Page 4

INDEX

Introduction

Section A

Section B

Section C

Section D

Section E

Section F

………………………………………………………………………..... ...PAGE

¡ Introduction ...................................................................2

¡¡ Fasteners ......................................................................2

¡¡¡ Identification ..................................................................3

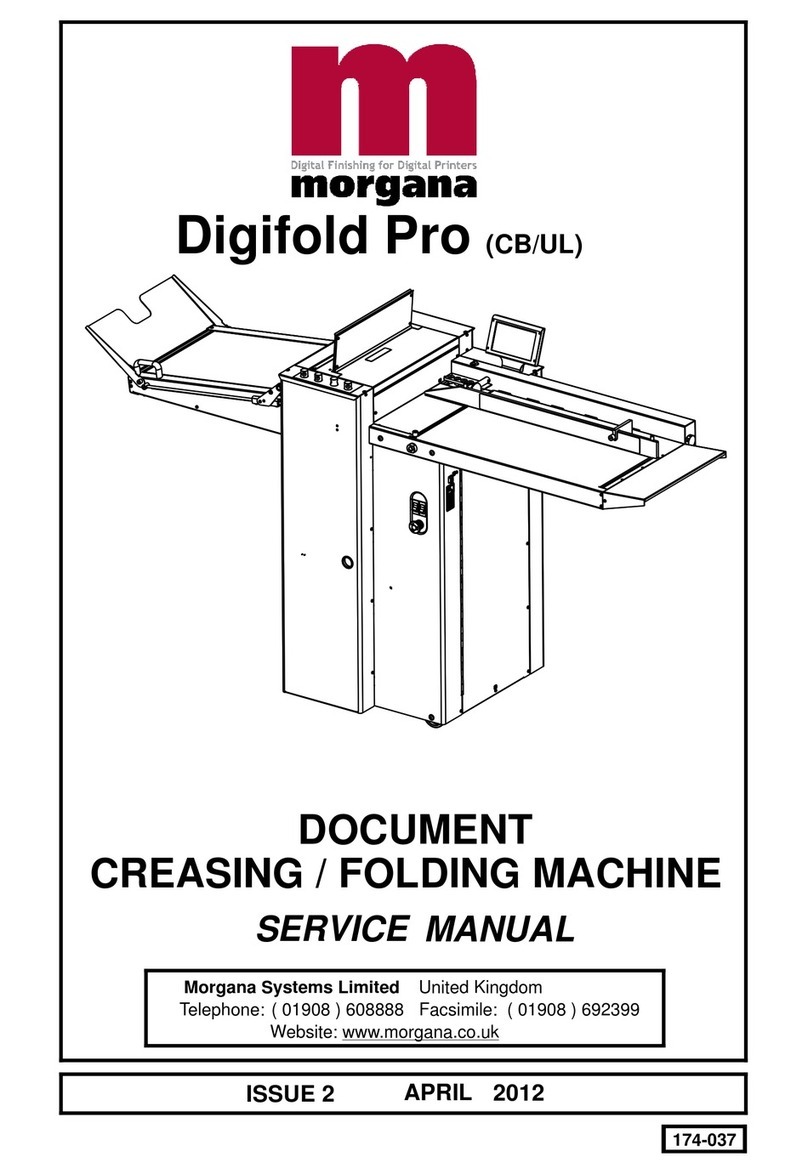

iv New Machine Preparation .............................................3

…… Covers………….…. ..................................................................

Operator and Lay edge Side Doors............................... 9

Rear Cover.................................................................... 9

Operator and Lay edge Columns ................................. 10

Top Cover Assembly .................................................... 10

Delivery Conveyor Removal......................................... 11

…….Feed Bed........................................................................

Accessing the Fans and Control Board........................12

Removal of Feed Bed...................................................13

…….Infeed Roller Removal/Replacement ...............………....………....14

…….Replacing the Touchscreen Assembly ........…….…………............16

…….Electrics………..………….…………………………….......……...

Removal/Refitting Control PCB and prog board...........18

Removal/Refitting USB Flash Drive .............................19

Removal/Replacement ITX Boards .............................22

Removal/Replacement ITX PSU .................................22

Removal/Replacement Stepper Drive PCB .................22

Removal/Replacement Large PSUs’............................22

Entering Engineers tools ..............................................23

Zero Total Count...........................................................23

Setting the Measurement System ................................23

…..Optical Sensors…….………………………………………….........

..................... ...................Cleaning Sensors ..........................................................24

..... ................ ...................Changing Sensors - Leading Edge................................25

..... ................ ...................Changing Sensors - Crunch..........................................25

.... ................. ...................Changing Sensors - Folder Unit Clip 1&2.....................26

FOLDING