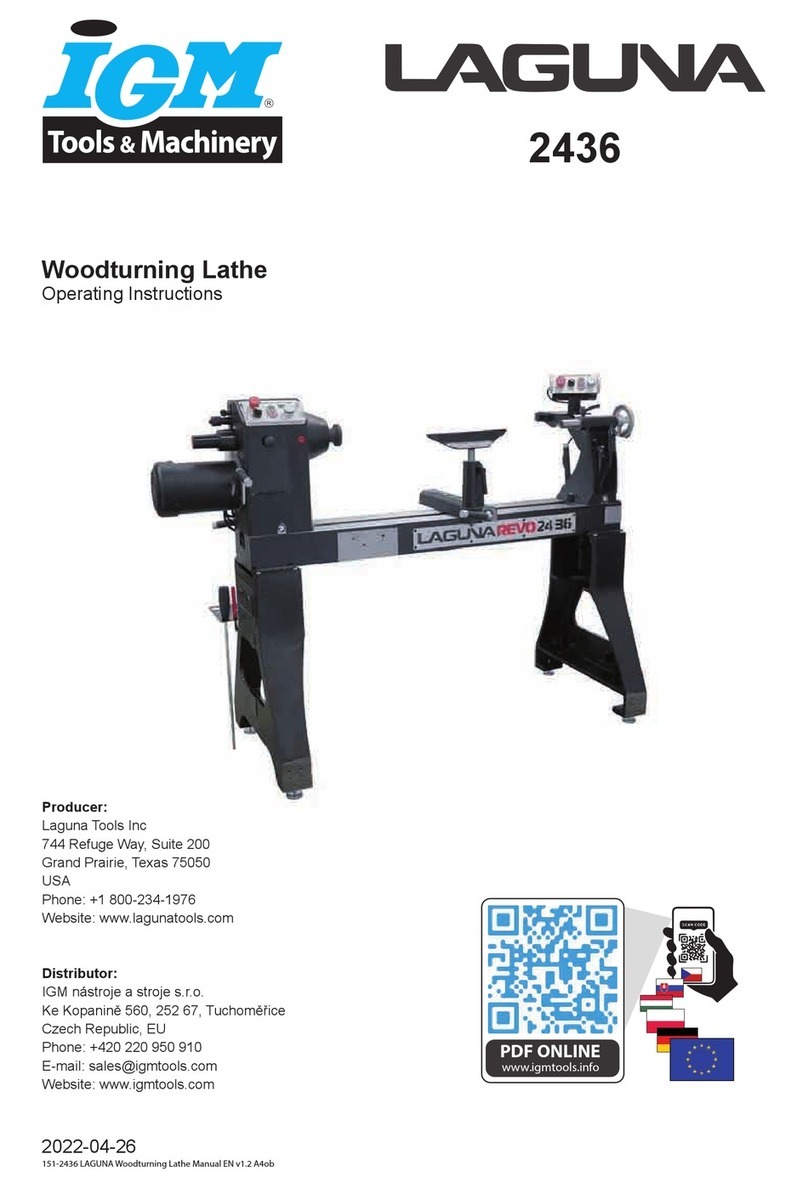

IGM LAGUNA Revo 1836 User manual

Producent

Laguna Tools Inc

2072 Alton Pkwy

Irvine, CA 92606,

USA

Phone: +1 800-234-1976

Website: www.lagunatools.com

Distributor

IGM nástroje a stroje s.r.o.

Ke Kopanině 560, 252 67, Tuchoměřice

Czech Republic, EU

Tel: +420 220 950 910

www.igmtools.com

2021-12-17

151-1836 LAGUNA Woodturning Lathe Manual EN v1.9 A4ob

Woodturning lathe

(Operating Instructions EN)

REVO 1836

www.igmtools.info

PDF ONLINE

-2-www.igmtools.com

-3-www.igmtools.com

Contents

1. Declaration of conformity

1.1 Warranty

2. About this manual

3. Specications

3.1 Parts of the machine

3.2 Technical data

3.3 Noise emission

4. General safety

4.1 Safety Rules

4.2 Electrical connections

5. Receiving your machine

5.1 Unpacking and transport

5.2 Receiving the lathe

5.3 Locating your machine

6. Assembly and setup

6.1 Assembling the legs to the bed of the lathe

6.2 Cleaning the machine

6.3 Fitting the rotating centre

6.4 Fitting the drive centre into the head stock

6.5 Fitting the face plate

6.6 Lathe controls

6.7 Variable speed adjustment knob

6.8 High / low speed

6.9 Indexing the spindle

7. Maintenance

8. Troubleshooting

1. Declaration of conformity

We declare that this product is in

compliance with the Directives and Standards

on page 2 of this manual.

1.1 Warranty

IGM Tools & Machinery strives to always

deliver high-quality machinery. The warranty is

governed by the valid terms and conditions of

IGM Tools & Machinery available at

www.igmtools.com.

2. About this manual

This manual is intended to thoroughly cover the

setup up, maintenance, and proper adjustments

of your new purchase. Aside from the

proceeding general safety considerations,

this manual DOES NOT cover woodworking

or metalworking techniques that are possible

with this product and the appropriate safety

precautions necessary for safe practices.

3. Specications

Wood turning lathes are typically used to shape

wood into cylindrical proles. Objects made on

a wood lathe include such items as furniture

legs, lamp posts, baseball bats, bowls and

other ornamental forms. Wood lathe tooling

consists of xtures and securing devices for the

work piece, a moveable tool rest, and hand-

held cutting tools.

3.1 Parts of the machine

The lathe consists of a number of major parts,

which are discussed in this manual. Take the

time to read this section and become familiar

with the machine.

Identication

There is a plate at the back of the machine

listing all the manufacturing data, including

the serial number, model, etc.

Lathe Bed

The bed is a heavy steel welded construction.

Pic. 1

Underside of lathe bed

Pic. 2

Lathe legs

The Legs are cast iron, and their heavy

construction gives the machine a low centre of

gravity and ensures that it is very stable. The

legs are supplied with adjustable feet to allow

the machine to be levelled.

Legs with adjustable feet assembled.

Pic. 3

Head stock

The head stock is cast iron and houses the

variable speed control and motor. The spindle

can be locked in 14 / 36 and 48 positions.

Headstock removed from the bed

Pic. 4

Headstock attached to bed

Pic. 5

Tail stock

The tail stock is of cast iron construction, and

the spindle has a travel of 4 1/2 in. It can

accommodate centres and other tools which

have a number 2 Morse Taper. The tail stock

can be moved to any position on the lathe bed

and locked to suit the job at hand.

Tail stock viewed from the back.

Pic. 6

EN - English

Operating instructions (Translation of original)

Dear Woodworker,

Thank you for your purchase and welcome to the Laguna Tools group of discerning woodworkers. We understand that you have a

choice of where to purchase your machines and appreciate the condence you have in the Laguna Tools brand.

Every machine manufactured by Laguna Tools has been carefully designed and well thought through from a woodworker’s perspective.

Through hands-on experience, Laguna Tools is constantly working hard to make innovative, precision products. Products that inspire

you to create works of art, are a joy to run and work on, and encourage your performance.

-4-www.igmtools.com

Tail stock viewed from the front

Pic. 7

Tool rest

The tool rest can be moved to any position on

the lathe bed and locked to suit the job at hand.

The tool rest has a tall prole to allow the bowl

turner to turn steep angles. The leading edge

is made from 6 mm hardened steel.

Tool rest assembled to the bed

Pic. 8

Tool rest

Pic. 9

Electrical system

220V: The electrical control system (VFD) is

housed at the back of the head stock, The VFD

converts single phase 220v to three phase.

There is a speed readout at the front of the

lathe with controls to ne adjust the rpm of

the spindle. A power cord with 220V plug is

provided.

Tail stock travel 115 mm

Tail stock removal Self-ejecting

Tail stock taper MK2

Faceplate 76 mm

Bed material Steel

Weight (net/ship) 194 kg / 206 kg

3.3 Noise emissions

Equivalent A-weighted Sound pressure level

according to EN ISO 3746: 75.66 dB(A).

Uncertainty, K in decibels: 4.0 dB (A) according

to EN ISO 4871 The gure quoted is emission

levels and are not necessarily safe working

levels. Whilst there is a correlation between the

emission and exposure levels, this cannot be

used reliably to determine whether or not further

precautions are required. Factors that inuence

the actual level of exposure of the workforce

include characteristics of the work room, the

other sources of noise, etc. i.e. the number of

machines and other adjacent processes. Also

the permissible exposure level can vary from

country to country, This information, however,

will enable the user of the machine to make a

better evaluation of the hazard and risk.

Pic. 13

4. General safety

“WARNING“: For Your Own Safety Read

Instruction Manual before Operating Lathe

4.1 Safety Rules

(a) Wear eye protection.

(b) Do not wear gloves, a necktie, or loose

clothing.

(c) Tighten all locks before operating.

(d) Rotate work piece by hand before applying

power.

(e) Rough out work piece before installing on

faceplate.

(f) Do not mount split work piece or one

containing a knot.

(g) Use lowest speed when starting new work

piece.

• Keep guards in place and in working order.

• Remove adjusting keys and wrenches. Form

habit of checking to see that keys and adjusting

wrenches are removed from tool before turning

it on.

• Keep work area clean. Cluttered areas and

benches invite accidents.

• Don‘t use in a dangerous environment. Don‘t

use power tools in damp or wet locations, or

expose them to rain. Keep work area well

lighted.

VFD with cover open

Pic. 10

Power cord

Pic. 11

Tool storage

A tool storage bracket which can be mounted

on either leg.

Tool storage bracket

Pic. 12

3.2 Technical data

Motor Induction, 1420 rpm, 1,5 kW, S1

Voltage 230V, 50 Hz, 1 Ph.

3 phase output

Recommended breaker size 16 A, tripping

characteristic C (16/1/C).

Swing over bed 457 mm

Swing over banjo 343 mm

Outboard swing max. 813 mm

Distance between centres 914 mm

Floor to spindle centre 1054 mm

Floor to bed height 826 mm

Dim. W x D x H 1524 x 660 x 1194 mm

Tool rest 305 mm

Speed range high: 135 – 3500 rpm

Speed range low: 50 – 1300 rpm

VFD Delta

Spindle M33 x 3.5 mm, righthanded

Spindle taper MK 2

Spindle lock Spring loaded

Spindle indexing 14 / 36 / 48 with lock

Head stock and tail stock bore 9,5 mm

-5-www.igmtools.com

• Keep children away. All visitors should be kept

at a safe distance from the work area.

• Make your workshop kid proof with padlocks,

master switches, or by removing starter keys.

• Don‘t force tool. It will do the job better and

safer at the rate for which it was designed.

• Use right tool. Don‘t force tool or attachment

to do a job for which it was not designed.

• Use proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and

overheating.

• Wear proper apparel do not wear loose

clothing, gloves, neckties, rings, bracelets, or

other jewellery which may get caught in moving

parts. Non-slip footwear is recommended. Wear

protective hair covering to contain long hair.

• Always use safety glasses. Also use a face

or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact resistant

lenses, they are not safety glasses.

• Secure work. Use clamps or a vice to hold the

work when practical. It‘s safer than using your

hand and it frees both hands to operate the tool.

• Don‘t overreach. Keep proper footing and

balance at all times.

• Maintain tools with care. Keep tools sharp

and clean for best and safest performance.

Follow instructions for lubricating and changing

accessories.

• Disconnect tools before servicing and when

changing accessories, such as blades, bits,

cutters, and the like.

• Reduce the risk of unintentional starting. Make

sure power switch is in the o position before

plugging the machine in.

• Use recommended accessories. Consult the

owner‘s manual for recommended accessories.

The use of improper accessories may cause

risk of injury to persons.

• Never stand on tool serious injury could

occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

• Check damaged parts. Before further use of

the tool, a guard or other part that is damaged

should be carefully checked to determine that

it will operate properly and perform its intended

function - check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any other conditions that may

aect its operation. A guard or other part that

is damaged should be properly repaired or

replaced.

• Direction of feed. Feed work into a blade or

cutter against the direction of rotation of the

blade or cutter only.

• Never leave tool running unattended. Turn

power o. Don‘t leave tool until it comes to a

complete stop.

Location of warning signs

Pic. 14

Locking the lathe

It is strongly recommended that the lathe is

never be left unattended in the unlocked

condition.

To lock the machine it is recommended that a

cover (not supplied) is made to lock the control

panel. We have supplied two concepts for

locking the panel (see below). The cover can

be made from wood or plastic.

First, push down the emergency stop. Then

lock the cover together by putting padlocks [not

included] on the two handles on the control

panel. To safeguard your machine from

unauthorized operation and accidental starting

by young children, the use of padlocks is

strongly recommended.

Pic. 15

Pic. 16

4.2 Electrical connections

Make sure that the power supply meets

the machine‘s requirements (230V). We

recommend using a 16 A breaker, tripping

characteristic C (16/1/C). Note.: Perform

adjustments with the help of a qualied

electrician.

VFD with cover open

Pic. 17

Wooden safety cover Padlocks

Padlocks

Emergency stop switch

Plastic safety cover

Other manuals for LAGUNA Revo 1836

1

This manual suits for next models

1

Table of contents

Other IGM Lathe manuals