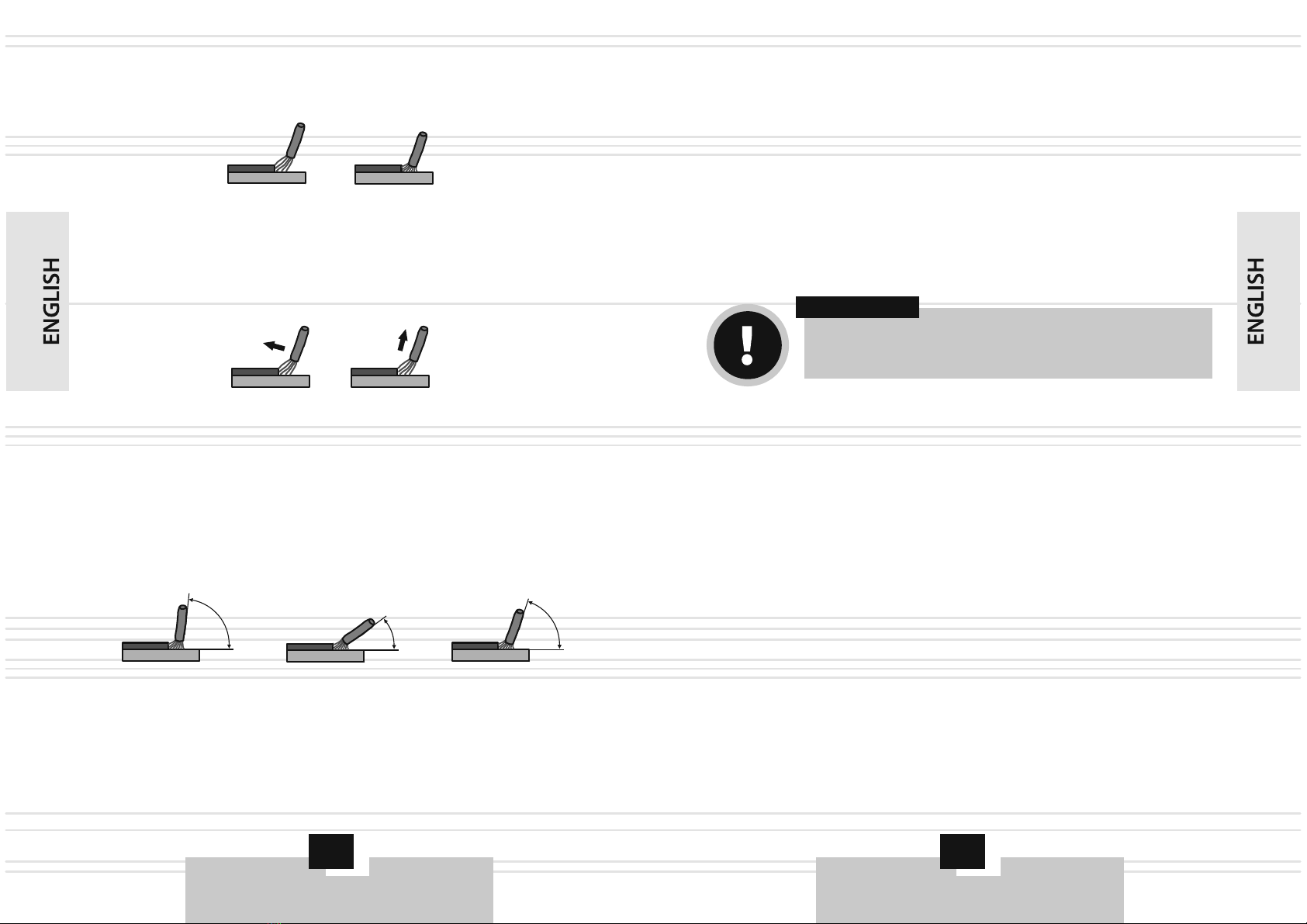

7. To stop the welding electrode take away from the work piece. The

correct direction of discharge electrode is shown in Figure 7

For a durable welded joint than the correct choice of welding current is

necessary to ensure the correct position of the electrode relative to the work

piece. The angle of inclination of the electrode should be 60-80 degrees (see

Figure 8). With too large inclination of the weld may be porous, at too small an

angle - a large amount of splash of molten metal and the arc becomes

unstable.

The length of the electrode in the welding process reduced. When the

electrode length is 15-20 mm, stop and replace the welding electrode,

electrode-clicking the handle.

Welding electrode with a protective coating layer accompanied by

formation of slag along the trajectory of movement of the electrode. To obtain a

uniform and smooth seal, as well as to avoid corrosion is formed on the seam,

it is necessary to remove the slag layer always after each pass through the

brush hammer.

After the termination of the arc on the electrode is always the peak of

plastering 1-2 mm long. When re-ignition of the arc must be dosed blow to

knock this electrode shield and the remains of slag.

Basic electrodes for DC welding (UONI 13/55, etc.) are preferably used in

cases where it is necessary to obtain high mechanical characteristics of the

weld, for example, when welding pipes, since such a coating imparts

increased viscosity of the molten pool and provides greater depth boiling

seam.

To get a quality weld such electrodes require mandatory baking. Welding is

performed by the DC reverse polarity (electrode is connected to the BNC

connector on the welding machine labeled "+").

Coated welding electrodes for alternating current (IR-3 ANO-21, etc.) can

perform a straight polarity ("-" of the electrode) and feedback ("+" on the

electrode). Polarity selection depends on the welding conditions. Reverse

polarity provides a more stable arc with low-quality electrodes heats the

workpiece less. Is mainly used for welding thin parts and to work in tight

spaces. The electrode is burned slowly. Straight polarity allows more heat to

the weld area. Is mainly used for welding the heat capacity of the massive

parts. The electrode burns faster .

WARNING!

The electrode and the slag heated to a high temperature. To

avoid burns, be careful when changing the electrode and

remove slag.

Not correct arc

(too long)

Correct arc

(1-1.5 diameter

of the electrode)

Wrong direction

stop the arc

Correct direction

stop the arc

Wrongs lope

> 80°

Wrongs lope

<0°6

Corrects lope

60°- 80°

figure 6

figure 7

figure 8

29

28

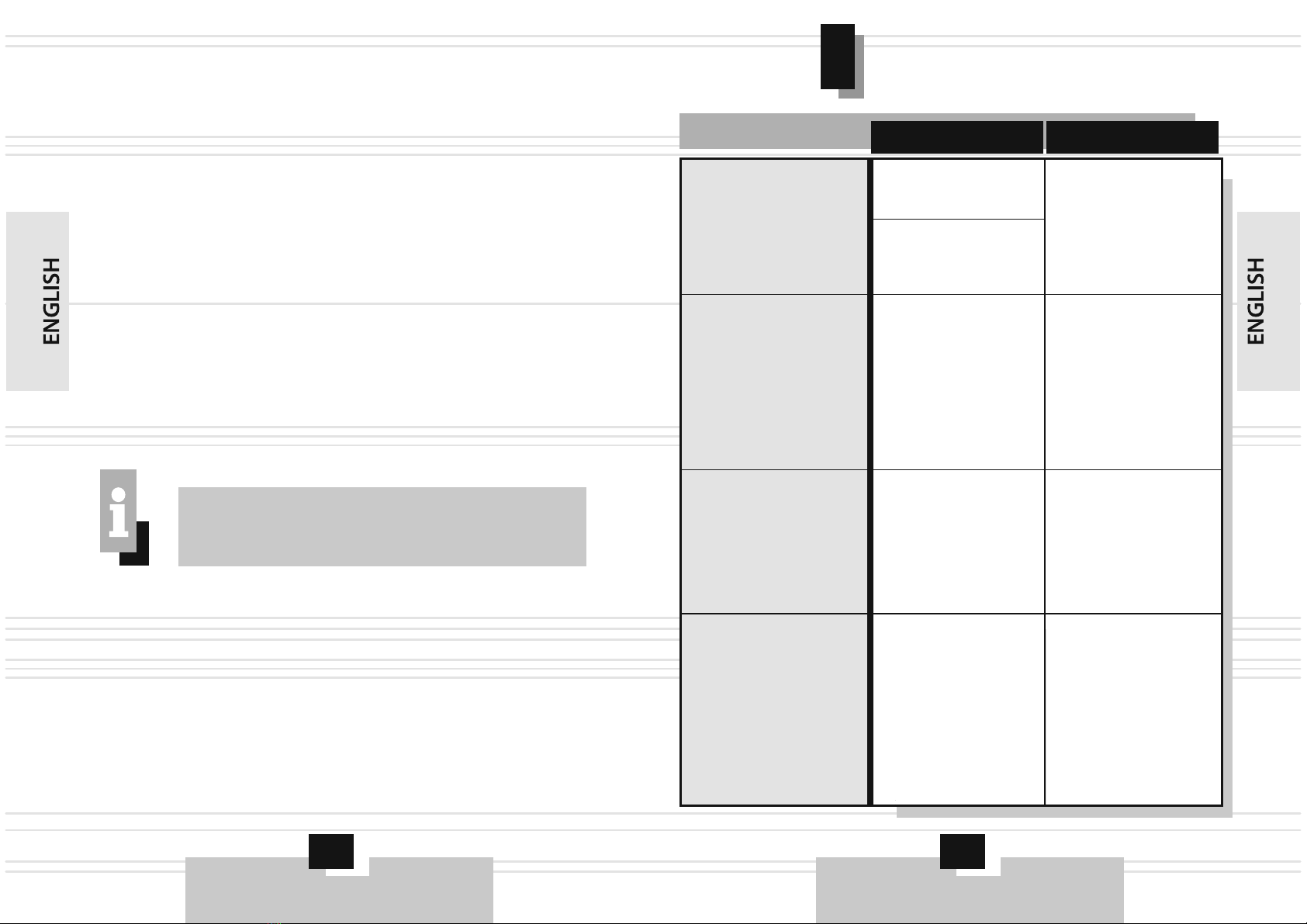

Valid values of welding current,

depending on the diameter of the electrode *

*This manual is not a manual on the welding business. For more information about the

welding process, contact a qualified technician or reference material.

WARNING!

Frequent operation of the system of protection welding

machine from overheating informs that the product operates

with a considerable overload. To prevent welding machine

fails, change the parameters of the welding process. To do

this, select a smaller diameter electrodes, decrease the

welding current, reduce the length of periods of continuous

welding and improve ventilation products.

Electrode

diameter, мм

The thickness of the

base metal, мм

The range of values of the

welding current А,

Rutile

electrode

Basic

coated

electrode

1,6

1,5 - 2,0

30-60

50-75

2,0

1,5 - 3,0

50-80

60 - 100

2,5

1,5 - 5,0

60-110

70 - 120

3,2

2,0 - 12,0

90 - 140

110 - 160

4,0

4,0 - 20,0

140 - 200

160 - 220

5,0

8,0 - 24,0

170 - 250

190 - 260

MAINTENANCE

6

The design of inverter welding machines "Vitals "Professional" Mi 200md,

Mi 200m, Mi 200da and Mi 225da applied the latest electronic components

and the latest technology, the converting electrical current. With this

apparatus does not require regular servicing, other than cleaning.

However, to ensure reliable operation of the product for a long period of use

and storage of necessary time to carry out maintenance.

visual inspection;

maintenance.

Control examination should be carried out before and after using the

welding machine or transportation. When the control examination, check all

connections are secure, no damage to the hull, controls, cables and power

supply cables.

Maintenance welding machine must be inspected at least once every two

months, to remove dust and dirt that have accumulated within the product

while it is running, check the status of connectors, terminals, cables.

The following types of service:

Aset of measures for maintenance:

visual inspection of the product (check the body, controls, BNC connectors,

terminals and clamps "earth" isolate network and welding cables, electrode

holder for damage);

clean the inside of the welding machine from dust and dirt;

checking, cleaning, broaching contact group (bayonet connectors, terminal

grounding clip "mass" and the electrode).

CAUTION!

Before starting maintenance welder shut off the power and

unplug the cables.

NOTE!

Depending on the frequency of use of the welding machine

and the environmental conditions, maintenance items should

be performed more frequently.

31

30

TRANSPORT AND STORAGE

7

7.1. TRANSPORTATION

The product can transported by all modes of transport, ensuring the safety

of the product, in accordance with the general rules of traffic.

During loading and unloading and transport of the product should not be

subjected to shock or rain.

Stowage and securing the welding machinein vehicles should ensure a

stable position the product and its lack of movement during transport.

Take care not to damage the power plant during transportation. Do not

place heavy objects on top.

Acceptable transportation welding machine: ambient temperature

from -15 °C to +55 °C, relative humidity up to 90%.

WARNING!

Keep the product in the same room with flammable

substances, acids, alkalis, fertilizers and other aggressive

substances prohibited.

NOTE!

To remove dust from the inside of the product casing

remove the protective housing, pre-loosening with a

screwdriver 10 screws. Carefully remove the dust with

compressed air (maximum pressure 1.5 - 2 atm.) Replace the

cover on a regular place and tighten the screws securely.

NOTE!

Maintenance products recommended for the experienced

professional. In case of difficulties with maintenance

products, please contact a service center.

WARNING!

When cleaning the product, and do not bend the cables do

not touch the circuit board in order to avoid damaging them.

WARNING!

Do not move the welding machine connected to the network

and cables.

WARNING!

Do not carry the unit by the power cord and cables.

33

32

7.2. STORAGE

In preparing the product for storage:

If the product is not used for a long time (more than 2 months), it must be

stored in a ventilated room at a temperature of -15 ° C to +55 ° C and a relative

humidity of 90%, having covered by the product off the dust and small debris.

The presence of vapors of acids, alkalis and other aggressive substances is

prohibited.

Welding machine before making the long-term storage should be

preserved.

1. Disconnect the product, disconnect the welding cables and grounding

wire.

2. Remove dust and dirt from the outer portion of the product, BNC

connectors and terminals "earth.”

3. Grease a thin layer of engine oil terminal.

NOTE!

After removing the product from the ground terminal

storage of clean lubricant.

POSSIBLE PROBLEMS AND

THEIR SOLUTION

8

Caution Ways to eliminate

TYPE OF DAMAGE*

Heard odor characteristic

of burning insulation from

inside the smoke, light is

"overheating" is not lit

Short circuit or overload

of critical system board

Isolate the product

immediately, even if it is

still possible to carry out

welding work, and

contact a service center

Out of order protection

products from

overheating

There is an electric shock

when touching the body of

the machine

There is no ground

Disconnect the welding

machine until you get a

good ground equipment

enclosures and electrical

outlet to which is

connected a power

cable welding machine

The welding machine is

turned on, the cooling fan

is working, but the light

indicator on the «ON /

OFF» is off (only models

Mi 200md, Mi 200m)

Faulty light or a

disruption to the system

board

Contact the service

center

The welding machine is

turned on (the light

indicator on the «ON /

OFF» lights - only for

models Mi 200md,

Mi 200m), the cooling fan

is working, but the arc

does not ignite

Damaged welding

cables. No contact in

the welding circuit

Check the condition of

welding cables, welding

cables, contact reliability

in BNC connectors

products at terminal

"weight" on the work

piece and the electrode

in the holder

35

34

Caution Ways to eliminate

TYPE OF DAMAGE*

The welding machine is

turned on (the light

indicator on the «ON /

OFF» lights - only for

models Mi 200md,

Mi 200m), the arc is

ignited but the cooling fan

is not working

Out of service charge

cooling system products

Immediately turn off the

welding machine and

contact a service center

The arc is ignited, but the

electrode immediately

sticks to the work piece

Set too low welding

current

Increase welding current

Insufficient power

supply voltage

Measure the voltage in

the power supply. If it is

below the acceptable

one, use the voltage

stabilization sufficient

power

The welding current is set

correctly, but can not start

welding - Electrode

immediately sticks to the

work piece

Are loose welding circuit

Check the contact

welding cables to BNC

connectors products at

terminal "weight" on the

work piece and the

electrode in the holder

Caution Ways to eliminate

TYPE OF DAMAGE*

The welding current is set

correctly, but can not start

welding - Electrode

immediately sticks to the

work piece

Poor quality or non-

optimal electrode his

position at the start of

the arc

Try to warm up the

electrode, after spending

a few times on the work

piece, adding a bit of

welding current. Having

achieved a stable arc,

reduce the current to the

desired value. If you

keep the arc ignition

electrode at an angle of

60°, 80° to the work

piece

In the process of welding

arc "breaks" and goes

Too great a distance

between the electrode

and the work piece

Keep the electrode

closer to the work piece

Electrodes for welding

"lead" itself in different

ways

Substandard electrodes

or electrodes of different

types

Check the condition of

the electrodes, if

necessary, dry them.

Pay attention to the size,

type and polarity of the

electrodes. The desired

polarity and magnitude

of the welding current is

usually indicated on the

package

37

36

* The list of damages, placed above doesn’t show all the occasions. If the problem happens

you should contact the service center.

Caution Ways to eliminate

TYPE OF DAMAGE*

Caution Ways to eliminate

TYPE OF DAMAGE*

Electrodes for welding

"lead" itself in different

ways

Substandard electrodes

or electrodes of different

types

Check the condition of

the electrodes, if

necessary, dry them.

Pay attention to the size,

type and polarity of the

electrodes. The desired

polarity and magnitude

of the welding current is

usually indicated on the

package

During the welding

process automatically

turns off the power supply

220V fuse ("knocks the

plug")

Mounted circuit breaker

rated at less than 40A

Response

Replace with a circuit

breaker rated at 40A

switching

Insufficient power

supply

Connect the welding

machine to a more

powerful power supply

220V

Lit LED "Overheat"

Fired thermal protection

welding machine

Wait (no more than 3-5

minutes, depending on

ambient temperature)

until the cooling system

is sufficiently cool the

system board

Lit LED "Overheat"

Mains voltage out of

tolerance

Measure the voltage in

the power supply. If it is

lower or higher than the

permissible one, use the

voltage stabilization

sufficient power

Excessive amounts of

sparks in welding

Maybe wrong

connection cables

Change the polarity

39

38

WARRANTY

9

Warranty period

is 1 (eighteen) months

specified in the warranty card date of retail sale.

During the warranty period, defective parts and components will be

replaced, subject to all the requirements and guidelines for damage related to

improper handling, storage and transportation of the product. For warranty

service, contact your nearest authorized service center.

The consumer has the right to free warranty troubleshooting, identified

and presented during the warranty period due to production and design

factors.

Troubleshooting warranty is made by the repair or replacement of

defective parts of the product to the certified service centers. Because of the

complex structure repair can last more than two weeks. The cause of the fault

and determine the terms of their elimination service personnel.

Warenty becomes valid in the following cases:

Absence or unread warranty card.

Improperly completed warranty card, it does not contain the date of the

sale or seal (stamp) and signature of the seller, the serial number of the

product.

The presence of corrections or erasures in the warranty card.

Complete or partial absence, unread serial number on the product, product

serial number mismatch the number listed in the warranty card.

Improper operation, in this manual, including the violation of rules of

maintenance.

Operation of defective or incomplete products, which caused its failure.

Ingestion of product foreign substances or objects.

The product has a significant mechanical or thermal damage, clear signs

of careless handling, storage or transportation.

of inverter welding machines "Vitals "Professional"

Mi 200md, Mi 200m, Mi 200da and Mi 225da 8

NOTE!

Product accepted for warranty only fully equipped,

carefully cleaned of dirt and dust.

Product has been used for other purposes.

Made unauthorized repairs, tampering or attempted development of the

product by the consumer or a third party.

The fault is due to a natural disaster (fire, flood, hurricane, etc.).

Replaced under warranty parts and assemblies available to move the

service center.

When the warranty on the warranty period increases the residence time of

repair products. Counting the added period starts from the date of acceptance

of the product warranty.

If for technical reasons, can not repair your product, service center gives

the act, based on the user to decide on the organization of the supplier of the

replacement product or refund.

After the warranty period service centers continue to perform

maintenance and repair of the product, but at the expense of the consumer.

The warranty does not cover damage caused by natural wear and

overloading of the product.

The warranty does not apply to the bat.

The warranty does not apply to the incompleteness of the product

structure, which could be detected by its sale. All transportation costs is a

consumer product.

Limited warranty is not a basis for other claims.

This manual suits for next models

3

Table of contents

Languages:

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual