Metallkraft RBM 610-8 User manual

03.05.2018 page 1Plate rolling machine RBM 610-8 ; Version 1.05

© 2018

GB

RBM 610-8

Operating instructions

RBM 610-8

RBM 610-8

Plate rolling machine

03.05.2018page 2 Plate rolling machine RBM 610-8 ; Version 1.05

© 2018 GB

Contents

1Safety

1.1 Safety instructions (Warnings) ...................................................................................... 5

1.1.1 Hazard classification ..................................................................................... 5

1.1.2 Further pictograms ........................................................................................ 5

1.2 Intended Use ................................................................................................................6

1.3 Dangers emanating from the plate rolling machine ...................................................... 7

1.4 Qualification of the staff ................................................................................................ 7

1.4.1 Target group .................................................................................................. 7

1.4.2 Authorized persons ....................................................................................... 7

1.5 Operator positions ........................................................................................................ 8

1.6 Safety equipment .......................................................................................................... 8

1.7 Security check ..............................................................................................................8

1.8 Protective clothing ........................................................................................................ 9

1.9 For your own safety during operation ........................................................................... 9

1.9.1 Using hoists ................................................................................................. 10

1.9.2 Mechanical maintenance ............................................................................. 10

1.9.3 Accident report ............................................................................................ 10

2 Technical Data

2.1 Machine date .............................................................................................................. 11

2.2 Environmental conditions ........................................................................................... 11

3 Assembly

3.1 Scope of supply .......................................................................................................... 12

3.2 Transport .................................................................................................................... 12

3.3 Storage ....................................................................................................................... 12

3.4 Setting up and mounting ............................................................................................. 12

3.4.1 Requirements for the installation site .......................................................... 12

3.4.2 Mounting the plate rolling machine .............................................................. 13

3.5 Set up ......................................................................................................................... 13

3.5.1 Fixing ........................................................................................................... 13

3.5.2 Before first use ............................................................................................ 14

3.5.3 First use ...................................................................................................... 14

4 Service

4.1 Safety ......................................................................................................................... 15

4.2 Operating and display elements ................................................................................. 15

4.2.1 Round bending machine ............................................................................. 15

4.3 Working with the plate rolling machine ....................................................................... 16

4.3.1 pre-bending ................................................................................................. 16

4.3.2 Sheet metal position during round bending ................................................. 17

4.3.3 Conical Bending .......................................................................................... 19

4.4 Swivel device .............................................................................................................. 19

5 Maintenance

5.1 Safety ......................................................................................................................... 21

5.1.1 Preparation .................................................................................................. 21

5.1.2 Recommissioning ........................................................................................ 21

5.2 Cleaning ..................................................................................................................... 21

5.3 Inspection and Maintenance ....................................................................................... 22

5.4 Lubricating plan .......................................................................................................... 23

5.5 Repair ......................................................................................................................... 23

03.05.2018 page 3Plate rolling machine RBM 610-8 ; Version 1.05

© 2018

GB

6 Spare Parts

6.1 Spare Parts Drawing .................................................................................................. 24

6.1.1 Spare Parts list ........................................................................................... 25

7 Annex

7.1 Copyright .................................................................................................................... 26

7.2 Disposal note / Recycling options: ............................................................................. 26

7.2.1 Decommission ............................................................................................. 26

7.2.2 Disposal of new equipment packaging ........................................................ 26

7.2.3 Disposal of the old device ........................................................................... 26

7.2.4 Disposal of electrical and electronic components ....................................... 27

7.2.5 Disposal of Lubricants and Coolants ........................................................... 27

7.3 Disposal via municipal collection points ..................................................................... 27

7.4 RoHS, 2011/65/EU ..................................................................................................... 27

7.5 Product monitoring ..................................................................................................... 28

8Notes

Preface

We are pleased that you have decided in favor of the RBM 610-8 plate rolling machine from

Metallkraft Metallbearbeitungsmaschinen - Stürmer GmbH.

The illustrations of the bender may differ in some details from the illustrations in this manual, but

this does not affect the operation of the bender.

Changes in construction, equipment and accessories are reserved for the benefit of further

development. Therefore, no claims can be derived from the information and descriptions.

Errors reserved!

Safety

03.05.2018page 4 Safety Plate rolling machine RBM 610-8 ; Version 1.05

© 2018 GB

1 Safety

Conventions of presentation

This part of the operating instructions

Explains the meaning and use of the warnings in this manual,

specifies the intended use of the bending machine,

Draws attention to the dangers that could arise for you and others if these instructions are

not followed,

informs you about how to avoid dangers.

Please note in addition to the operating instructions

the applicable laws and regulations,

the legal regulations for accident prevention,

the prohibition, warning and mandatory signs as well as the warnings on the bending

machine.

A nameplate is attached to the machine, which contains the name of the machine, the article

number and the most important technical data. Always keep it clean and in a readable condition.

Always keep the documentation near the bender.

INFORMATION

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Phone: +49 (0) 951 96 555 - 0

gives additional hints

calls you to action

enumerations

Safety

03.05.2018 page 5Safety Plate rolling machine RBM 610-8 ; Version 1.05

© 2018

GB

1.1 Safety instructions (Warnings)

1.1.1 Hazard classification

We divide the safety instructions into different levels. The table below gives you an overview of the

assignment of symbols (pictograms) and signal words to the actual danger and the (possible) conse-

quences

.

1.1.2 Further pictograms

Pictograms Signal word Definition / Consequences

DANGER! Immediate danger that will result in serious injury to per-

sons or death.

WARNING! Risk: Hazardousness could result in serious personal

injury or death.

ATTENTION! Dangerous or unsafe practices that could result in per-

sonal injury or property damage.

CAUTION!

Situation that could damage the bender and the pro-

duct and cause other damage.

No risk of injury to persons.

Information

Application tips and other important / useful information

and instructions.No dangerous or harmful conse-

quences for persons or property.

We replace the pictogram for specific dangers

or

general danger by a warning Hand injuries, rotating parts.

Wear safety

glasses!

Wear ear

protection!

Wearing safety

gloves!

Safety

03.05.2018page 6 Safety Plate rolling machine RBM 610-8 ; Version 1.05

© 2018 GB

1.2 Intended Use

WARNING!

If the plate rolling machine is not used as intended

• there are risks for the personnel,

• the machine and other assets of the operator are endangered,

the function of the Machine may be impaired.

The RBM 610-8 is a plate rolling machine for the production of cylindrical and conical bends in

sheet steel and other metallic materials, as well as materials that are suitable for processing due

to their plastic deformability. Editing brittle and brittle materials is prohibited. The machine is

intended and suitable for commercial use. The workpieces must be in the form of sheet metal or

flat profiles so that they can be safely captured and transported by the rollers.

The machine may only be used as described in this manual. It may only be operated by persons

trained and trained in the use and maintenance of bending machines.

If the round bending machine is used differently than stated above, without the permission of the

company Stürmer Maschinen GmbH changed, the round bending machine is no longer used as

intended.

We assume no liability for damage due to improper use.

We expressly point out that constructive, technical or procedural changes not approved by the

company Stürmer Maschinen GmbH also invalidate the warranty.

Part of the intended use is that you

adhere to the limits of the bender,

observe the operating instructions,

comply with the inspection and maintenance instructions.

"Technical data" on page 12

WARNING!

Heaviest injuries.

Modifications and changes in the operating values of the bending machine are prohibi-

ted! They endanger people and can damage the bender.

Wear safety

shoes!

Wear a protective

suit!

Pay attention to the

protection of the

environment!

Address of the

manufacturer

Safety

03.05.2018 page 7Safety Plate rolling machine RBM 610-8 ; Version 1.05

© 2018

GB

1.3 Dangers emanating from the round bending machine

The round bending machine corresponds to the state of the art.

Nevertheless, there is still a residual risk, because the round bending machine works with

rotating parts

We have minimized the risk to the health of persons through these hazards constructively and

through safety technology.

In the case of operation and maintenance of the bender by insufficiently qualified personnel,

dangers may arise from the bender due to incorrect operation or improper maintenance.

INFORMATION

All persons involved in assembly, commissioning, operation and maintenance must

have the required qualifications,

Pay close attention to these operating instructions.

In case of improper use

can be dangerous for the staff,

the machine and other property can be endangered,

the function of the bender may be impaired.

Always turn off the bender when performing cleaning or maintenance or stop working on it.

WARNING!

The bender may only be operated with functioning safety devices.

Switch off the bending machine immediately if you find out that a safety device is faulty

or disassembled!

All operator-side auxiliary systems must be equipped with the prescribed safety devices.

You as the operator are responsible!

"Safety devices" on page 8

1.4 Qualification of the staff

1.4.1 Target group

This manual is intended for you

the operators,

the operators,

the staff for maintenance work.

Therefore, the warnings refer both to the operation and to the maintenance of the bending

machine.

Determine clearly who is responsible for the various activities on the machine (operation, main-

tenance and repair).

Unclear competencies are a security risk!

1.4.2 Authorized persons

WARNING!

Incorrect operation and maintenance of the bending machine creates risks for people,

objects and the environment.

Safety

03.05.2018page 8 Safety Plate rolling machine RBM 610-8 ; Version 1.05

© 2018 GB

Only authorized persons are allowed to work on the bending machine!

Authorized persons for the operation and maintenance are the instructed and trained specialists

of the operator and the manufacturer.

The operator must

Obligations

of the opera-

tor

train the staff,

instruct the staff at regular intervals (at least once a year) about

all safety regulations concerning the machine,

the operation,

the accepted rules of technology,

check the level of knowledge of the staff,

document the training / instruction,

have the participation in the training / instruction confirmed by signature,

Check whether the staff works safety-conscious and follows the operating instructions.

The operator has to

Obligations

of the opera-

tor

- have received training in handling the bending machine

- know the function and mode of action,

- before commissioning

- have read and understood the operating instructions

- be familiar with all safety devices and regulations.

1.5 Operator positions

The operator position is in front of the bender.

1.6 Safety equipment

Operate the bender only with properly functioning safety devices. Stop the bender immediately if

a safety device is faulty or becomes ineffective. You are responsible! After the response or the

failure of a safety device, you must not use the bender again until you have

have eliminated the cause of the disorder,

have convinced themselves that this creates no danger to persons or property

WARNING!

If you bypass, remove or otherwise disable a safety device, you endanger yourself and

other people working on the bending machine. Possible consequences are

• Injuries from flung-off workpieces or workpiece parts,

• touching rotating parts.

The round bending machine has the following safety features:

Protective cover of the gearbox.

a safety rope

1.7 Security check

Check the bending machine before each new start or at least once per shift. Immediately report

damage or defects and changes in operating behavior to the responsible manager.

Check all safety devices

at the beginning of each shift (in interrupted operation),

once a week (during continuous operation),

Safety

03.05.2018 page 9Safety Plate rolling machine RBM 610-8 ; Version 1.05

© 2018

GB

after each maintenance and repair.

Check that the prohibition, warning and information labels as well as the markings on the

bending machine

are readable (possibly clean),

are complete (replace if necessary).

INFORMATION

Use the overview below to organize the exams.

1.8 Protective clothing

For some jobs you need body protection as protective equipment.

Protect your face and eyes: Wear a helmet with a face shield for any work that puts your face

and eyes at risk.

Use protective gloves when picking up sharp-edged parts.

Wear safety shoes when attaching, removing or transporting heavy parts.

Wear ear protection if the noise level (immission) at your workstation is greater than 80 dB (A).

Before starting work, make sure that the prescribed body protection products are available at the

workplace.

ATTENTION!

Contaminated, potentially contaminated body protection agents can cause illnesses.

Clean them after each use and once a week.

1.9 For your own safety during operation

We refer you to concrete dangers when working with and on the bending machine in the

description of this work.

WARNING!

Before switching on the bending machine, make sure that it does not endanger persons

or damage things.

Refrain from any safety-related work:

Make sure that no one is endangered by your work.

Be sure to adhere to the instructions in this manual during installation, operation, main-

tenance and repair.

Standard check

Facility Inspection OK

Protective covers Mounted, firmly screwed and not damaged

Signs and Marks Installed and readable

Date: Examiner (signature):

Safety

03.05.2018page 10 Safety Plate rolling machine RBM 610-8 ; Version 1.05

© 2018 GB

Do not work on the ring bending machine, if your ability to concentrate for some reason -

such. B. the influence of drugs - is reduced.

Make sure that nobody puts your work at risk.

Only work on the machine when the bending rollers are free to run.

Do not use the machine for purposes it is not intended to, for example for bending mineral

materials.

Observe the maximum dimensions of the workpieces + "Machine data" on page 12 given in

the technical data.

Note that using tools other than those recommended by the manufacturer may result in injury

to you and other accessories.

Do not leave any tools stuck. Before starting work, check that all repair and adjustment tools

have been removed.

Do not leave the machine unattended and keep a sufficient safety distance to the moving

machine parts.

1.9.1 Using hoists

WARNING!

Severe to fatal injuries from damaged or unsuitable hoists and load lifting devices that

break under load.

Check hoisting gear and load attachment

• sufficient carrying capacity,

• perfect condition.

Observe the accident prevention regulations of the professional association responsible

for your company or other supervisory authorities.

Fix the loads carefully. Never step under suspended loads!

1.9.2 Mechanical maintenance

After your work, install all the protective and safety equipment removed for the maintenance

work, such as:

covers,

Safety instructions and warning labels,

Ground wire.

After the replacement, check their function!

1.9.3 Accident report

Inform supervisors and the company Stürmer Maschinen GmbH immediately about accidents,

possible sources of danger and "near misses".

"Almost" accidents can have many causes.

The faster they are reported, the faster the causes can be resolved.

Technical Data

03.05.2018 page 11Technical Data Plate rolling machine RBM 610-8 ; Version 1.05

© 2018

GB

2 Technical Data

The following data are dimensional and weight specifications and the machine data approved by

the manufacturer

* Bending power ratings refer to S235JR with a tensile strength of 400 N / mm²

* Sheet bending capacity in VA = factor 0.75; Conical bending with half of the max. Sheet thickness possible

2.1 Machine data RBM 610 - 8

Max. working width [mm] 610

Max. sheet thickness [mm] 0,80

Roller Ø [mm] 38

Bending Ø min. min. 60

Weight [kg] 37

Dimensions LxBxH [mm] 885x220x340

2.2 Environmental

conditions

Temperature 5 - 35 °C

Relative humidity 25 - 80 %

Stretch limit

Example of the RBM 3030-60 E Pro

Roll diameter: 220 mm

Previous bending capacity: 4 mm

Bending Capacity: 6 mm

Material with a yield strength of 470 N / mm2 up to one

Diameter 660 mm with a thickness of 2 mm

Material with a yield strength of 235 N / mm2 up to one

Diameter 660 mm with a thickness of 3 mm

Material with a yield strength 175 N / mm2 up to one

Diameter 660 mm with a thickness of 4 mm

The conical bending can be done easily.

t = Bending capacity

(Material

thickness) Ratio

of conical

bending

Conical bending as a function of the bending capacity

Note: The values have been increased accordingly 3 times the roll diameter

Assembly

03.05.2018page 12 Assembly Plate rolling machine RBM 610-8 ; Version 1.05

© 2018 GB

3 Assembly

3.1 Scope of supply

Check the round bending machine immediately after delivery for transport damage and

shortages. Compare the scope of delivery with the enclosed packing list.

3.2 Transport

WARNING!

Severe to fatal injuries from falling and falling of machine parts from forklift or transport

vehicle. Follow the instructions and information on the transport box.

WARNING!

Severe to fatal injuries from damaged or unsuitable hoists and load lifting devices that

break under load. Check the lifting gear and load securing devices for sufficient load

capacity and perfect condition.

Observe the accident prevention regulations of the professional association responsible

for your company or other supervisory authorities.

Fix the loads carefully.

Never step under suspended loads!

3.3 Storage

WARNING!

Incorrect and improper storage can damage and destroy mechanical machine components.

Store the packed or unpacked parts only under the intended environmental conditions.

Follow the instructions and information on the transport box.

Contact Metallkraft Metallbearbeitungsmaschinen-Stürmer GmbH if the machine and accesso-

ries must be stored for longer than three months and under conditions other than those

specified in the regulations + "Ambient Conditions" on page 12.

3.4 Setting up and mounting

3.4.1 Requirements for the installation site

Design the work space around the bender according to the local safety regulations.

INFORMATION

In order to achieve good functionality and high machining accuracy, as well as long life of the

bender, the site should meet certain criteria.

The following points should be noted:

The device may only be installed and operated in dry, ventilated rooms.

Avoid places near chips or dusting machines.

The substrate must be suitable for the round bending machine. Also pay attention to load

capacity and flatness of the soil.

The substrate must be prepared so that any lubricant used can not penetrate the soil.

Assembly

03.05.2018 page 13Assembly Plate rolling machine RBM 610-8 ; Version 1.05

© 2018

GB

Protruding parts - such as stops, handles, etc. - are to be secured if necessary by on-site

measures so that persons are not endangered.

Provide enough space for set-up and operating personnel and material transport.

Also consider the accessibility for adjustment and maintenance work.

Ensure adequate lighting (minimum value: 500 lux, measured at the tip of the tool). With

lower illuminance, additional lighting must be ensured, for example by means of a separate

workplace luminaire.

3.4.2 Mounting the round bending machine

WARNING!

Danger of crushing when assembling, mounting and straightening the machine com-

ponents.

WARNING!

Risk of crushing and tipping. The erection of the bending machine must be carried out by

at least 2 persons.

INFORMATION

The Machine will be delivered already assembled.

3.5 Set up

‘Check the surface of the bender with a spirit level for horizontal alignment.

‘Check the substrate for sufficient load capacity and rigidity.

‘Place the round bending machine on the intended surface.

‘Attach the round bender to the provided through holes on the machine base.

WARNING!

The nature of the substrate and the method of fixing the machine base with the substrate

must be able to absorb the stresses of the round bending machine. The substrate must

be at ground level. Check the base of the bender with a spirit level for horizontal

alignment.

3.5.1 Fixing

In order to achieve the required stability

of the round bending machines, the

round bending machine must be firmly

connected to the base at its base.

We recommend the use of composite

anchor cartridges or heavy duty

anchors.

‘Attach the round bender to the provi-

ded through holes on the base with

the substrate.

Fig.3-1: Fasten

Through Hole

Assembly

03.05.2018page 14 Assembly Plate rolling machine RBM 610-8 ; Version 1.05

© 2018 GB

Danger!

Tighten the fastening screws on the bending machine so that they are secure and can not be

torn or tilted during operation.

Over-tightening mounting screws, especially in combination with uneven ground, may break the

base of the machine.

3.5.2 Before first use

DANGER!

Before using the round bending machine for the first time, lubricate the bearings!

We assume no liability for damages due to improper commissioning.

Before putting the bending machine into operation, carefully read the operating instructions. This

allows you to safely start up the machine. Follow the safety instructions in the operating instruc-

tions.

3.5.3 First use

WARNING!

The first time the bender is put into operation by inexperienced personnel, you endanger people

and equipment.

We assume no liability for damages due to improper commissioning.

"Qualification of staff" on page 7

Service

03.05.2018 page 15Service Plate rolling machine RBM 610-8 ; Version 1.05

© 2018

GB

4 Service

4.1 Safety

Only operate the machine under the following conditions:

The technical condition of the machine is flawless.

The machine is used as intended.

The operating instructions are observed.

All safety devices are present and active.

Eliminate faults or have them rectified immediately. In the event of malfunctions, immediately

shut down the machine and secure it against unintentional or unauthorized switching on.

Report any change immediately to the responsible body.

"For your own safety during operation" on page 10

4.2 Operating and display elements

4.2.1 Round bending machine

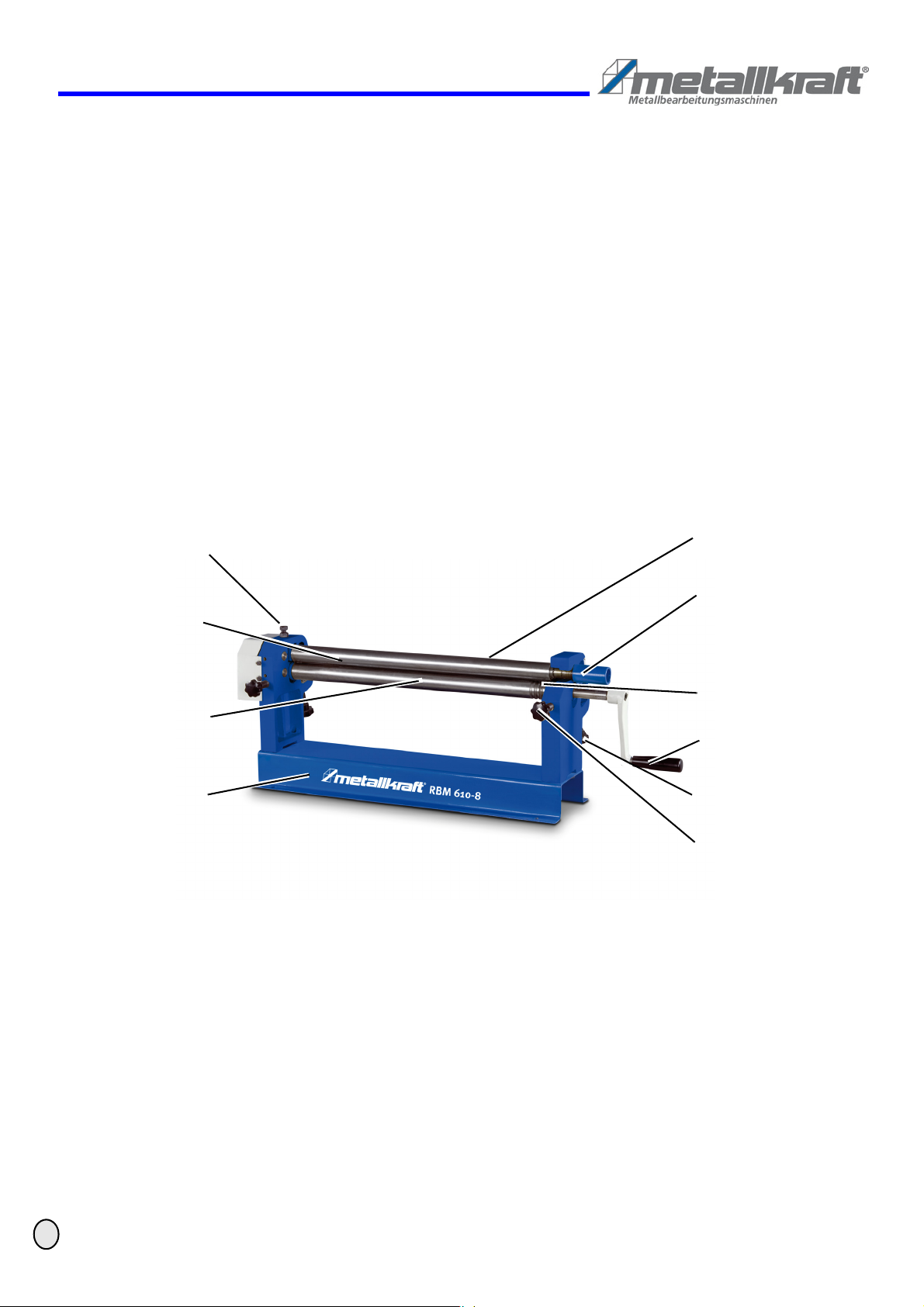

Fig.4-1: RBM 610-8

Rear guide roller (rear

roller, concealed)

Locking the pivoting

device

Area for bending round

profiles

Handkurbel

Handwheel for adjusting

the rear guide roller (rear

roller)

Handwheel for adjusting

the lower feed roller

Swivel bearing for upper

feed roller

Upper feed roller swi-

veling (upper roller)

Lower feed roller (lower

roller)

Machine frame

Service

03.05.2018page 16 Service Plate rolling machine RBM 610-8 ; Version 1.05

© 2018 GB

4.3 Working with the plate rolling machine

CAUTION!

Bending may only be performed by qualified personnel experienced on these machines.

All steps of bending, pre-bending and conical bending must be carried out extremely

carefully. It should be noted that a small radius is made by repeating the bending process

several times; Once too much bent, this step can not be undone.

4.3.1 Pre-bending

Pre-bending is the operation whereby the ends of the material are bent to the same radius as

the final radius. As a result, the best results are achieved at full radii z. B. in production of pipes)

or for operations in which no flat ends are desired.

Before editing:

The workpiece must be able to be fed in evenly from the upper and lower feed rollers.

Note that the material must be level.

Free the material surfaces from dirt and oil.

The material ends must be free of chips, chisels and burnt residues.

Note that burned material is harder at the points of separation than in the remaining area.

It is recommended to make a stencil of cardboard or cardboard from the desired radius as a

reference for the bending process.

Adjust the distance between the feed roller with the handwheel to adjust the lower roller so

that the workpiece is drawn in continuously with evenly distributed force.

Make sure that the rear roller is parallel to the feed rollers, if necessary, readjust them using

the handwheels.

WARNING!

Only bend workpieces whose material is known to you and check whether it is suitable

for cold forming.

Do not bend brittle materials that can break or splinter parts.

For processing

‘Be sure to always work in the middle of

the rollers.

‘Follow the steps shown below for round

bending + "sheet metal position for round

bending" on page 18.

‘Rotate the crank to selectively retract or

move the workpiece through the feed

rollers.

Fig.4-2: Processing

Service

03.05.2018 page 17Service Plate rolling machine RBM 610-8 ; Version 1.05

© 2018

GB

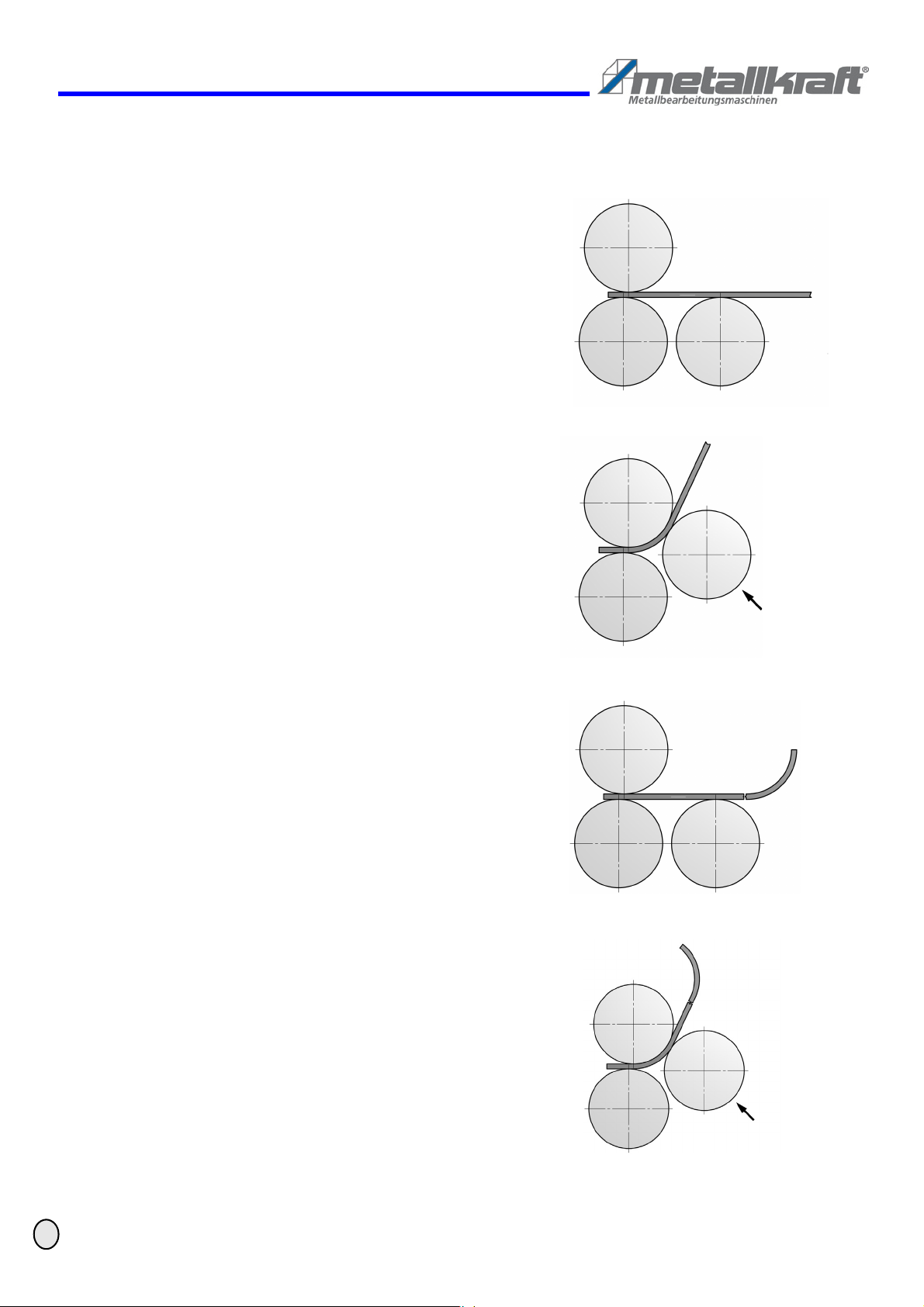

4.3.2 Sheet metal position during round bending

Upper and lower rollers in a straight posi-

tion

Fig.4-3: About turn

At the end of pre-bending, bring the back

roller up.

Fig.4-4: Round bending

Turn sheet metal and position for the

second pre-bending.

Fig.4-5: Round bending

At the end of pre-bending, bring the back roller

up.

Fig.4-6: Round bending

Service

03.05.2018page 18 Service Plate rolling machine RBM 610-8 ; Version 1.05

© 2018 GB

Roll to the desired diameter.

Fig.4-7: Round bending

Last pass.

Fig.4-8: Round bending

INFORMATION

The material hardens after each pass. When processing stainless steel, several passes must be

made because this material is work hardening material.

WARNING!

Before working, it is important to free the rollers from oil and grease residues.

Service

03.05.2018 page 19Service Plate rolling machine RBM 610-8 ; Version 1.05

© 2018

GB

4.3.3 Conical Bending

CAUTION!

Conical bending reduces the maximum permissible material thickness by 30% - 50%.

Before editing

INFORMATION

Conic bending is more difficult than normal bending. The machine power must be reduced to 0%

to 50% in order to determine the conical bending capacity. Also, the machine must be prepared

for this type of bending as follows:

Important in conical bending is that you first cut the sheet to the required size before

machining.

The workpiece must be able to be fed in evenly from the upper and lower feed rollers.

Note that the material must be level.

Free the material surfaces from dirt and oil.

The material ends must be free of chips, chisels and burnt residues.

Note that burned material is harder at the points of separation than in the remaining area.

Use the handwheels to adjust the distance between the pickup roller so that the workpiece

retracts evenly and continuously.

Adjust the rear roller in its angular position by turning the assigned handwheels so that the

diameter of the workpiece cone makes the roller closer to the tightening rollers. As a result, a

narrower radius is created at the bend.

For processing

Slide the sheet between the two rollers.

Place the narrower side of the sheet metal part on the side where the smaller radius is set.

Turn the crank to create the conical bend.

Depending on the degree of bending required, repeat the workpiece feed several times.

4.4 Swivel device

In order to remove a closed, bent workpiece (e.g., cylindrical tube) from the machine, it is

necessary to pivot the top roller out of the machine.

Release the top roller lock to remove the workpiece from the machine.

In the swung out state, the workpiece can then be pulled down.

Maintenance

03.05.2018page 20 Maintenance Plate rolling machine RBM 610-8 ; Version 1.05

© 2018 GB

5 Maintenance

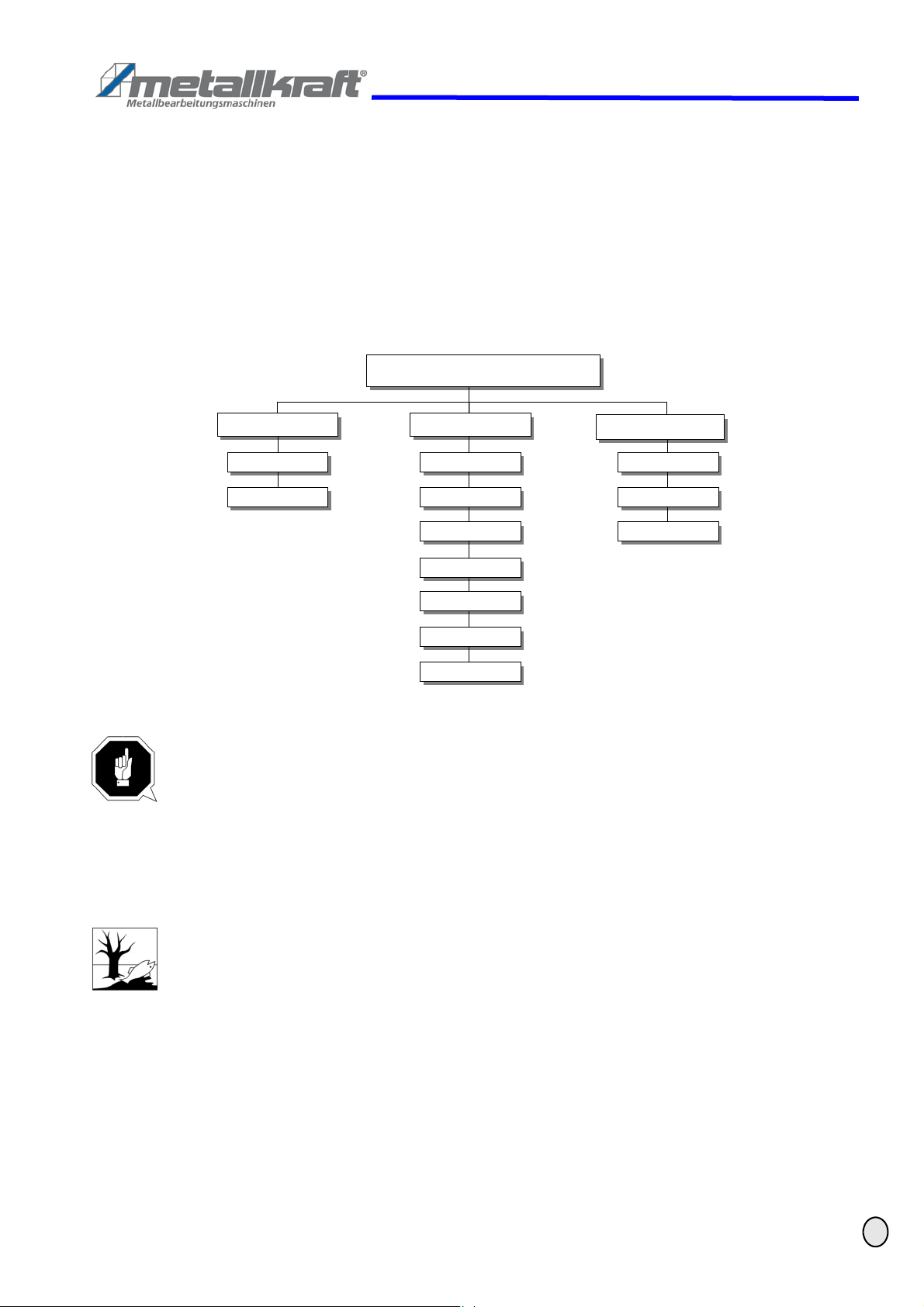

This chapter contains important information

- Inspection,

- Maintenance,

- Repair.

The diagram shows you which works fall under these terms.

Fig.5-1: Maintenance

CAUTION!

Regular, properly performed maintenance is an essential requirement for

• the operational safety,

• trouble-free operation,

• a long life of the machine and

• the quality of the products you produce.

The equipment and devices of other manufacturers must be in perfect condition.

ENVIRONMENT PROTECTION

Be careful when working on the bending head

• Can be used, the capacity of which is sufficient for the amount of liquid to be collec-

ted.

• Liquids and oils do not fall into the soil.

Immediately tie spilled fluids and oils with suitable oil absorbents and dispose of them in

accordance with the applicable environmental protection regulations.

Catching leaks

Do not return fluids that are generated during repair or leaks outside the system to the reservoir

but collect them in a collection container for disposal.

INSTANDHALTUNG

Inspektion Wartung Instandsetzung

Messen Säubern Ausbessern

Prüfen Reinigen Austauschen

Konservieren

Schmieren

Ergänzen

Auswechseln

Nachstellen

Einstellen

Maintenance

Inspection

Measure up

Check

Service

Clean

Washing

Conserve

Lubricate

Recruit

Replacement

Readjust

Reconditioning

Refinishing

Replace

Setting

Table of contents

Other Metallkraft Lathe manuals