Metallkraft SBM 110-08 User manual

SBM 140-12

Operating Instructions

SBM 110-08

SBM-SERIES

Bead Bending Machine

SBM 110-08

SBM 140-12

2 SBM-Series | Version 2.02

Imprint

Product identification

Bead Bending Machine Item number

SBM 110-08 3814001

SBM 140-12 3814002

Manufacturer

Stürmer Maschinen mbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049(0)951 96555-55

E-Mail: [email protected]

Internet: www.metallkraft.de

Information about the operating instructions

enuine operating instructions

Published: 02.04.2020

Version: 2.02

Language: English

Author: FL

Copyright information

Copyright © 2020 Stürmer Maschinen mbH, Hallstadt,

ermany.

Stürmer Maschinen mbH is the sole owner of the con-

tent of these operating instructions.Forwarding and re-

production of this document as well as use and notifica-

tion of its content is not permitted without explicit con-

sent. Infringements will lead to claims for damages.

Subject to technical changes and errors.

Contents

1 Introduction ............................................ 3

1.1 Copyright ........................................................... 3

1.2 Customer service............................................... 3

1.3 Limitation of liability............................................ 3

2 Safety ...................................................... 3

2.1 Legend of symbols............................................. 3

2.2 Operating staff qualification ............................... 4

2.3 Personal protective equipment .......................... 4

2.4 Norms and directives......................................... 5

2.5 eneral safety instructions ................................ 5

2.6

Safety instructions for the protection of persons

... 5

2.7 Safety instructions for the use of tools............... 6

2.8 Safety Instructions for processing......................6

2.9

Safety measures for maintenance and servicing

... 6

2.10 Safety label on the beading machine............... 6

3 Intended use ........................................... 7

3.1 Residual risks .................................................... 7

3.2 Technical state................................................... 7

4 echnical Data........................................ 8

4.1 Table.................................................................. 8

4.2 Type plate.......................................................... 8

4.3 Scope of delivery ............................................... 8

4.4 Accessories (not included).................................8

5 ransport, packaging and storage ....... 9

5.1 Delivery and transport........................................ 9

5.2 Packaging.......................................................... 9

5.3 Storage .............................................................. 9

5.4 Placement.......................................................... 9

6 Description of device..............................10

7 Description of the roller sets.................10

7.1 Roller set S1 to S5.............................................10

7.2 Roller set S6 ...................................................... 11

7.3 Roller set S7 ...................................................... 11

7.4 Roller set S8 ...................................................... 11

8 Replacing the rollers...............................11

9

Working with the bead bending machine

...12

10

Care, maintenance and repair/ servicing

..13

10.1 Care by cleaning..............................................13

10.2 Lubrication schedule........................................ 13

11 roubleshooting....................................14

12

Disposal, recycling of old equipment....

14

12.1 Decommission ................................................. 14

12.2 Disposal of new equipment packaging ............ 14

12.3 Disposal of the old device................................ 14

12.4 Disposal of lubricants....................................... 14

12.5 Disposal via municipal collection points........... 15

13 Spare parts.............................................15

13.1 Spare parts order.............................................15

13.2 Spare parts drawings....................................... 16

Introduction

SBM-Series | Version 2.02 3

1 Introduction

You have made an excellent choice in purchasing a

METALLKRAFT bead bending machine.

Carefully read the operating instructions prior to

commissioning.

They describe correct commissioning, intended use and

safe as well as efficient operation and maintenance of

the bead bending machine.

The operating instructions form part of the bead bending

machine. Always keep them at the bead bending ma-

chine´s location of use. Please also observe the local ac-

cident prevention regu-lations and general safety regula-

tions for the use of the bead bending machine.

1.1 Copyright

The contents of these operating instructions are pro-

tected by copyright. Their use is permitted within the con-

text of using the bead bending machine. Any further use

shall not be permitted without written consent by the ma-

nufacturer.

To protect our products, we register our rights to our

brands, patents and designs where possible in each in-

dividual case. We take strong action against any viola-

tion of our intellectual property.

1.2 Customer service

Please contact your specialist retailer if you have any

questions regarding your bead bending machine or re-

quire any technical information. Your specialist retailer

will be happy to support you with specialist advice and

information.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair service:

Fax: 0049 (0) 951 96555-111

E-Mail: service@stuermer-maschinen.de

Internet: www.metallkraft.de

Spare parts orders:

Fax: 0049 (0) 951 96555-119

E-Mail: ersatzteile@stuermer-maschinen.de

Please submit any information and experiences you

make during application of the machine as these may be

valuable for product improvements.

1.3 Limitation of liability

All data in this operation manual has been compiled on

the basis of the state-of-the-art, valid standards and gui-

delines as well as our many years of expertise and ex-

perience.

The manufacturer shall not be liable for damage in the

following cases:

- Failure to comply with the operation manual,

- Unintended use

- Deployment of untrained staff

- Conversions at one's own responsibility

- Technical modifications

- Use of unauthorised spare parts

The actual scope of delivery may deviate from the des-

criptions and illustrations in this document as a result of

special variants, optional extras or recent, technical mo-

difications.

The obligations defined in the supply con-tract shall ap-

ply in addition to the general terms and conditions and

the manufacturer's general terms and conditions as well

as the statutory regulations valid at the time of the con-

clusion of the contract.

2 Safety

This section provides an overview of all important safety

packages for personal protection as well as safe and re-

liable operation. The individual sections contain additio-

nal, taskspecific safety information.

2.1 Legend of symbols

Safety instructions

Safety instructions in this operation manual have been

highlighted with symbols. Safety instructions are indica-

ted by signal terms that express the degree of risk

involved.

DANGER!

This combination of symbol and signal term indica-

tes a potentially dangerous situation which may

cause death or serious injury if not averted.

WARNING!

This combination of symbol and signal term indica-

tes a immediate dangerous situation which may

cause death or serious injury if not averted.

4 SBM-Series | Version 2.02

Safety

ips and recommendations

Observe the safety information in these operating in-

structions to minimise the risk of personal injury as well

as material damage and prevent hazardous situations.

2.2 Operating staff qualification

The different tasks described in these operating instruc-

tions require different levels of skills in terms of the qua-

lifications of operating staff working with the machine.

Exclusively persons of whom it can be expected that

they reliably complete assigned tasks shall be authori-

sed to carry out any tasks. Persons whose reactions

have been impaired shall not be authorized, e.g. drug

users, users under the influence of alcohol or medica-

tion.

These operating instructions specify the following per-

sonal qualifications for the different tasks:

Operating staff:

Operating staff has undergone an induction by the ope-

rator about the entrusted tasks and potential hazards re-

sulting from improper behaviour. Tasks which go beyond

normal operation may only be carried out by the operator

if they are listed in the operation manual and the opera-

tor has made him/herself familiar with them.

Qualified electrician:

Due to the electrician's specialised training, know-how,

experience and knowledge of pertinent standards and

regulations the electrician is in a position to work on the

electrical systems, and autonomously identify and avoid

potential hazards.

Specialist staff:

As a result of specialist training, expertise, experience

and skills in terms of the relevant standards and regula-

tions, specialist staff is able to complete the tasks they

are entrusted with and independently identify hazards

and avert risks.

Manufacturer:

Certain work must be carried out by manufacturer spe-

cialist staff only. Other staff is not permitted to carry out

this work. Contact our customer service to have the work

carried out.

2.3 Personal protective equipment

Personal protective equipment is intended to protect the

health and safety of persons at work. Staff must wear the

personal protective equipment indicated in individual

sections of these operating instructions when carrying

out the different tasks on the machine.

The personal protective equipment is described in the

following section:

A EN ION!

This combination of symbol and signal term indica-

tes a potentially hazardous situation which may

cause minor or light injuries if it is not averted.

CAU ION!

This combination of symbol and signal word indica-

tes a potentially dangerous situation. It will result in

death or serious injury if not avoided.

NO E!

This combination of symbol and signal term indicates

a potentially dangerous situation which may cause

material damage or harm the environment if it is not

averted.

ips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for efficient and reliable

operation.

WARNING!

Risk from inadequately qualified

persons!

Inadequately qualified persons are unable to assess

the risks when handling the machine, thus putting

themselves and others at risk of severe injuries.

- All work must be carried out by qualified persons

only.

- Keep inadequately qualified persons and children

away from the work area.

Protective gloves

The protective gloves prevent the hands from sharp-

edged components, as well as from friction, abrasi-

ons or deeper injuries.

Safety boots

The safety boots protect the feet from crushing, falling

parts and slipping on slippery underground.

Protective clothes

The protective clothing is tight-fitting clothing with low

tear resistance.

Safety

SBM-Series | Version 2.02 5

2.4 Norms and directives

The basic safety and health requirements of the applica-

ble laws, standards and directives were applied in the

design. The safety of the machine is documented by the

CE marking and the declaration of conformity.

All information on safety refers to the currently valid re-

gulations of the European Community. In other coun-

tries, the applicable laws and national regulations must

be observed.

In addition to the safety instructions in these operating in-

structions, the generally applicable regulations for acci-

dent prevention and environmental protection must be

observed and adhered to.

2.5 General safety instructions

Please note the following:

1. Despite compliance with all working instructions,

safety and accident prevention regulations, there is

still a residual risk when handling the machine. You

can reduce the residual risk by working and acting

with concentration and foresight.

2. The machine may only be operated and maintained by

persons who have read and understood these opera-

ting instructions. The operator must be adequately

trained in application, adjustment and operation.

3. If you give this machine to others, you must hand over

all tools and documents supplied with the machine.

4. Never open the protective covers by hand while you

are working with the machine.

5. Keep the workplace and the floor around the machine

free from any objects that could endanger your stabi-

lity or pose a risk of tripping. Keep the workplace tidy.

Disorder can result in accidents.

6. Check the danger area before and during work to en-

sure that no unauthorised persons are located there.

Do not allow other persons, especially children, to

touch the machine.

7. Only use the machine in dry rooms or in a dry environ-

ment and ensure that the working area is adequately

illuminated.

8. Protect your workplace from rain, wet and humidity.

9. Take care of the machine. Keep the bending machine

functional and clean in order to be able to work with it

well and safely in the long term. Observe the instructi-

ons for maintenance and servicing.

10. At the end of its service life, the machine and all re-

placed wear and spare parts, as well as all consu-

mables, such as lubricants, must be disposed of in ac-

cordance with environmental and regulatory

requirements.

2.6 Safety instructions for the protection of

persons

Please note the following:

1. Do not operate the machine if you are not concentra-

ted.

2. operating or maintaining the machine is prohibited for

persons under 16 years of age or for persons under

the influence of alcohol, drugs or medication.

3. Inform yourself about the type of material to be machi-

ned before you start machining. If necessary, take

appropriate precautions.

4. Always wear safety glasses when working with the

machine. It is forbidden to wear loose clothing (ties,

neck shawls, open jackets and clothing that does not

fit tightly). There is a risk of injury from getting caught

or being drawn into moving machine parts. A hair net

must be worn for long hair.

5. Protect yourself from noise by wearing suitable and

approved hearing protection.

6. Profiles can be sharp-edged. Wear protective gloves if

necessary. Pay attention to your posture and keep

your balance at all times. Wear work shoes to in-

crease your stability. Wear appropriate work clothing.

WARNING!

Danger in case of misuse!

The bead bending machine may only be operated in

a technically perfect condition. Any faults must be

rectified immediately. Unauthorised modifications to

the bead bending machine or improper use of the

bead bending machine as well as non-compliance

with the safety regulations or the operating instructi-

ons exclude the manufacturer's liability for any resul-

ting damage to persons or objects and invalidate the

warranty claim!

A EN ION!

The instructions for use and maintenance must be

read carefully before starting, using, servicing or

otherwise working on the machine. Handling and

working with the machine is only permitted to per-

sons who are thoroughly familiar with the handling

and mode of operation of the machine.

WARNING!

Repairs, maintenance and upgrades may only be

carried out by qualified personnel with the machine

secured!

6 SBM-Series | Version 2.02

Safety

2.7 Safety instructions for the use of tools

Please note the following:

1. Use only bending rollers that are not deformed or da-

maged.

2. Only use original bending rollers.

3 Replace deformed and damaged bending rollers im-

mediately. Use of the machine is prohibited until the

bending rollers have been replaced.

4. Always use bending rollers adapted to the workpiece.

5. Only use bending rollers with suitable sizes.

6. Check the drive components of the bending rollers for

contamination. Clean the clamping area of the ben-

ding rollers before assembly.

2.8 Safety Instructions for processing

Please note the following:

1. Use the machine only for carrying out the intended

work.

2. Do not use the machine for purposes for which it is not

intended, such as bending brittle materials.

3. Observe the maximum dimensions of the workpieces

specified in the technical data (see chapter "Technical

data").

4. Do not overload the machine. It works better and safer

in the specified performance range. Do not use the

machine for heavy work that requires a more powerful

machine.

5. Check the stability of the machine and the secure bol-

ting to the foundation.

6. Note that the use of tools and accessories other than

those recommended by the manufacturer may result

in injury.

7. Do not leave any tools inserted. Before switching on,

check that all repair and adjustment tools have been

removed.

8. Do not leave the machine unattended during machi-

ning and keep a sufficient safety distance from the

moving machine parts.

9. Only start the machine if the bending rollers can run

freely.

10. If the bending rollers are blocked during machining by

clamping the workpiece, stop the machine.

11. Workpieces may only be clamped or removed when the

bending rollers have come to a complete standstill.

2.9 Safety measures for maintenance and

servicing

Please note the following:

1. During maintenance and repair work, always switch

off the machine at the main switch and take suitable

measures to secure it against being switched on again

by unauthorised persons.

2. After maintenance, repair and cleaning work, check

that all covers and protective devices have been pro-

perly installed on the machine and that no tools are

left inside the machine or in the machining area.

3. Damaged safety devices, machine parts and switches

must be replaced or repaired by an approved specia-

list workshop.

4. Only original spare parts may be used. Otherwise

there is a risk of accident for the operator.

2.10 Safety label on the beading machine

A safety label is attached to the bead bending machine

which must be observed and followed. The safety mar-

king placed on the bead bending machine must not be

removed. Damaged or missing safety markings can lead

to wrong actions, personal injury and material damage.

They must be replaced immediately. If the safety mar-

king is not immediately visible and understandable, the

bead bending machine must be taken out of operation

until the new safety marking has been affixed.

Fig. 1: Safety label - Rotating parts

Intended use

SBM-Series | Version 2.02 7

3 Intended use

The bead bending machine SBM 110-08 and SBM 140-

12 is a manually operated bending machine. The ma-

chine may only be used as described in this manual. The

bead bending machine is designed for beading and flan-

ging up to a maximum sheet thickness of 0,8 and 1,2

mm. It may only be operated by persons who have been

trained and instructed in the use and maintenance of

bead bending machines.

Intended use also includes compliance with all informa-

tion in these instructions. Any use beyond the intended

use or any other use is considered misuse. Any use of

the bead bending machine in other areas and for other

purposes is considered to be contrary to the intended

purpose. Stürmer Maschinen mbH assumes no liability

for constructive and technical changes to the bead ben-

ding machine. Claims of any kind due to damage due to

improper use are excluded.

3.1 Residual risks

Even if all safety regulations are observed and the ma-

chine is used correctly, there are still residual risks,

which are listed below:

- There is a risk of injury to the upper limbs (e.g.

hands, fingers).

- Danger from falling workpieces.

3.2 Technical state

The design and construction of the machine comply with

the current state of the art and are built in accordance

with the recognized safety regulations. CE conformity

expressly refers only to the machine as delivered.

Please note the following:

1. The functionality of the protective covers and guards

must be ensured.

2. Any manipulation of protective covers and other safety

devices is prohibited.

3. Before each use, the machine should be checked for

externally visible damage.

4. In the event of safety-relevant deviations from the deli-

very condition, the machine must be inspected and, if

necessary, repaired by an authorised specialist.

5. From the time when the machine no longer corre-

sponds to the regular operating condition, the bead

bending machine must be taken out of operation until

it is repaired.

WARNING!

Risk of misuse!

Misuse of the bead bending machine can lead to dan-

gerous situations.

- Only operate the bead bending machine in the po-

wer range specified in the technical data.

- Never bypass or override the safety devices.

- Never work on other materials than specified in the

intended use.

- Only operate the bead bending machine in a techni-

cally perfect condition.

WARNING!

Danger!

Unauthorized rebuilds or modifications, especially

those that affect the safety of the machine operator,

are strictly prohibited.

Technical modifications, rebuilds and extensions

made to the machine by the user may invalidate the

CE conformity of the machine and are the responsibi-

lity of the operator.

A EN ION!

The manufacturer reserves the right to make chan-

ges to the characteristics of the product at any time

and without prior notice in the interests of technical

development or changing regulations.

8 SBM-Series | Version 2.02

echnical Data

4 Technical Data

4.1 Table

*Performance data related to material with tensile strength 100N/mm²

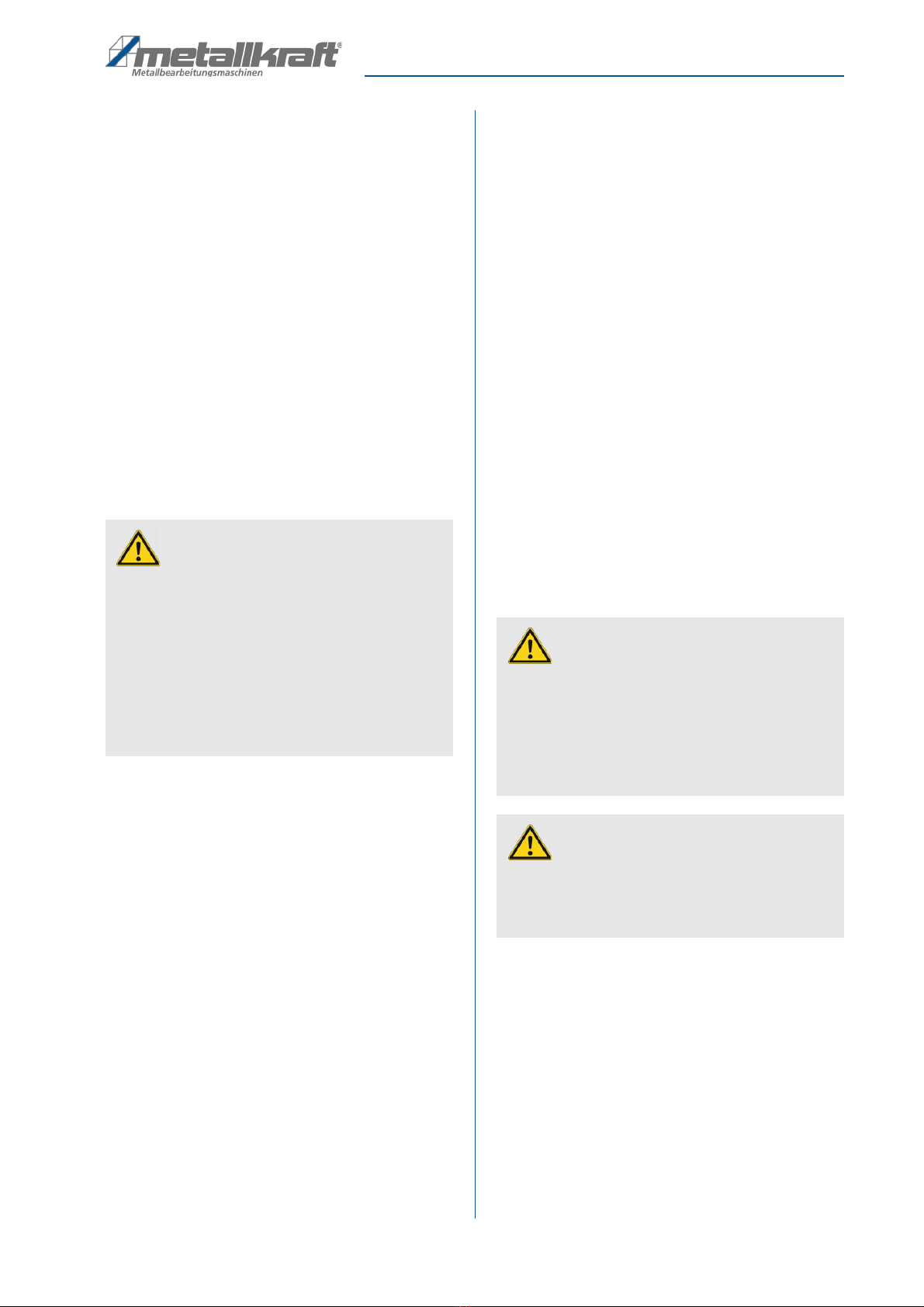

4.2 Type plate

Fig. 2: Type plate SBM 110-08

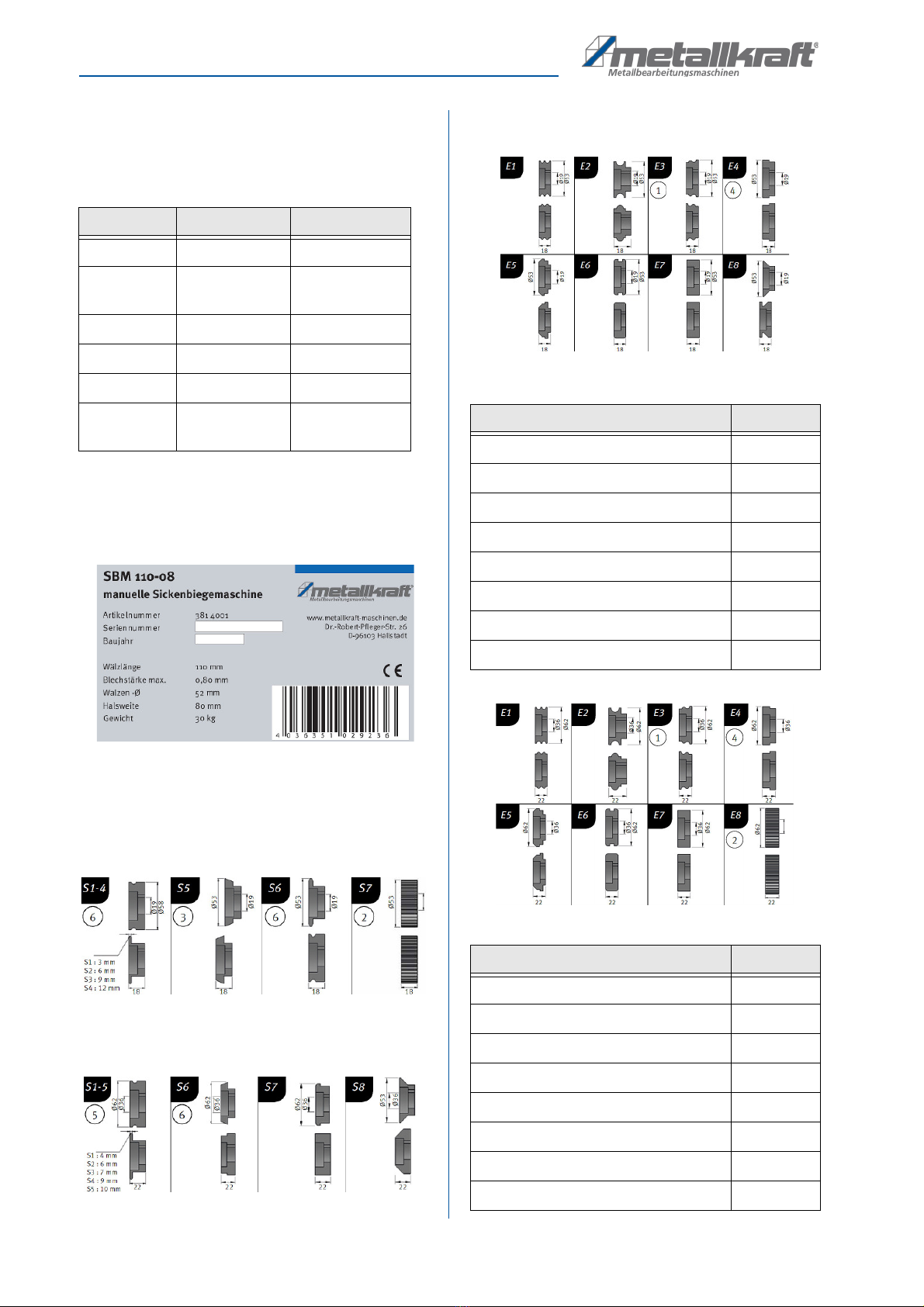

4.3 Scope of delivery

SBM 110-08

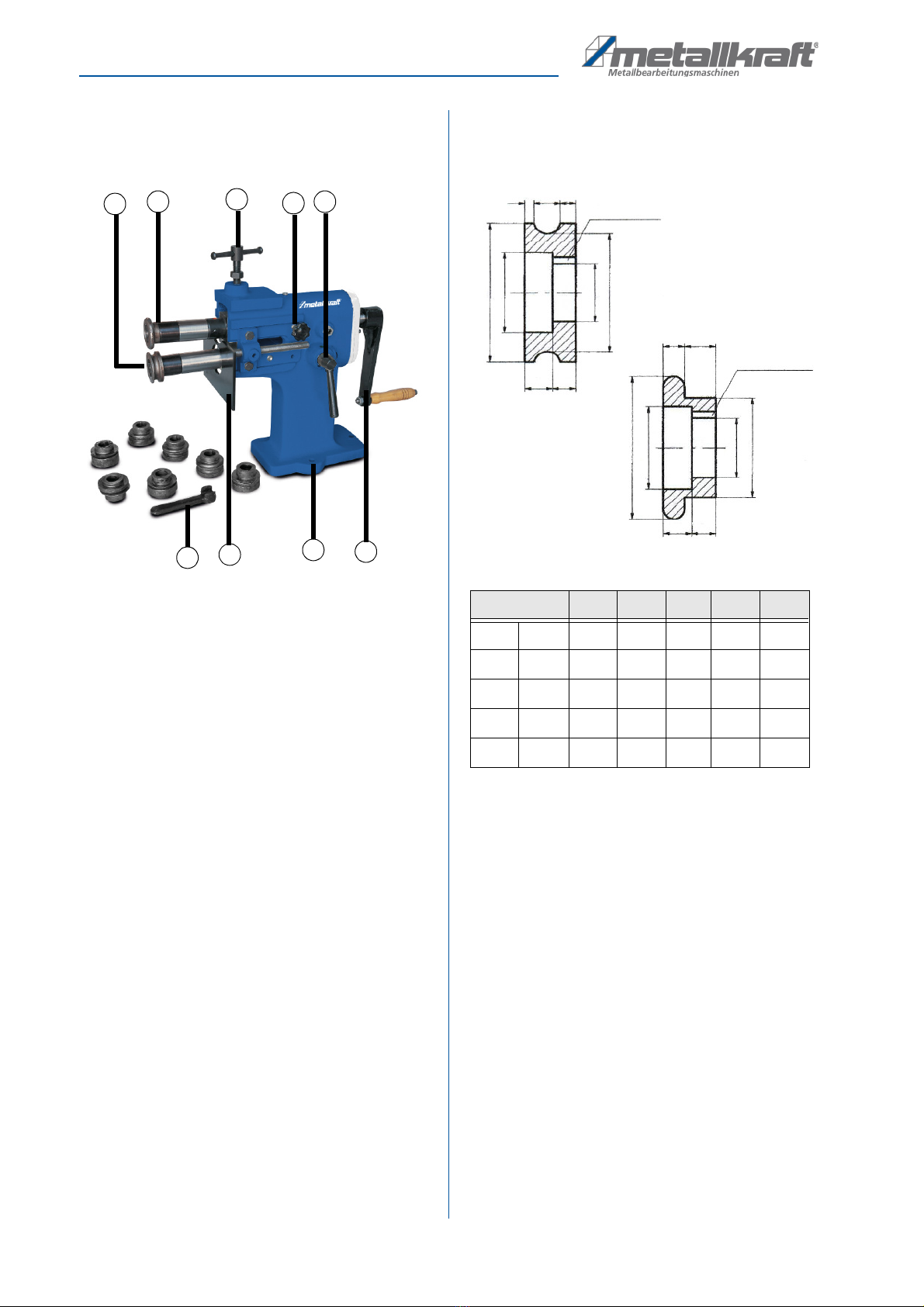

Fig. 3: Standard rollers

SBM 140-12

Fig. 4: Standard rollers

4.4 Accessories (not included)

Fig. 5: Accessories rollers for SBM 110-08

Fig. 6: Accessories rollers for SBM 140-12

Model SBM 110-08 SBM 140-12

Roller length 110 mm 140 mm

Max. sheet

thickness*

0,80 mm 1,2 mm

Roller Ø 52 mm 62 mm

Collar width 80 mm 100 mm

Weight 30 kg 50 kg

Dimensions

L x W x H

380 x180 x 380

mm

560 x 220 x 500

mm

Description Art. Nr.

Bending rollers type E1 3880121

Bending rollers type E2 3880122

Bending rollers type E3 3880123

Bending rollers type E4 3880124

Bending rollers type E5 3880125

Bending rollers type E6 3880126

Bending rollers type E7 3880127

Bending rollers type E8 3880128

Description Item. Nr.

Bending rollers type E1 3880131

Bending rollers type E2 3880132

Bending rollers type E3 3880133

Bending rollers type E4 3880134

Bending rollers type E5 3880135

Bending rollers type E6 3880136

Bending rollers type E7 3880137

Bending rollers type E8 3880138

ransport, packaging and storage

SBM-Series | Version 2.02 9

5 Transport, packaging and storage

5.1 Delivery and transport

5.1.1 Delivery

After delivery, check the bead bending machine for vi-

sible transport damage. If the bead bending machine

shows any damage, this must be reported immediately

to the transport company or the dealer.

All packaging must be removed; the corresponding in-

structions in this operating manual for installation must

be read. Possible transport damage must be immedi-

ately documented photographically for the purpose of in-

surance benefits.

To avoid accidents, the necessary precautions must be

taken when unloading and transporting the machine.

See the chapter on safe handling of this machine.

5.1.2 Transport

5.2 Packaging

All packaging materials and packaging aids used in the

machine are recyclable and must always be recycled.

Cardboard packaging components must be shredded for

collection of waste paper.

The foils are made of polyethylene (PE) and the uphol-

stery parts made of polystyrene (PS). These substances

must be handed over to a recycling center or to the re-

sponsible disposal company.

5.3 Storage

The bead bending machine must be thoroughly cleaned

before it is stored in a dry, clean and frost-free environ-

ment.

5.4 Placement

In order to achieve good functionality and a long service

life of the bead bending machine, the installation site

should meet the following criteria:

- The underground must be even, solid and vibration-

free.

- The machine should be firmly anchored to ensure a

safe stand.

- There must be sufficient space for the operating per-

sonnel, for material transport and for adjustment and

maintenance work.

A EN ION!

When transporting and lifting the bead bending

machine make sure that the transport and lifting

equipment can support the load.

WARNING!

Risk of fatal injury!

If the weight of the machine and the permissible load

capacity of the lifting equipment are not observed

during transport or lifting work, the machine may tip

over or fall.

Use protective gloves!

Wear safety boots!

CAU ION!

Danger of crushing!

The bead bending machine can tilt during installation

and lead to serious injuries.

10 SBM-Series | Version 2.02

Description of device

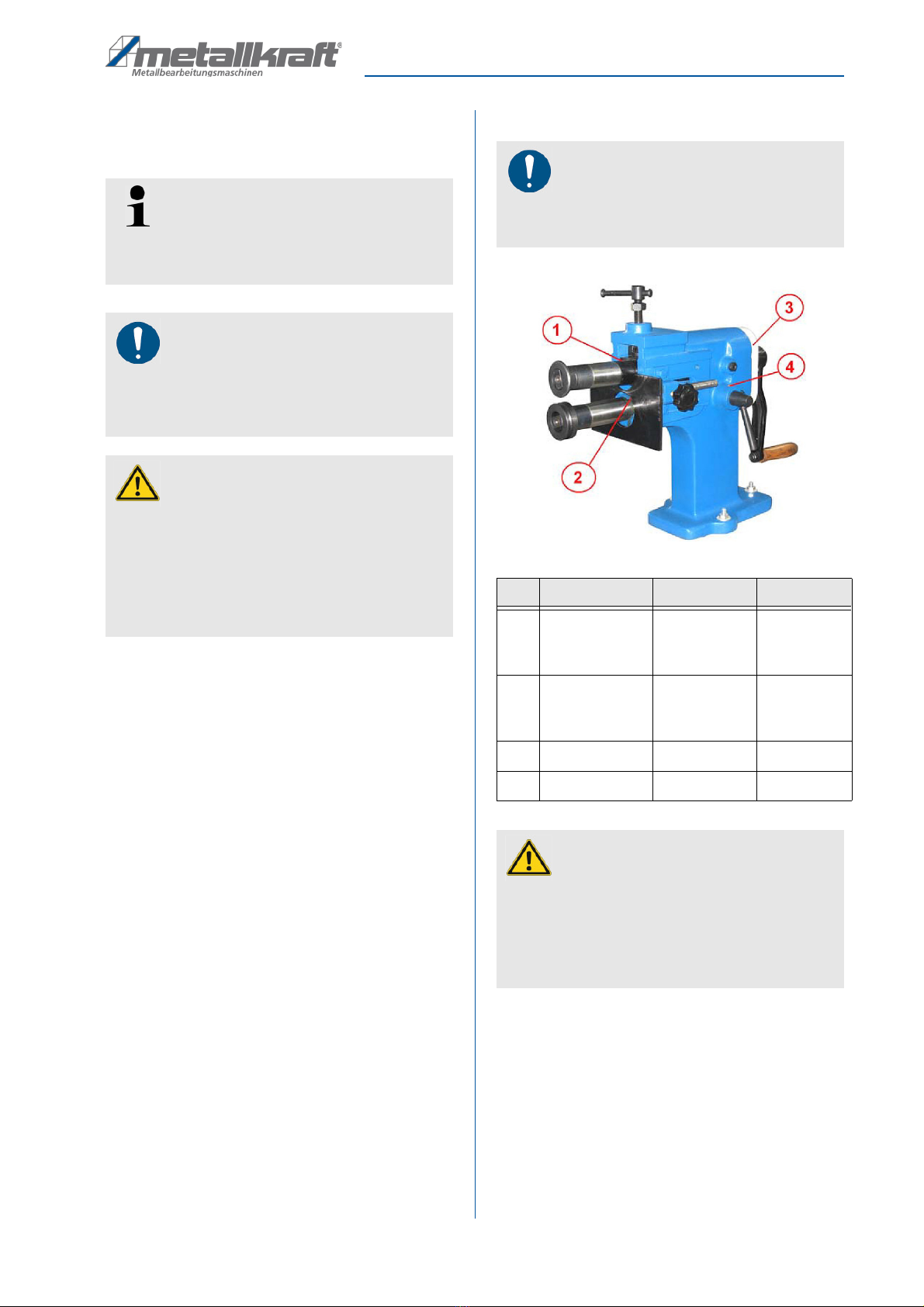

6 Description of device

Operating elements

Fig. 7: Description SBM 140-12

1. Bending roller (right-hand thread)

2. Bending roller (left hand thread)

3. Height adjustment

4. Locking screw

5. Lever „longitudinal adjustment“

6. Drive lever of the bending rolls

7. Anchoring boring hole

8. Stop plate

9. Tool for changing the rollers

7 Description of the roller sets

7.1 Roller set S1 to S5

Fig. 8: Dimensions of rollers S1-S5

The dimensions of the standard bending roller sets are li-

sted in the table. This means S1 for roller set 1, S2 for

roller set 2, etc.

12

876

5

4

3

9

Description S1 S2 S3 S4 S5

A mm 3 3,5 4 4 4

B mm 6,4 8,4 9,4 11,4 12,4

C mm 12,6 10,1 8,6 6,6 5,6

D mm 4 6 7 9 10

E mm 18 16 15 13 12

3x6 Feather key groove

3x6

A B C

Ø 62

Ø 43

Ø 26

Ø 36

Ø 53

Ø 26

Ø 36

Ø 62

12 10

DE

12 10

Feather key grove

Replacing the rollers

SBM-Series | Version 2.02 11

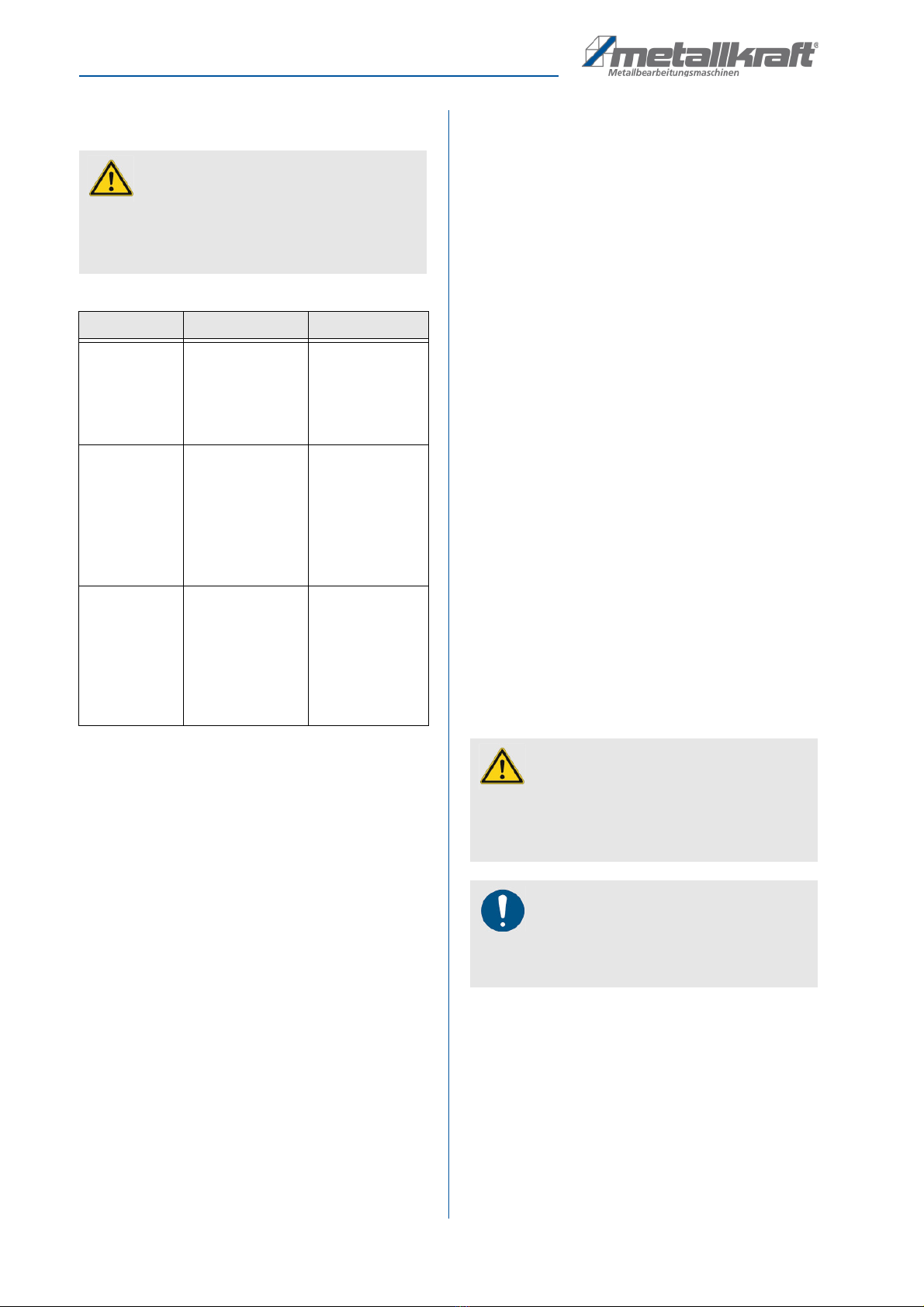

7.2 Roller set S6

Fig. 9: Dimensions of roller set S6

7.3 Roller set S7

Fig. 10: Dimensions of roller set S7

7.4 Roller set S8

Fig. 11: Dimensions of roller set S8

8 Replacing the rollers

Step 1: Move the upper drive shaft a little upwards using

the toggle screw so that the rollers are free and

can be removed.

Step 2: Open the two fixing nuts from the bending rollers.

Use the special key provided for this purpose.

Step 3: Pull off the two rollers and mount the the ones

they want..

3x6 Feather key grove

3x6

22

616

Ø 26

Ø 26

Ø 43

10

12

Ø 62

Ø 55

Ø 38

6 16

1,5

12 10

Ø 62

Ø 58

Ø 38

Feather key grove

3x6 Feather key grove

3x6

22

Ø 62

Ø 36

Ø 26

12 10 913

12 10

Ø 36

Ø 49

Ø 62

Ø 43

Ø 26

Feather key grove

A EN ION!

The thread on the upper roller is a right-hand thread

and the thread on the lower roller is a left-hand

thread.

A EN ION!

To prevent the upper and lower rollers from being

interchanged, the shaft diameters are different.

3x6 Feather key grove

3x6

814

Ø 43

Ø 38

Ø 62

Ø 48

Ø 43

Ø 38

Ø 62

Ø 26

Ø 26

12 10

8410

12 10

Feather key grove

12 SBM-Series | Version 2.02

Working with the bead bending machine

Step 4: Tighten the two nuts after mounting the bending

rolls.

Step 5: Then pull the rollers to the middle. To do this,

open the locking screw of the longitudinal adjust-

ment and adjust the rollers to the middle using

the lever on the opposite side.

Fig. 12: Replacing the rollers

9 Working with the bead bending ma-

chine

Step 1: First of all, the required bending rollers must be

mounted. The upper bending roll is secured by a

nut with right-hand thread, the lower bending roll

by a nut with left-hand thread. These two nuts

must be tightened securely after the assembly of

the bending rolls to guarantee safe working!

Step 2: To adjust the parallelism of the bending rolls, loo-

sen the locking screw on the left side and adjust

the length of the lower shaft using the lever on

the right side. After you have aligned the bending

rollers, fix the shaft by tightening the locking

screw on the left side again.

Step 3: Now adjust the stop plate by loosening the two

locking screws on the left and right and moving

the stop plate by hand to the desired dimension.

Then fix the stop plate again with the two locking

screws.

Step 4: Set the maximum infeed by adjusting the upper

shaft to the desired dimension using the height

adjustment/infeed lever and turning the nut down

to the stop.

Step 5: Use the height adjustment lever to move the up-

per shaft upwards until the material fits between

the bending rolls. Push the material up to the

stop plate.

Step 6: Now turn the upper shaft down to the stop screw

(set in step 4).

Step 7: Move the lever to drive the shafts / rollers in the

desired direction and shape your sheet metal.

If it is not possible to the complete infeed in one pass due

to high material thickness, this is also possible in several

partial steps. Repeat steps 6 to 7 until the desired infeed

depth/forming is reached.

Left-hand

Stop plate

Locking screw for

longitudinal adjust-

Locking screw for

stop plate

Right-hand

thread

thread

Height adjust-

ment/ Upper roller

Lever for longitudinal adju-

stment of the lower drive

Special key for changing

the rollers

Care, maintenance and repair/ servicing

SBM-Series | Version 2.02 13

10 Care, maintenance and repair/

servicing

After maintenance, repair and cleaning work, check that

all covers and protective devices have been properly fit-

ted to the bead bending machine and that no tools are

left inside or in the working area of the bead bending ma-

chine

10.1 Care by cleaning

Clean the bead bending machine regularly with a soft,

damp cloth.

10.2 Lubrication schedule

Fig. 13: Lubrication points

The bead bending machine must be lubricated regularly at the points

marked in Fig.13 according to the table. If the service life of the machine

is more than 8 hours per day, it must be lubricated more often.

Note that some of the lubrication points are located in the machine

housing (2 and 3). You may need to remove the covers to get to these

points.

ips and recommendations

Proper and correct maintenance is a prerequisite for

maximum service life, good working conditions and

machine productivity.

NO E!

The maintenance instructions must be read carefully

before care and maintenance of the bead bending

machine. Only persons familiar with the bead ben-

ding machine are permitted to use it

DANGER!

Danger if insufficient qualification

of persons!

Insufficiently qualified persons cannot assess the

risks associated with maintenance work on the

machine and expose themselves and other persons

to the risk of serious injury.

- Have all maintenance work carried out by qualified

personnel only.

NO E!

The bead bending machine must be lubricated at

regular intervals to ensure efficient operation and a

long service life of the machine.

No. Location Interval Lubricant

1 Lubrication

bore of the up-

per shaft

Once a week rease

2 Lubrication

bore of the

lower shaft

Once a week rease

3 earbox Once a week rease

4 earbox Once a week rease

A EN ION!

The bending rollers of the bead bending machine

must never be lubricated or oiled, as otherwise the

material could slip through and is not bent. Always

keep the bending rolls free of oil and grease. Also

make sure that the material to be bent is free of oil,

grease and dirt.

14 SBM-Series | Version 2.02

roubleshooting

11 Troubleshooting

12 Disposal, recycling of old equipment

In your own interests and in the interest of the environ-

ment, please ensure that all components of the machine

are disposed of in the proper and approved way.

12.1 Decommission

Disused equipment must be taken out of service immedi-

ately in order to avoid later misuse and endangering the

environment or people.

Step 1: Remove all environmentally hazardous fluids

from the old unit.

Step 2: If necessary, dismantle the machine into mana-

geable and usable assemblies and compo-

nents.

Step 3: uide the machine components and operating

materials to the appropriate disposal routes.

12.2 Disposal of new equipment packaging

All packaging materials and packaging aids used in the

machine are recyclable and must always be recycled.

The packaging wood can be disposed of or recycled.

Cardboard packaging components can be crushed and

sent for waste paper collection.

The films are made of polyethylene (PE) or padded parts

of polystyrene (PS). These materials can be reused after

processing if they are passed on to a recycling collection

point or to the disposal company responsible for them.

Only pass on the packaging material sorted by type so

that it can be directly recycled.

12.3 Disposal of the old device

Electrical equipment contains a variety of recyclable ma-

terials and environmentally harmful components.

These components must be disposed of separately and

properly. In case of doubt, contact the municipal waste

disposal department.

If necessary, a specialist waste disposal company

should be called upon to help with processing.

12.4 Disposal of lubricants

The disposal instructions for the lubricants used are pro-

vided by the lubricant manufacturer. If necessary, ask for

the product-specific data sheets.

A EN ION!

If one of the following errors occurs, stop working

with the machine immediately. Serious injury could

result. All repairs and replacement work may only be

carried out by qualified and trained personnel.

Fault Possible cause Solution

The bead

bending ma-

chine does

not work.

1. The mechani-

cal system is

defective.

1. Check the

mechanics.

2. Contact the

dealer/manu-

facturer.

The bead

bending ma-

chine does

not bend the

material cor-

rectly.

1. The material

thickness

could be

wrong.

2. The wrong

material has

been used.

1. Observe max.

sheet thick-

ness.

2. insert only the

correct mate-

rial.

The machine

does not

bend the ma-

terials as indi-

cated in the

catalogue.

1. The material

thickness

could be

wrong.

2. The mecha-

nics are faulty.

1. Check the

bending ma-

terial.

2. Contact the

dealer/manu-

facturer.

A EN ION!

Please ensure that the coolants and lubricants used

are disposed of in an environmentally friendly man-

ner. Observe the disposal instructions of your local

waste disposal company.

NO E

Used cooling lubricant emulsions and oils should not

be mixed, as only unmixed waste oils can be used

without pre-treatment.

Spare parts

SBM-Series | Version 2.02 15

12.5 Disposal via municipal collection points

Disposal of used electrical and electronic equipment (to

be used in the countries of the European Union and

other European countries with a separate collection sy-

stem for this equipment)

The symbol on the product or its packaging

indicates that this product is not to be dispo-

sed of as normal household waste, but must

be returned to a collection point for the recy-

cling of electrical and electronic equipment.

By contributing to the correct disposal of this

product, you protect the environment and the health of

your fellow human beings. Environment and health are

endangered by incorrect disposal. Material recycling

helps to reduce the consumption of raw materials. For

more information about recycling this product, contact

your local community, municipal waste management

company or the store where you purchased the product.

13 Spare parts

13.1 Spare parts order

The spare parts can be obtained from the dealer or di-

rectly from the manufacturer. The contact details are in

chapter 1.2 Customer Service.

Specify the following key data for inquiries or when orde-

ring spare parts:

- machine type

- item number

- position number

- construction year

- amount

- desired shipping method (post, freight, sea, air, ex-

press)

- delivery address

Spare parts orders without above given information can

not be considered. If the shipping method is missing,

shipping will be at the discretion of the supplier.

Information on the machine type, article number and

year of manufacture can be found on the nameplate,

which is attached to the machine.

Example

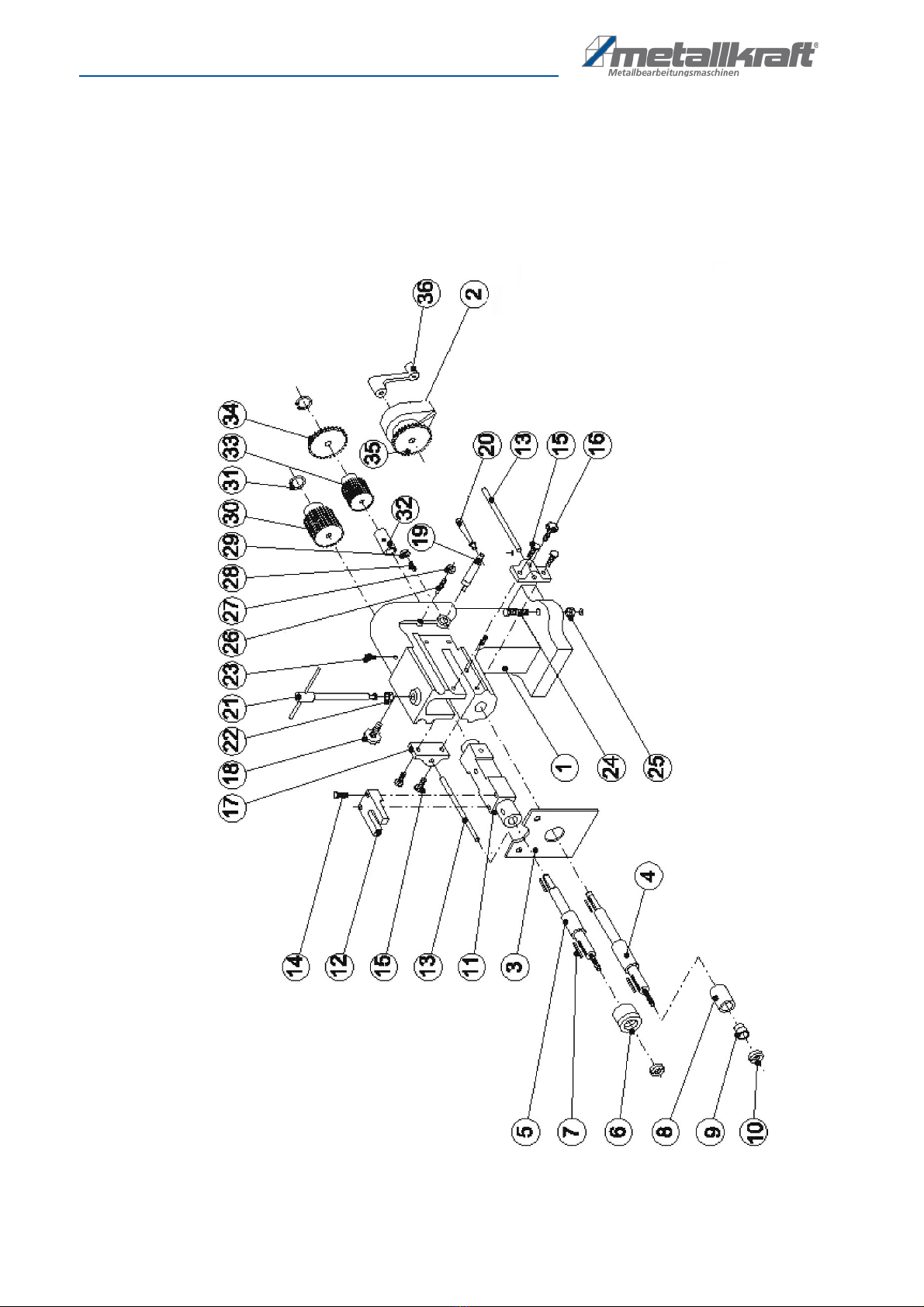

The Crank handle for the Bead Bending Machine SBM

110-08 must be ordered. The Crank handle has the num-

ber 36 in the spare parts drawing 1.

By ordering spare parts, send a copy of the spare parts

drawing (1) with the marked part (Crank handle) and

marked positon number (36) to the dealer or spare parts

department and provide the following information:

- Type of machine: Bead Bending Machine

SBM 110-08

- Item number: 3814001

- Drawing number: 1

- Position number: 36

he item number of your machine:

Bead Bending Machine SBM 140-12: 3814002

Bead Bending Machine SBM 110-08: 3814001

DANGER!

Risk of injury by using wrong spare

parts!

Dangers may result for the user and damages as well

as malfunctions may be caused by using wrong or

damaged spare parts.

- Only use original spare parts of the manufacturer or

spare parts admitted by the manufacturer.

- Always contact the manufacturer in case of uncer-

tainties.

NO E!

Loss of warranty!

The manufacturer's warranty will become null and

void if non admitted spare parts are being used.

16 SBM-Series | Version 2.02

Spare parts

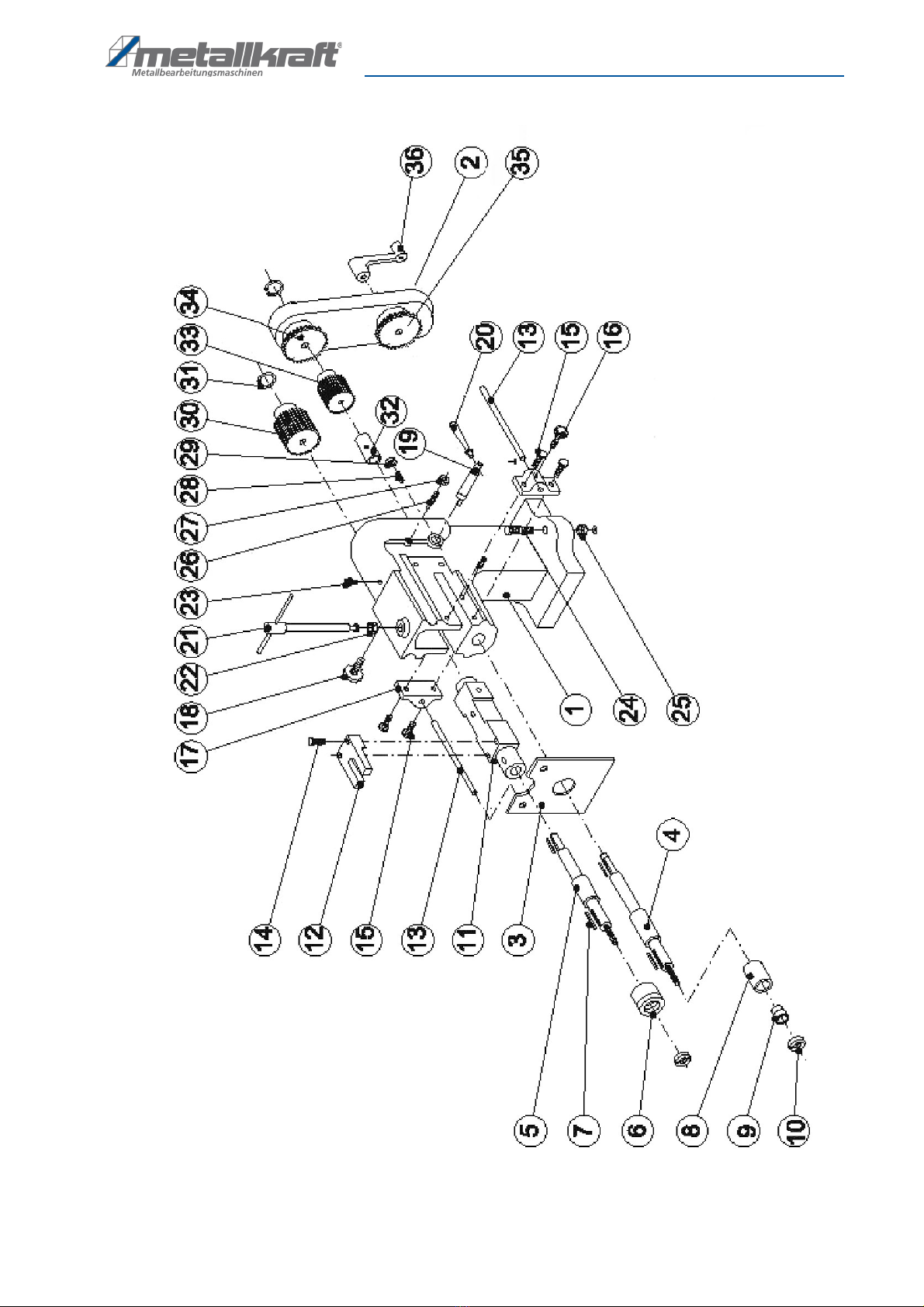

13.2 Spare parts drawings

The following drawings should help to identify necessary spare parts in case of service. To order, send a copy of the parts

drawing with the marked components to your authorized dealer.

13.2.1Spare parts drawing SBM 110-08

Fig. 14: Spare parts drawing SBM 110-08

Spare parts

SBM-Series | Version 2.02 17

13.2.2Spare parts drawing SBM 140-12

Fig. 15: Spare parts drawing SBM 140-12

www.metallkraft.de

This manual suits for next models

3

Table of contents

Other Metallkraft Lathe manuals