Metallkraft FSBM 1020-25E User manual

FSBM 1270-20 HS2

Operating Instructions

FSBM 1520-15 E, FSBM 2020-12 E

ERIES

Folding Machine

FSBM 1020-20 S2, FSBM 1270-20 HS2

FSBM 1020-20 HSG

FSBM 1020-25 E, FSBM 1270-20 E

2FSBM Series | Version 1.06

Imprint

Product Identification

Type of machine Article Number

FSBM 1020-25 E 3772125

FSBM 1270-20 E 3772127

FSBM 1520-15 E 3772129

FSBM 2020-12 E 3772130

FSBM 1020-20 S2 3772102

FSBM 1270-20 HS2 3772128

FSBM 1020-20 HSG 3770103

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt/Bamberg

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.metallkraft.de

Indications regarding the operating instructions

Original Instructions

Edition: 28.09.2020

Version: 1.06

Language: English

Author: ES/MS

Indications regarding the copyright

Copyright © 2020 Stuermer Maschinen GmbH,

Hallstadt, Germany.

The contents of these operating instructions is the sole

property of the company Stürmer Maschinen GmbH.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not explic-

itly permitted. Contraventions are liable to compensa-

tion.

Subject to technical modifications and error.

Content

Imprint..................................................................... 2

Content ................................................................... 2

1 Introduction ............................................................. 3

1.1 Copyright ............................................................ 3

1.2 Customer Service ............................................... 3

1.3 Limitation of Liability ........................................... 3

2 Safety ....................................................................... 3

2.1 Symbol Explanation............................................ 3

2.2 Qualification of personnel ................................... 4

2.3 Personal protective equipment ........................... 4

2.4 General safety notes........................................... 5

2.5 Safety signs on the machine............................... 5

2.6 Intended use ....................................................... 5

3 Technical Data......................................................... 6

3.1 Type plate........................................................... 6

3.2 Table................................................................... 6

4 Transport, Packaging, Storage.............................. 7

4.1 Delivery and Transport ....................................... 7

4.2 Packaging........................................................... 8

4.3 Storage ............................................................... 8

5 Description of the machine.................................... 8

5.1 Scope of delivery ................................................ 8

5.2 Accessory for option ........................................... 9

6 Installation and Operation...................................... 9

6.1 Installation........................................................... 9

6.2 Mounting of the back gauge (optional) ............. 10

7 Operation ............................................................... 11

8 Care, maintenance and repair ............................ 12

8.1 Care by cleaning............................................... 12

8.2 Maintenance and repair.................................... 12

8.3 Troubleshooting................................................ 12

9 Disposal, recycling of used devices ................... 13

9.1 Decommissioning ............................................. 13

9.2 Disposal of lubricants........................................ 13

10 Spare parts .......................................................... 13

10.1 Order of spare parts........................................ 13

10.2 Spare parts drawings...................................... 14

11 EC Declaration of Conformity............................ 18

12 Notes .................................................................... 19

Introduction

FSBM Series | Version 1.06 3

1 Introduction

You have made a good choice by purchasing the Folding

Machine made by METALLKRAFT.

Thoroughly read the operating instructions before

commissioning the machine.

It informs you about the proper commissioning, the in-

tended use as well as the safe and efficient operation

and maintenance of your Folding Machine.

The operating instructions are part of the Folding Ma-

chine. Always keep it at the place of use of the Folding

Machine. Furthermore, the local accident prevention reg-

ulations and the general safety notes are applicable for

the field of application of the Folding Machine.

The illustrations in these operating instructions serve the

general comprehension and may deviate from the actual

type.

1.1 Copyright

The contents of these instructions are copyright. Their

application is admissible in the frame of the Folding Ma-

chine utilisation. An application beyond the described

application is not allowed without written approval of the

manufacturer.

For the protection of our products, we shall register

trademark, patent and design rights, as this is possible in

individual cases. We strongly oppose any infringement

of our intellectual property

1.2 Customer Service

Please contact your dealer if you have questions on the

machine or if you need technical advice. They will help

you with specialist information and expert advice.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair Service:

Fax: 0049 (0) 951 96555-111

E-Mail: service@stuermer-maschinen.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

E-Mail: ersatzteile@stuermer-maschinen.de

We are always interested in valuable experience and

knowledge gained from using the application, which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of Liability

All information and notes in these operating instructions

were summarised taking the applicable standards and

rules, the state-of-the-art and our long-term knowledge

and experiences into consideration.

the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use,

- Use of untrained staff,

- Unauthorised modifications,

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the expla-

nations and presentations described here in case of spe-

cial models, when using additional ordering options or

due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-

tions of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This paragraph will give you an overview of all important

safety packages for the protection of the people using it

well as for a safe and undisturbed operation. Other task-

based safety notes are included in the individual chap-

ters.

2.1 Symbol Explanation

Safety Instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are introduced by

signal words which express the concern of the risk.

WARNING!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injuries if they are not

avoided.

CAUTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to minor or light injuries if they are not avoided.

4FSBM Series | Version 1.06

Safety

Tips and recommendations

It is necessary to observe the safety notes quoted in

these operating instructions in order to reduce the risks

for personal injuries and damages to property.

2.2 Qualification of personnel

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

Operator:

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behaviour. Any tasks which need to be per-

formed beyond the operation in the standard mode must

only be performed by the operator if it is indicated in

these instructions and if the operating company ex-pres-

sively commissioned the operator.

Specialist staff:

Due to their professional training, knowledge and expe-

rience as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them-

selves.

Manufacturer:

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.3 Personal protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while

working. The staff has to wear personal protective equip-

ment while performing different works on and with the

appliance which are indicated in the individual para-

graphs of these instructions.

The personal protective equipment is explained in the

following paragraph:

ATTENTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

NOTE!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

WARNING!

Danger in case of insufficient quali-

fication of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the machine and expose them-

selves and others to the danger of severe injuries.

- Have all works only performed by qualified per-

sons.

- Keep insufficiently qualified persons and children

out of the working area.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

The safety boots protect the feet against crushes,

falling parts and slipping over on slippery under-

ground.

Protective clothes

The protective clothes are tight clothes of little ten-

sile strength.

Safety

FSBM Series | Version 1.06 5

2.4 General safety notes

Please observe the following points:

- Use the protective devices and securely fix them. Never

work without protective devices and make sure that

they are working properly.

- Always keep the machine and its working environment

proper. Provide for sufficient illumination.

- The design of the folding machine must not be modified

and it must not be used for any other purposes than the

processes intended by the manufacturer.

- Never work under the influence of diseases resulting in

concentration disorders, over fatigue, drugs, alcohol or

medications.

- Keep children and persons who are not familiar with the

machine away from your working environment.

- Immediately remove any disturbances which influence

the safety.

- Protect the machine against humidity.

- Before each use of the machine, make sure that no

parts are damaged. Immediately replace damaged

parts in order to avoid sources of danger.

- Do not overload the machine! It is working better and

safer in the specified range. Use proper tools! Make

sure that the tools are not damaged.

- Only use original spare parts and accessories in order

to avoid possible dangers and risks of accidents.

2.5 Safety signs on the machine

At the Folding Machine safety signs are attached, which

must be observed and followed.

Fig. 1: 1 Mandatory Signs I 2 Prohibition Sign I 3 Warning Sign

The safety markings which are applied on the machine

must not be removed. Damaged or missing safety mark-

ings may lead to errors, personal and material dam-

ages. Immediately replace them. The machine must be

put out of operation from the moment when the signs are

unable to be recognized and understood at first glance,

until new signs are attached.

2.6 Intended use

The Folding Machine is exclusively intended for bending

of sheets of stainless steel and non-ferrous metals. The

material to be operated must not exceed the max. thick-

ness given in the technical data. The machine must only

be operated by a single person, who is trained on the

machine and who is familiar with operating and mainte-

nance of the Folding Machine.

The proper use also includes observing all indications in

these operating instructions. Any use beyond the proper

use or any other use is regarded as misuse. The com-

pany Stürmer Maschinen GmbH is not liable for any de-

sign and technical modifications on the appliance. Any

claims due to damages because of not intended use are

excluded.

Misuse

The folding machine must not be used for bending of

other materials as described for the intended use.

Residual risks

Even if all safety regulations are observed and if the ma-

chine is operated properly, there are residual risks which

are listed as follows:

- Risk of injury on the upper limbs (e. g. hands, fingers).

- Hazards by objects falling or flying around.

WARNING!

Danger in case of misuse!

The folding machine may only be operated in techni-

cally perfect condition. Any faults must be rectified

immediately. Unauthorised modifications to the folding

machine or improper use of the folding machine and

the disregard for the safety or the user's guide exclude

the manufacturer's liability for any resulting damage to

persons or property and cause loss of warranty!

123

WARNING!

Danger in case of misuse!

A misuse of the appliance can result in dangerous

situation.

- Only operate the machine in the range given in the

technical specifications.

- Never bypass or override the safety devices.

- Only operate the machine in a technically flawless

status.

6FSBM Series | Version 1.06

Technical Data

3 Technical Data

3.1 Type plate

Fig. 2: Type plate of FSBM 1020-20 HSG

3.2 Table

*Performance specifications based on material with tensile strength of 400N/mm²; Bending capacity VA: factor of 0,75;

Bending performance aluminum: factor of 1,2; Hardened segments are required for bending VA

**Segments have a hardness of HRC24-26

Technical Data FSBM 1020-20 S2 FSBM 1270-20 HS2 FSBM 1020-20 HSG**

Max. bending length 1020 mm 1270 mm 1020 mm

Max. bending thickness S235* 2,0 mm 2,0 mm 2,0 mm

Max. bending thickness VA-steel 1,2 mm 1,2 mm 1,2 mm

Max. Bending angle 135° 135° 150°

Weight 325 kg 370 kg 360 kg

Dimensions LxWxH 1350 x 800 x 1130 mm 1600 x 800 x 1130 mm 1280 x 620 x 1200 mm

Technical Data FSBM 1020-25 E FSMBM 1270-20 E FSMBM 1520-15 E FSMBM 2020-12 E

Max. bending length 1020 mm 1270 mm 1520 mm 2020 mm

Max. bending thickness

S235*

2,5 mm 2,0 mm 1,5 mm 1,2 mm

Max. bending thickness

VA-steel

1,5 mm 1,2 mm 0,9 mm 0,7 mm

Max. Bending angle 135° 135° 135° 135°

Weight 290 kg 340 kg 415 kg 540 kg

Dimensions LxWxH [mm] 1350 x 800 x 1130 1600 x 800 x 1130 1850 x 770 x 1130 2290 x 820 x 1180

Transport, Packaging, Storage

FSBM Series | Version 1.06 7

4 Transport, Packaging, Stor-

age

4.1 Delivery and Transport

Delivery

Check if there are any visible transportation damages af-

ter delivery of the machine. If the machine shows any

damages, immediately inform the carrier or the distribu-

tor.

Transport

Improper transport is accident-prone and can cause da-

mage or malfunctions for which we do not grant any liabi-

lity or guarantee.

Transport the scope of delivery secured against shifting

or tilting with a sufficiently dimensioned industrial truck to

the installation site.

General risks during internal transport

Devices may only be transported by authorized and qua-

lified persons. Act responsibly during transport and al-

ways consider the consequences. Refrain from daring

and risky actions.

Gradients and descents (e.g. driveways, ramps and the

like) are particularly dangerous. If such passages are

unavoidable, special caution is required.

Before starting the transport check the transport route for

possible danger points, unevenness and disturban-ces

as well as for sufficient strength and load capacity.

Danger points, unevenness and disturbance points must

be inspected before transport. The removal of danger

spots, disturbances and unevenness at the time of trans-

port by other employees leads to considerable dangers.

Careful planning of internal transport is therefore essen-

tial.

Transport with a forklift/pallet truck:

For delivery the machine is permanently mounted on a

pallet so that it can be transported with a forklift or a pal-

let truck.

WARNING!

Severe or fatal injuries may occur if parts of the

machine tumble or fall down from the forklift

truck, pallet truck or from the transport vehicle.

Follow the instructions and information on the trans-

port box.

Note the total weight of the machine. The weight of

the machine is indicated in the "Technical data" of the

machine. When the machine is unpacked, the weight

of the machine can also be read on the rating plate.

Only use transport devices and load suspension gear

that can hold the total weight of the machine.

WARNING!

The use of unstable lifting and load suspension

equipment that might break under load can cause

severe injuries or even death. Check that the lifting

and load suspension gear has sufficient load-bea-

ring capacity and that it is in perfect condition.

Observe the accident prevention regulations issued

by your Employers Liability Insurance Association or

other competent supervisory authority, responsible

for your company.

Fasten the loads properly.

WARNING: DANGER OF TIPPING

The device may be lifted unsecured by a maximum

of 2cm.

Employees must be outside the danger zone, the

reach of loads.

Warn employees and, if necessary, advise employ-

ees of the hazard.

ATTENTION!

Take care that the handling and lifting equipment can

accommodate the load during transport and with lift-

ing of the Folding Machine.

WARNING!

Danger to life!

Failure to observe the weight of the device as well as

the safe working load of the lifting means during

transport or lifting operations, can tilt or topple the

unit.

- During transportation and lifting work note the

weight of the machine and also the safe working

load of the lifting device.

- Check lifting and handling slings are in good condi-

tion.

8FSBM Series | Version 1.06

Description of the machine

Transport with a crane:

The machine can be placed by a crane at a suitable loca-

tion. For this, the machine must be secured in accor-

dance with regulations on the crane. There are the spe-

cial bolts for transport [Fig. 3; 1] to be used on the

machine. The bolts for transport are to be tightened be-

fore the beginning of the transport.

Fig. 3: Transport with a crane

In order to achieve optimal results, the frame should be

mounted stably by a sufficient fixation on the ground (see

Figure 4).

To protect against moisture and dirt all shining parts of

metal are greased. This protective layer has to be re-

moved prior to commissioning.

Fig. 4: Fixation to the ground

4.2 Packaging

All used packaging materials and packaging aids of the

appliance are recyclable and generally need to be trans-

ported to the material recycling.

Crush the packaging material made of cardboard and

supply it to the waste paper collection.

The films are made of polyethylene (PE) and the uphol-

stery parts are made of polystyrene (PS). These materi-

als have to be delivered to a recycling station of the re-

sponsible dumping company.

4.3 Storage

The machine must be stored thoroughly cleaned in a dry,

clean and frost-free environment. It must not be placed in

the same room together with chemicals.

5 Description of the machine

The illustrations in these operating instructions

serve the general comprehension and may deviate

from the actual type.

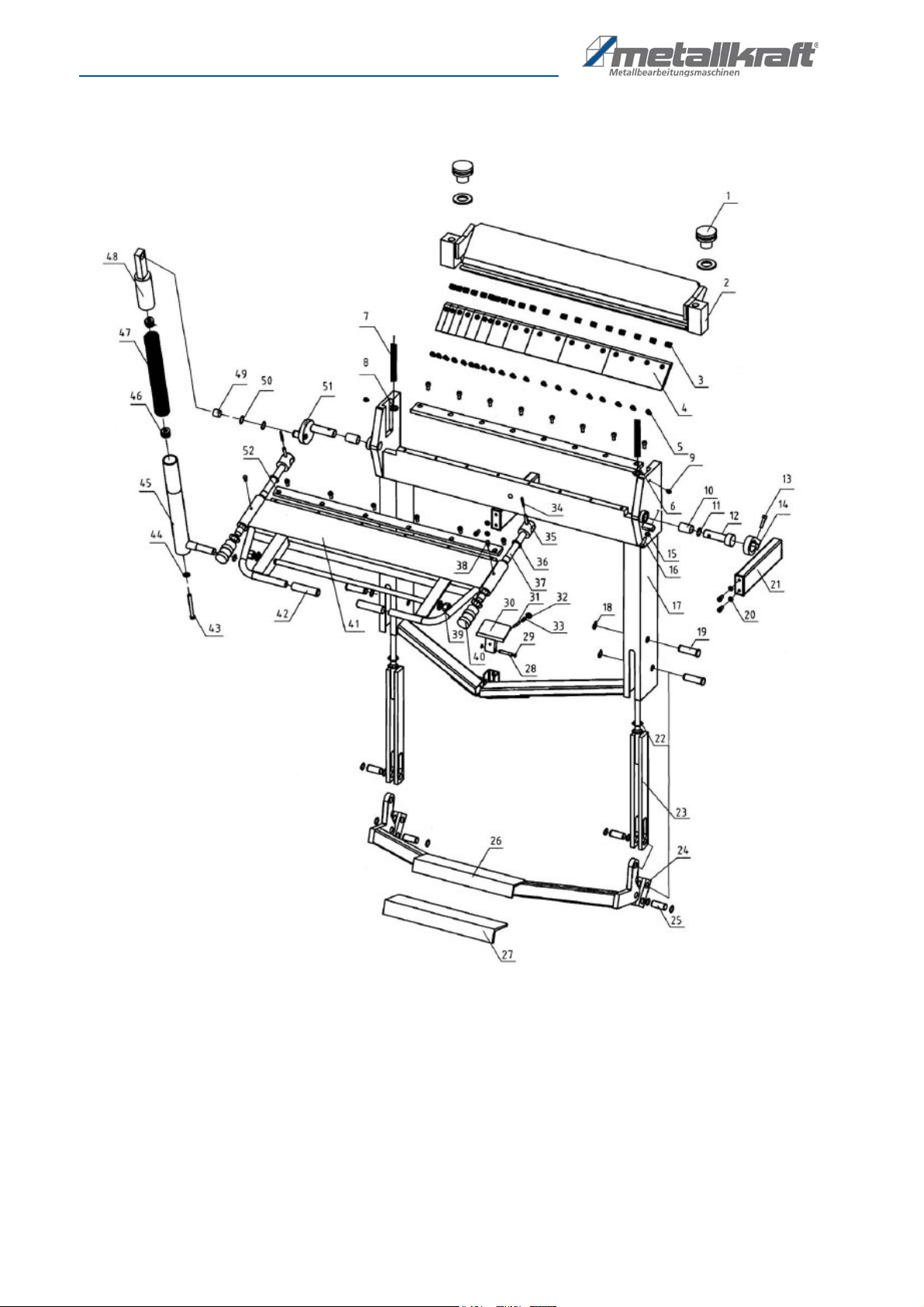

Fig. 5: Machine parts

1 Pedal for clamping

2 Bending beam

3 Segments of clamping beam

4 Segments of bending beam

5 Handle

6 Adjustment of hight position and pressing power of

clamping beam

7 End stop of bending angle

8 Adjustment of material thickness

9 Fixation of adjusted material thickness

10 Auxiliary Cylinder

11 Fixation screws of bending beam

5.1 Scope of delivery

Scope of delivery:

- Operating Instructions

- Rod for exchangement of segments (FSBM 1020-20 HSG)

NOTE!

- The machine must only be handled by experienced

personnel for loading, unloading and transport.

- Never place the forks of the forklift directly under

the machine for lifting!

NOTE!

- To transport all the covers must be mounted on the

machine frame.

- The machine must not be rocked during transport

by crane.

1

Installation and Operation

FSBM Series | Version 1.06 9

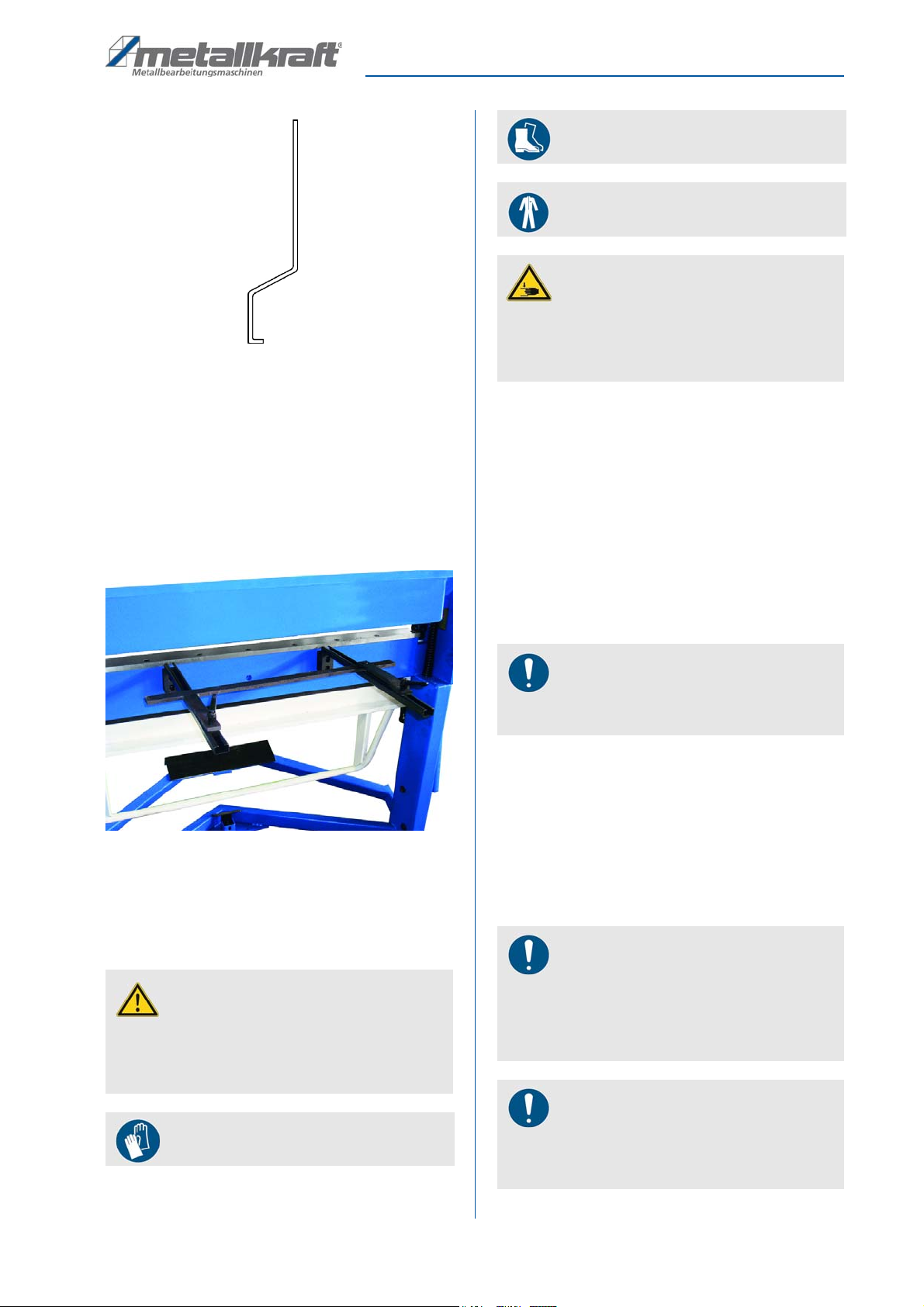

Fig. 6: Rod for release of segments. For FSBM 1020-20 HSG only!

5.2 Accessory for option

Back gauge (until 300 mm) for following models:

- FSBM 1020-20S2

- FSBM 1020-25E

- FSBM 1270-20E

- FSBM 1270-20HS2

Fig. 7: Back gauge

6 Installation and Operation

6.1 Installation

To achieve a good functioning of the folding machine

and a long service life, the location should meet the fol-

lowing criteria:

- The ground must be level, stable and free of vibra-

tions

- The working area must be dry and well ventilated

- Machines causing dust and chips should not be op-

erated in the vicinity of the folding machine.

- There must be enough space for the operating per-

sonnel, for the transport of material as well as for

adjusting and maintenance.

- The working area must have good lighting.

Step 1: Check the ground for horizontal orientation, sta-

bility and evenness.

Step 2: Take all parts out of the packaging.

Step 3: If necessary protruding parts, such as e.g. end

stops, handles, etc., must be made safe by addi-

tional safety constructions, so that persons are

not at risk.

ATTENTION!

Check the floor loading capacity before you install

the machine. The place of installation must be capa-

ble of bearing the weight of the machine and the

workpieces.

Use protective gloves!

Use protective boots!

Wear protective clothes!

WARNING!

Risk of crushing!

The machine may tip when setting up and cause

serious injury.

- The machine should be established by at least 2

persons.

NOTE!

- The bending machine is pre-assembled when deliv-

ered.

NOTE!

After installation remove the grease from the blank

metal parts which has been applied for protection.

- Use normal solvents for this.

- Do not use water, nitro solvents, or similar!

NOTE!

The moving parts must be free of dirt and dust.

- Lubricate moving parts, where appropriate, as indi-

cated in Section Cleaning and Maintenance.

10 FSBM Series | Version 1.06

Installation and Operation

6.2 Mounting of the back gauge (optio-

nal)

Step 1: Screw the two guide rails (Pos. 2, Fig. 8) to the

back of the machine (Fig. 11) using the four long

screws (Pos. 6, Fig. 8). Use the four long screws

(Pos. 6, Fig.8).

Step 2: Fasten the two scales in the guide rails so that

they are suitable for the intended purpose.

Step 3: Insert the clamping handle (Pos.4, Fig. 8 and Fig.

9) into the hole on the short bracket of the stop

angle (Pos. 1, Fig. 8 and Fig. 9).

Step 4: Slide the T-slot nut (Pos. 4, Fig. 8 and Fig. 9)

into the guide rail (Pos. 2, Fig. 8) and fasten the

stop angle (Pos. 1, Fig. 8) to the left guide rail

(Pos. 2, Fig. 8) using the clamping handle (Pos.

4, Fig. 8). Do not tighten the clamping lever com-

pletely so that the stop angle can still be aligned.

Fig. 8: Components of the back gauge

Legend:

1 Stop angle 2 Guide rail (2x)

3 Distance scale (2x) 4 Handle with slot nut (2x)

5 Screws small (1x) 6 Screws long (4x)

7 Bended connector

Fig. 9: Back gauge assembled

Step 5: Insert the second clamping handle Pos.4, Fig. 8

and Fig. 9) into the hole in the curved area of the

connector (Pos. 7, Fig.10).

Step 6: Then attach the bended connecting piece (Pos.

7, Fig. 8) to the right guide rail using the second

clamping handle and the second T-slot nut

(Fig.10). Do not completely tighten the clamping

lever so that the connector can still be aligned.

Fig. 10: Mounting of the bended connector

Fig. 11: Back gauge mounted on the machine

7

1

2

3

4

6

5

2

7

1

4

5

6

2

4

7

1

4

6

5

2

4

Operation

FSBM Series | Version 1.06 11

Step 7: Fasten the bended connector (Pos. 7, Fig. 9)

with the small screw (Pos. 5, Fig. 9) in the

threaded hole in the junction of the angle bracket

(Fig.10).

Step 8: Set the long boom of the angle stop parallel to

the bending edge.

Step 9: Tighten the small screw and the clamping

levers.

7 Operation

In order to operate steady and safe, please make sure

that the machine is grounded firmly, well fixed to the

ground and levelled horizontally.

The numbered machine parts of the following description

can be found in Figure 5 "Machine parts"

Step 1: Before working with the machine, the bending

angle end stop (7) has to be released. Subse-

quently, the desired clamping pressure must be

set by the regulating screws (6). These must be

screwed in as far that the foot pedal (1) still en-

gages upon pressing.

Step 2: By screwing the adjustment screws (M8) the

bending gap of the machine is set for the sheet

to be processed. Tip: To achieve an optimal re-

sult, the bending gap should be uniform and

slightly wider than the plate thickness.

Step 3: Now the locking device (1) for the upper beam

may be released and the upper beam may be

lifted by pressing of the pedal, and the sheet can

be inserted. By subsequent pressure on the foot

pedal (1) the upper beam lowers and the plate is

clamped safely.

Take care of crushing hazards for the upper

limbs!

Step 4: By raising the lower beam, you now can bend

your plate to the desired angle. The auxiliary

cylinder (10) helps the force to be applied. In or-

der to maintain the angle adjustment for multiple

bending operations, adjust the folding angle stop

(7) in the desired position. It can be rotated to the

desired angle individually or together with the

bending beam, and can be clamped there.

Using the removable segments, it is possible to prepare

box-shaped and complex profiles, for example.

Use protective gloves!

Use protective boots!

Wear protective clothes!

WARNING!

Danger in case of insufficient qualification

of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the machine and expose yourself

and others to the danger of severe injuries.

- Have all works only performed by qualified persons.

- Keep insufficiently qualified persons out of the work-

ing area.

WARNING!

There is danger for the operator and for other per-

sons if they do not comply with the following rules.

- The operator must not work if he is under the influ-

ence of alcohol, drugs or medication.

- The operator must not work if he is overworked or

suffers from fatigue and difficulties in concentrating.

- Operators must be familiar with the structure and

function of this machine.

- The folding machine may only be operated by one

skilled person. Other persons must not enter the

working area during operation.

WARNING!

Risk of crushing!

In case of improper works on the folding machine

there is a risk of injury on the upper limbs.

Keep your hands away from the clamping beam and

the bending beam

NOTE!

Before start up, note the following:

- The safety devices as well as the protective covers

must be functional.

NOTE!

When working with the FSBM 1020-20 HS2 make

sure that bending segments of the same size are

mounted opposite.

12 FSBM Series | Version 1.06

Care, maintenance and repair

8 Care, maintenance and repair

After maintenance, repair and cleaning works, check if

all claddings and protective equipment are properly reas-

sembled to the machine and that there are no more tools

inside or in the working area of the appliance.

8.1 Care by cleaning

Clean the machine in regular intervals using a soft and

moistened cloth.

Treat blank metallic working surfaces with anti-rust

spray.

8.2 Maintenance and repair

Lubricate all moving parts and bearings once per month.

Maintenance and repair works must only be performed

by specialists. If the machine does not work properly,

please contact a specialised dealer or our customer ser-

vice. Please find the contact data on chapter 1.2 Cus-

tomer service.

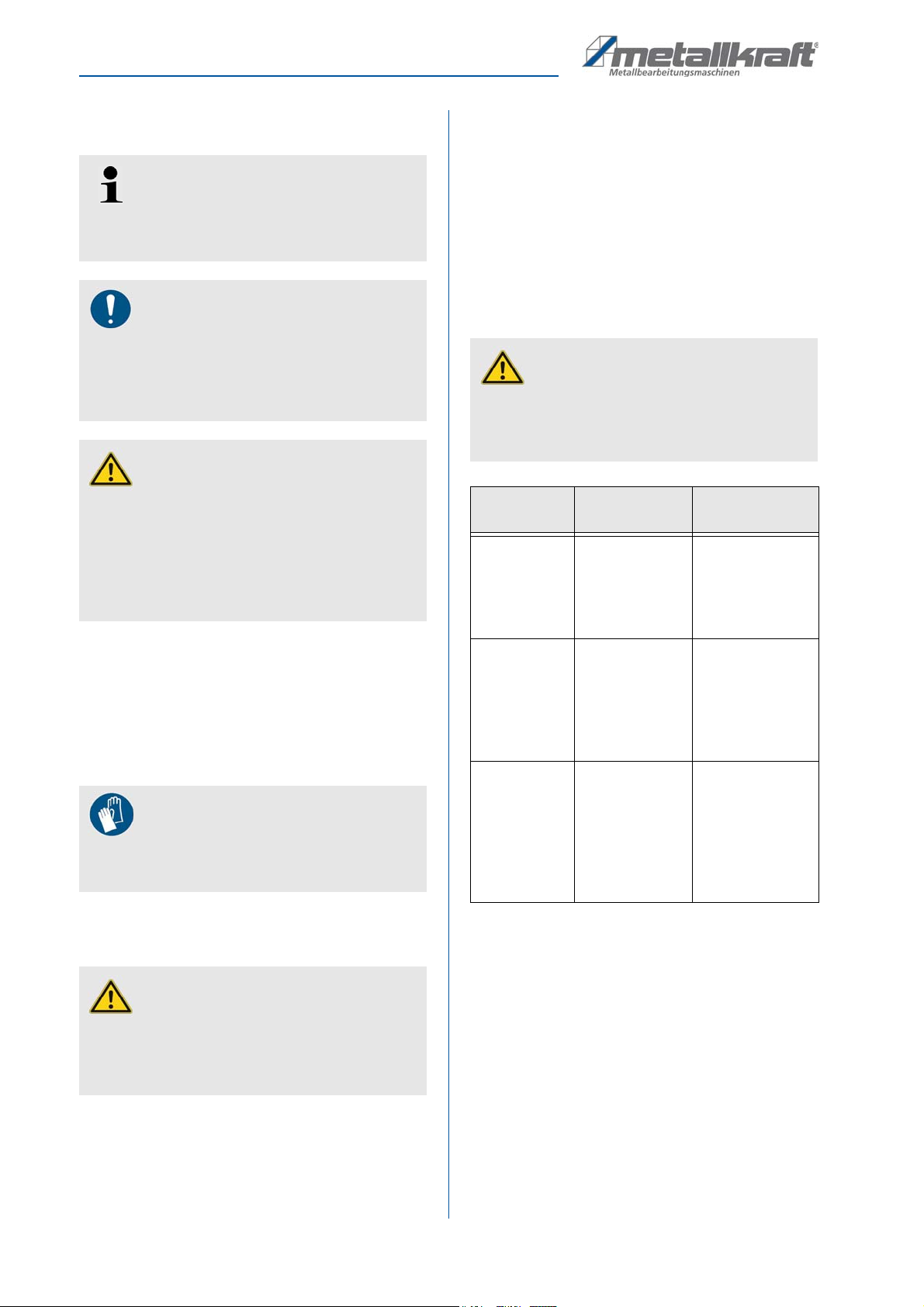

8.3 Troubleshooting

Tips and recommendations

In order that the machine is always in good operat-

ing status, it is necessary to regularly perform care

and maintenance works.

NOTE!

Before Care and maintenance of the folding

machine, the maintenance instructions must be read

carefully. Dealing with the bending machine is only

permitted for persons who are familiar with the fold-

ing machine.

WARNING!

Danger in case of insufficient quali-

fication of the staff!

Insufficiently qualified persons cannot estimate the

risks while performing repair work at the appliance

and expose themselves and others to the danger of

severe injuries.

- Have all maintenance works only performed by

qualified persons.

Use protective gloves!

Wear suitable protective gloves when cleaning the

machine in order to protect yourself against injuries

caused by chips.

ATTENTION!

Never use solvents or cleaning solutions to clean

plastic parts or lacquered surfaces. The surface may

be dissolved and consequential damage may occur.

use water containing mild cleaning detergents.

ATTENTION!

If one of the following errors may occur, discontinue

working with the machine. It could result in serious

injury. All repairs and replacement work must be car-

ried out by qualified and trained personnel.

Fault Possible

cause

Remedy

The machine

does not

work.

1. Faulty me-

chanics.

1. Check me-

chanics.

2. Contact the

dealer or Ser-

vice.

The machine

does not

bend the ma-

terial cor-

rectly.

1. The sheet

thickness

might be

wrong.

2. Wrong mate-

rial is used.

1. Take care of

max. sheet

thickness.

2. Only use cor-

rect material

The machine

does not

bend the ma-

terial as de-

scribed in the

catalog.

1. The sheet

thickness

might be

wrong.

2. Faulty me-

chanics.

1. Check the

sheet thick-

ness.

2. Contact the

dealer or Ser-

vice.

Disposal, recycling of used devices

FSBM Series | Version 1.06 13

9 Disposal, recycling of used

devices

ImFor environmental benefits it is necessary to ensure

that all components of the machine are only disposed of

by the provided and allowed means.

9.1 Decommissioning

Immediately decommission used machines in order to

avoid later misuse and endangering of the environment

or of persons.

- Dispose of all environmentally hazardous operating

materials of the used device.

- If required, disassemble the machine into easy-to-han-

dle and usable components and parts.

- Supply the machine components and operating mate-

rials to the provided disposal routes.

9.2 Disposal of lubricants

The manufacturer of the lubricant makes the disposal in-

structions for the used lubricants available. If applicable,

ask for the product-specific data sheets.

10 Spare parts

10.1 Order of spare parts

The spare parts may be purchased with the authorised

dealer or directly with the manufacturer. Please find the

corresponding contact data in Chapter 1.2 Customer

service.

Indicate the following basic information for spare part or-

ders:

- Type of device

- Article number

- Part number

- Quantity

- Year of manufacturing

- Required mode of dispatch (mail, freight, sea, air,

express)

- Address of dispatch

Spare part orders which do not include the above indi-

cations may not be taken into consideration. If the indica-

tions regarding the mode of dispatch are missing, the

product is dispatched at the discretion of the supplier.

You will find indications regarding the device type, article

number and year of manufacturing on the type plate

which is fixed on the machine.

Example

The bending arm for the Folding Machine FSBM 1020-20

HSG must be ordered. The bending arm has the number

42 in the spare parts drawing 1.

By ordering spare parts, send a copy of the spare parts

drawing (1) with the marked part (bending arm) and mar-

ked positon number (42) to the dealer or spare parts de-

partment and provide the following information:

- Type of machine: Folding Machine

FSBM 1020-20 HSG

- Article number: 3770103

- Drawing number: 1

- Position number: 42

Item number of your device:

Type of machine Article Number

FSBM 1020-25 E 3772125

FSBM 1270-20 E 3772127

FSBM 1520-15 E 3772129

FSBM 2020-12 E 3772130

FSBM 1020-20 S2 3772102

FSBM 1270-20 HS2 3772128

FSBM 1020-20 HSG 3770103

DANGER!

Danger of injury by the use of

wrong spare parts!

Dangers may result for the user and damages as well

as malfunctions may be caused by using wrong or

damaged spare parts.

- Only use original spare parts of the manufacturer or

spare parts admitted by the manufacturer.

- Always contact the manufacturer in case of uncer-

tainties.

NOTE!

The manufacturer's warranty will become null and

void if non admitted spare parts are being used.

14 FSBM Series | Version 1.06

Spare parts

10.2Spare parts drawings

In case of service, the following drawings shall help to identify the necessary spare parts. Send a copy of parts drawing

with the marked components to your authorised dealer when ordering spare parts.

Spare parts drawing FSBM 1020-20 S2_1270-20 HS2

Fig. 12: Spare parts FSBM 1020-20 S2 and 1270-20 HS2

Spare parts

FSBM Series | Version 1.06 15

Spare parts drawing FSBM 1020-20 HSG

Fig. 13: Spare parts FSBM 1020-20 HSG

16 FSBM Series | Version 1.06

Spare parts

Spare parts drawing FSBM 1020-25 E_1270-20 E_1520-15 E

Fig. 14: Spare parts FSBM 1020-25 E_1270-20 E_1520-15 E

Spare parts

FSBM Series | Version 1.06 17

Spare parts drawing FSBM 2020-12 E

Fig. 15: Spare parts FSBM 2020-12 E

18 FSBM Series | Version 1.06

EC Declaration of Conformity

According to Machinery Directive 2006/42/EC Annex II 1.A

Manufacturer / distributor: Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Straße 26

D-96103 Hallstadt

hereby declares, that the following product

Product Group: Metallkraft®Metal working machines

Machine type: Folding machine

Designation of the machine *: FSBM 1020-25 E Item number *: 3772125

FSBM 1270-20 E 3772127

FSBM 1520-15 E 3772129

FSBM 2020-12 E 3772130

FSBM 1020-20 S2 3772102

FSBM 1270-20 HS2 3772128

FSBM 1020-20 HSG 3770103

Serial number*: ____________________

Year of manufacture*: 20____

* please fill in according to the information on the type plate

Due to its design and construction, as well as in the version we have placed on the market, it complies with the relevant

basic health and safety requirements of the Machinery Directive 2006/42 / EC Annex II 1.A.

The following harmonized standards have been applied:

DIN EN ISO 12100:2011-03 Safety of machinery. General principles for design -

Risk assessment and risk reduction (ISO 12100:2010)

Responsible for documentation: Kilian Stürmer, Stürmer Maschinen GmbH,

Dr.-Robert-Pfleger-Str. 26, D-96103 Hallstadt

Hallstadt, 28.09.2020

______________________

Kilian Stürmer

CEO, Director

11 EC Declaration of Conformity

Notes

FSBM Series | Version 1.06 19

12 Notes

www.metallkraft.de

This manual suits for next models

13

Table of contents